Professional Documents

Culture Documents

Shell Gadus S3 V220 C 2

Shell Gadus S3 V220 C 2

Uploaded by

chandan sahooCopyright:

Available Formats

You might also like

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- Manual de Partes M44 and M44 EXDocument160 pagesManual de Partes M44 and M44 EXJose Giacomino100% (1)

- Shell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsMiguel ArizaNo ratings yet

- TDS - Shell Gadus S3 V220C 2 - ENDocument2 pagesTDS - Shell Gadus S3 V220C 2 - ENdtcuongNo ratings yet

- Shell Gadus S3 V220C 2: Performance, Features & BenefitsDocument2 pagesShell Gadus S3 V220C 2: Performance, Features & BenefitsDaniel PrecupNo ratings yet

- Shell Gadus S3 V220C 2Document2 pagesShell Gadus S3 V220C 2Xavier DiazNo ratings yet

- TDS - Shell Gadus S3 V220C 3 - ENDocument2 pagesTDS - Shell Gadus S3 V220C 3 - ENdtcuongNo ratings yet

- TDS Shell Gadus S3 V220C - 2 - EngDocument2 pagesTDS Shell Gadus S3 V220C - 2 - EngKamil ShabriNo ratings yet

- Shell Gadus S3 V220 C2Document2 pagesShell Gadus S3 V220 C2regisNo ratings yet

- Shell Gadus S3 V220C 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S3 V220C 2: Performance, Features & Benefits Main ApplicationsregisNo ratings yet

- TDS - Gadus S2 V220ac 2Document2 pagesTDS - Gadus S2 V220ac 2Roger ObregonNo ratings yet

- Shell Gadus S2 V220AC 2Document2 pagesShell Gadus S2 V220AC 2Muhammad SaputraNo ratings yet

- TDS Shell Gadus S3 V220 C 3Document2 pagesTDS Shell Gadus S3 V220 C 3Rach RachmanNo ratings yet

- Shell Gadus S2 V460D 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S2 V460D 2: Performance, Features & Benefits Main ApplicationsMUHAMMAD LUTHFINo ratings yet

- Gpcdoc Gtds Shell Gadus s3 v460xd 2 (En) TdsDocument2 pagesGpcdoc Gtds Shell Gadus s3 v460xd 2 (En) TdsRoger ObregonNo ratings yet

- Shell Gadus S3 V460D 2: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Gadus S3 V460D 2: Performance, Features & Benefits Specifications, Approvals & Recommendationsrstec pyNo ratings yet

- PDS Gadus S3 V460D 2 - SHELLDocument2 pagesPDS Gadus S3 V460D 2 - SHELLGilmer Williams Cáceres BenaventeNo ratings yet

- S3 V460D 2 - TDS PDFDocument2 pagesS3 V460D 2 - TDS PDFWawanDarmawanNo ratings yet

- GPCDOC Local TDS Hong Kong Shell Gadus S2 V220 2 (en-HK) TDS PDFDocument2 pagesGPCDOC Local TDS Hong Kong Shell Gadus S2 V220 2 (en-HK) TDS PDFQatar home RentNo ratings yet

- Shell Gadus S2 V220 2Document2 pagesShell Gadus S2 V220 2dicha gilangNo ratings yet

- Especificaciones GADUS S2 V220 AD 2Document2 pagesEspecificaciones GADUS S2 V220 AD 2Andres OchoaNo ratings yet

- Shell Gadus S1 V220 2Document2 pagesShell Gadus S1 V220 2Álgøkár ÁhmēdNo ratings yet

- Gadus S5 V220 2Document2 pagesGadus S5 V220 2Luqman Cuopreakt'zNo ratings yet

- S2 V150C 3Document2 pagesS2 V150C 3Raden ArdyNo ratings yet

- Shell Gadus s2v220 AdDocument2 pagesShell Gadus s2v220 AdKeny AnchtNo ratings yet

- Shell Gadus S3 V460D 2: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Gadus S3 V460D 2: Performance, Features & Benefits Specifications, Approvals & RecommendationsGera BdNo ratings yet

- Gadus S3 V460D 2Document2 pagesGadus S3 V460D 2Lubricants ServerNo ratings yet

- TDS Shell Gadus S2 V220 2Document2 pagesTDS Shell Gadus S2 V220 2regisNo ratings yet

- TDS - Shell Gadus S3 V460 1 - EN PDFDocument2 pagesTDS - Shell Gadus S3 V460 1 - EN PDFdtcuongNo ratings yet

- Gadus S2 V 1000 Ad 2 PDFDocument2 pagesGadus S2 V 1000 Ad 2 PDFsrikanth siddhardhaNo ratings yet

- Shell Gadus S2 V1000AD 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S2 V1000AD 2: Performance, Features & Benefits Main ApplicationsEmerson 2140No ratings yet

- TDS Gadus S5 V220 2Document2 pagesTDS Gadus S5 V220 2Nokiabhre WijayaNo ratings yet

- Shell Gadus S2 V220 0: Performance, Features & BenefitsDocument2 pagesShell Gadus S2 V220 0: Performance, Features & BenefitsRinki KashyapNo ratings yet

- Shell Gadus S2 V220 0 TDSDocument2 pagesShell Gadus S2 V220 0 TDSsvntamil_159541837No ratings yet

- Shell Gadus S2 V100 2Document2 pagesShell Gadus S2 V100 2Muhammad SaputraNo ratings yet

- Shell Gadus S5 V220 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S5 V220 2: Performance, Features & Benefits Main ApplicationsWawanDarmawanNo ratings yet

- Shell Gadus S2 V220D 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S2 V220D 2: Performance, Features & Benefits Main ApplicationsMUHAMMAD LUTHFINo ratings yet

- GPCDOC Local TDS United Kingdom Shell Gadus S3 V770D 1 (en-GB) TDSDocument2 pagesGPCDOC Local TDS United Kingdom Shell Gadus S3 V770D 1 (en-GB) TDSSalem IereebiNo ratings yet

- TDS Shell Gadus S2 V220 2Document2 pagesTDS Shell Gadus S2 V220 2Rach RachmanNo ratings yet

- GPCDOC Local TDS United Kingdom Shell Gadus S2 A320 2 (en-GB) TDSDocument2 pagesGPCDOC Local TDS United Kingdom Shell Gadus S2 A320 2 (en-GB) TDSsyuhaimi82No ratings yet

- Shell Gadus S3 V220C: Premium Multipurpose Extreme-Pressure GreaseDocument2 pagesShell Gadus S3 V220C: Premium Multipurpose Extreme-Pressure GreaseZlatko LazicNo ratings yet

- Shell Gadus S1 V220 2: Multi-Purpose Extreme Pressure GreaseDocument2 pagesShell Gadus S1 V220 2: Multi-Purpose Extreme Pressure GreaseFEBRIANSYAH NUSANTARANo ratings yet

- S3 V460DM 2 - TDSDocument2 pagesS3 V460DM 2 - TDSWawanDarmawanNo ratings yet

- Shell Gadus S2 V220 0: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S2 V220 0: Performance, Features & Benefits Main ApplicationsWawanDarmawanNo ratings yet

- Shell Gadus S2 A320 2Document3 pagesShell Gadus S2 A320 2Álgøkár ÁhmēdNo ratings yet

- FICHA Shell Gadus s4 v2600 AdDocument2 pagesFICHA Shell Gadus s4 v2600 AdGianella Xenia Cisneros MartinezNo ratings yet

- 11 Gadus S3 V460 2Document2 pages11 Gadus S3 V460 2Prakash GauravNo ratings yet

- ShellDocument2 pagesShellFAVIONo ratings yet

- Gadus S2 V 220 0Document2 pagesGadus S2 V 220 0AMITNo ratings yet

- Shell Gadus S2 V220 0: Performance, Features & BenefitsDocument2 pagesShell Gadus S2 V220 0: Performance, Features & BenefitsAnonymous 2vhqpcI6No ratings yet

- Shell Gadus S2 V220 00: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S2 V220 00: Performance, Features & Benefits Main Applicationsreport2510No ratings yet

- Gadus S2 V220 1 TDSDocument2 pagesGadus S2 V220 1 TDSKarim AbouhigaNo ratings yet

- PDS Shell GadusDocument2 pagesPDS Shell GadusTaufik BinasrNo ratings yet

- TDS - Shell Gadus S2 V220 0Document2 pagesTDS - Shell Gadus S2 V220 0Sunario YapNo ratings yet

- Pds Shell Gadus S2 V220-0Document2 pagesPds Shell Gadus S2 V220-0andri putrantoNo ratings yet

- Shell Gadus S2 A320 2Document2 pagesShell Gadus S2 A320 2Raden ArdyNo ratings yet

- Gadus S2 A320 2Document2 pagesGadus S2 A320 2Aaron ChanNo ratings yet

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingFrom EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingNo ratings yet

- Omala S2 G 100Document3 pagesOmala S2 G 100AMITNo ratings yet

- Shell Tellus S1 M 46: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Tellus S1 M 46: Performance, Features & Benefits Specifications, Approvals & RecommendationsAMITNo ratings yet

- Rimula R2 Extra 15W40Document2 pagesRimula R2 Extra 15W40AMITNo ratings yet

- Omala S2 G 220Document3 pagesOmala S2 G 220AMITNo ratings yet

- Shell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsAMITNo ratings yet

- Shell Rimula R3+ 30: Performance, Features & BenefitsDocument2 pagesShell Rimula R3+ 30: Performance, Features & BenefitsAMITNo ratings yet

- Shell Corena S4 R 68: Performance, Features & BenefitsDocument3 pagesShell Corena S4 R 68: Performance, Features & BenefitsAMITNo ratings yet

- Tellus S2 MX 32Document15 pagesTellus S2 MX 32AMITNo ratings yet

- ROIC How To Find Companies With Moats - Value Research - The Complete Guide To Mutual Funds PDFDocument3 pagesROIC How To Find Companies With Moats - Value Research - The Complete Guide To Mutual Funds PDFAMITNo ratings yet

- GS-54 Operations ManualDocument33 pagesGS-54 Operations Manualjohnstn4544No ratings yet

- Esab Price List 14 Jan 19Document1 pageEsab Price List 14 Jan 19Praveen driving ytNo ratings yet

- Mechanical IdentificationDocument6 pagesMechanical IdentificationObaidAliKhanNo ratings yet

- A - V Waterjet Parts Manual v1.7Document14 pagesA - V Waterjet Parts Manual v1.7Robert MorrellNo ratings yet

- Lecture 1 Machines and Machine MountingDocument7 pagesLecture 1 Machines and Machine Mountingodeke aronNo ratings yet

- Girth Gears - More Than Just Metal and Teeth: Steve LovellDocument8 pagesGirth Gears - More Than Just Metal and Teeth: Steve LovellFurqan ShabbirNo ratings yet

- PCM 2.0l 3 de 5Document2 pagesPCM 2.0l 3 de 5Felix VelasquezNo ratings yet

- Shindaiwa 394 Spare ManualDocument14 pagesShindaiwa 394 Spare ManualGiovanni MarinoNo ratings yet

- 2 Interference in Spur GearsDocument2 pages2 Interference in Spur Gearschris100% (1)

- Design of Double Slab at SHC-A1Document24 pagesDesign of Double Slab at SHC-A1dhee2608No ratings yet

- Product CatalogueDocument84 pagesProduct Cataloguerizaldy fachrulNo ratings yet

- Anti-Lock Brake System / Accelera-Tion GeneralDocument165 pagesAnti-Lock Brake System / Accelera-Tion GeneralLe ThanhNo ratings yet

- Brand Valve SDCFDocument4 pagesBrand Valve SDCFanon_211685604No ratings yet

- CPP Energy Generation Using Speed Breaker LDocument39 pagesCPP Energy Generation Using Speed Breaker Latharvsalunkhe6105No ratings yet

- CW 630 PJDocument1 pageCW 630 PJSuryacendra PuramegahNo ratings yet

- Regular Machining Dimension ToleranceDocument1 pageRegular Machining Dimension ToleranceSIVA 1010No ratings yet

- Daily Report LP Gas Compressor B - 10000 HRS PMDocument10 pagesDaily Report LP Gas Compressor B - 10000 HRS PMdikaNo ratings yet

- Alcaldia Mixed Rendering PlantDocument1 pageAlcaldia Mixed Rendering Plantgrovertarqui77No ratings yet

- The Process Control, The Control of Your WorldDocument8 pagesThe Process Control, The Control of Your WorldChristian Van MensidorNo ratings yet

- Manual ZF 6WG 211Document85 pagesManual ZF 6WG 211Yasser YasserNo ratings yet

- 304SS WR Spiral Wound GasketDocument3 pages304SS WR Spiral Wound GasketMarkNo ratings yet

- Pin Bambu - Google SearchDocument1 pagePin Bambu - Google SearchAgung Seras PerdanaNo ratings yet

- Section A-A Scale 1 / 2: Pete Lenz 8/21/2010Document8 pagesSection A-A Scale 1 / 2: Pete Lenz 8/21/2010Manish PatilNo ratings yet

- Government College of Technology, Coimbatore - 13 Department of Mechanical Engineering - Ug Course: Semester: Subject: Assignment: 03Document2 pagesGovernment College of Technology, Coimbatore - 13 Department of Mechanical Engineering - Ug Course: Semester: Subject: Assignment: 03SakthiNo ratings yet

- REGO - Pressure Builder - Economizer CBH CBCDocument1 pageREGO - Pressure Builder - Economizer CBH CBCcriuvosNo ratings yet

- Cengg11 Midterm 2021Document2 pagesCengg11 Midterm 2021Angelo VilleroNo ratings yet

- Tailing Frame DesignDocument5 pagesTailing Frame DesignfkamunityNo ratings yet

- G1000 IE2 60Hz EN 2815 1Document566 pagesG1000 IE2 60Hz EN 2815 1Charles SarmientoNo ratings yet

- Design Capacity of HCS: 265 Carpark 2 - Basement Level 1Document9 pagesDesign Capacity of HCS: 265 Carpark 2 - Basement Level 1anilkv66No ratings yet

Shell Gadus S3 V220 C 2

Shell Gadus S3 V220 C 2

Uploaded by

chandan sahooCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell Gadus S3 V220 C 2

Shell Gadus S3 V220 C 2

Uploaded by

chandan sahooCopyright:

Available Formats

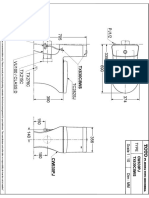

Technical Data Sheet

Formerly Known As: Shell Albida Grease EP 2, Shell Retinax LX 2

• Extra Protection

Shell Gadus S3 V220C 2 • High Temperature

• Red Lithium Complex

Premium multipurpose extreme-pressure grease

Shell Gadus S3 V220C greases are premium multi-purpose greases based on high viscosity index mineral oil

and a lithium complex soap thickener. They contain the latest additives to offer excellent high temperature

oxidation performance and other additives to enhance its anti-oxidation, anti-wear and anti-corrosion properties.

Shell Gadus S3 V220C greases are especially suitable for bearings operating at high temperature and under

load.

Performance, Features & Benefits · Shell Gadus S3 V220C greases are used for the grease

· Excellent mechanical stability even under vibrating

conditions.

lubrication of heavy-duty bearings used in machinery found

in the following applications:

Consistency retained over long periods, even in conditions · Continuous casting

of severe vibration.

· Vibrating sieves

· Enhanced extreme-pressure properties.

· Quarries

·

Excellent load-carrying performance.

· Breakers

Good water resistance.

· Roller conveyors

Ensures lasting protection even in the presence of large

amounts of water. · Automotive Wheelbearings

· High dropping point. Specifications, Approvals & Recommendations

· Long operational life at high temperatures. · ASTM D4950 LB-GC

· Effective corrosion protection.

Ensures components/bearings do not fail due to corrosion.

· SEB 18 12 53

For a full listing of equipment approvals and

recommendations, please consult your local Shell Technical

Main Applications

Helpdesk.

Typical Physical Characteristics

Properties Method Shell Gadus S3 V220C 2

NLGI Consistency 2

Colour Red

Soap Type Lithium complex

Base Oil Type Mineral

Base Oil Viscosity @400C cSt IP 71 / ASTM D445 220

Base Oil Viscosity @1000C cSt IP 71 / ASTM D445 19

Cone Penetration, Worked @250C 0.1mm IP 50 / ASTM D217 265-295

Dropping Point 0

C IP 396 240

Pumpability Long Distance Fair

Page 1 of 2 Gadus S3 V220C 2, v 2.6 14.12.2017.11.19

Properties Method Shell Gadus S3 V220C 2

Four Ball Weld Load Kg minimum ASTM D2596 315

These characteristics are typical of current production. Whilst future production will conform to Shell's specification,

variations in these characteristics may occur.

Health, Safety & Environment

· Health and Safety

Shell Gadus S3 V220C Grease is unlikely to present any significant health or safety hazard when properly used in the

recommended application and good standards of personal hygiene are maintained.

Avoid contact with skin. Use impervious gloves with used oil. After skin contact, wash immediately with soap and water.

Guidance on Health and Safety is available on the appropriate Material Safety Data Sheet, which can be obtained from

http://www.epc.shell.com/

· Protect the Environment

Take used oil to an authorised collection point. Do not discharge into drains, soil or water.

Additional Information

· Operating Temperature

Operating temperature range -200C to 1400C (peak 1500C)

· Re-greasing Intervals

For bearings operating near their maximum recommended temperatures, re-greasing intervals should be reviewed

· Advice

Advice on applications not covered here may be obtained from your Shell representative.

Page 2 of 2 Gadus S3 V220C 2, v 2.6 14.12.2017.11.19

You might also like

- Don Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboFrom EverandDon Casey's Complete Illustrated Sailboat Maintenance Manual: Including Inspecting the Aging Sailboat, Sailboat Hull and Deck Repair, Sailboat Refinishing, SailboRating: 4.5 out of 5 stars4.5/5 (12)

- Manual de Partes M44 and M44 EXDocument160 pagesManual de Partes M44 and M44 EXJose Giacomino100% (1)

- Shell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S3 A1000XD 2: Performance, Features & Benefits Main ApplicationsMiguel ArizaNo ratings yet

- TDS - Shell Gadus S3 V220C 2 - ENDocument2 pagesTDS - Shell Gadus S3 V220C 2 - ENdtcuongNo ratings yet

- Shell Gadus S3 V220C 2: Performance, Features & BenefitsDocument2 pagesShell Gadus S3 V220C 2: Performance, Features & BenefitsDaniel PrecupNo ratings yet

- Shell Gadus S3 V220C 2Document2 pagesShell Gadus S3 V220C 2Xavier DiazNo ratings yet

- TDS - Shell Gadus S3 V220C 3 - ENDocument2 pagesTDS - Shell Gadus S3 V220C 3 - ENdtcuongNo ratings yet

- TDS Shell Gadus S3 V220C - 2 - EngDocument2 pagesTDS Shell Gadus S3 V220C - 2 - EngKamil ShabriNo ratings yet

- Shell Gadus S3 V220 C2Document2 pagesShell Gadus S3 V220 C2regisNo ratings yet

- Shell Gadus S3 V220C 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S3 V220C 2: Performance, Features & Benefits Main ApplicationsregisNo ratings yet

- TDS - Gadus S2 V220ac 2Document2 pagesTDS - Gadus S2 V220ac 2Roger ObregonNo ratings yet

- Shell Gadus S2 V220AC 2Document2 pagesShell Gadus S2 V220AC 2Muhammad SaputraNo ratings yet

- TDS Shell Gadus S3 V220 C 3Document2 pagesTDS Shell Gadus S3 V220 C 3Rach RachmanNo ratings yet

- Shell Gadus S2 V460D 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S2 V460D 2: Performance, Features & Benefits Main ApplicationsMUHAMMAD LUTHFINo ratings yet

- Gpcdoc Gtds Shell Gadus s3 v460xd 2 (En) TdsDocument2 pagesGpcdoc Gtds Shell Gadus s3 v460xd 2 (En) TdsRoger ObregonNo ratings yet

- Shell Gadus S3 V460D 2: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Gadus S3 V460D 2: Performance, Features & Benefits Specifications, Approvals & Recommendationsrstec pyNo ratings yet

- PDS Gadus S3 V460D 2 - SHELLDocument2 pagesPDS Gadus S3 V460D 2 - SHELLGilmer Williams Cáceres BenaventeNo ratings yet

- S3 V460D 2 - TDS PDFDocument2 pagesS3 V460D 2 - TDS PDFWawanDarmawanNo ratings yet

- GPCDOC Local TDS Hong Kong Shell Gadus S2 V220 2 (en-HK) TDS PDFDocument2 pagesGPCDOC Local TDS Hong Kong Shell Gadus S2 V220 2 (en-HK) TDS PDFQatar home RentNo ratings yet

- Shell Gadus S2 V220 2Document2 pagesShell Gadus S2 V220 2dicha gilangNo ratings yet

- Especificaciones GADUS S2 V220 AD 2Document2 pagesEspecificaciones GADUS S2 V220 AD 2Andres OchoaNo ratings yet

- Shell Gadus S1 V220 2Document2 pagesShell Gadus S1 V220 2Álgøkár ÁhmēdNo ratings yet

- Gadus S5 V220 2Document2 pagesGadus S5 V220 2Luqman Cuopreakt'zNo ratings yet

- S2 V150C 3Document2 pagesS2 V150C 3Raden ArdyNo ratings yet

- Shell Gadus s2v220 AdDocument2 pagesShell Gadus s2v220 AdKeny AnchtNo ratings yet

- Shell Gadus S3 V460D 2: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Gadus S3 V460D 2: Performance, Features & Benefits Specifications, Approvals & RecommendationsGera BdNo ratings yet

- Gadus S3 V460D 2Document2 pagesGadus S3 V460D 2Lubricants ServerNo ratings yet

- TDS Shell Gadus S2 V220 2Document2 pagesTDS Shell Gadus S2 V220 2regisNo ratings yet

- TDS - Shell Gadus S3 V460 1 - EN PDFDocument2 pagesTDS - Shell Gadus S3 V460 1 - EN PDFdtcuongNo ratings yet

- Gadus S2 V 1000 Ad 2 PDFDocument2 pagesGadus S2 V 1000 Ad 2 PDFsrikanth siddhardhaNo ratings yet

- Shell Gadus S2 V1000AD 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S2 V1000AD 2: Performance, Features & Benefits Main ApplicationsEmerson 2140No ratings yet

- TDS Gadus S5 V220 2Document2 pagesTDS Gadus S5 V220 2Nokiabhre WijayaNo ratings yet

- Shell Gadus S2 V220 0: Performance, Features & BenefitsDocument2 pagesShell Gadus S2 V220 0: Performance, Features & BenefitsRinki KashyapNo ratings yet

- Shell Gadus S2 V220 0 TDSDocument2 pagesShell Gadus S2 V220 0 TDSsvntamil_159541837No ratings yet

- Shell Gadus S2 V100 2Document2 pagesShell Gadus S2 V100 2Muhammad SaputraNo ratings yet

- Shell Gadus S5 V220 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S5 V220 2: Performance, Features & Benefits Main ApplicationsWawanDarmawanNo ratings yet

- Shell Gadus S2 V220D 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S2 V220D 2: Performance, Features & Benefits Main ApplicationsMUHAMMAD LUTHFINo ratings yet

- GPCDOC Local TDS United Kingdom Shell Gadus S3 V770D 1 (en-GB) TDSDocument2 pagesGPCDOC Local TDS United Kingdom Shell Gadus S3 V770D 1 (en-GB) TDSSalem IereebiNo ratings yet

- TDS Shell Gadus S2 V220 2Document2 pagesTDS Shell Gadus S2 V220 2Rach RachmanNo ratings yet

- GPCDOC Local TDS United Kingdom Shell Gadus S2 A320 2 (en-GB) TDSDocument2 pagesGPCDOC Local TDS United Kingdom Shell Gadus S2 A320 2 (en-GB) TDSsyuhaimi82No ratings yet

- Shell Gadus S3 V220C: Premium Multipurpose Extreme-Pressure GreaseDocument2 pagesShell Gadus S3 V220C: Premium Multipurpose Extreme-Pressure GreaseZlatko LazicNo ratings yet

- Shell Gadus S1 V220 2: Multi-Purpose Extreme Pressure GreaseDocument2 pagesShell Gadus S1 V220 2: Multi-Purpose Extreme Pressure GreaseFEBRIANSYAH NUSANTARANo ratings yet

- S3 V460DM 2 - TDSDocument2 pagesS3 V460DM 2 - TDSWawanDarmawanNo ratings yet

- Shell Gadus S2 V220 0: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S2 V220 0: Performance, Features & Benefits Main ApplicationsWawanDarmawanNo ratings yet

- Shell Gadus S2 A320 2Document3 pagesShell Gadus S2 A320 2Álgøkár ÁhmēdNo ratings yet

- FICHA Shell Gadus s4 v2600 AdDocument2 pagesFICHA Shell Gadus s4 v2600 AdGianella Xenia Cisneros MartinezNo ratings yet

- 11 Gadus S3 V460 2Document2 pages11 Gadus S3 V460 2Prakash GauravNo ratings yet

- ShellDocument2 pagesShellFAVIONo ratings yet

- Gadus S2 V 220 0Document2 pagesGadus S2 V 220 0AMITNo ratings yet

- Shell Gadus S2 V220 0: Performance, Features & BenefitsDocument2 pagesShell Gadus S2 V220 0: Performance, Features & BenefitsAnonymous 2vhqpcI6No ratings yet

- Shell Gadus S2 V220 00: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S2 V220 00: Performance, Features & Benefits Main Applicationsreport2510No ratings yet

- Gadus S2 V220 1 TDSDocument2 pagesGadus S2 V220 1 TDSKarim AbouhigaNo ratings yet

- PDS Shell GadusDocument2 pagesPDS Shell GadusTaufik BinasrNo ratings yet

- TDS - Shell Gadus S2 V220 0Document2 pagesTDS - Shell Gadus S2 V220 0Sunario YapNo ratings yet

- Pds Shell Gadus S2 V220-0Document2 pagesPds Shell Gadus S2 V220-0andri putrantoNo ratings yet

- Shell Gadus S2 A320 2Document2 pagesShell Gadus S2 A320 2Raden ArdyNo ratings yet

- Gadus S2 A320 2Document2 pagesGadus S2 A320 2Aaron ChanNo ratings yet

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingFrom EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingNo ratings yet

- Omala S2 G 100Document3 pagesOmala S2 G 100AMITNo ratings yet

- Shell Tellus S1 M 46: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Tellus S1 M 46: Performance, Features & Benefits Specifications, Approvals & RecommendationsAMITNo ratings yet

- Rimula R2 Extra 15W40Document2 pagesRimula R2 Extra 15W40AMITNo ratings yet

- Omala S2 G 220Document3 pagesOmala S2 G 220AMITNo ratings yet

- Shell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsDocument2 pagesShell Rimula R4 L 15W-40: Performance, Features & Benefits Specifications, Approvals & RecommendationsAMITNo ratings yet

- Shell Rimula R3+ 30: Performance, Features & BenefitsDocument2 pagesShell Rimula R3+ 30: Performance, Features & BenefitsAMITNo ratings yet

- Shell Corena S4 R 68: Performance, Features & BenefitsDocument3 pagesShell Corena S4 R 68: Performance, Features & BenefitsAMITNo ratings yet

- Tellus S2 MX 32Document15 pagesTellus S2 MX 32AMITNo ratings yet

- ROIC How To Find Companies With Moats - Value Research - The Complete Guide To Mutual Funds PDFDocument3 pagesROIC How To Find Companies With Moats - Value Research - The Complete Guide To Mutual Funds PDFAMITNo ratings yet

- GS-54 Operations ManualDocument33 pagesGS-54 Operations Manualjohnstn4544No ratings yet

- Esab Price List 14 Jan 19Document1 pageEsab Price List 14 Jan 19Praveen driving ytNo ratings yet

- Mechanical IdentificationDocument6 pagesMechanical IdentificationObaidAliKhanNo ratings yet

- A - V Waterjet Parts Manual v1.7Document14 pagesA - V Waterjet Parts Manual v1.7Robert MorrellNo ratings yet

- Lecture 1 Machines and Machine MountingDocument7 pagesLecture 1 Machines and Machine Mountingodeke aronNo ratings yet

- Girth Gears - More Than Just Metal and Teeth: Steve LovellDocument8 pagesGirth Gears - More Than Just Metal and Teeth: Steve LovellFurqan ShabbirNo ratings yet

- PCM 2.0l 3 de 5Document2 pagesPCM 2.0l 3 de 5Felix VelasquezNo ratings yet

- Shindaiwa 394 Spare ManualDocument14 pagesShindaiwa 394 Spare ManualGiovanni MarinoNo ratings yet

- 2 Interference in Spur GearsDocument2 pages2 Interference in Spur Gearschris100% (1)

- Design of Double Slab at SHC-A1Document24 pagesDesign of Double Slab at SHC-A1dhee2608No ratings yet

- Product CatalogueDocument84 pagesProduct Cataloguerizaldy fachrulNo ratings yet

- Anti-Lock Brake System / Accelera-Tion GeneralDocument165 pagesAnti-Lock Brake System / Accelera-Tion GeneralLe ThanhNo ratings yet

- Brand Valve SDCFDocument4 pagesBrand Valve SDCFanon_211685604No ratings yet

- CPP Energy Generation Using Speed Breaker LDocument39 pagesCPP Energy Generation Using Speed Breaker Latharvsalunkhe6105No ratings yet

- CW 630 PJDocument1 pageCW 630 PJSuryacendra PuramegahNo ratings yet

- Regular Machining Dimension ToleranceDocument1 pageRegular Machining Dimension ToleranceSIVA 1010No ratings yet

- Daily Report LP Gas Compressor B - 10000 HRS PMDocument10 pagesDaily Report LP Gas Compressor B - 10000 HRS PMdikaNo ratings yet

- Alcaldia Mixed Rendering PlantDocument1 pageAlcaldia Mixed Rendering Plantgrovertarqui77No ratings yet

- The Process Control, The Control of Your WorldDocument8 pagesThe Process Control, The Control of Your WorldChristian Van MensidorNo ratings yet

- Manual ZF 6WG 211Document85 pagesManual ZF 6WG 211Yasser YasserNo ratings yet

- 304SS WR Spiral Wound GasketDocument3 pages304SS WR Spiral Wound GasketMarkNo ratings yet

- Pin Bambu - Google SearchDocument1 pagePin Bambu - Google SearchAgung Seras PerdanaNo ratings yet

- Section A-A Scale 1 / 2: Pete Lenz 8/21/2010Document8 pagesSection A-A Scale 1 / 2: Pete Lenz 8/21/2010Manish PatilNo ratings yet

- Government College of Technology, Coimbatore - 13 Department of Mechanical Engineering - Ug Course: Semester: Subject: Assignment: 03Document2 pagesGovernment College of Technology, Coimbatore - 13 Department of Mechanical Engineering - Ug Course: Semester: Subject: Assignment: 03SakthiNo ratings yet

- REGO - Pressure Builder - Economizer CBH CBCDocument1 pageREGO - Pressure Builder - Economizer CBH CBCcriuvosNo ratings yet

- Cengg11 Midterm 2021Document2 pagesCengg11 Midterm 2021Angelo VilleroNo ratings yet

- Tailing Frame DesignDocument5 pagesTailing Frame DesignfkamunityNo ratings yet

- G1000 IE2 60Hz EN 2815 1Document566 pagesG1000 IE2 60Hz EN 2815 1Charles SarmientoNo ratings yet

- Design Capacity of HCS: 265 Carpark 2 - Basement Level 1Document9 pagesDesign Capacity of HCS: 265 Carpark 2 - Basement Level 1anilkv66No ratings yet