Professional Documents

Culture Documents

Legends: L-Lecture T - Tutorial/Teacher Guided Student Activity P - Practical C - Credit ESE - End

Legends: L-Lecture T - Tutorial/Teacher Guided Student Activity P - Practical C - Credit ESE - End

Uploaded by

Sher Hai HamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Legends: L-Lecture T - Tutorial/Teacher Guided Student Activity P - Practical C - Credit ESE - End

Legends: L-Lecture T - Tutorial/Teacher Guided Student Activity P - Practical C - Credit ESE - End

Uploaded by

Sher Hai HamCopyright:

Available Formats

Man Made Fiber Technology Course Code: 3352901

GUJARAT TECHNOLOGICAL UNIVERSITY, AHMEDABAD, GUJARAT

COURSE CURRICULUM

COURSE TITLE: MAN MADE FIBER TECHNOLOGY

(COURSE CODE: 3352901)

Diploma Programme in which this courses offered Semester in which offered

Textile Manufacturing Technology 5th Semester

1. RATIONALE

Manmade fiber technology is a part of textile engineering where textile fibers are developed

from artificial sources. The demand of manmade fibers is on the rise and they are required in

the ever growing market for apparel, industrial applications and for functional uses. Global

demands for manmade fiber is continuously increasing year by year and innovations continue

to generate the new products. This subject provide knowledge regarding manmade fiber

technology and various manmade fibers, their classification, physical property, and

manufacturing process which is very essential for yarn spinning, weaving and processing also.

2. LIST OF COMPETENCY

The course content should be taught and implemented with the aim to develop require skills

in students so that they are able to acquire following competency:

Plan and supervise production of different manmade fiber

3. COURSE OUTCOMES

The theory should be taught and practical should be carried out in such a manner that students

are able to acquire required learning out comes in cognitive, psychomotor and affective

domain to demonstrate following course outcomes.

i. Maintain polymerization process technologies efficiently

ii. Plan and supervise production process of Nylon 6, Nylon 6.6 fiber and Acrylic fiber

iii. Use Melt, Wet and Dry spinning process technologies.

iv. Explain Spin Finish and Specialty in manmade fibers

v. Describe Tow-to-Top conversion technologies.

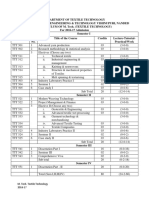

4. TEACHING AND EXAMINATION SCHEME

Teaching Scheme Total Examination Scheme

(In Hours) Credits Theory Marks Practical Marks Total

(L+T+P) Marks

L T P C ESE PA ESE PA 150

3 0 2 5 70 30 20 30

Legends: L-Lecture; T – Tutorial/Teacher Guided Student Activity; P -Practical; C – Credit;; ESE -End

Semester Examination; PA - Progressive Assessment.

GTU/ NITTTR Bhopal/14-15 Gujarat State

1

Man Made Fiber Technology Course Code: 3352901

5. COURSE DETAILS

Unit Major Learning Outcomes Topics and Sub-topics

(in cognitive domain)

Unit – I 1a. Differentiate between 1.1 Properties of manmade fibre and

Linear manmade and synthetic synthetic fibre.

Polymer fibres 1.2 Raw material used for manmade fiber:

and Raw 1b. Describe the features of the DMT, TPA, MEG, CAPLROLACTM,

Material raw materials used for the ADIPIC ACID, ACRYLONITRYLE

production of manmade 1.3 Polymerisation process

fibers 1.4 Monomer, Polymer, degree of

1c. Describe the salient features Polymerization.

of Polymerization process 1.5 Polymers: Criteria for fiber forming

1d. Distinguish Monomer, polymers

Polymer and degree of 1.6 Polymerisation reactions

Polymerization 1.7 Condensation polymerisation and

1e. Identify the different types Addition polymerisation

of polymers.

1f. Differentiate the

polymerization reactions.

Unit– II 2a. Describe the structure, Production process of important Man

Production properties of fibers and the Made Fibers

Process of polymerization process 2.1 Polyester Fiber: Structure, properties

Important 2b. Explain the production Polymerization process

Manmade process of Polyester using 2.2 Nylon 6 and Nylon 6.6 fibers:

Fiber flow diagram. structure, properties, continuous

2c. Describe the production polymerization process (V.K. tube

process of Nylon 6 and method), poly condensation

Nylon 6.6 fibers mechanism

2d. Describe the production 2.3 Acrylic Fiber: structure, properties,

process of Acrylic fibers Suspension polymerization, solution

and the criteria for selecting polymerization

raw material 2.4 Viscose Rayon fibers: Raw material

2e. Sketch the flow chart of the structure, properties, flow diagram of

production of viscose rayon production of Viscose rayon fiber.

fibers. 2.5 High performance fibres: structure,

2f. Describe the salient features properties, Aramid Fibers like Nomax,

of high performance kevlar. Carbon. Polypropylene,

fibers. Polyethylene, Micro fibers.

2g. Describe the salient features 2.6 HSHM fibres and application.

of HSHM fibers. Glass fibre – structure, properties.

Silicon Carbide - structure, properties.

Boron- structure, properties

GTU/ NITTTR Bhopal/14-15 Gujarat State

2

Man Made Fiber Technology Course Code: 3352901

Unit Major Learning Outcomes Topics and Sub-topics

(in cognitive domain)

Unit–III 3a. Explain Melt spinning Melt spinning

Melt, Wet process. 3.1 Melt spinning equipment

and Dry 3b. Distinguish Single, Double Single and Double Extruder.

spinning Extruder, Manifold and spin Mani fold – spin block section.

block. Quenching system.

3c. Determine process 3.2 Variables and condition for Melt

parameters related to spinning and High speed spinning.

manmade fibers 3.3 Variables and condition for Melt

3d. Describe the salient features spinning and High speed spinning.

of high speed spinning. 3.4 Spin draw processes: H4S process and

3e. Explain spin draw process. FDY process.

3f. Explain wet spinning Wet and Dry spinning

process. Preparation of Dope (Solution).

3g. Determine process Wet spinning process: Affecting factors

parameters related to Fiber Post spinning operation.

formation and coagulation Fiber formation and coagulation

variables. variables.

3h. Differentiate between Dry Dry spinning process.: Affecting factors

spinning process and dry jet

Dry jet Wet spinning process.

Wet spinning process

3.5 Melt, Wet and Dry Spinning.

3i. Distinguish the Melt, Wet

3.6 Drawing process.

and Dry Spinning

3j. Explain Drawing process.

Unit-IV 4a. Describe the properties and Spin Finish

Spin Finish functions of spin finish. 4.1 Spin finish: Functions, Desirable

and 4b. Compare the method of properties, Chemical constitute,

Specialty in applications of Spin finish. affecting factors

Manmade 4c. Determine Factors affecting 4.2 Method of application: Dipping roller

Fibers spin finish. method, Metered finish system

4.3 Problems encountered during the use of

Spin Finish.

4d. Explain limitations of Specialty Man Made Fibers (Modified

synthetic fibers. synthetic fibers)

4e. Describe the salient 4.4 Limitations of synthetic fibers.

features of modified 4.5 Modified polyester fibers: Hydrophilic,

polyester fibers and Hollow, Low pilling, Flame Retardant

modified nylon fiber Silky, Cationic Dyeable polyester fiber

4f. Distinguish between Bi- 4.6 Modified nylon fiber

component fiber and 4.7 Bi-component fiber and Lycra

Lycra (elastomeric fiber) (elastomeric fiber)

Unit-V 5a. Explain principle of 5.1 Principle of operation and objectives

Tow-to-Top operation of Tow-to-top Tow-to-top conversion

Conversion conversion. 5.2 Cutting methods: Crush cutting,

5b. Differentiate the features of Stretch break, Abrasive method.

various cutting methods.

GTU/ NITTTR Bhopal/14-15 Gujarat State

3

Man Made Fiber Technology Course Code: 3352901

6. SUGGESTED SPECIFICATION TABLE WITH HOURS and MARKS (THEORY)

Unit Teaching Distribution of Theory Marks

No. Unit Title Hours R U A Total

Level Level Level

I Linear Polymer and Raw Material 04 2 2 2 06

II Production Process of Important 12 6 10 4 20

Manmade Fiber

III Melt, Wet and Dry Spinning 11 4 12 2 18

IV Spin Finish and Specialty in 12 4 10 4 18

Manmade Fibers

V Tow-to-Top conversion 3 2 4 2 8

Total 42 18 38 14 70

Legends: R = Remember; U= Understand; A= Apply and above levels (Bloom’s Revised Taxonomy)

Note: This specification table shall be treated as a general guideline for students and teachers. The actual

distribution of marks in the question paper may vary slightly from above table.

7. SUGGESTED LIST OF EXERCISES / PRACTICALS:

Note: Here performance outcomes in psychomotor domain are listed as practical/exercises.

However, if these practical/exercises are completed and demonstrated appropriately, they

would contribute to the development of demonstrated learning in behavioral terms in

affective domain.

As a whole, the total approach towards acquisition of knowledge, skills, abilities and

behavior and demonstration of the same would lead to the development of Course

Outcomes. Thus over all development of Programme Outcomes (as given in a common list

at the beginning of curriculum document for this programme) would be assured.

Faculty should refer to that common list and should ensure that students also acquire

outcomes in affective domain which are required for overall achievement of Programme

Outcomes/Course Outcomes.

S. Unit Practical Exercises Hrs.

No. No. (Outcomes in Psychomotor Domain) required

1 I Obtain important features of manmade fibre. 02

2 II Draw and explain the process flow chart for Polyester fibre 02

3 II Draw and explain the process flow chart for Nylon fibre. 02

4 II Draw and explain the process flow chart for Acrylic fibre. 02

5 II Draw and explain the process flow chart for viscose rayon fibre. 02

Describe structure property and application of high performance

6 II 04

fibers.

7 III Draw and explain melt spinning equipments. 04

8 III Draw sketch and Explain melt spinning process. 02

9 III Draw sketch and Explain spin draw process. 02

10 III Draw sketch and Explain wet spinning process. 02

11 IV Obtain salient features of spin finish. 02

12 IV Describe methods of spin finish. 02

13 IV Sketch the microscopic view of modified synthetic fibre. 04

GTU/ NITTTR Bhopal/14-15 Gujarat State

4

Man Made Fiber Technology Course Code: 3352901

S. Unit Practical Exercises Hrs.

No. No. (Outcomes in Psychomotor Domain) required

14 V Demonstrate tow to top conversion process. 02

Total 32

8. SUGGESTED LIST OF STUDENT ACTIVITIES

Following is the list of proposed student activities like: course/topic based seminars, internet

based assignments, teacher, guided self learning activities, course/library/internet/lab based

mini-projects.

i. Explore library/internet for production technologies being used for production of

different manmade fibers and make a report.

ii. Collect Sample of manmade fibers.

iii. Visit to manmade fiber industry and preparing report with sketches.

iv. Prepare production flow chart of different manmade fibers.

9. SPECIAL INSTRUCTIONAL STRATEGIES (if any)

i. Educational video and CDs related to production technologies for manmade fiber

ii. Demonstrate models of production plants based on different technologies.

iii. Arrange expert lectures of experienced textile engineers working in manmade fiber

industry.

10. SUGGESTED LEARNING RESOURCES

A) List of Books

S. Title of Books Author Publication

No.

1 Synthetic fibres Vaidya, A.A. Mahajan Publishers Pvt.

Limited, Ahmedabad

2 Manmade fibres: Production, Gupta, V.B. and IIT Delhi

Processing, structure and Kothari, V.K.

applications

3 Textile Asia (T) 1976 16 Nigam Banerjee, N. N .

4 High polymers, Structure and Plastic Institute.

Properties.

5 Manmade fibres Moncrief

6 Manmade fibres V.A. Shenai

B) List of Major Equipment/ Instrument with Broad Specifications

i. Textile Laboratory – projection microscope

C) List of Software/Learning Websites

i. http:// www.uptti.ac.in/manmadefibre.php

ii. http:// www.minglebox.com/.../Diploma-in-Textile-Technology-Man-Made-Fibre-

Technology

iii. http:// www.uptti.ac.in/manmadefibre.php

iv. http:// en.wikipedia.org/wiki/Uttar_Pradesh_Textile_Technology_Institute

v. http:// www.engineering.careers360.com/man-made-fiber-technology

vi. www.fibersource.com

GTU/ NITTTR Bhopal/14-15 Gujarat State

5

Man Made Fiber Technology Course Code: 3352901

vii. www.whatispolyester.com

viii. www.epa.gov.

ix. www.textileschool.com

11. COURSE CURRICULUM DEVELOPMENT COMMITTEE

Faculty Members from Polytechnics

Prof. V. N. Soni, HOD Textile Manufacturing , R.C T I, Ahmedabad

Prof. Y.M. Gandhi, HOD Textile Manufacturing , B.P.T I, Bhavnagar

Prof. R T Patel, Lecturer in Textile Manufacturing, R.C T I, Ahmedabad

Prof. B.B. Bhatt, Lecturer in Textile Manufacturing, B.P.T I, Bhavnagar

Prof. S. M. Zala, Lecturer in Textile Manufacturing, Sir B.P.T.I, Bhavanagar

Prof.Ms. P.M.Parmar, Lecturer in Textile Manufacturing, R.C T I, Ahmedabad

Co-ordinator and Faculty Member from NITTTR Bhopal

Dr. C. K. Chugh, Professor Department of Mechanical Engineering

Dr. Joshua Earnest, Professor, Department of Electrical and Electronics Engineering

GTU/ NITTTR Bhopal/14-15 Gujarat State

6

You might also like

- The Rieter Manual of Spinning Vol. 1-Pages 40 PDFDocument80 pagesThe Rieter Manual of Spinning Vol. 1-Pages 40 PDFAbdul RafayNo ratings yet

- Stag Pressure Evaluation Manual PDFDocument162 pagesStag Pressure Evaluation Manual PDFAlex DabijaNo ratings yet

- Texturising Processing of Microfilament On Texturising MachineDocument5 pagesTexturising Processing of Microfilament On Texturising MachineSher Hai HamNo ratings yet

- Syllabus-PULP & PAPER TECHNOLOGYDocument5 pagesSyllabus-PULP & PAPER TECHNOLOGYVijai B RaghavanNo ratings yet

- 3322902WT IDocument5 pages3322902WT ISinaiDasNo ratings yet

- 3352902Document7 pages3352902Sher Hai HamNo ratings yet

- Textile EngineeringDocument14 pagesTextile EngineeringNabeel BhuttaNo ratings yet

- 3352905Document5 pages3352905Sher Hai HamNo ratings yet

- The Rieter Manual of Spinning Vol. 7 2451-v1 en Original 68509 PDFDocument78 pagesThe Rieter Manual of Spinning Vol. 7 2451-v1 en Original 68509 PDFVishnuMaliNo ratings yet

- POLYMER TECHNOLOGY SYLLABUS Polytechnic KeralaDocument3 pagesPOLYMER TECHNOLOGY SYLLABUS Polytechnic KeralaprasobhaNo ratings yet

- Project Final File 000Document102 pagesProject Final File 000usmanazeemNo ratings yet

- 16ST106J RonbunDocument108 pages16ST106J RonbunianNo ratings yet

- Visvesvaraya Technological University: "Reuse of Waste Cotton Textile As An Ultrafiltration Membrane"Document24 pagesVisvesvaraya Technological University: "Reuse of Waste Cotton Textile As An Ultrafiltration Membrane"meghna GowdaNo ratings yet

- Fiber Science Bookby KSVDocument134 pagesFiber Science Bookby KSVGolda MadhuNo ratings yet

- Manmade Fibre TechnologyDocument4 pagesManmade Fibre Technologykanagaraj sreenathNo ratings yet

- LT 11 304 Footwear Workshp Practice - II C - 6 6 - 50 - 50Document33 pagesLT 11 304 Footwear Workshp Practice - II C - 6 6 - 50 - 50Thahseen AfzalNo ratings yet

- Elements of Textile and Garment TechnologyDocument7 pagesElements of Textile and Garment Technologypavan panwalaNo ratings yet

- ECCM19 - AbstractDocument3 pagesECCM19 - AbstractmelosNo ratings yet

- Nptel: Introduction To Composites - Web CourseDocument3 pagesNptel: Introduction To Composites - Web CourseAnu PriyaNo ratings yet

- Nptel: Textile Fibres - Web CourseDocument2 pagesNptel: Textile Fibres - Web CourseAks Bijnori100% (1)

- (Download PDF) Advanced Textile Engineering Materials First Edition Edition Butola Online Ebook All Chapter PDFDocument35 pages(Download PDF) Advanced Textile Engineering Materials First Edition Edition Butola Online Ebook All Chapter PDFdana.jones670100% (12)

- (Download PDF) Advanced Textile Engineering Materials First Edition Butola Online Ebook All Chapter PDFDocument42 pages(Download PDF) Advanced Textile Engineering Materials First Edition Butola Online Ebook All Chapter PDFdana.jones670100% (10)

- Underground Mining of Coal Course Code: 3362203Document6 pagesUnderground Mining of Coal Course Code: 3362203Santosh KumarNo ratings yet

- PDF Nanotechnology in Textiles Advances and Developments in Polymer Nanocomposites 1St Edition Mangala Joshi Editor Ebook Full ChapterDocument54 pagesPDF Nanotechnology in Textiles Advances and Developments in Polymer Nanocomposites 1St Edition Mangala Joshi Editor Ebook Full Chapterlydia.favila698100% (1)

- Polymer Foams Handbook: Engineering and Biomechanics Applications and Design GuideFrom EverandPolymer Foams Handbook: Engineering and Biomechanics Applications and Design GuideNo ratings yet

- JTP - Volume 8 - Issue 2 - Pages 1-14Document12 pagesJTP - Volume 8 - Issue 2 - Pages 1-14José Roberto LazoNo ratings yet

- Effect of Yarn Wetting On Some Physical Properties of Polyamide 6 False-Twist Textured YarnDocument8 pagesEffect of Yarn Wetting On Some Physical Properties of Polyamide 6 False-Twist Textured YarnFahima RashidNo ratings yet

- Technical Textile SyllabusDocument5 pagesTechnical Textile SyllabusSujit GulhaneNo ratings yet

- Thông Tin Sợi Thủy Tinh Bản t.anhDocument70 pagesThông Tin Sợi Thủy Tinh Bản t.anhhue558110No ratings yet

- Syllabus III and IV SemDocument16 pagesSyllabus III and IV Semadityakushwaha371No ratings yet

- Full Ebook of Textile Chemistry Second Edition Thomas Bechtold Online PDF All ChapterDocument69 pagesFull Ebook of Textile Chemistry Second Edition Thomas Bechtold Online PDF All Chapterthomasguess572493100% (6)

- Full Ebook of Textile Chemistry 2Nd Edition Thomas Bechtold Online PDF All ChapterDocument69 pagesFull Ebook of Textile Chemistry 2Nd Edition Thomas Bechtold Online PDF All Chaptermabchelleanakinskywalkeb633100% (7)

- Effect of Core Draft On The Properties o PDFDocument40 pagesEffect of Core Draft On The Properties o PDFDyeing DyeingNo ratings yet

- Syllabus For Textile ProcessingDocument3 pagesSyllabus For Textile ProcessingSakthi TharanNo ratings yet

- Renata Thesis Final THS 02Document236 pagesRenata Thesis Final THS 02IHSAN Sons - PM NonwovensNo ratings yet

- End Breakage Control in OEDocument7 pagesEnd Breakage Control in OEadama spinningNo ratings yet

- Blended Project (Cotton, Polyester, Flax)Document6 pagesBlended Project (Cotton, Polyester, Flax)Towfic Aziz KanonNo ratings yet

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum Chemical Process Technology-I (Code: 3330505)Document5 pagesGujarat Technological University, Ahmedabad, Gujarat Course Curriculum Chemical Process Technology-I (Code: 3330505)joshi madhavNo ratings yet

- Course Outline Course Information: Total Hours/SemesterDocument7 pagesCourse Outline Course Information: Total Hours/SemestersurayaNo ratings yet

- SyllabusDocument6 pagesSyllabusAbhishek Gond100% (1)

- Inductrial Training Report FormatDocument5 pagesInductrial Training Report FormatAyush VishwakarmaNo ratings yet

- Rieter Special Print Recycling 3379 v1n en 02 PDFDocument44 pagesRieter Special Print Recycling 3379 v1n en 02 PDFMohamed NaeimNo ratings yet

- Full Download Book Bio Based Nanomaterials Synthesis Protocols Mechanisms and Applications PDFDocument41 pagesFull Download Book Bio Based Nanomaterials Synthesis Protocols Mechanisms and Applications PDFmichael.helm936100% (28)

- Plastics Materials: Properties and ApplicationsDocument7 pagesPlastics Materials: Properties and ApplicationsArnold SigeyNo ratings yet

- Tex-217 Textile Fiber 2Document3 pagesTex-217 Textile Fiber 2Tauhidul Islam NaeemNo ratings yet

- Research About Manufacturing ProcessesDocument6 pagesResearch About Manufacturing ProcessesArturo Herrera HdzNo ratings yet

- Full ThesisDocument92 pagesFull ThesisIzza MiftaaNo ratings yet

- Advances in Bio Based Fiber Moving Towards A Green Society Sanjay Mavinkere Rangappa Full ChapterDocument51 pagesAdvances in Bio Based Fiber Moving Towards A Green Society Sanjay Mavinkere Rangappa Full Chaptervicki.rodriguez989100% (16)

- SE TextileDocument21 pagesSE TextileAbhishekNo ratings yet

- Full Text 01Document54 pagesFull Text 01venkatspinnerNo ratings yet

- 20384-Polymers Information and ActivityDocument164 pages20384-Polymers Information and ActivityAbdodada DadaNo ratings yet

- Polymer Matrix Composite Materials Structural and Functional Applications 1st Edition Debdatta Ratna Bikash Chandra ChakrabortyDocument70 pagesPolymer Matrix Composite Materials Structural and Functional Applications 1st Edition Debdatta Ratna Bikash Chandra Chakrabortydavid.young537100% (8)

- MeltSpinning Genel (Bikomponent)Document32 pagesMeltSpinning Genel (Bikomponent)Uscan UskanerNo ratings yet

- Lab Report: BGMEA University of Fashion and TechnologyDocument6 pagesLab Report: BGMEA University of Fashion and TechnologyRian HossainNo ratings yet

- All Students Are Expected To Be On Time For The Lectures, Late Arrival, Is Disruptive To Class Therefore, Will Not Be ToleratedDocument6 pagesAll Students Are Expected To Be On Time For The Lectures, Late Arrival, Is Disruptive To Class Therefore, Will Not Be ToleratedSamantha KachelNo ratings yet

- Textile TechnologyDocument20 pagesTextile TechnologyMinh Hoang100% (1)

- PDFDocument3 pagesPDFYogesh SharmaNo ratings yet

- Full Download Book Advances in Bio Based Fiber Moving Towards A Green Society PDFDocument41 pagesFull Download Book Advances in Bio Based Fiber Moving Towards A Green Society PDFtonja.oneal380100% (31)

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- Introduction to Microsystem Technology: A Guide for StudentsFrom EverandIntroduction to Microsystem Technology: A Guide for StudentsRating: 5 out of 5 stars5/5 (1)

- JBF Investor Presentation - March 2013Document30 pagesJBF Investor Presentation - March 2013Sher Hai HamNo ratings yet

- JBF Investor Presentation - NovembeDocument37 pagesJBF Investor Presentation - NovembeSher Hai HamNo ratings yet

- Uiltipleat Polymer Candle Doubles Filtration CapacityDocument2 pagesUiltipleat Polymer Candle Doubles Filtration CapacitySher Hai HamNo ratings yet

- April 28, 1970 K. Kohl 3,508,419: Filed June 25, 1968Document3 pagesApril 28, 1970 K. Kohl 3,508,419: Filed June 25, 1968Sher Hai HamNo ratings yet

- Advertisement For Admissions Into Diploma To Degree Engineering English1654691609Document1 pageAdvertisement For Admissions Into Diploma To Degree Engineering English1654691609Sher Hai HamNo ratings yet

- 1629454705-pfg402 Polymer Brochure Aug21Document8 pages1629454705-pfg402 Polymer Brochure Aug21Sher Hai HamNo ratings yet

- Curriculum - Spinning TechnicianDocument62 pagesCurriculum - Spinning TechnicianSher Hai HamNo ratings yet

- 4ReviewontheManufacturingProcessesofPolyester PETandNylon 6FilamentYarnDocument7 pages4ReviewontheManufacturingProcessesofPolyester PETandNylon 6FilamentYarnSher Hai HamNo ratings yet

- 2021 Approved Circular 100ACTIVITY Internal Approval 523087Document1 page2021 Approved Circular 100ACTIVITY Internal Approval 523087Sher Hai HamNo ratings yet

- M.Tech Textile Syllabus 2016-17Document18 pagesM.Tech Textile Syllabus 2016-17Sher Hai HamNo ratings yet

- Yarn Manufacturing-I Subject Code:-3322901Document36 pagesYarn Manufacturing-I Subject Code:-3322901Sher Hai HamNo ratings yet

- Air Jet Weaving Government Polytechnicnagpur - CompressDocument12 pagesAir Jet Weaving Government Polytechnicnagpur - CompressSher Hai HamNo ratings yet

- 3352902Document7 pages3352902Sher Hai HamNo ratings yet

- Gujarat Technological University, Ahmedabad, Gujarat Course Curriculum Course Title: CourseDocument6 pagesGujarat Technological University, Ahmedabad, Gujarat Course Curriculum Course Title: CourseSher Hai HamNo ratings yet

- Texturising Processing of Microfilament On Texturising MachineDocument5 pagesTexturising Processing of Microfilament On Texturising MachineSher Hai HamNo ratings yet

- 3352905Document5 pages3352905Sher Hai HamNo ratings yet

- Fabric DefectsDocument48 pagesFabric Defectstheoneandonlyvicky100% (5)

- Handbook of Textile Fibres - J. Gordon CookDocument20 pagesHandbook of Textile Fibres - J. Gordon CookSajawal Anwaar100% (1)

- Textile Handbook-1Document36 pagesTextile Handbook-1Celeste Rodríguez100% (1)

- Controlled Substances in Alphabetical OrderDocument17 pagesControlled Substances in Alphabetical Orderthor888888No ratings yet

- Introduction To Seaweed Polysaccharides: July 2017Document10 pagesIntroduction To Seaweed Polysaccharides: July 2017duverney.gaviriaNo ratings yet

- Unit 5 A - Mec108tDocument62 pagesUnit 5 A - Mec108tHariDharan MNo ratings yet

- Presentation 16Document149 pagesPresentation 16rasagna reddyNo ratings yet

- Biodegradable Polymers in Controlled Drug DeliveryDocument36 pagesBiodegradable Polymers in Controlled Drug Deliveryraghanaveen100% (6)

- Method To Access Quality of ProcessDocument55 pagesMethod To Access Quality of Processnagpal_aakashNo ratings yet

- Composite Materials and Mechanics Anna University Question PaperDocument3 pagesComposite Materials and Mechanics Anna University Question Papermagesh.mx67% (3)

- RopesDocument34 pagesRopesabhishekverma86No ratings yet

- Isomerism Test With AnswerDocument5 pagesIsomerism Test With AnswerPRATHAMNo ratings yet

- Theol Heat Transfer FluidDocument3 pagesTheol Heat Transfer Fluidgautam_96948069No ratings yet

- Color Mixing For ArtistDocument2 pagesColor Mixing For ArtistMervi Hjelmroos-Koski100% (1)

- Household Words. Apparently, The Item Was Invented by Winsor & Newton Some Time During TheDocument2 pagesHousehold Words. Apparently, The Item Was Invented by Winsor & Newton Some Time During Thestemi stemiNo ratings yet

- Restrepo Et Al 2019 Erythroxylum in FocusDocument27 pagesRestrepo Et Al 2019 Erythroxylum in FocusLauritha CortesNo ratings yet

- Petroleum Facilites of Germany 1945 100Document33 pagesPetroleum Facilites of Germany 1945 100ENAK9000100% (1)

- European Patent Application: (19) (11) (12) Published in Accordance With Art. 153 (4) EPCDocument18 pagesEuropean Patent Application: (19) (11) (12) Published in Accordance With Art. 153 (4) EPCyigitilgazNo ratings yet

- Module 4 in ConChem 3rd GradingDocument2 pagesModule 4 in ConChem 3rd Gradingjohncarlodc99No ratings yet

- 08 Aparupa ReviewDocument3 pages08 Aparupa ReviewAnanda Olivia HamzahNo ratings yet

- Diamond Drillings and Its TypesDocument12 pagesDiamond Drillings and Its TypesPranjal Poudel0% (1)

- Pla+phb Blend CompositeDocument200 pagesPla+phb Blend Compositesush_24kumarNo ratings yet

- 5th Proff Past Papers - University of SargodhaDocument24 pages5th Proff Past Papers - University of Sargodhaaalishba6a2b9cNo ratings yet

- American Riggers CatalogDocument124 pagesAmerican Riggers CatalogJogi Oscar Sinaga100% (2)

- Extraction of Natural Dye From Butea Monosperma (Lam.) Taub. Flower Dyeing Cotton - Polyester FabricDocument3 pagesExtraction of Natural Dye From Butea Monosperma (Lam.) Taub. Flower Dyeing Cotton - Polyester FabricIJAR JOURNALNo ratings yet

- Nonfiction Reading Test 7 KevlarDocument2 pagesNonfiction Reading Test 7 Kevlarapi-306891613No ratings yet

- The Chemistry of Novolac Resins. I A Review On The Use of ModelsDocument9 pagesThe Chemistry of Novolac Resins. I A Review On The Use of ModelsELIZANo ratings yet

- Brochure - Electrical Insulating PapersDocument28 pagesBrochure - Electrical Insulating Papersbpd21No ratings yet

- Engineering Chemistry Polymers and Polymerization: BSC 102: Course Name: Topic Course CodeDocument21 pagesEngineering Chemistry Polymers and Polymerization: BSC 102: Course Name: Topic Course CodeAshok KumarNo ratings yet