Professional Documents

Culture Documents

Kiln Controller: Summary: The System I Use in My Own Shop

Kiln Controller: Summary: The System I Use in My Own Shop

Uploaded by

Justin WellsCopyright:

Available Formats

You might also like

- 17th Edition Exam QuestionsDocument18 pages17th Edition Exam Questionspete16No ratings yet

- 30.72 KWP SLDDocument1 page30.72 KWP SLDDaniel Gnanaselvam100% (1)

- Rele Detrol ControlsDocument4 pagesRele Detrol ControlsLJ GustavoNo ratings yet

- Low Voltage Circuit Breakers: Meta-MECDocument16 pagesLow Voltage Circuit Breakers: Meta-MECFrank FacebNo ratings yet

- 270-275 Series Data SheetDocument4 pages270-275 Series Data SheetkimhaeNo ratings yet

- Gps Airman Generator BrochureDocument6 pagesGps Airman Generator BrochureThành Long NguyễnNo ratings yet

- NEMA Configuration Chart - SECTION RDocument4 pagesNEMA Configuration Chart - SECTION RElMocoVengadorNo ratings yet

- MCCB GB e 1003Document16 pagesMCCB GB e 1003GIOVANNI BAUTISTANo ratings yet

- 04 - 860E - 24v Aux - Mech PDFDocument51 pages04 - 860E - 24v Aux - Mech PDFChester Dalitso Mwanza100% (1)

- Siemens Circuit Switcher BrochureDocument16 pagesSiemens Circuit Switcher BrochureCarlos FernandezNo ratings yet

- Spec SEC-2425UL FICHA TECNICA SAMLEX SEC-2425UL 25APM - 24VOLDocument1 pageSpec SEC-2425UL FICHA TECNICA SAMLEX SEC-2425UL 25APM - 24VOLAdriana martinezNo ratings yet

- Cable Schedule P 90916 E D2 8532 124 01 PCS PARLI Revision 2Document18 pagesCable Schedule P 90916 E D2 8532 124 01 PCS PARLI Revision 2AnilNo ratings yet

- Onan P9500 DF Portatil Dual Fuel Gas LPG 0059501Document2 pagesOnan P9500 DF Portatil Dual Fuel Gas LPG 0059501Alan MtzNo ratings yet

- Sedecal HF Series X Ray Generator Service Manual 390 427Document38 pagesSedecal HF Series X Ray Generator Service Manual 390 427humberto bedoyaNo ratings yet

- Binder Wiring Escalator Modification Atrium Senen Food MartDocument13 pagesBinder Wiring Escalator Modification Atrium Senen Food MartWiratama MudaNo ratings yet

- SMF Instruction ManualDocument4 pagesSMF Instruction ManualKan KhabourNo ratings yet

- Solid-State Relays: FeaturesDocument22 pagesSolid-State Relays: FeaturesBryanJermyHendrikNo ratings yet

- 0859 Solid State Relays Data SheetDocument23 pages0859 Solid State Relays Data SheetGerardo LozanoNo ratings yet

- DM311Document16 pagesDM311Hernan Ortiz EnamoradoNo ratings yet

- FPA18 Series Technical DataDocument8 pagesFPA18 Series Technical Datajore77No ratings yet

- manual-topworx-d-esd-partial-stroke-emergency-shut-down-iom-topworx-en-4852782 (1)Document28 pagesmanual-topworx-d-esd-partial-stroke-emergency-shut-down-iom-topworx-en-4852782 (1)yazuk599No ratings yet

- 150Khz, 3A PWM Buck DC/DC Converter: Advanced Power Electronics CorpDocument12 pages150Khz, 3A PWM Buck DC/DC Converter: Advanced Power Electronics CorpOjahan HNo ratings yet

- Electrical and IgnitionDocument26 pagesElectrical and IgnitionmartinbexnerNo ratings yet

- Cable Sizing CalculationDocument522 pagesCable Sizing Calculationadi_sofa100% (4)

- SLR 5 e 100Document4 pagesSLR 5 e 100valeriamoyarojasNo ratings yet

- LC1Kpp: WarningDocument1 pageLC1Kpp: WarningJavier LazoNo ratings yet

- Pv3000 LMPK 2021 New UpdatedDocument1 pagePv3000 LMPK 2021 New UpdatedPedro Noriega CardozoNo ratings yet

- 2298 GasboyDocument13 pages2298 GasboyAhmed AbdoNo ratings yet

- Em 8677Document4 pagesEm 8677solisiusNo ratings yet

- 7805 Voltage Regulator CircuitDocument2 pages7805 Voltage Regulator CircuitArmoured SmilerNo ratings yet

- 1794-OW8 Installation Instructions FLEX IO 8 Relay Output Module-4Document1 page1794-OW8 Installation Instructions FLEX IO 8 Relay Output Module-4zeroseyaNo ratings yet

- Chipown: 3A, 18V Synchronous Rectified Step-Down ConverterDocument9 pagesChipown: 3A, 18V Synchronous Rectified Step-Down ConverterBashar MohammadNo ratings yet

- Trafo-1 Test ReportDocument16 pagesTrafo-1 Test ReportramNo ratings yet

- KAM07Document3 pagesKAM07vvvNo ratings yet

- Solid State Relays Data SheetDocument23 pagesSolid State Relays Data SheetRizki AlNo ratings yet

- KA3842Document7 pagesKA3842QXNNo ratings yet

- 220kv Greenko Feeder-2 Eqipment DetailsDocument34 pages220kv Greenko Feeder-2 Eqipment DetailsVeera ChaitanyaNo ratings yet

- Hach-Camp Revised (11.10.23)Document15 pagesHach-Camp Revised (11.10.23)SubhadipSamanta OfficialNo ratings yet

- PWM Top221-227Document21 pagesPWM Top221-227gilsonNo ratings yet

- Ppl-Npl-Fosl-Egb-Pwis-Ele-Dwg-001 - Single Line Diagram C01Document1 pagePpl-Npl-Fosl-Egb-Pwis-Ele-Dwg-001 - Single Line Diagram C01segunNo ratings yet

- Sse-Bom-020-R3-2425 Date 23-05-2024Document1 pageSse-Bom-020-R3-2425 Date 23-05-2024neerav saxenaNo ratings yet

- BeforeDocument7 pagesBeforebambangperbonNo ratings yet

- 60V 3A LT3430 Aug02 MagDocument3 pages60V 3A LT3430 Aug02 MagMes BenNo ratings yet

- Features: TPIC74100-Q1 Buck/Boost Switch-Mode RegulatorDocument30 pagesFeatures: TPIC74100-Q1 Buck/Boost Switch-Mode RegulatorSyah NormanNo ratings yet

- Ax 3001Document12 pagesAx 3001cuervituNo ratings yet

- Plate 3 Electrical Load Additional Reqmts Group 7...Document2 pagesPlate 3 Electrical Load Additional Reqmts Group 7...Arguelles NicoleNo ratings yet

- Zero Voltage Switch CA3059: ON SemiconductorDocument8 pagesZero Voltage Switch CA3059: ON SemiconductordangthanhlinhNo ratings yet

- Pressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesDocument2 pagesPressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesNatalia BeltránNo ratings yet

- Pressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesDocument2 pagesPressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesJulio Andres Garcia PabolaNo ratings yet

- 2018 - Pressure Operated Switch PDFDocument2 pages2018 - Pressure Operated Switch PDFNatalia BeltránNo ratings yet

- Side-Power: Series / Paralell Switch BoxDocument8 pagesSide-Power: Series / Paralell Switch BoxAsep TatangNo ratings yet

- INVERSOR HIBRIDO PV3000 LVHM 1KW-6KW Solar Inverter 110V MUSTDocument1 pageINVERSOR HIBRIDO PV3000 LVHM 1KW-6KW Solar Inverter 110V MUSTDaniel Perez OsorioNo ratings yet

- Bremas 2010 Cam-Switches CA PDFDocument26 pagesBremas 2010 Cam-Switches CA PDFJonathan CastilloNo ratings yet

- 1 Part 28Document1 page1 Part 28mamunfauziNo ratings yet

- 0.25 To 0.75 KW 230V Standard Control: RelayDocument1 page0.25 To 0.75 KW 230V Standard Control: RelaysimbamikeNo ratings yet

- Sistema Edc VolvoDocument4 pagesSistema Edc VolvoJuan Carlos Callas GarayNo ratings yet

- PsinstallDocument1 pagePsinstallipekdursunNo ratings yet

- Model Sheet 115 - 25 Terminal 9 - 20Document2 pagesModel Sheet 115 - 25 Terminal 9 - 20Gusukuma JGNo ratings yet

- ManualDocument2 pagesManualFernando Tsuyoshi KikuchiNo ratings yet

- Main Cable Sizing BB RL TWISTEDDocument2 pagesMain Cable Sizing BB RL TWISTEDIsnan ArsyadNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- of PDP Dec-21Document28 pagesof PDP Dec-21BHUVANESH MNo ratings yet

- Section-7.3 Substation EquipmentDocument84 pagesSection-7.3 Substation EquipmentBRB CABLENo ratings yet

- Voltage Protector Model:AFMEP-2P/63P: DescriptionDocument2 pagesVoltage Protector Model:AFMEP-2P/63P: Descriptionabboud1294No ratings yet

- Delta and Wye 3-Phase Circuits - AC Electric Circuits WorksheetsDocument10 pagesDelta and Wye 3-Phase Circuits - AC Electric Circuits WorksheetsMohamad SannanNo ratings yet

- 1450RC Mars 100Document3 pages1450RC Mars 100Mr_UniversalNo ratings yet

- HA 25.71 Medium Voltage Switchgear NXAIR 2010Document28 pagesHA 25.71 Medium Voltage Switchgear NXAIR 2010Ayman Saber100% (1)

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityHardik MehtaNo ratings yet

- Areva MBCHDocument16 pagesAreva MBCHronald_chan_2100% (3)

- Star and Delta SystemDocument7 pagesStar and Delta Systemjagadeeshkumar116No ratings yet

- 1SDA054412R1-t5h-630-pr221ds-ls-i-in-630-3p-f-f - ABB RevisionDocument3 pages1SDA054412R1-t5h-630-pr221ds-ls-i-in-630-3p-f-f - ABB RevisionWangunNo ratings yet

- Trip Circuit Supervision Relays - Type v95rsDocument4 pagesTrip Circuit Supervision Relays - Type v95rsParva NailiNo ratings yet

- R&T 2007 - Electrical Best Practices - HeeresDocument14 pagesR&T 2007 - Electrical Best Practices - Heeresprasad_rvsNo ratings yet

- 110 - Power Distribution Wiring SchematicsDocument34 pages110 - Power Distribution Wiring SchematicsGedas GvildysNo ratings yet

- 37, 46N, 50/51, 50N/51N, 51BF, 68: Capacitor Overload, Earth Fault and Unbalance ProtectionDocument2 pages37, 46N, 50/51, 50N/51N, 51BF, 68: Capacitor Overload, Earth Fault and Unbalance ProtectionjjcanoolivaresNo ratings yet

- Multi-Functional Primary Test System For Substation Commissioning and MaintenanceDocument44 pagesMulti-Functional Primary Test System For Substation Commissioning and MaintenanceMajid Raja ChauhanNo ratings yet

- 23 - A StudyDocument5 pages23 - A StudySherry SherNo ratings yet

- Current Transformer CT Class Ratio Error Phase Angle Error in Current Transformer - Electrical EngineeringDocument5 pagesCurrent Transformer CT Class Ratio Error Phase Angle Error in Current Transformer - Electrical Engineeringgaurang1111No ratings yet

- Design EngineeringDocument6 pagesDesign EngineeringNoel JenningsNo ratings yet

- SSB 3 (Eng)Document88 pagesSSB 3 (Eng)syahadah98No ratings yet

- CB RelaysDocument144 pagesCB RelaysnagarajaNo ratings yet

- Dry Type Transformer 1DAT01Document6 pagesDry Type Transformer 1DAT01Santoshkumar GuptaNo ratings yet

- Dtf-016 - 400kv Gis BushingDocument1 pageDtf-016 - 400kv Gis BushingAnonymous EVFw59No ratings yet

- How Avr Operate. How To Size Up Avr.77006Document6 pagesHow Avr Operate. How To Size Up Avr.77006Rafat ThongNo ratings yet

- MCB CharacteristicsDocument11 pagesMCB CharacteristicsYasmin IsmailNo ratings yet

- FT DVPOWER TRT500 Rev1 PDFDocument14 pagesFT DVPOWER TRT500 Rev1 PDFUlyyszesz AalvaaraadooNo ratings yet

- Design BasisDocument30 pagesDesign BasisRahulNo ratings yet

- Tmax t7-t7mDocument88 pagesTmax t7-t7misraelteteuNo ratings yet

- Best Practice Personal Protective GroundingDocument17 pagesBest Practice Personal Protective GroundingShung Tak ChanNo ratings yet

- Industrial Electronics Lab 4Document4 pagesIndustrial Electronics Lab 4Prio DurjoyNo ratings yet

Kiln Controller: Summary: The System I Use in My Own Shop

Kiln Controller: Summary: The System I Use in My Own Shop

Uploaded by

Justin WellsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kiln Controller: Summary: The System I Use in My Own Shop

Kiln Controller: Summary: The System I Use in My Own Shop

Uploaded by

Justin WellsCopyright:

Available Formats

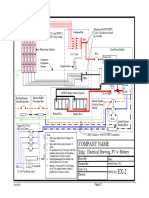

Summary: The system I use in my own shop –

After a good many years of experimenting with different hookup arrangements I would like

to share with you what I do in my own shop. Each kiln has its own mercury relay hard wired to

the kiln. The kiln is plugged into a source of power which is protected by fuses or breaker box.

Controller Kiln

Type "K" Thermocouple

For OverTemp Control

(Use ALM2) #13-14

120 VAC

-

1 13 14 6 SSR

25 AMP

+ 12VDC

2 7

+

-

3 8

+ 4 9

- 5 10

Neutral

120 VAC

POWER

UP

Mercury

TOGGLE

Relay

ON/OFF

120 VAC, 1 AMP FUSE

6" x 6" x 6" Euro Box Housing Shell GROUND

Use #6 Gauge

SHELL

Ground Line

Supply Line Ground Kiln Shell

Schematic of Component Parts 50 AMP

NOT TO SCALE FUSE

120 VAC

240 VAC

15 AMP

50 AMP

Power Supply

Power Supply

for Controller

with Ground Line

Fig. 14 Schematic for controller and kiln with internal over temperature control through the use of the Alm-2 function. This kiln has a 240 volt

power source with 3 elements for heat and it draws 42 amps of power. The kiln and mercury relay are “hard wired” and the control box is hooked

onto a cool side of the kiln and plugged in to a wall outlet. The mercury relay is plugged into the control box and the pyrometer is inserted through

the kiln wall to read the internal kiln temperature.

And finally I want to discuss a little more about over temperature control. I have never

experienced what is call a “lock-on” or a melt down since I’ve been using automatic controllers. I

had plenty of that foolish stuff when I was manually running things in my gas annealer or in chro-

malox controlled annealers. But as has already been mentioned the Auber controller has two alarm

circuits which work perfectly for our purposes and the one I most prefer is the Alm-2, what is

called the low alarm. This means if the temperature of the probe is under the set parameter the cir-

cuit is closed. Say with an annealer you don’t want the temperature to ever get above 965˚ F. you

would set the parameter of Alm-2 at 965. Put this relay inline with the power going to the mercury

relay coil. Now if ever the temperature goes above 965˚ F. the power to mercury relay coil is shut

off which in turn kills the power to the elements. When the temperature drops below 965 the

power goes back on. The advantage of this system is you don’t loose your glass which would hap-

pen from a latching relay which essentially would crash the kiln. If you wanted to know this event

was in process you could set the Alm-1 to 965˚F too. This relay works just the opposite. When the

temperature event occurs this circuit will close (not open as Alm-2 does) which can send power to an

alarm light or buzzer or both. Again, if you like the latching relay idea use the DigiKey #PB472-ND.

I want to devote a few pages to the actual construction of this handy controller.

How to Build Your Own Controller, Page 11

You might also like

- 17th Edition Exam QuestionsDocument18 pages17th Edition Exam Questionspete16No ratings yet

- 30.72 KWP SLDDocument1 page30.72 KWP SLDDaniel Gnanaselvam100% (1)

- Rele Detrol ControlsDocument4 pagesRele Detrol ControlsLJ GustavoNo ratings yet

- Low Voltage Circuit Breakers: Meta-MECDocument16 pagesLow Voltage Circuit Breakers: Meta-MECFrank FacebNo ratings yet

- 270-275 Series Data SheetDocument4 pages270-275 Series Data SheetkimhaeNo ratings yet

- Gps Airman Generator BrochureDocument6 pagesGps Airman Generator BrochureThành Long NguyễnNo ratings yet

- NEMA Configuration Chart - SECTION RDocument4 pagesNEMA Configuration Chart - SECTION RElMocoVengadorNo ratings yet

- MCCB GB e 1003Document16 pagesMCCB GB e 1003GIOVANNI BAUTISTANo ratings yet

- 04 - 860E - 24v Aux - Mech PDFDocument51 pages04 - 860E - 24v Aux - Mech PDFChester Dalitso Mwanza100% (1)

- Siemens Circuit Switcher BrochureDocument16 pagesSiemens Circuit Switcher BrochureCarlos FernandezNo ratings yet

- Spec SEC-2425UL FICHA TECNICA SAMLEX SEC-2425UL 25APM - 24VOLDocument1 pageSpec SEC-2425UL FICHA TECNICA SAMLEX SEC-2425UL 25APM - 24VOLAdriana martinezNo ratings yet

- Cable Schedule P 90916 E D2 8532 124 01 PCS PARLI Revision 2Document18 pagesCable Schedule P 90916 E D2 8532 124 01 PCS PARLI Revision 2AnilNo ratings yet

- Onan P9500 DF Portatil Dual Fuel Gas LPG 0059501Document2 pagesOnan P9500 DF Portatil Dual Fuel Gas LPG 0059501Alan MtzNo ratings yet

- Sedecal HF Series X Ray Generator Service Manual 390 427Document38 pagesSedecal HF Series X Ray Generator Service Manual 390 427humberto bedoyaNo ratings yet

- Binder Wiring Escalator Modification Atrium Senen Food MartDocument13 pagesBinder Wiring Escalator Modification Atrium Senen Food MartWiratama MudaNo ratings yet

- SMF Instruction ManualDocument4 pagesSMF Instruction ManualKan KhabourNo ratings yet

- Solid-State Relays: FeaturesDocument22 pagesSolid-State Relays: FeaturesBryanJermyHendrikNo ratings yet

- 0859 Solid State Relays Data SheetDocument23 pages0859 Solid State Relays Data SheetGerardo LozanoNo ratings yet

- DM311Document16 pagesDM311Hernan Ortiz EnamoradoNo ratings yet

- FPA18 Series Technical DataDocument8 pagesFPA18 Series Technical Datajore77No ratings yet

- manual-topworx-d-esd-partial-stroke-emergency-shut-down-iom-topworx-en-4852782 (1)Document28 pagesmanual-topworx-d-esd-partial-stroke-emergency-shut-down-iom-topworx-en-4852782 (1)yazuk599No ratings yet

- 150Khz, 3A PWM Buck DC/DC Converter: Advanced Power Electronics CorpDocument12 pages150Khz, 3A PWM Buck DC/DC Converter: Advanced Power Electronics CorpOjahan HNo ratings yet

- Electrical and IgnitionDocument26 pagesElectrical and IgnitionmartinbexnerNo ratings yet

- Cable Sizing CalculationDocument522 pagesCable Sizing Calculationadi_sofa100% (4)

- SLR 5 e 100Document4 pagesSLR 5 e 100valeriamoyarojasNo ratings yet

- LC1Kpp: WarningDocument1 pageLC1Kpp: WarningJavier LazoNo ratings yet

- Pv3000 LMPK 2021 New UpdatedDocument1 pagePv3000 LMPK 2021 New UpdatedPedro Noriega CardozoNo ratings yet

- 2298 GasboyDocument13 pages2298 GasboyAhmed AbdoNo ratings yet

- Em 8677Document4 pagesEm 8677solisiusNo ratings yet

- 7805 Voltage Regulator CircuitDocument2 pages7805 Voltage Regulator CircuitArmoured SmilerNo ratings yet

- 1794-OW8 Installation Instructions FLEX IO 8 Relay Output Module-4Document1 page1794-OW8 Installation Instructions FLEX IO 8 Relay Output Module-4zeroseyaNo ratings yet

- Chipown: 3A, 18V Synchronous Rectified Step-Down ConverterDocument9 pagesChipown: 3A, 18V Synchronous Rectified Step-Down ConverterBashar MohammadNo ratings yet

- Trafo-1 Test ReportDocument16 pagesTrafo-1 Test ReportramNo ratings yet

- KAM07Document3 pagesKAM07vvvNo ratings yet

- Solid State Relays Data SheetDocument23 pagesSolid State Relays Data SheetRizki AlNo ratings yet

- KA3842Document7 pagesKA3842QXNNo ratings yet

- 220kv Greenko Feeder-2 Eqipment DetailsDocument34 pages220kv Greenko Feeder-2 Eqipment DetailsVeera ChaitanyaNo ratings yet

- Hach-Camp Revised (11.10.23)Document15 pagesHach-Camp Revised (11.10.23)SubhadipSamanta OfficialNo ratings yet

- PWM Top221-227Document21 pagesPWM Top221-227gilsonNo ratings yet

- Ppl-Npl-Fosl-Egb-Pwis-Ele-Dwg-001 - Single Line Diagram C01Document1 pagePpl-Npl-Fosl-Egb-Pwis-Ele-Dwg-001 - Single Line Diagram C01segunNo ratings yet

- Sse-Bom-020-R3-2425 Date 23-05-2024Document1 pageSse-Bom-020-R3-2425 Date 23-05-2024neerav saxenaNo ratings yet

- BeforeDocument7 pagesBeforebambangperbonNo ratings yet

- 60V 3A LT3430 Aug02 MagDocument3 pages60V 3A LT3430 Aug02 MagMes BenNo ratings yet

- Features: TPIC74100-Q1 Buck/Boost Switch-Mode RegulatorDocument30 pagesFeatures: TPIC74100-Q1 Buck/Boost Switch-Mode RegulatorSyah NormanNo ratings yet

- Ax 3001Document12 pagesAx 3001cuervituNo ratings yet

- Plate 3 Electrical Load Additional Reqmts Group 7...Document2 pagesPlate 3 Electrical Load Additional Reqmts Group 7...Arguelles NicoleNo ratings yet

- Zero Voltage Switch CA3059: ON SemiconductorDocument8 pagesZero Voltage Switch CA3059: ON SemiconductordangthanhlinhNo ratings yet

- Pressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesDocument2 pagesPressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesNatalia BeltránNo ratings yet

- Pressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesDocument2 pagesPressure Operated Switch Data Sheet: K-85-0524 Rev AA FeaturesJulio Andres Garcia PabolaNo ratings yet

- 2018 - Pressure Operated Switch PDFDocument2 pages2018 - Pressure Operated Switch PDFNatalia BeltránNo ratings yet

- Side-Power: Series / Paralell Switch BoxDocument8 pagesSide-Power: Series / Paralell Switch BoxAsep TatangNo ratings yet

- INVERSOR HIBRIDO PV3000 LVHM 1KW-6KW Solar Inverter 110V MUSTDocument1 pageINVERSOR HIBRIDO PV3000 LVHM 1KW-6KW Solar Inverter 110V MUSTDaniel Perez OsorioNo ratings yet

- Bremas 2010 Cam-Switches CA PDFDocument26 pagesBremas 2010 Cam-Switches CA PDFJonathan CastilloNo ratings yet

- 1 Part 28Document1 page1 Part 28mamunfauziNo ratings yet

- 0.25 To 0.75 KW 230V Standard Control: RelayDocument1 page0.25 To 0.75 KW 230V Standard Control: RelaysimbamikeNo ratings yet

- Sistema Edc VolvoDocument4 pagesSistema Edc VolvoJuan Carlos Callas GarayNo ratings yet

- PsinstallDocument1 pagePsinstallipekdursunNo ratings yet

- Model Sheet 115 - 25 Terminal 9 - 20Document2 pagesModel Sheet 115 - 25 Terminal 9 - 20Gusukuma JGNo ratings yet

- ManualDocument2 pagesManualFernando Tsuyoshi KikuchiNo ratings yet

- Main Cable Sizing BB RL TWISTEDDocument2 pagesMain Cable Sizing BB RL TWISTEDIsnan ArsyadNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- of PDP Dec-21Document28 pagesof PDP Dec-21BHUVANESH MNo ratings yet

- Section-7.3 Substation EquipmentDocument84 pagesSection-7.3 Substation EquipmentBRB CABLENo ratings yet

- Voltage Protector Model:AFMEP-2P/63P: DescriptionDocument2 pagesVoltage Protector Model:AFMEP-2P/63P: Descriptionabboud1294No ratings yet

- Delta and Wye 3-Phase Circuits - AC Electric Circuits WorksheetsDocument10 pagesDelta and Wye 3-Phase Circuits - AC Electric Circuits WorksheetsMohamad SannanNo ratings yet

- 1450RC Mars 100Document3 pages1450RC Mars 100Mr_UniversalNo ratings yet

- HA 25.71 Medium Voltage Switchgear NXAIR 2010Document28 pagesHA 25.71 Medium Voltage Switchgear NXAIR 2010Ayman Saber100% (1)

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityHardik MehtaNo ratings yet

- Areva MBCHDocument16 pagesAreva MBCHronald_chan_2100% (3)

- Star and Delta SystemDocument7 pagesStar and Delta Systemjagadeeshkumar116No ratings yet

- 1SDA054412R1-t5h-630-pr221ds-ls-i-in-630-3p-f-f - ABB RevisionDocument3 pages1SDA054412R1-t5h-630-pr221ds-ls-i-in-630-3p-f-f - ABB RevisionWangunNo ratings yet

- Trip Circuit Supervision Relays - Type v95rsDocument4 pagesTrip Circuit Supervision Relays - Type v95rsParva NailiNo ratings yet

- R&T 2007 - Electrical Best Practices - HeeresDocument14 pagesR&T 2007 - Electrical Best Practices - Heeresprasad_rvsNo ratings yet

- 110 - Power Distribution Wiring SchematicsDocument34 pages110 - Power Distribution Wiring SchematicsGedas GvildysNo ratings yet

- 37, 46N, 50/51, 50N/51N, 51BF, 68: Capacitor Overload, Earth Fault and Unbalance ProtectionDocument2 pages37, 46N, 50/51, 50N/51N, 51BF, 68: Capacitor Overload, Earth Fault and Unbalance ProtectionjjcanoolivaresNo ratings yet

- Multi-Functional Primary Test System For Substation Commissioning and MaintenanceDocument44 pagesMulti-Functional Primary Test System For Substation Commissioning and MaintenanceMajid Raja ChauhanNo ratings yet

- 23 - A StudyDocument5 pages23 - A StudySherry SherNo ratings yet

- Current Transformer CT Class Ratio Error Phase Angle Error in Current Transformer - Electrical EngineeringDocument5 pagesCurrent Transformer CT Class Ratio Error Phase Angle Error in Current Transformer - Electrical Engineeringgaurang1111No ratings yet

- Design EngineeringDocument6 pagesDesign EngineeringNoel JenningsNo ratings yet

- SSB 3 (Eng)Document88 pagesSSB 3 (Eng)syahadah98No ratings yet

- CB RelaysDocument144 pagesCB RelaysnagarajaNo ratings yet

- Dry Type Transformer 1DAT01Document6 pagesDry Type Transformer 1DAT01Santoshkumar GuptaNo ratings yet

- Dtf-016 - 400kv Gis BushingDocument1 pageDtf-016 - 400kv Gis BushingAnonymous EVFw59No ratings yet

- How Avr Operate. How To Size Up Avr.77006Document6 pagesHow Avr Operate. How To Size Up Avr.77006Rafat ThongNo ratings yet

- MCB CharacteristicsDocument11 pagesMCB CharacteristicsYasmin IsmailNo ratings yet

- FT DVPOWER TRT500 Rev1 PDFDocument14 pagesFT DVPOWER TRT500 Rev1 PDFUlyyszesz AalvaaraadooNo ratings yet

- Design BasisDocument30 pagesDesign BasisRahulNo ratings yet

- Tmax t7-t7mDocument88 pagesTmax t7-t7misraelteteuNo ratings yet

- Best Practice Personal Protective GroundingDocument17 pagesBest Practice Personal Protective GroundingShung Tak ChanNo ratings yet

- Industrial Electronics Lab 4Document4 pagesIndustrial Electronics Lab 4Prio DurjoyNo ratings yet