Professional Documents

Culture Documents

C11000 (Electrolytic Tough Pitch)

C11000 (Electrolytic Tough Pitch)

Uploaded by

Giang NguyenCopyright:

Available Formats

You might also like

- Hydraulic/Hydrostatic Schematic S100 (S/N A2G811001 AND ABOVE) (S/N A8ET11001 AND ABOVE)Document2 pagesHydraulic/Hydrostatic Schematic S100 (S/N A2G811001 AND ABOVE) (S/N A8ET11001 AND ABOVE)Vladis0710100% (1)

- C36000 (Free-Cutting Brass)Document2 pagesC36000 (Free-Cutting Brass)Eminent RishNo ratings yet

- SM490 Ya-Yb ChemicalDocument1 pageSM490 Ya-Yb ChemicalJoko TrisnantoNo ratings yet

- Is 1030 GR340-570WDocument2 pagesIs 1030 GR340-570WAnkit Singh100% (1)

- Offered in Round Bar and Plate: Typical Uses Similar or Equivalent Specs Chemical CompositionDocument2 pagesOffered in Round Bar and Plate: Typical Uses Similar or Equivalent Specs Chemical CompositionAdnan KhanNo ratings yet

- Calitate EN - OTEL CARBON SI DE CALITATEDocument2 pagesCalitate EN - OTEL CARBON SI DE CALITATETudor SerbanNo ratings yet

- CHEMISTRY Raw MaterialDocument6 pagesCHEMISTRY Raw Materialaditya18decNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaHassan MostajabNo ratings yet

- Material SpecDocument456 pagesMaterial SpecAyush Narang70% (10)

- Chemical Composition of Some SteelsDocument3 pagesChemical Composition of Some Steelspratik bhoiteNo ratings yet

- BQ PlateDocument2 pagesBQ PlateAvishay TufikianNo ratings yet

- Thành phần hóa học thép - Steel bars for concrete reinforcementDocument3 pagesThành phần hóa học thép - Steel bars for concrete reinforcementDuẩn VũNo ratings yet

- Acos Ferramenta Ligados Astm A 681Document2 pagesAcos Ferramenta Ligados Astm A 681Wenderson SouzaNo ratings yet

- Steel Specification PDFDocument8 pagesSteel Specification PDFPeter AntonyNo ratings yet

- Tabelle VOC PCR FinderDocument30 pagesTabelle VOC PCR Findertama catNo ratings yet

- 6-Carbon SteelsDocument20 pages6-Carbon SteelsMunim DarNo ratings yet

- Special Steel Products PDFDocument4 pagesSpecial Steel Products PDFArijit MajumdarNo ratings yet

- AS2074 CastSteel Specifications PDFDocument5 pagesAS2074 CastSteel Specifications PDFZac NastNo ratings yet

- Surface Area Calc.Document1 pageSurface Area Calc.estimationNo ratings yet

- 110 1 WZDocument2 pages110 1 WZAyman MufarehNo ratings yet

- Pakistan Ssteel Mills Mild Steel Grades SpecificationDocument3 pagesPakistan Ssteel Mills Mild Steel Grades SpecificationWaqas WaqasNo ratings yet

- Cross Astriman A MalagapyDocument1 pageCross Astriman A MalagapyAnonymous TJVwVNKy8qNo ratings yet

- QuadriDocument76 pagesQuadrisvenNo ratings yet

- Mesh (Scale) : Mesh Series Have Been EstablishedDocument4 pagesMesh (Scale) : Mesh Series Have Been EstablishedKewell LimNo ratings yet

- Chemical Compo - TupiplDocument2 pagesChemical Compo - TupiplMadhubalan AlagarNo ratings yet

- Chemical PropertiesDocument1 pageChemical PropertiesDanny TriwibowoNo ratings yet

- Ligas de Aco DZ UltraDocument2 pagesLigas de Aco DZ Ultraaldofernandes100% (1)

- All Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconDocument3 pagesAll Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconkartikNo ratings yet

- S355J2Document5 pagesS355J2jon perez diezNo ratings yet

- Worksheet in RC Retaining WallDocument1 pageWorksheet in RC Retaining WallteweldeNo ratings yet

- Analisa - Penjualan - Bks - KTN - KG - 050224 SMAX RING PIZZADocument3 pagesAnalisa - Penjualan - Bks - KTN - KG - 050224 SMAX RING PIZZAmotoris.bontehNo ratings yet

- Square Rectangular Hollow SectionDocument76 pagesSquare Rectangular Hollow Sectionbusiness.developmentNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetprabhu vijayanNo ratings yet

- Optimization Input DataDocument3 pagesOptimization Input DataJuan OsorioNo ratings yet

- Steelmet Industries Grade C MN Si CR Ni en EqvtDocument34 pagesSteelmet Industries Grade C MN Si CR Ni en Eqvtdesign1983No ratings yet

- En 10025-2-2004 BS HotRolledProductDocument7 pagesEn 10025-2-2004 BS HotRolledProductChrill DsilvaNo ratings yet

- Spring Steel Chemical CompositionDocument5 pagesSpring Steel Chemical CompositionSunil Dinanath Joshi100% (1)

- Astm A653a 653M 4Document1 pageAstm A653a 653M 4Barbado BlancoNo ratings yet

- Cast Iron Material Comparison Chart ASTM CompilationDocument1 pageCast Iron Material Comparison Chart ASTM CompilationCésar Cristov León OrtegaNo ratings yet

- Cast Iron Material Comparison Chart ASTM CompilationDocument1 pageCast Iron Material Comparison Chart ASTM CompilationCésar Cristov León OrtegaNo ratings yet

- Cast Iron Material Comparison Chart PDFDocument1 pageCast Iron Material Comparison Chart PDFavnishchauhan8_46499No ratings yet

- Site Sector Azimuth Tilt Gsm/dcs Hba Mech 2g 3g 4g 3g Tilt 3g AzimuthDocument26 pagesSite Sector Azimuth Tilt Gsm/dcs Hba Mech 2g 3g 4g 3g Tilt 3g AzimuthAhmad ZubairNo ratings yet

- Steel Grade: Material Data SheetDocument4 pagesSteel Grade: Material Data SheetAlin ChehadeNo ratings yet

- Manufacturing Planning and ControlDocument2 pagesManufacturing Planning and ControlVishvajit KumbharNo ratings yet

- Propiedades Mecanicas Del B7Document1 pagePropiedades Mecanicas Del B7alejandrorhino2 rhinoNo ratings yet

- Steel Specification-Kalyani ForgeDocument8 pagesSteel Specification-Kalyani ForgedramiltNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetdinesh kumarNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetBouremana AnèsNo ratings yet

- Chemical Composition of Nickel AlloysDocument1 pageChemical Composition of Nickel AlloyscandraNo ratings yet

- Alpha Opcost2013Document20 pagesAlpha Opcost2013Mrjunecarlo HazerahnNo ratings yet

- Libro Con Datos Del PMXDocument28 pagesLibro Con Datos Del PMXLuis Ivan SalgueiroNo ratings yet

- En 10025-2 ExtractDocument1 pageEn 10025-2 Extractpalani.djpNo ratings yet

- Alloy Steel ChartDocument4 pagesAlloy Steel Chartmodi_mihirNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Seal Kit DesignDocument7 pagesSeal Kit DesignAbbas Mohammed AbbasNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetRushangNo ratings yet

- 1 Composicao Quimica Das Ligas de AluminioDocument1 page1 Composicao Quimica Das Ligas de AluminioNorberto A. GhiggiNo ratings yet

- C Si MN P S CR Mo Ni NB Ti Worknorme DIN BS Astm / Aisi GostDocument4 pagesC Si MN P S CR Mo Ni NB Ti Worknorme DIN BS Astm / Aisi GostSWPriestNo ratings yet

- RoboVac G40 - Manual - ENDocument12 pagesRoboVac G40 - Manual - ENGiang NguyenNo ratings yet

- Aerospace 08 00128 v2Document18 pagesAerospace 08 00128 v2Giang NguyenNo ratings yet

- TranscriptDocument2 pagesTranscriptGiang NguyenNo ratings yet

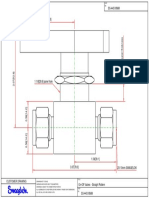

- SS 4 RS 2V SwagelokCompany 2DSalesDrawing 05 21 2023Document1 pageSS 4 RS 2V SwagelokCompany 2DSalesDrawing 05 21 2023Giang NguyenNo ratings yet

- SS 8M0 1 4RP MaleConnector (ISOParallelThreadRP) MetricDocument1 pageSS 8M0 1 4RP MaleConnector (ISOParallelThreadRP) MetricGiang NguyenNo ratings yet

- Inspection of Curvic Couplings Using A CMMDocument10 pagesInspection of Curvic Couplings Using A CMMGiang NguyenNo ratings yet

- SS 8M0 3 SwagelokCompany 2DSalesDrawing 01 06 2023Document1 pageSS 8M0 3 SwagelokCompany 2DSalesDrawing 01 06 2023Giang NguyenNo ratings yet

- High Pressure OxygenDocument2 pagesHigh Pressure OxygenGiang NguyenNo ratings yet

- Education:: "The Noise Generation in Mechanical Systems"Document3 pagesEducation:: "The Noise Generation in Mechanical Systems"Giang NguyenNo ratings yet

- The Mixture of The Phase Stabilized Ammonium Nitrate Containing Potassium Nitrate and 1HT As The New Gas Generant CompositionDocument7 pagesThe Mixture of The Phase Stabilized Ammonium Nitrate Containing Potassium Nitrate and 1HT As The New Gas Generant CompositionGiang NguyenNo ratings yet

- NTU Intnlpros HiRes Jul2011Document28 pagesNTU Intnlpros HiRes Jul2011Giang NguyenNo ratings yet

- SS 44S10MM SwagelokCompany SalesDrawing 12 28 2022Document1 pageSS 44S10MM SwagelokCompany SalesDrawing 12 28 2022Giang NguyenNo ratings yet

- Dynamics of Contained Liquids: A Personal Odyssey: H Norman AbramsonDocument7 pagesDynamics of Contained Liquids: A Personal Odyssey: H Norman AbramsonGiang NguyenNo ratings yet

- Roland Bouanais: Research InterestsDocument10 pagesRoland Bouanais: Research InterestsGiang NguyenNo ratings yet

- Influence of Geometry On The Performance of Simplex Nozzles Under Constant Pressure DropDocument5 pagesInfluence of Geometry On The Performance of Simplex Nozzles Under Constant Pressure DropGiang NguyenNo ratings yet

- Sakman2000 Parametric Study of Simplex Fuel Nozzle Internal Flow and PerformanceDocument5 pagesSakman2000 Parametric Study of Simplex Fuel Nozzle Internal Flow and PerformanceGiang NguyenNo ratings yet

- 3oz Lip: Trijong Pham NAM PhricDocument3 pages3oz Lip: Trijong Pham NAM PhricGiang NguyenNo ratings yet

- Preliminary Gas Turbine Combustor Design Using A Network ApproachDocument8 pagesPreliminary Gas Turbine Combustor Design Using A Network ApproachGiang NguyenNo ratings yet

- 0674 - Spray Dynamics of Aeroengine Fuel InjectorsDocument3 pages0674 - Spray Dynamics of Aeroengine Fuel InjectorsGiang NguyenNo ratings yet

- Average Viscosities LiquidsDocument1 pageAverage Viscosities LiquidsGiang NguyenNo ratings yet

- Vapor-Liquid Equilibrium For Binary Systems of Methyl Ethyl Ketone and Methyl Isobutyl KetoneDocument5 pagesVapor-Liquid Equilibrium For Binary Systems of Methyl Ethyl Ketone and Methyl Isobutyl KetoneApurv PatelNo ratings yet

- Phase Diagram of A Three-Component Liquid SystemDocument20 pagesPhase Diagram of A Three-Component Liquid SystemNas DiNo ratings yet

- Torsion Bar MaterialDocument10 pagesTorsion Bar MaterialParichay SaxenaNo ratings yet

- System PracticesDocument27 pagesSystem PracticesMechanicalNo ratings yet

- Spread Footing DesignDocument9 pagesSpread Footing DesignLeonardo PimentelNo ratings yet

- Finite Element Prediction of Progressively FormedDocument14 pagesFinite Element Prediction of Progressively FormedfernandoNo ratings yet

- Optimization of Wind Turbine Airfoils - Blades and Wind Farm LayoutDocument184 pagesOptimization of Wind Turbine Airfoils - Blades and Wind Farm LayoutNilesh KumarNo ratings yet

- Chapter - 6 - Thermochemistry Updated Feb 12Document43 pagesChapter - 6 - Thermochemistry Updated Feb 12prince jann ellix dela cruzNo ratings yet

- How To Design A Beam GuidelinesDocument8 pagesHow To Design A Beam Guidelines22le2-035No ratings yet

- Disclosure To Promote The Right To Information: IS 14329 (1995) : Malleable Iron Castings (MTD 6: Pig Iron and Cast Iron)Document13 pagesDisclosure To Promote The Right To Information: IS 14329 (1995) : Malleable Iron Castings (MTD 6: Pig Iron and Cast Iron)anand.bharadwaj50% (2)

- Simplified Scaling Relationships For Fluidized Beds: L.R. Glicksman, M. Hyre and K. WoloshunDocument23 pagesSimplified Scaling Relationships For Fluidized Beds: L.R. Glicksman, M. Hyre and K. WoloshunMogahed OsmanNo ratings yet

- Determination of Johnson HolmquistDocument4 pagesDetermination of Johnson Holmquistsime13No ratings yet

- Installation Instructions Air Conditioning & Heat Pump Indoor Coils IntroductionDocument6 pagesInstallation Instructions Air Conditioning & Heat Pump Indoor Coils IntroductionSehar KhanNo ratings yet

- SW1 Shear Wall Design Based On ACI 318-02Document2 pagesSW1 Shear Wall Design Based On ACI 318-02nhulugallaNo ratings yet

- Science 4 q3 Module 3 Weeks 4-5Document18 pagesScience 4 q3 Module 3 Weeks 4-5kristel guanzonNo ratings yet

- Lecture Rheology 4 Final 1586777231827 PDFDocument16 pagesLecture Rheology 4 Final 1586777231827 PDFShubhamGuptaNo ratings yet

- Steel Beam Design Flowchart EUROCODEDocument7 pagesSteel Beam Design Flowchart EUROCODELong Live TauNo ratings yet

- Mul Tivector Review and Training Center: Esas Trivia 2Document3 pagesMul Tivector Review and Training Center: Esas Trivia 2War LockNo ratings yet

- BEAM Idp ProjectDocument14 pagesBEAM Idp ProjectSiti Nurulsyazni RusliNo ratings yet

- SeismicDocument8 pagesSeismicV.m. RajanNo ratings yet

- Simple DistillationDocument5 pagesSimple DistillationJheian Christian TubleNo ratings yet

- Air Duct Sizing - SI & Imperial UnitsDocument1 pageAir Duct Sizing - SI & Imperial UnitsAbu Jasim K UNo ratings yet

- Marcet Boiler Final 21 EditedDocument9 pagesMarcet Boiler Final 21 EditedIbraheem MahmoodNo ratings yet

- 00087167Document11 pages00087167JohnSmith100% (1)

- Equilibrium NEET PYQ SOLUTIONDocument28 pagesEquilibrium NEET PYQ SOLUTIONsomeone nooneNo ratings yet

- Basic SOil MechanicsDocument36 pagesBasic SOil MechanicsshenNo ratings yet

- Introduction To Heat Transfer PDFDocument15 pagesIntroduction To Heat Transfer PDFMohamed RadwanNo ratings yet

- Sheet #7Document4 pagesSheet #7AHMED BAKRNo ratings yet

- A Counter-Rotating Vortex Pair in Inviscid FluidDocument9 pagesA Counter-Rotating Vortex Pair in Inviscid FluidMadeeha MalikNo ratings yet

C11000 (Electrolytic Tough Pitch)

C11000 (Electrolytic Tough Pitch)

Uploaded by

Giang NguyenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C11000 (Electrolytic Tough Pitch)

C11000 (Electrolytic Tough Pitch)

Uploaded by

Giang NguyenCopyright:

Available Formats

C11000 (Electrolytic Tough Pitch)

US EPA Registered Antimicrobial

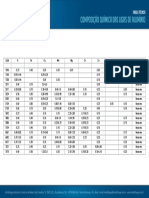

Chemical Composition

(%max., unless shown as range or min.)

(1)

Cu O

Min./Max. 99.90 min -

Nominal - .04

(1) Cu value includes Ag.

Note: This is a high conductivity copper which has, in the annealed condition a minimum concuctivity of

100% IACS except for Alloy C10100 which has a minimum conductivity of 101% IACS.

Note: Oxygen and trace elements may vary depending on the process.

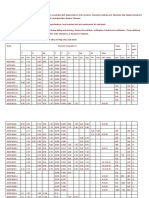

Mechanical Properties (measured at room temperature, 68 F (20 C)

Yield Yield Yield

Izod

Section Cold Typ/ Tensile Strength StrengthStrength Rockwell Vickens Brinell Shear Fatigue

Temper Temp El Impact

Size Work Min Strength (0.5% ext. (0.2% (0.05% Hardness Hard. Hard. StrengthStrength*

Strength

under load) offset) offset)

in. % F ksi ksi ksi ksi % B CF 30T500 500 3000ksi ksi ft-lb

mm. C MPa MPa MPa MPa MPa MPa J

Flat Products

H02 0.04 0 TYP 68 42 36 - - 1440- 8450 - - - 26 13 0.0

1 20 290 248 - - 1440- 8450 - - - 179 90 0.0

M20 0.025 0 TYP 68 32 10 - - 50- - 40- - - - 22 - 0.0

0.64 20 221 69 - - 50- - 40- - - - 152 - 0.0

Rod

M20 1 0 TYP 68 32 10 - - 55- - 40- - - - 22 - 0.0

25.4 20 221 69 - - 55- - 40- - - - 152 - 0.0

Shapes

M30 0.5 0 TYP 68 32 10 - - 50- - 40- - - - 22 - 0.0

12.7 20 221 69 - - 50- - 40- - - - 152 - 0.0

M20 0.5 0 TYP 68 32 10 - - 50- - 40- - - - 22 - 0.0

12.7 20 221 69 - - 50- - 40- - - - 152 - 0.0

Flat Products

H04 0.04 0 TYP 68 50 45 - - 6 50- 9057 - - - 28 - 0.0

1 20 345 310 - - 6 50- 9057 - - - 193 - 0.0

Rod

H04 0.25 40 TYP 68 55 50 - - 1060- 94- - - - 29 - 0.0

6.35 20 379 345 - - 1060- 94- - - - 200 - 0.0

Wire

OS050 0.08 0 TYP 68 35 - - - 35- - - - - - - 24 - 0.0

2 20 241 - - - 35- - - - - - - 165 - 0.0

Flat Products

H08 0.04 0 TYP 68 55 50 - - 4 60- 9463 - - - 29 14 0.0

1 20 379 345 - - 4 60- 9463 - - - 200 97 0.0

H01 0.025 0 TYP 68 38 30 - - 3525- 70- - - - 25 - 0.0

0.64 20 262 207 - - 3525- 70- - - - 172 - 0.0

Rod

OS050 1 0 TYP 68 32 10 - - 55- - 40- - - - 22 - 0.0

25.4 20 221 69 - - 55- - 40- - - - 152 - 0.0

Wire

H08 0.08 0 TYP 68 66 - - - 1 - - - - - - - 33 - 0.0

2 20 455 - - - 1 - - - - - - - 228 - 0.0

Flat Products

H04 1 0 TYP 68 45 40 - - 2045- 85- - - - 26 - 0.0

25.4 20 310 276 - - 2045- 85- - - - 179 - 0.0

OS050 0.025 0 TYP 68 32 10 - - 50- - 40- - - - 22 - 0.0

0.64 20 221 69 - - 50- - 40- - - - 152 - 0.0

H00 0.025 0 TYP 68 36 28 - - 4010- 60- - - - 25 - 0.0

0.64 20 248 193 - - 4010- 60- - - - 172 - 0.0

Rod

H04 2 16 TYP 68 45 40 - - 2045- 85- - - - 26 - 0.0

51 20 310 276 - - 2045- 85- - - - 179 - 0.0

H04 1 35 TYP 68 48 44 - - 1647- 87- - - - 27 17 0.0

25.4 20 331 303 - - 1647- 87- - - - 186 117 0.0

Tube

OS025 0.065 0 TYP 68 34 11 - - 45- - 45- - - - 23 - 0.0

1.65 20 234 76 - - 45- - 45- - - - 159 - 0.0

H80 0.065 40 TYP 68 55 50 - - 8 60- 9563 - - - 29 - 0.0

1.65 20 379 345 - - 8 60- 9563 - - - 200 - 0.0

H55 0.065 15 TYP 68 40 32 - - 2535- 7745 - - - 26 - 0.0

1.65 20 276 221 - - 2535- 7745 - - - 179 - 0.0

Flat Products

M20 0.04 0 TYP 68 34 10 - - 45- - 45- - - - 23 - 0.0

1 20 234 69 - - 45- - 45- - - - 159 - 0.0

Shapes

OS050 0.5 0 TYP 68 32 10 - - 50- - 40- - - - 22 - 0.0

12.7 20 221 69 - - 50- - 40- - - - 152 - 0.0

Wire

H04 0.08 0 TYP 68 55 - - - 1 - - - - - - - 29 - 0.0

2 20 379 - - - 1 - - - - - - - 200 - 0.0

Flat Products

OS050 0.04 0 TYP 68 32 10 - - 45- - 40- - - - 22 - 0.0

1 20 221 69 - - 45- - 40- - - - 152 - 0.0

Shapes

H04 0.5 15 TYP 68 40 32 - - 3035- - - - - - 26 - 0.0

12.7 20 276 221 - - 3035- - - - - - 179 - 0.0

Tube

OS050 0.065 0 TYP 68 32 10 - - 45- - 40- - - - 22 - 0.0

1.65 20 221 69 - - 45- - 40- - - - 152 - 0.0

Flat Products

OS025 0.04 0 TYP 68 34 11 - - 45- - 45- - - - 23 11 0.0

1 20 234 76 - - 45- - 45- - - - 159 76 0.0

H10 0.04 0 TYP 68 57 53 - - 4 62- 9564 - - - 29 - 0.0

1 20 393 365 - - 4 62- 9564 - - - 200 - 0.0

H01 0.04 0 TYP 68 38 30 - - 2525- 7036 - - - 25 - 0.0

1 20 262 207 - - 2525- 7036 - - - 172 - 0.0

H00 0.04 0 TYP 68 36 28 - - 3010- 6025 - - - 25 - 0.0

1 20 248 193 - - 3010- 6025 - - - 172 - 0.0

H04 0.025 0 TYP 68 50 45 - - 1250- 90- - - - 28 - 0.0

0.64 20 345 310 - - 1250- 90- - - - 193 - 0.0

6

*Fatigue Strength: 100 x 10 cycles,

6

unless indicated as [N]X 10 .

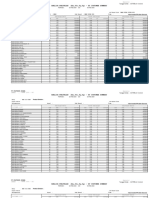

Physical Properties

<="" b=""> US Customary

Melting Point - Liquidus 1981 F

Melting Point - Solidus 1949 F

3

Density* 0.322 lb/in at 68 F

Specific Gravity 8.910

Electrical Resistivity 10.30 ohms-cmil/ft @ 68 F

Electrical Conductivity** 101 %IACS @ 68 F

o

Thermal Conductivity 226 Btu · ft/(hr · ft2· F)at 68F

-6 o

Coefficient of Thermal Expansion 9.40 ·10 per F (68-212 F)

-6 o

Coefficient of Thermal Expansion 9.60 ·10 per F (68-392 F)

-6 o

Coefficient of Thermal Expansion 9.80 ·10 per F (68-572 F)

o

Specific Heat Capacity 0.092 Btu/lb/ F at 68 F

Modulas of Elasticity in Tension 17000 ksi

Modulus of Rigidity 6400 ksi

*Actual value .321 - .323.

**Volume and weight basis.

You might also like

- Hydraulic/Hydrostatic Schematic S100 (S/N A2G811001 AND ABOVE) (S/N A8ET11001 AND ABOVE)Document2 pagesHydraulic/Hydrostatic Schematic S100 (S/N A2G811001 AND ABOVE) (S/N A8ET11001 AND ABOVE)Vladis0710100% (1)

- C36000 (Free-Cutting Brass)Document2 pagesC36000 (Free-Cutting Brass)Eminent RishNo ratings yet

- SM490 Ya-Yb ChemicalDocument1 pageSM490 Ya-Yb ChemicalJoko TrisnantoNo ratings yet

- Is 1030 GR340-570WDocument2 pagesIs 1030 GR340-570WAnkit Singh100% (1)

- Offered in Round Bar and Plate: Typical Uses Similar or Equivalent Specs Chemical CompositionDocument2 pagesOffered in Round Bar and Plate: Typical Uses Similar or Equivalent Specs Chemical CompositionAdnan KhanNo ratings yet

- Calitate EN - OTEL CARBON SI DE CALITATEDocument2 pagesCalitate EN - OTEL CARBON SI DE CALITATETudor SerbanNo ratings yet

- CHEMISTRY Raw MaterialDocument6 pagesCHEMISTRY Raw Materialaditya18decNo ratings yet

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaDocument1 pageWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaHassan MostajabNo ratings yet

- Material SpecDocument456 pagesMaterial SpecAyush Narang70% (10)

- Chemical Composition of Some SteelsDocument3 pagesChemical Composition of Some Steelspratik bhoiteNo ratings yet

- BQ PlateDocument2 pagesBQ PlateAvishay TufikianNo ratings yet

- Thành phần hóa học thép - Steel bars for concrete reinforcementDocument3 pagesThành phần hóa học thép - Steel bars for concrete reinforcementDuẩn VũNo ratings yet

- Acos Ferramenta Ligados Astm A 681Document2 pagesAcos Ferramenta Ligados Astm A 681Wenderson SouzaNo ratings yet

- Steel Specification PDFDocument8 pagesSteel Specification PDFPeter AntonyNo ratings yet

- Tabelle VOC PCR FinderDocument30 pagesTabelle VOC PCR Findertama catNo ratings yet

- 6-Carbon SteelsDocument20 pages6-Carbon SteelsMunim DarNo ratings yet

- Special Steel Products PDFDocument4 pagesSpecial Steel Products PDFArijit MajumdarNo ratings yet

- AS2074 CastSteel Specifications PDFDocument5 pagesAS2074 CastSteel Specifications PDFZac NastNo ratings yet

- Surface Area Calc.Document1 pageSurface Area Calc.estimationNo ratings yet

- 110 1 WZDocument2 pages110 1 WZAyman MufarehNo ratings yet

- Pakistan Ssteel Mills Mild Steel Grades SpecificationDocument3 pagesPakistan Ssteel Mills Mild Steel Grades SpecificationWaqas WaqasNo ratings yet

- Cross Astriman A MalagapyDocument1 pageCross Astriman A MalagapyAnonymous TJVwVNKy8qNo ratings yet

- QuadriDocument76 pagesQuadrisvenNo ratings yet

- Mesh (Scale) : Mesh Series Have Been EstablishedDocument4 pagesMesh (Scale) : Mesh Series Have Been EstablishedKewell LimNo ratings yet

- Chemical Compo - TupiplDocument2 pagesChemical Compo - TupiplMadhubalan AlagarNo ratings yet

- Chemical PropertiesDocument1 pageChemical PropertiesDanny TriwibowoNo ratings yet

- Ligas de Aco DZ UltraDocument2 pagesLigas de Aco DZ Ultraaldofernandes100% (1)

- All Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconDocument3 pagesAll Single Values Except EN8D Show Maximum Limit: Elements SR No Grade Carbon Manganese Phosphorus Sulfur SiliconkartikNo ratings yet

- S355J2Document5 pagesS355J2jon perez diezNo ratings yet

- Worksheet in RC Retaining WallDocument1 pageWorksheet in RC Retaining WallteweldeNo ratings yet

- Analisa - Penjualan - Bks - KTN - KG - 050224 SMAX RING PIZZADocument3 pagesAnalisa - Penjualan - Bks - KTN - KG - 050224 SMAX RING PIZZAmotoris.bontehNo ratings yet

- Square Rectangular Hollow SectionDocument76 pagesSquare Rectangular Hollow Sectionbusiness.developmentNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetprabhu vijayanNo ratings yet

- Optimization Input DataDocument3 pagesOptimization Input DataJuan OsorioNo ratings yet

- Steelmet Industries Grade C MN Si CR Ni en EqvtDocument34 pagesSteelmet Industries Grade C MN Si CR Ni en Eqvtdesign1983No ratings yet

- En 10025-2-2004 BS HotRolledProductDocument7 pagesEn 10025-2-2004 BS HotRolledProductChrill DsilvaNo ratings yet

- Spring Steel Chemical CompositionDocument5 pagesSpring Steel Chemical CompositionSunil Dinanath Joshi100% (1)

- Astm A653a 653M 4Document1 pageAstm A653a 653M 4Barbado BlancoNo ratings yet

- Cast Iron Material Comparison Chart ASTM CompilationDocument1 pageCast Iron Material Comparison Chart ASTM CompilationCésar Cristov León OrtegaNo ratings yet

- Cast Iron Material Comparison Chart ASTM CompilationDocument1 pageCast Iron Material Comparison Chart ASTM CompilationCésar Cristov León OrtegaNo ratings yet

- Cast Iron Material Comparison Chart PDFDocument1 pageCast Iron Material Comparison Chart PDFavnishchauhan8_46499No ratings yet

- Site Sector Azimuth Tilt Gsm/dcs Hba Mech 2g 3g 4g 3g Tilt 3g AzimuthDocument26 pagesSite Sector Azimuth Tilt Gsm/dcs Hba Mech 2g 3g 4g 3g Tilt 3g AzimuthAhmad ZubairNo ratings yet

- Steel Grade: Material Data SheetDocument4 pagesSteel Grade: Material Data SheetAlin ChehadeNo ratings yet

- Manufacturing Planning and ControlDocument2 pagesManufacturing Planning and ControlVishvajit KumbharNo ratings yet

- Propiedades Mecanicas Del B7Document1 pagePropiedades Mecanicas Del B7alejandrorhino2 rhinoNo ratings yet

- Steel Specification-Kalyani ForgeDocument8 pagesSteel Specification-Kalyani ForgedramiltNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data Sheetdinesh kumarNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetBouremana AnèsNo ratings yet

- Chemical Composition of Nickel AlloysDocument1 pageChemical Composition of Nickel AlloyscandraNo ratings yet

- Alpha Opcost2013Document20 pagesAlpha Opcost2013Mrjunecarlo HazerahnNo ratings yet

- Libro Con Datos Del PMXDocument28 pagesLibro Con Datos Del PMXLuis Ivan SalgueiroNo ratings yet

- En 10025-2 ExtractDocument1 pageEn 10025-2 Extractpalani.djpNo ratings yet

- Alloy Steel ChartDocument4 pagesAlloy Steel Chartmodi_mihirNo ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Seal Kit DesignDocument7 pagesSeal Kit DesignAbbas Mohammed AbbasNo ratings yet

- Steel Grade: Material Data SheetDocument3 pagesSteel Grade: Material Data SheetRushangNo ratings yet

- 1 Composicao Quimica Das Ligas de AluminioDocument1 page1 Composicao Quimica Das Ligas de AluminioNorberto A. GhiggiNo ratings yet

- C Si MN P S CR Mo Ni NB Ti Worknorme DIN BS Astm / Aisi GostDocument4 pagesC Si MN P S CR Mo Ni NB Ti Worknorme DIN BS Astm / Aisi GostSWPriestNo ratings yet

- RoboVac G40 - Manual - ENDocument12 pagesRoboVac G40 - Manual - ENGiang NguyenNo ratings yet

- Aerospace 08 00128 v2Document18 pagesAerospace 08 00128 v2Giang NguyenNo ratings yet

- TranscriptDocument2 pagesTranscriptGiang NguyenNo ratings yet

- SS 4 RS 2V SwagelokCompany 2DSalesDrawing 05 21 2023Document1 pageSS 4 RS 2V SwagelokCompany 2DSalesDrawing 05 21 2023Giang NguyenNo ratings yet

- SS 8M0 1 4RP MaleConnector (ISOParallelThreadRP) MetricDocument1 pageSS 8M0 1 4RP MaleConnector (ISOParallelThreadRP) MetricGiang NguyenNo ratings yet

- Inspection of Curvic Couplings Using A CMMDocument10 pagesInspection of Curvic Couplings Using A CMMGiang NguyenNo ratings yet

- SS 8M0 3 SwagelokCompany 2DSalesDrawing 01 06 2023Document1 pageSS 8M0 3 SwagelokCompany 2DSalesDrawing 01 06 2023Giang NguyenNo ratings yet

- High Pressure OxygenDocument2 pagesHigh Pressure OxygenGiang NguyenNo ratings yet

- Education:: "The Noise Generation in Mechanical Systems"Document3 pagesEducation:: "The Noise Generation in Mechanical Systems"Giang NguyenNo ratings yet

- The Mixture of The Phase Stabilized Ammonium Nitrate Containing Potassium Nitrate and 1HT As The New Gas Generant CompositionDocument7 pagesThe Mixture of The Phase Stabilized Ammonium Nitrate Containing Potassium Nitrate and 1HT As The New Gas Generant CompositionGiang NguyenNo ratings yet

- NTU Intnlpros HiRes Jul2011Document28 pagesNTU Intnlpros HiRes Jul2011Giang NguyenNo ratings yet

- SS 44S10MM SwagelokCompany SalesDrawing 12 28 2022Document1 pageSS 44S10MM SwagelokCompany SalesDrawing 12 28 2022Giang NguyenNo ratings yet

- Dynamics of Contained Liquids: A Personal Odyssey: H Norman AbramsonDocument7 pagesDynamics of Contained Liquids: A Personal Odyssey: H Norman AbramsonGiang NguyenNo ratings yet

- Roland Bouanais: Research InterestsDocument10 pagesRoland Bouanais: Research InterestsGiang NguyenNo ratings yet

- Influence of Geometry On The Performance of Simplex Nozzles Under Constant Pressure DropDocument5 pagesInfluence of Geometry On The Performance of Simplex Nozzles Under Constant Pressure DropGiang NguyenNo ratings yet

- Sakman2000 Parametric Study of Simplex Fuel Nozzle Internal Flow and PerformanceDocument5 pagesSakman2000 Parametric Study of Simplex Fuel Nozzle Internal Flow and PerformanceGiang NguyenNo ratings yet

- 3oz Lip: Trijong Pham NAM PhricDocument3 pages3oz Lip: Trijong Pham NAM PhricGiang NguyenNo ratings yet

- Preliminary Gas Turbine Combustor Design Using A Network ApproachDocument8 pagesPreliminary Gas Turbine Combustor Design Using A Network ApproachGiang NguyenNo ratings yet

- 0674 - Spray Dynamics of Aeroengine Fuel InjectorsDocument3 pages0674 - Spray Dynamics of Aeroengine Fuel InjectorsGiang NguyenNo ratings yet

- Average Viscosities LiquidsDocument1 pageAverage Viscosities LiquidsGiang NguyenNo ratings yet

- Vapor-Liquid Equilibrium For Binary Systems of Methyl Ethyl Ketone and Methyl Isobutyl KetoneDocument5 pagesVapor-Liquid Equilibrium For Binary Systems of Methyl Ethyl Ketone and Methyl Isobutyl KetoneApurv PatelNo ratings yet

- Phase Diagram of A Three-Component Liquid SystemDocument20 pagesPhase Diagram of A Three-Component Liquid SystemNas DiNo ratings yet

- Torsion Bar MaterialDocument10 pagesTorsion Bar MaterialParichay SaxenaNo ratings yet

- System PracticesDocument27 pagesSystem PracticesMechanicalNo ratings yet

- Spread Footing DesignDocument9 pagesSpread Footing DesignLeonardo PimentelNo ratings yet

- Finite Element Prediction of Progressively FormedDocument14 pagesFinite Element Prediction of Progressively FormedfernandoNo ratings yet

- Optimization of Wind Turbine Airfoils - Blades and Wind Farm LayoutDocument184 pagesOptimization of Wind Turbine Airfoils - Blades and Wind Farm LayoutNilesh KumarNo ratings yet

- Chapter - 6 - Thermochemistry Updated Feb 12Document43 pagesChapter - 6 - Thermochemistry Updated Feb 12prince jann ellix dela cruzNo ratings yet

- How To Design A Beam GuidelinesDocument8 pagesHow To Design A Beam Guidelines22le2-035No ratings yet

- Disclosure To Promote The Right To Information: IS 14329 (1995) : Malleable Iron Castings (MTD 6: Pig Iron and Cast Iron)Document13 pagesDisclosure To Promote The Right To Information: IS 14329 (1995) : Malleable Iron Castings (MTD 6: Pig Iron and Cast Iron)anand.bharadwaj50% (2)

- Simplified Scaling Relationships For Fluidized Beds: L.R. Glicksman, M. Hyre and K. WoloshunDocument23 pagesSimplified Scaling Relationships For Fluidized Beds: L.R. Glicksman, M. Hyre and K. WoloshunMogahed OsmanNo ratings yet

- Determination of Johnson HolmquistDocument4 pagesDetermination of Johnson Holmquistsime13No ratings yet

- Installation Instructions Air Conditioning & Heat Pump Indoor Coils IntroductionDocument6 pagesInstallation Instructions Air Conditioning & Heat Pump Indoor Coils IntroductionSehar KhanNo ratings yet

- SW1 Shear Wall Design Based On ACI 318-02Document2 pagesSW1 Shear Wall Design Based On ACI 318-02nhulugallaNo ratings yet

- Science 4 q3 Module 3 Weeks 4-5Document18 pagesScience 4 q3 Module 3 Weeks 4-5kristel guanzonNo ratings yet

- Lecture Rheology 4 Final 1586777231827 PDFDocument16 pagesLecture Rheology 4 Final 1586777231827 PDFShubhamGuptaNo ratings yet

- Steel Beam Design Flowchart EUROCODEDocument7 pagesSteel Beam Design Flowchart EUROCODELong Live TauNo ratings yet

- Mul Tivector Review and Training Center: Esas Trivia 2Document3 pagesMul Tivector Review and Training Center: Esas Trivia 2War LockNo ratings yet

- BEAM Idp ProjectDocument14 pagesBEAM Idp ProjectSiti Nurulsyazni RusliNo ratings yet

- SeismicDocument8 pagesSeismicV.m. RajanNo ratings yet

- Simple DistillationDocument5 pagesSimple DistillationJheian Christian TubleNo ratings yet

- Air Duct Sizing - SI & Imperial UnitsDocument1 pageAir Duct Sizing - SI & Imperial UnitsAbu Jasim K UNo ratings yet

- Marcet Boiler Final 21 EditedDocument9 pagesMarcet Boiler Final 21 EditedIbraheem MahmoodNo ratings yet

- 00087167Document11 pages00087167JohnSmith100% (1)

- Equilibrium NEET PYQ SOLUTIONDocument28 pagesEquilibrium NEET PYQ SOLUTIONsomeone nooneNo ratings yet

- Basic SOil MechanicsDocument36 pagesBasic SOil MechanicsshenNo ratings yet

- Introduction To Heat Transfer PDFDocument15 pagesIntroduction To Heat Transfer PDFMohamed RadwanNo ratings yet

- Sheet #7Document4 pagesSheet #7AHMED BAKRNo ratings yet

- A Counter-Rotating Vortex Pair in Inviscid FluidDocument9 pagesA Counter-Rotating Vortex Pair in Inviscid FluidMadeeha MalikNo ratings yet