Professional Documents

Culture Documents

HEALTH, SAFETY AND ENVIRONMENTAL (Responsible Group(s) For Consultation: HSE)

HEALTH, SAFETY AND ENVIRONMENTAL (Responsible Group(s) For Consultation: HSE)

Uploaded by

Visnu Manimaran0 ratings0% found this document useful (0 votes)

10 views5 pagesThe following 10 mandatory documented information are needed to ensure the effectiveness of an occupational safety and health management system:

1. Risk assessments including hazard reviews, job safety analyses, and consideration of risks to the public.

2. Compliance with regulations including those regarding hazardous materials, confined spaces, fire protection, and noise levels.

3. Procedures for isolation of systems, demolition, and disposal of materials.

4. Requirements for equipment layout, platforms, barricades, and fall protection.

5. Plans for personal protective equipment and management of hazardous exposures.

6. Permits and plans for storage of chemicals and management of waste and discharges.

Original Description:

Original Title

TEN MANDATORY

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe following 10 mandatory documented information are needed to ensure the effectiveness of an occupational safety and health management system:

1. Risk assessments including hazard reviews, job safety analyses, and consideration of risks to the public.

2. Compliance with regulations including those regarding hazardous materials, confined spaces, fire protection, and noise levels.

3. Procedures for isolation of systems, demolition, and disposal of materials.

4. Requirements for equipment layout, platforms, barricades, and fall protection.

5. Plans for personal protective equipment and management of hazardous exposures.

6. Permits and plans for storage of chemicals and management of waste and discharges.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

10 views5 pagesHEALTH, SAFETY AND ENVIRONMENTAL (Responsible Group(s) For Consultation: HSE)

HEALTH, SAFETY AND ENVIRONMENTAL (Responsible Group(s) For Consultation: HSE)

Uploaded by

Visnu ManimaranThe following 10 mandatory documented information are needed to ensure the effectiveness of an occupational safety and health management system:

1. Risk assessments including hazard reviews, job safety analyses, and consideration of risks to the public.

2. Compliance with regulations including those regarding hazardous materials, confined spaces, fire protection, and noise levels.

3. Procedures for isolation of systems, demolition, and disposal of materials.

4. Requirements for equipment layout, platforms, barricades, and fall protection.

5. Plans for personal protective equipment and management of hazardous exposures.

6. Permits and plans for storage of chemicals and management of waste and discharges.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

Describe TEN mandatory documented information (procedures and records) needed to ensure the effectiveness of the occupational

safety and health management system implementation.

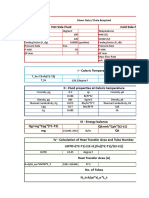

DB = Design Basis Review DE= Design Engineering Review

1.0 HEALTH , SAFETY AND ENVIRONMENTAL (Responsible Group(s) for Consultation: HSE) Y N N ST

A G

1.1 PERSONNEL HAZARDS - Do the modifications create any unusual exposure to personnel from: flame, DB

noise, heated or cold surfaces, electrical hazards, toxic or flammable gas leaks, cryogenic leaks? Can the

design be changed to minimize the possibility of such exposures?

1.2 Are additional engineering controls required (shielding, fans, ventilation, continuous gas monitors, alarms, DB

remote indication)?

1.3 OCCUPATIONAL HEALTH AND SAFETY REGULATIONS - Has a review been made of any HSE DB

regulations (factories Act, EPCA etc) that may apply to this modification?

1.4 STATUTORY COMPLIANCE - Need to consider compliance to MOM regulations, NEA requirements DB

etc? Require consideration of the relevant Codes of Practice and Specifications?

1.5 RISK ASSESSMENT - Is Hazard review (QRA, HAZOP, Job Safety Analysis, Risk matrix) required? DB

1.5.1 Has the risk assessment considered the site changes and any new exposures to the public? DB

1.6 LARGE STORAGE TANKS - Does the site modification involve the addition of large storage tanks DB

that could create an off-site risk if a leak or spill occurs? Are tanks containing flammables being added

to the

site?

1.7 FIRE PROTECTION SYSTEMS – Is there any changes to the existing fire protection system or are any DB

new fire protection systems required in accordance with good engineering practice or local building

codes? Has the SCDF been notified of any changes or additions to the site fire protections systems?

1.8 CONFINED SPACE REQUIREMENTS – Sometimes we need the contractor to provide special safety DE

requirements such as full time site safety officers , or lifting supervisors,or Confined space attendents,

continuous gas monitoring portable devices near hot work area, adequate ventilation blowers etc; we need

to inform or specify in Scope of Work for contractors. This will allow them to budget and plan for the

requirements. Otherwise, they will find it unviable to comply. Is the inclusion into Scope of Work

necessary?

1.9 EQUIPMENT LAYOUT – Sometimes piping and equipment layout can cause maintainability or DE

operability problems. Best way to avoid is formally inform the contractor upfront on layout quidelines and

best practices. Make it mandatory for the contractor to submit the Isometric drawings to the Unit Opn

supervisors for signature endorsement before fabricating. The O&M SV must visit the site itself to

physically check against the isometrics drawings before endorsing it. The principle here is to avoid

tripping hazards and overhead obstructions unnecessarily; while ensuring ergonomically easy access to

important valves and equipments for operation and maintenance. When the layout is congested, have steps,

walkways, walking surfaces, signposts, sufficient lighting to ensure that personnel do not become

exposed to ergonomic hazards. Is this required?

1.10 NOISE - Will noise levels increase? Have mitigation methods been considered (lagging, noise curtains, DB

barriers, vent or in-line silencers, enclosures, levels at plant boundary)? Is the cost for noise

mitigating devices such as noise hoods factor into the modification Budget?

1.11 PLATFORMS, HANDRAILS DE

Will the addition require the installation of equipment to work at elevations or gain access to the

modification at unsafe heights? Check the requirements for additions of platforms, handrails, guard rails,

ladders.

1.12 BARRICADES - Are barricades, machine guards, bump posts, chain guards to restrict access, or railings DE

needed?

1.13.1 CHEMICAL USE - Will new chemicals (including catalysts) be brought onsite? DB

1.13.2 Will the volume of existing chemicals stored onsite increase? DB

1.13.3 Will there be new or increased sources of oil created, e.g., compressors, expanders, machinery? If so,

changes in chemical inventories may need to be reported to government agencies and emergency DB

response agencies. Site emergency and spill contingency plans may need to be modified.

1.13.4 Has the MSDS been considered for the affect on handling, design for maintenance, or installation DB

methods?

1.13.5 Flammable material – Are any new flammable materials to be introduced. Does any licence required by DB

SCDF?

1.14 RESPIRATORY PROTECTION

Is additional respiratory protection required because of personnel hazards created by air contaminants DB

released or created during installation, startup, normal operation or maintenance of the modification?

1.15.1 PROCESS AND UTILITY VENTS – Will there be any new vents being added to the site? DE

1.15.2 Have these been considered for proper location and size to prevent the formation of a hazardous DE

atmosphere in the working areas?

1.15.3 Is vent location, elevation adequate to prevent exposure to personnel? DE

1.15.4 If The vent is a flammable vent stack, an analysis of heat radiation from the stack must be performed to DE

ensure personnel are not exposed to unsafe levels of heat.

1.15.5 Are any new ladders, platforms, or walkways being located where personnel could be exposed to a DE

hazardous release from existing process and utility vents?

1.16.1 DEMOLITION - Will the change require demolition of equipment? DE

1.16.2 Will this cause any specific health or safety problems as a result of contained materials being released or DE

discharged during demolition (asbestos, mercury, lead, catalyst dust, rockwool fibers, etc.)?

1.16.3 Is monitoring required to assess exposure during the demolition process? DE

1.17 SYSTEM ISOLATION - To accomplish the tie-in of the new equipment to the existing system, determine DE

if the proper systems isolation can be accomplished in accordance with lockout-tagout procedures. Will

additional valves, blinds, or vent be needed to perform safe maintenance of the system?

1.18 DISPOSAL - Will demolition or disposal of any of the unused equipment create special health or safety DE

hazards that must be considered in the change?

1.19.1 LIFTING DEVICES - Have cranes been considered for the removal of heavy objects? DE

1.19.2 Do the lifting devices meet safety standards? DE

1.19.3 Check capacity, stability, location, etc. Is lifting Supervisor required during the construction? DE

1.19.3 Do we need to put this requirement in the Scope of Work? DE

1.20.1 PROCESS, SANITARY, HYDROSTATIC TEST WASTEWATER - Will any new discharges be DB

created?

1.20.2 Will any existing discharges be modified (volume, cooling water chemistry, chemical content, increase in DB

cooling tower cycles of concentrate, location of discharge point)? If so, permits or permit modifications may

be required.

1.21 CHEMICAL AND PRODUCT STORAGE TANKS - Does the storage involve the installation of DB

aboveground or underground tanks (for chemicals, lubes, products, and byproducts)? If so, proper

containment and leak detection monitoring must be provided and the site emergency and spill contingency

plans may need to be modified. Registration of tanks with agencies may be required. Changing raw

materials stored in existing tanks may require agency notification. (UNDERGROUND TANKS SHOULD

BE AVOIDED!)

Y N NA STG

1.22 INDUSTRIAL WASTE

1.22.1 Alter the amount, composition or means of disposal of effluent? DB

1.22.2 Will any new or increased waste streams be created? DB

1.22.3 Will construction/demolition waste, asbestos waste, tank clean-out waste, excess freons, PCBs, catalysts, DB

paint wastes, blast material with paint chips, or other waste chemicals or oils be generated as a result of the

project? If so, waste testing, disposal arrangements, and waste registrations may be required.

1.23 RADIOACTIVE MATERIALS - Will any new sources of radioactive materials be created, e.g., analyzers, DB

special level gauges, etc.? If so, registration of materials with government agencies may be required.

1.24.1 EXCAVATION/FILL MATERIALS - Will excess excavation fill be generated? Will this fill be hauled DB

offsite?

1.24.2 If so, an evaluation of suspected soil contamination may be required prior to offsite disposal. Will fill DB

materials be brought onsite? If so, an evaluation of the source may be required to prevent contaminated fill

from being brought onsite.

1.25 ENVIRONMENTALLY-FRIENDLY CHEMICALS - Have any new chemicals been reviewed to select DB

the most environmentally-friendly substitute? Chemicals to avoid include certain freons (CFCs and

HCFCs),

ammonia, chlorine, mercury and mercury-containing devices, PCBs, 1,1,1-Trichloroethane, etc.

2.0 OPERATING PROCEDURES, OPERABILITY, PROCESS SAFET (Responsible Group(s) for

Consultation: Operations) Y N NA STG

2.1 COOLING DUTY - Will change increase the cooling duty on any particular coolers? Is there any DB

exceeding of loadings here?

2.2 PUMPING CAPACITY - Will change increase the requirement for cooling water pump capacity? Is DB

there any exceeding of loadings here?

2.3 CHEMICAL FEED - Will change affect the water treatment equipment including side stream filters or DB

chemical feed systems?

2.4 CHEMICAL TREATMENT PROGRAM - Will change affect water treatment chemistry program? DB

2.5 UPSTREAM OR DOWNSTREAM PROCESSES - Will any upstream or downstream processes or DB

equipment be affected by changes in pressure, temperature, fluid compositions and flow rate?

2.6.1 PRODUCT QUALITY - Do the modifications jeopardize product integrity? DB

2.6.2 Is product quality changed in any way as to affect any special customers or customer contractual DB

requirements?

2.7 PRODUCTIVITY OR EFFICIENCY - Do you forsee that the modifications will adversely affect DB

productivity or efficiency?

2.8 CRITICAL SAFETY SYSTEMS - Do the modifications change any critical safety shutdown interlock DB

systems?

2.9 INCOMPATIBLE FLUIDS - Are any materials being used potentially incompatible with process fluids DB

or inconsistent with Engineering Standards?

2.10 TOXIC OR FLAMMABLE GAS - Will this change result in any possibility of introducing TOXIC or DB

flammable gas into machinery or equipment that was previously on air or inert service?

2.11.1 PROCESS HAZARDS - Will the new process changes introduce any of the following hazards: Over DB

pressurization due to boiling of trapped saturated liquids?

2.11.2 Any other new over pressurization possibilities; e.g., (1) high pressure source added, (2) increase in valve DB

size between high- and low-pressure systems, (3) new pump or compressor or change of capacity.

2.11.3 Introduce or alter any potential cause of over or under pressurizing (or lowering or raising temperature) DB

in the system?

2.11.4 Introducing air or oxygen into flammable gases? DB

2.11.5 Introducing flammable into air? DB

2.11.6 Introducing flammable into an inert header? DB

2.11.7 Introduce a risk of creating a vacuum in the system or part of it? DB

2.11.8 In any way affect equipment already installed for the purpose of preventing or minimizing over or under DB

pressure?

2.11.9 Alter the chemical composition or the physical properties of the process material? DB

2.11.10 Affect the reaction stability or controllability of the process? DB

2.11.11 Affect any existing trip or alarm system or require additional trip or alarm protection? DB

2.11.12 If so, comment on the hazards and the corrective actions required to prevent control the hazard? DB

2.12 MAINTAINABILITY – Do the modifications design incorporate positive isolation means (such as DB

double

block & bleed, flanges for inserting spectacle blinds, spools etc) to ensure safety when isolating

equipment for performing maintenance work?

2.13 OPERABILITY – Are there valves or means for depressurization, defrosting, thermal relief,

draining, releasing of vapor lock etc? All details, such as the addition of check valves, bleed valves for DB

depressurization, defrost, purge points or drain valves for dead-legs, sampling points , pressure guages ,

regulators, insulation, etc., have been reviewed and are included in the submitted marked-up PID?

Operability studies must be done before approving it for construction.

2.14 NEW RELIEF DEVICES - Are new relief devices required? It is not acceptable to use a lock-open DB

valve to eliminate the need for a relief device. In most cases, safety valves or other safety devices will

have

to be downstream of check valves.

2.15.1 PROCEDURES – Directly alter the operating procedure of existing system? DB

2.15.2 Affect drastically existing operating & maintenance or quality procedures? DB

2.15.3 Need to prepare procedure before modification goes live? DB

2.16 TRAINING NEEDS - Is it necessary to spell in the Scope of Work for contractor to include Vendor DB

training for specialised & expensive equipments such as analysers, flow computers etc?

2.17 COOLING WATER BALANCE - Will change affect the cooling water balance within the facility? DB

2.18 LOAD ON THE COOLING TOWER / CHILLER - Will change increase the loading excessively on DB

the cooling tower or cooling capacity of heat exchangers or chiller?

2.19 PRECLEANING – Will change require pre-cleaning? Will this create environmental issues? DB

2.20 Boiler Systems Y N NA STG

2.20.1 EXISTING STEAM, CONDENSATE, OR BFW feed - Will change affect the existing steam, DB

condensate, or BFW water load?

2.20.2 CHEMICAL CONTROL – Will change require special chemical control, i.e., anti-corrosion DB

chemicals, amine addition?

2.20.3 CONTAMINANTS – Will change add any contaminants to the boiler system? DB

2.20.4 STEAM PURITY – Will change affect steam purity due to carryover, desuperheating or modified DB

steam drum operation?

2.20.5 PROCESS CONTROL – Will change require special process control, i.e., de-superheating? DB

2.20.6 WATER OR STEAM ANALYZERS – Will change affect existing steam or water analyzers? Will DB

change equire additional analyzers?

2.20.7 SYSTEM OPERATING PRESSURE – Will change affect system operating pressure? DB

2.20.8 CHEMICAL FEED SYSTEMS – Will change affect chemical feed systems? DB

2.20.9 MAKEUP WATER PRETREATMENT – Will change affect makeup water pretreatment system? DB

2.20.10 PRECLEANING – Will change require pre-cleaning? Will this create environmental issues? DB

2.20.11 BASIC ENGINEERING PRACTICES FOR SAFETY – Has a review been performed of the Basic DB

Engineering Practices for Safety to determine if specific hazards are being introduced or created by the

change and has the design included all the necessary countermeasures?

2.20.12 If specific hazards are being introduced or created by the change and has the design included all the DB

necessary countermeasures?

2.21 Is there any Site Acceptance Test that should be carried out before allowing commissioning to DB

proceed? The Project Chart or Gnatt Chart should be reviewed by the Operations to ensure that

they are carried out ahead before commissioning can be allowed to takes place.

3.0 MACHINERY AND MECHANICAL EQUIPMENT, PIPING, VESSELS AND MATERIALS OF

CONSTRUCTION (Responsible Group(s) for Consultation: Mechanical Engineering) Y N NA STG

3.1 SAFETY FEATURES – Will this change alter safety features or safety requirements of affected DB

machinery and equipment?

3.2 MIS-OPERATION – Will there be an affect on the machinery or mechanical equipment due to mis- DB

operation or failure of the intended modification?

3.3 AUXILIARY SYSTEMS – Will this change affect any of the auxiliary systems for the affected DB

machinery or equipment: lube system, seal gas system, vent system, cooling water system, etc.?

3.4 RELIABILITY – Will this change reduce the reliability of affected machinery or equipment? DB

3.5 SPARES – Will this change involve replacement of parts with modified or non-OEM parts? Is there a DB

risk here?

3.6 DESIGN CONDITIONS

3.6.1 Will new modifications cause the process conditions to exceed the design maximum conditions – DB

pressures, temperatures and flows?

3.6.2 Are there any cyclic pressure/temperature conditions or vibrations? Cyclic pressure/temp changes may DB

cause material fatigue and failure.

3.6.3 Will the design conditions be changed? DB

3.7 CODES/SPECIFICATIONS – What design/fabrication codes and specs apply? Are they specified DE

upfront in the new equipment design specifications?

3.8 MATERIALS - Are all the materials compatible with process fluid within design envelope? For oxygen DE

service, check velocity and compatibility against Eng. Stds. And O 2 Compatibility Manual. For process

fluid which is corrosive, special gaskets and suitable piping material need to be used.

3.9.1 'CODED' VESSEL OR PIPEWORK - Is an authorized or independent inspection authority required? DE

3.9.2 What is scope of their involvement in both design and fabrication? DNV or ABS engineering DE

review required?

You might also like

- Astm D2321Document12 pagesAstm D2321Emre Akınay100% (1)

- 20 0650 Demolition Method StatementDocument23 pages20 0650 Demolition Method StatementFazrin inasNo ratings yet

- 001 MEP Checklist - Jun-19Document29 pages001 MEP Checklist - Jun-19Đức Huấn Đỗ100% (2)

- Pre Construction Risk Assessment RSDocument4 pagesPre Construction Risk Assessment RSAlisya Anindita FebrianiNo ratings yet

- Idoc - Pub - Check List Api RP 14jDocument18 pagesIdoc - Pub - Check List Api RP 14jLuis LazardeNo ratings yet

- Logical Sequence ApproachDocument22 pagesLogical Sequence ApproachV. BalasubramaniamNo ratings yet

- Annexure1 PSSR CheklistDocument12 pagesAnnexure1 PSSR Cheklistanjna100% (1)

- Plant LayoutDocument12 pagesPlant LayoutKrishnamoorthy SubramaniamNo ratings yet

- Pre-Construction Risk AssessmentDocument4 pagesPre-Construction Risk AssessmentTri WidiastutiNo ratings yet

- Pre-Construction Risk AssessmentDocument12 pagesPre-Construction Risk AssessmentYoan BeatrixNo ratings yet

- Check List API RP 14jDocument18 pagesCheck List API RP 14jMIGUELONOFRE100% (1)

- Health and Safety FCX-HS17Document5 pagesHealth and Safety FCX-HS17berry trisnamuktiNo ratings yet

- Offshore Production Installation2Document8 pagesOffshore Production Installation2Anonymous aIuHKoKZjNo ratings yet

- Tees Valley 2 Commissioning Plan Rev0Document22 pagesTees Valley 2 Commissioning Plan Rev0NabilBouabanaNo ratings yet

- Ete 142 Module IDocument12 pagesEte 142 Module ITsalachNo ratings yet

- D5 - Management of Tailings and Water Storage August 2015: StandardDocument6 pagesD5 - Management of Tailings and Water Storage August 2015: StandardFrancklin TokimitondrasoaNo ratings yet

- C 17 Plant LayoutDocument5 pagesC 17 Plant LayoutSufiyan AhmedNo ratings yet

- Appendix 10 - Environmental Management Compliance Audit FormDocument2 pagesAppendix 10 - Environmental Management Compliance Audit FormGerardoNo ratings yet

- E1200 - Civil and Structural PDFDocument23 pagesE1200 - Civil and Structural PDFgerrzen64No ratings yet

- Cop101 Version 14 Black LettersDocument49 pagesCop101 Version 14 Black LettersEdouard LiangNo ratings yet

- Design Standard-Tauranga City CouncilDocument37 pagesDesign Standard-Tauranga City Counciljunhe898No ratings yet

- Final CrudeOil and Petroleum Product TerminalsDocument14 pagesFinal CrudeOil and Petroleum Product Terminalsbalavengu100% (1)

- DTS Catalog 2016Document206 pagesDTS Catalog 2016duque_sade100% (1)

- Pre-Commissioning Checklist: Site Address / Details: EngineerDocument2 pagesPre-Commissioning Checklist: Site Address / Details: Engineerariadi supriyantoNo ratings yet

- KLM TechnologyDocument12 pagesKLM TechnologyBari Ipung GunturNo ratings yet

- MS-10178 Atmosferas PeligrosasDocument14 pagesMS-10178 Atmosferas PeligrosasAndrés Acosta LaraNo ratings yet

- 6.1 Construction Materials ExtractionDocument13 pages6.1 Construction Materials ExtractionGang QiaoNo ratings yet

- Pre Construction Risk Assessment (PCRA) 7-10-2015Document2 pagesPre Construction Risk Assessment (PCRA) 7-10-2015dr.yogaNo ratings yet

- RT Management Tailings Water Storage StandardDocument6 pagesRT Management Tailings Water Storage StandardJohn KalvinNo ratings yet

- Capital Requirements For Process PlantsDocument46 pagesCapital Requirements For Process PlantsSrija SureshNo ratings yet

- MS-001 R0Document10 pagesMS-001 R0eshwarNo ratings yet

- Dangote Refinery ResumeDocument2 pagesDangote Refinery ResumemjunaidNo ratings yet

- 02 - SafetyDocument3 pages02 - Safetyyusuf.yuzuakNo ratings yet

- Care and Use of Casing and TubingDocument6 pagesCare and Use of Casing and TubingAnonymous aIuHKoKZjNo ratings yet

- Sec02 - SafetyDocument3 pagesSec02 - SafetyYusufNo ratings yet

- Lamp IranDocument14 pagesLamp IranRina MariantiNo ratings yet

- Process Industry Practices Piping: PIP PNE00003 Process Unit and Offsites Layout GuideDocument14 pagesProcess Industry Practices Piping: PIP PNE00003 Process Unit and Offsites Layout GuideSilambarasan PalanisamyNo ratings yet

- Environmental Compliance ChecklistDocument5 pagesEnvironmental Compliance ChecklistNIJESH100% (1)

- 08-01 CompletionDocument31 pages08-01 CompletionMustafa AlrikabiNo ratings yet

- Oil-Fuel SeparatorDocument24 pagesOil-Fuel SeparatorSiva SubramaniyanNo ratings yet

- 1-LL Template and Instructions - NewDocument4 pages1-LL Template and Instructions - NewHassoub Abdul Shafy HassoubNo ratings yet

- Brown Field ProjectDocument17 pagesBrown Field Projectnick1244100% (1)

- Mechanical Design GuidelinesDocument23 pagesMechanical Design GuidelinesmohamednavaviNo ratings yet

- Strer PDFDocument36 pagesStrer PDFAli Ben AmorNo ratings yet

- Structural Integrity Management of Ageing Offshore InstallationsDocument36 pagesStructural Integrity Management of Ageing Offshore InstallationsAli Ben AmorNo ratings yet

- Structural Integrity Management of Ageing Offshore InstallationsDocument36 pagesStructural Integrity Management of Ageing Offshore InstallationsAli Ben AmorNo ratings yet

- 70KB725 Nusa Dua Bali Renaissance Sprinkler Review - enDocument6 pages70KB725 Nusa Dua Bali Renaissance Sprinkler Review - entotoNo ratings yet

- Pre Construction Risk Assessment (PCRA) 7 10 2015Document4 pagesPre Construction Risk Assessment (PCRA) 7 10 2015yeremia PratamaNo ratings yet

- Offshore Production Installations - Requirements and Guidelines For Emergency Response (Amendments-Supplements To ISO 15544-2000)Document10 pagesOffshore Production Installations - Requirements and Guidelines For Emergency Response (Amendments-Supplements To ISO 15544-2000)Jacob PhilipNo ratings yet

- Pre-Construction/Safety Risk Assessment: Building 1 Section C Courtyard 0462Document4 pagesPre-Construction/Safety Risk Assessment: Building 1 Section C Courtyard 0462Gaharu NisaaNo ratings yet

- ASTM D2321 14e1Document6 pagesASTM D2321 14e1tosheNo ratings yet

- Airport Mechanical Design Standards July 2017Document14 pagesAirport Mechanical Design Standards July 2017mohammadNo ratings yet

- Remote Operated ESD Vales PDFDocument19 pagesRemote Operated ESD Vales PDFprocessnishuNo ratings yet

- Dem 1Document12 pagesDem 1Vicks BTBNo ratings yet

- Design Review Checklist: Heating, Ventilating, and Air ConditioningDocument13 pagesDesign Review Checklist: Heating, Ventilating, and Air ConditioningZineddine AlicheNo ratings yet

- Various Considerations in Equipment Layout in The Equipment and Plot PlanDocument10 pagesVarious Considerations in Equipment Layout in The Equipment and Plot Planbikas_sahaNo ratings yet

- Lesson Learned Feb 22Document6 pagesLesson Learned Feb 22இராம் குமார்No ratings yet

- CS E10:2014: Guidelines on Design Loads for Skyrise GreeneryFrom EverandCS E10:2014: Guidelines on Design Loads for Skyrise GreeneryNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- W1 Chapter Revision ArrayDocument74 pagesW1 Chapter Revision ArrayVisnu ManimaranNo ratings yet

- Setting Up A Live Website: Mohd Hasbullah OmarDocument21 pagesSetting Up A Live Website: Mohd Hasbullah OmarVisnu ManimaranNo ratings yet

- HTHB3034-Hospitality Purchasing and Supply ManagementDocument4 pagesHTHB3034-Hospitality Purchasing and Supply ManagementVisnu ManimaranNo ratings yet

- Unit 9 The Supply of MoneyDocument15 pagesUnit 9 The Supply of MoneyVisnu ManimaranNo ratings yet

- Topic 5 (Project Initialization - MOV Business Case)Document33 pagesTopic 5 (Project Initialization - MOV Business Case)Visnu ManimaranNo ratings yet

- W2 Chapter Algorithm AnalysisDocument28 pagesW2 Chapter Algorithm AnalysisVisnu ManimaranNo ratings yet

- 5G Wireless: A Transformative, Disruptive Technology: Industrial Management (Norcross, Georgia) June 2019Document7 pages5G Wireless: A Transformative, Disruptive Technology: Industrial Management (Norcross, Georgia) June 2019Visnu ManimaranNo ratings yet

- Dutch Lady Milk Industries BerhadDocument34 pagesDutch Lady Milk Industries BerhadVisnu Manimaran100% (2)

- Supply ChainDocument10 pagesSupply ChainVisnu ManimaranNo ratings yet

- Install NotesDocument1 pageInstall NotesVisnu ManimaranNo ratings yet

- Entrepreneurial Ethics: Topic 2Document22 pagesEntrepreneurial Ethics: Topic 2Visnu ManimaranNo ratings yet

- Unit Planner Support GuideDocument90 pagesUnit Planner Support GuideVisnu ManimaranNo ratings yet

- School of Languages, Civilisation and Philosophy Uum College of Arts and SciencesDocument4 pagesSchool of Languages, Civilisation and Philosophy Uum College of Arts and SciencesVisnu ManimaranNo ratings yet

- Stid3074 1 2018 2019Document13 pagesStid3074 1 2018 2019Visnu ManimaranNo ratings yet

- Plagiarism Scan Report: Plagiarised Unique Words CharactersDocument2 pagesPlagiarism Scan Report: Plagiarised Unique Words CharactersVisnu ManimaranNo ratings yet

- EntrepreneurDocument3 pagesEntrepreneurVisnu ManimaranNo ratings yet

- Assgnmt 3 PROJECT ITPMDocument33 pagesAssgnmt 3 PROJECT ITPMVisnu ManimaranNo ratings yet

- Logistics: Join Our T.V.E.T Level 3 Certificate in E-Commerce Logistic and Supply ChainDocument1 pageLogistics: Join Our T.V.E.T Level 3 Certificate in E-Commerce Logistic and Supply ChainVisnu ManimaranNo ratings yet

- Deadpool: A191 STIN1013 Introduction To Artificial Intelligence LecterurDocument12 pagesDeadpool: A191 STIN1013 Introduction To Artificial Intelligence LecterurVisnu ManimaranNo ratings yet

- Vishal NaikDocument12 pagesVishal NaikMai PhuNo ratings yet

- Selection of Recombinant ClonesDocument2 pagesSelection of Recombinant ClonesKV Deepika100% (1)

- DNA LibraryDocument73 pagesDNA LibraryDGA GAMINGNo ratings yet

- Water Analysis Journal (Group5) PDFDocument7 pagesWater Analysis Journal (Group5) PDFDominic CareoNo ratings yet

- Syltherm 800 Silicone Heat Transfer Fluid MSDSDocument8 pagesSyltherm 800 Silicone Heat Transfer Fluid MSDSNasser AlshalwyNo ratings yet

- TEPZZ 9 5 - 9 B - T: European Patent SpecificationDocument11 pagesTEPZZ 9 5 - 9 B - T: European Patent SpecificationLê CôngNo ratings yet

- COG Broschuere O-Ring 1x1 enDocument52 pagesCOG Broschuere O-Ring 1x1 entehnoNo ratings yet

- Technical Catalogue: Pipes - Tubes - Fittings - Flanges Revision 1Document121 pagesTechnical Catalogue: Pipes - Tubes - Fittings - Flanges Revision 1Дмитрий РыбаковNo ratings yet

- TEX - CHEM 103 Organic ChemistryDocument52 pagesTEX - CHEM 103 Organic ChemistrychioNo ratings yet

- Na Mlbio Ch09Document28 pagesNa Mlbio Ch09Life with CourteneyNo ratings yet

- Ipc-M-107 Standards For Printed Board Materials ManualDocument1 pageIpc-M-107 Standards For Printed Board Materials Manualttao1100% (1)

- Transition Metals B.SC - II (Hons)Document20 pagesTransition Metals B.SC - II (Hons)Hari sankar MuniNo ratings yet

- IB Chem2 5 Assess T5Document2 pagesIB Chem2 5 Assess T5Trúc HồNo ratings yet

- Chapter 2Document9 pagesChapter 2Fadhiran YahyaNo ratings yet

- Forging NotesDocument20 pagesForging NotesDheeraj JoshiNo ratings yet

- Dissolved Oxygen in Natural WaterDocument3 pagesDissolved Oxygen in Natural Waterapi-546041117No ratings yet

- Module 2 Nucleophilic SubstitutionDocument24 pagesModule 2 Nucleophilic Substitutionkeerthi srijithNo ratings yet

- Biomarkers: PetroleumDocument13 pagesBiomarkers: PetroleumMohamed HaboNo ratings yet

- BIOC 2061 Tutorial 3Document4 pagesBIOC 2061 Tutorial 3Kavita MaharajNo ratings yet

- Thermal Design of Heat ExchangerDocument9 pagesThermal Design of Heat ExchangerNaqqash SajidNo ratings yet

- Lab 89Document3 pagesLab 89Keron BretalNo ratings yet

- Modelling and Simulation of A Direct Contact Rotary DryerDocument16 pagesModelling and Simulation of A Direct Contact Rotary DryerVinh Do ThanhNo ratings yet

- JebChem Productlist AntifoamDocument4 pagesJebChem Productlist AntifoamCao LongNo ratings yet

- Chemcoat CRDocument3 pagesChemcoat CRICPL-RWPNo ratings yet

- Donaldson Fuel FiltrationDocument42 pagesDonaldson Fuel FiltrationIongornistu100% (1)

- Petroleum Exploration MetDocument10 pagesPetroleum Exploration MetShiraz NajatNo ratings yet

- Common Mistakes Made by Students in SPM Chemistry Paper 2Document9 pagesCommon Mistakes Made by Students in SPM Chemistry Paper 2leemayjuin100% (1)

- 1 8550-34CrAlNi710Document2 pages1 8550-34CrAlNi710Michel PortalNo ratings yet

- HandoutsDocument2 pagesHandoutsGaurav Mani PrasadNo ratings yet

- Dwnload Full Foundations of Materials Science and Engineering 5th Edition Smith Solutions Manual PDFDocument36 pagesDwnload Full Foundations of Materials Science and Engineering 5th Edition Smith Solutions Manual PDFroxaneblyefx100% (13)