Professional Documents

Culture Documents

FP WW Cbox d1280cb

FP WW Cbox d1280cb

Uploaded by

Maziya AnisahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FP WW Cbox d1280cb

FP WW Cbox d1280cb

Uploaded by

Maziya AnisahCopyright:

Available Formats

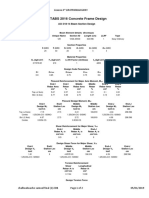

No : WW-FPST-(CBOX - D 1280 CB ) - 12

Hal : 1/1 CV. PREMIERE WOOD MANUFACTURING

Revisi

Tanggal

: 00

2-Feb-20 FLOW PROCESS & STANDART TIME

Model : SHARP CBOX - D 1280 CB DIVISI WOOD WORKING

Prepared : Aisyah (Prod Eng) Checked : Soryanto (RnD) Approved : Imam. M (Prod Eng) Approved : Dakun (Wood Working)

1. Body Board A/P

Running

Start Moulder Wrapping V-Cut ASSY FA

Saw

2.Front Board A/P

Start CNC Sending Membran Multi Bor Router ASSY FA

3.Back Board A/P

Flat Running

Start DET Router Multi Bor ASSY FA

Laminasi Saw

4.Square Board

Start Table Saw Cross Cut ASSY FA

5.Brace Board

Start Table Saw Cross Cut ASSY FA

NO PART BOX SET MACHINE/TOOL PROCESS OT (SEC) NET(SEC) MAN PWR KETERANGAN / JIG

1 BODY BOARD ACTIVE A 1 RUNNING SAW Cutting Material 10.02 10.02 2

( MDF - 12 MM ) A 1 MOULDER 15 15 2

P = 2368 MM A 1 WRAPPING 45 50 5 PVC Sheet Carbon Fabric

L = 259.5 MM A 1 V-CUT V-Cut Body 30 30 2

TOTAL(SEC) : 100.02 105.02

2 BODY BOARD PASSIVE P 1 RUNNING SAW Cutting Material 10.02 10.02 2

( MDF - 12 MM ) P 1 MOULDER 15 15 2

P = 2368 MM P 1 WRAPPING 45 50 5 PVC Sheet Carbon Fabric

L = 259.5 MM P 1 V-CUT V-Cut Body 30 30 2

TOTAL(SEC) : 100.02 105.02

3 FRONT BOARD ACTIVE A 1 CNC 54 54 2

( MDF MOLD - 16 MM ) A 1 MEMBRAN Sanding 50 50 1

P = 791 MM Spray lem 40 40 2

L = 357 MM Membran PVC Sheet Membran High Gloos 53.3 53.3 2 PVC Black Sand Emboss Membran

Cutting PVC + Cleaning 83 83 1

A 1 MULTI BOR 19.8 19.8 1

A 1 ROUTER 45 45 1

TOTAL(SEC) : 345.1 345.1

4 FRONT BOARD PASSIVE P 1 CNC 54 54 2

( MDF MOLD - 16 MM ) P 1 MEMBRAN Sanding 50 50 1

P = 791 MM Spray lem 40 40 2

L = 357 MM Membran PVC Sheet Membran High Gloos 53.3 53.3 2 PVC Black Sand Emboss Membran

Cutting PVC + Cleaning 83 83 1

P 1 MULTI BOR 19.8 19.8 1

P 1 ROUTER 45 45 1

TOTAL(SEC) : 345.1 345.1

5 BACK BOARD ACTIVE A 1 FLAT LAMINASI 3.75 7.5 4 Flat PVC Black Sand Emboss

( MDF 8 MME 2 ) A 1 RUNNING SAW Cutting Material 4.2 8.4 2

P = 790 MM A 1 DET 24 35 2

L = 358 MM A 1 ROUTER 60 60 1

A 1 MULTI BOR 30 30 1

TOTAL(SEC) : 122.0 140.9

6 BACK BOARD PASSIVE P 1 FLAT LAMINASI 3.75 7.5 4 Flat PVC Black Sand Emboss

( MDF 8 MME 2 ) P 1 RUNNING SAW Cutting Material 4.2 8.4 2

P = 790 MM P 1 DET 24 35 2

L = 358 MM P 1 ROUTER 60 60 1

P 1 MULTI BOR 30 30 1

TOTAL(SEC) : 122 140.9

7 BRACE BOARD PART 1 & 2 TABLE SAW 20 20 1 Laminasi PVC SHEET BLACK SAND EMBOSS

P = 265 MM & 272 MM CROSS CUT 20 20 1 1Kali CNC 11Mnt=12Pcs

L = 40 MM

TOTAL(SEC) : 40 40

8 SQUARE BOARD 35 TABLE SAW 105 105 1

CROSS CUT 140 140 1

TOTAL(SEC) : 245 245

NOTE OT (SEC) NET(SEC) MAN PWR REV NB.

MAN PWR = JUMLAH OPERATOR TOTAL : 1419.14 1467.04 66

QTY (PCS) = QUANTITY (PCS) MINIMUM : 4 8 1

ST (MNT) = STANDART TIME (MNT) MAXIMUM : 140 140 5

NET (SEC) = NET OPERATION RATE (ACTUAL PROSESSING TIME)

OT(SEC) = OPERATING TIME (WAKTU OPERASI MESIN) STANDARD TIME / SET = TOTAL + 15% TOLERANCE 27.2 28.1 MENIT

SET = (A = ACTIVE ; P = PASIVE)

PE - FM - 001, Rev : 00.29.03.07

You might also like

- Fitting and Machining Book by Ron Culley (L341)Document8 pagesFitting and Machining Book by Ron Culley (L341)Mahmud RochyNo ratings yet

- P111 Exer Wid SolDocument30 pagesP111 Exer Wid SolAlliver Sapitula100% (2)

- FOR35 5crAB09 PDFDocument30 pagesFOR35 5crAB09 PDFFleRexNo ratings yet

- Re4ro1a PDFDocument106 pagesRe4ro1a PDFженя евчин100% (1)

- 15 Ciac Ducted Air Conditioning System 60hz R410a FinalDocument2 pages15 Ciac Ducted Air Conditioning System 60hz R410a FinalLuis MoraNo ratings yet

- Start Running Saw Wrapping V-Cut Moulder: Divisi Wood WorkingDocument1 pageStart Running Saw Wrapping V-Cut Moulder: Divisi Wood WorkingMaziya AnisahNo ratings yet

- Divisi Wood Working: Running Saw Moulder V-CutDocument1 pageDivisi Wood Working: Running Saw Moulder V-CutMaziya AnisahNo ratings yet

- Pe-Fp-Ww-Roadmaster Bass Series 12Document1 pagePe-Fp-Ww-Roadmaster Bass Series 12Maziya AnisahNo ratings yet

- Pe FPST WW (Hbpro 8) 02Document4 pagesPe FPST WW (Hbpro 8) 02Maziya AnisahNo ratings yet

- Pe-Fp-Ww-Pnt-Roadmaster Bass Series 16Document1 pagePe-Fp-Ww-Pnt-Roadmaster Bass Series 16Maziya AnisahNo ratings yet

- Fp-Ww-Cbox Max 09 PaDocument1 pageFp-Ww-Cbox Max 09 PaMaziya AnisahNo ratings yet

- Fp-Ww-Cbox D808XWBDocument1 pageFp-Ww-Cbox D808XWBMaziya AnisahNo ratings yet

- Kolom K1Document1 pageKolom K1Al-Fatih Kids ChannelNo ratings yet

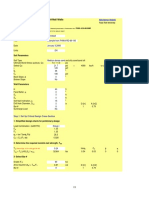

- ETABS 2015 Concrete Frame Design: ACI 318-11 Beam Section DesignDocument2 pagesETABS 2015 Concrete Frame Design: ACI 318-11 Beam Section DesignMuhammad AhsunNo ratings yet

- SU-47 Parts 6mm Depron PDFDocument19 pagesSU-47 Parts 6mm Depron PDFAlejandro LabléeNo ratings yet

- Beam Calculation: ETABS 2016 16.2.1 License # 1FNVN5QQGG7FMGFDocument2 pagesBeam Calculation: ETABS 2016 16.2.1 License # 1FNVN5QQGG7FMGFrikhi khadkaNo ratings yet

- ACI 318-14 Beam Section DesigneDocument2 pagesACI 318-14 Beam Section DesigneAl-Fatih Kids ChannelNo ratings yet

- 124915-AJ Series Consumable Item (Nozzle and Lens) Lists (ENSIS-AJM2 Gen3 3kw Spec.) Rev.FDocument1 page124915-AJ Series Consumable Item (Nozzle and Lens) Lists (ENSIS-AJM2 Gen3 3kw Spec.) Rev.FAlexNo ratings yet

- Carport Structure BOM TECH PECIFICDocument14 pagesCarport Structure BOM TECH PECIFICEr Navneet JassiNo ratings yet

- SloofDocument2 pagesSloofAl-Fatih Kids ChannelNo ratings yet

- DS - Aaac 150Document1 pageDS - Aaac 150nnNo ratings yet

- Restrained Slab Design To BS8110Document1 pageRestrained Slab Design To BS8110Sumedha MayadunnaNo ratings yet

- CJ21013 L05 LT AHU Indoor Breakin 20231031 R1Document4 pagesCJ21013 L05 LT AHU Indoor Breakin 20231031 R1Eddy NgNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1MRJ287JMT4QHDKDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1MRJ287JMT4QHDKBimalBhandariNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1BQHXYNV96LV5B5Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1BQHXYNV96LV5B5Rasec Otusgus ToNo ratings yet

- 6.99m BeamDocument2 pages6.99m BeamChristian ReyesNo ratings yet

- How To Use CT-30seriesDocument13 pagesHow To Use CT-30seriesmauro2k6No ratings yet

- Stand Jack CalculationDocument6 pagesStand Jack Calculationageng sakokoNo ratings yet

- Series 83 DelMonitor Limit Switch BoxDocument2 pagesSeries 83 DelMonitor Limit Switch BoxProcess Controls & ServicesNo ratings yet

- Kolom K2Document1 pageKolom K2Al-Fatih Kids ChannelNo ratings yet

- Polea para Cables 2020-1Document9 pagesPolea para Cables 2020-1yodemir -No ratings yet

- A2ASDocument22 pagesA2ASNajibNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1JR4TRHNJAKGHNYDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1JR4TRHNJAKGHNYR Michael QMNo ratings yet

- Vsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeDocument5 pagesVsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeSri RamprasathNo ratings yet

- TV - SW2 T D10 C9 XX en Version12Document1 pageTV - SW2 T D10 C9 XX en Version12Fernanda SequeraNo ratings yet

- ALUMINI en Technical Data SheetDocument8 pagesALUMINI en Technical Data SheetwsdslwoplhjrpxeytjNo ratings yet

- HS-901D Technical Data SheetDocument4 pagesHS-901D Technical Data SheetAji SetiawanNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1JXCLPR5B4Z7ACJDocument2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.1 License # 1JXCLPR5B4Z7ACJMohamed Kadafi KaswarNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1G83KMAGR458AC8Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.2.0 License # 1G83KMAGR458AC8Sandip BudhathokiNo ratings yet

- ETABS 2016 Concrete Frame Design: ETABS 2016 16.0.2 License # 1SVK7TR5A72FZP3Document2 pagesETABS 2016 Concrete Frame Design: ETABS 2016 16.0.2 License # 1SVK7TR5A72FZP3Roshan KejariwalNo ratings yet

- 19167-2 Front Bumper FlamingDocument1 page19167-2 Front Bumper FlamingIsaque Carlos music entertainmentNo ratings yet

- MM05-List of Machinery - All DeptDocument5 pagesMM05-List of Machinery - All DeptHAMPI JBNo ratings yet

- ETABS Concrete Frame Design: ACI 318-14 Column Section DesignDocument2 pagesETABS Concrete Frame Design: ACI 318-14 Column Section DesignJashury Fernanda Astete EscalanteNo ratings yet

- ETABS Concrete Frame Design: ACI 318-14 Column Section DesignDocument2 pagesETABS Concrete Frame Design: ACI 318-14 Column Section DesignJashury Fernanda Astete EscalanteNo ratings yet

- ETABS Concrete Frame Design: ACI 318-14 Column Section DesignDocument2 pagesETABS Concrete Frame Design: ACI 318-14 Column Section DesignJashury Fernanda Astete EscalanteNo ratings yet

- Daily Progress Report: Working LocationDocument2 pagesDaily Progress Report: Working Locationbiswajit samantaNo ratings yet

- Interfacing and Installatione2390d01a000Document1 pageInterfacing and Installatione2390d01a000omero faniNo ratings yet

- DrawingDocument13 pagesDrawingxanihog657No ratings yet

- SloofDocument2 pagesSloofAl-Fatih Kids ChannelNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-11 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-11 Beam Section DesignRey GonzalesNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-11 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-11 Beam Section DesignRey GonzalesNo ratings yet

- Design E-100 GT PMB N GN Kemala 15 MM Main CaseDocument103 pagesDesign E-100 GT PMB N GN Kemala 15 MM Main Casewahyu hidayatNo ratings yet

- Staircase 4m 150Document2 pagesStaircase 4m 150edward the iiiNo ratings yet

- Onsrud CatalogDocument104 pagesOnsrud CatalogDaniel AustinNo ratings yet

- ETABS 2016 Shear Wall Design: ETABS 2016 16.2.1 License # 1B2PQL2Z6AFQJAFDocument1 pageETABS 2016 Shear Wall Design: ETABS 2016 16.2.1 License # 1B2PQL2Z6AFQJAFA&T. IngenieriaNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignNur KhalidaNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Column Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Column Section DesignjccajamarcaNo ratings yet

- ETABS Concrete Frame DesignDocument2 pagesETABS Concrete Frame DesignzulbahriNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Beam Section DesigntapubitcivilNo ratings yet

- T Beam To BS 8110Document11 pagesT Beam To BS 8110Samitha SoysaNo ratings yet

- Cover Assy. SAI Valve-N7040290Document22 pagesCover Assy. SAI Valve-N7040290M Senthil SenthilNo ratings yet

- SHIMANO 105 Front Derailleur: (2x11-Speed) Black / SilverDocument1 pageSHIMANO 105 Front Derailleur: (2x11-Speed) Black / SilverBrandon GomezNo ratings yet

- Fp-Ww-Cbox Max 09 PaDocument1 pageFp-Ww-Cbox Max 09 PaMaziya AnisahNo ratings yet

- Pe-Fp-Ww-Roadmaster Bass Series 12Document1 pagePe-Fp-Ww-Roadmaster Bass Series 12Maziya AnisahNo ratings yet

- Start Running Saw Wrapping V-Cut Moulder: Divisi Wood WorkingDocument1 pageStart Running Saw Wrapping V-Cut Moulder: Divisi Wood WorkingMaziya AnisahNo ratings yet

- Divisi Wood Working: Running Saw Moulder V-CutDocument1 pageDivisi Wood Working: Running Saw Moulder V-CutMaziya AnisahNo ratings yet

- Fp-Ww-Cbox D808XWBDocument1 pageFp-Ww-Cbox D808XWBMaziya AnisahNo ratings yet

- Standard Time Final Assy: No. Model FA Grille Satuan TotalDocument20 pagesStandard Time Final Assy: No. Model FA Grille Satuan TotalMaziya AnisahNo ratings yet

- FP WW Cbox d1280cbDocument1 pageFP WW Cbox d1280cbMaziya AnisahNo ratings yet

- Pe FPST WW (Hbpro 8) 02Document4 pagesPe FPST WW (Hbpro 8) 02Maziya AnisahNo ratings yet

- Pe-Fp-Ww-Pnt-Roadmaster Bass Series 16Document1 pagePe-Fp-Ww-Pnt-Roadmaster Bass Series 16Maziya AnisahNo ratings yet

- Academic & Scientific Poster Presentation Visualising Knowledge As A Means To Facilitate Knowledge TransferDocument19 pagesAcademic & Scientific Poster Presentation Visualising Knowledge As A Means To Facilitate Knowledge TransferMaziya AnisahNo ratings yet

- SAE-J1926 Port Reference DimensionsDocument1 pageSAE-J1926 Port Reference DimensionsSamuel RochetteNo ratings yet

- Sandvik Versatile Tools 2018Document153 pagesSandvik Versatile Tools 2018jaajaNo ratings yet

- Bearings For Conveyor Belt Tensioners: Stainless Steel Bearings Are Corrosion ResistantDocument3 pagesBearings For Conveyor Belt Tensioners: Stainless Steel Bearings Are Corrosion ResistantRamNo ratings yet

- 00 Bedroom ToiletDocument1 page00 Bedroom ToiletKhushi RathodNo ratings yet

- c190ts-c230ts Parts Manual CompairDocument68 pagesc190ts-c230ts Parts Manual CompairCe Bayona67% (3)

- All Id Skins 0.22.0Document22 pagesAll Id Skins 0.22.0Nikita ShterevNo ratings yet

- True Temper 1957 A57 HammersDocument24 pagesTrue Temper 1957 A57 HammersJay SNo ratings yet

- s03 Drill Feed - TFX 6.12Document60 pagess03 Drill Feed - TFX 6.12hyserperusacNo ratings yet

- Niwatec Presentation EnglDocument27 pagesNiwatec Presentation EnglmohamedwalyNo ratings yet

- Sectional Elevation: Toilet DetailsDocument1 pageSectional Elevation: Toilet DetailsAparna MahajanNo ratings yet

- DDCP SF 04 04aDocument6 pagesDDCP SF 04 04aMohammad FarajNo ratings yet

- Types of HVAC SystemsDocument18 pagesTypes of HVAC SystemsIsrael raju2003No ratings yet

- Mep Hvac 2Document170 pagesMep Hvac 2Muhammad MusaNo ratings yet

- Daystate Brochure 2018 Rev1Document12 pagesDaystate Brochure 2018 Rev1yeahbaby!No ratings yet

- Catalogo TANDocument20 pagesCatalogo TANCesar MessiasNo ratings yet

- Emco Mill250 SpecifDocument43 pagesEmco Mill250 Specifandre sebastian ruiz trujilloNo ratings yet

- SW Astik Furnaces Pvt. LTDDocument7 pagesSW Astik Furnaces Pvt. LTDpakyabhai143No ratings yet

- Argos FD 700Document20 pagesArgos FD 700Tony Humberto Gutierrez100% (1)

- Liberty Parts ManualDocument19 pagesLiberty Parts Manualapi-3854769No ratings yet

- PDL Ware House Inventory 2Document29 pagesPDL Ware House Inventory 2Enwereji Bertram UdoNo ratings yet

- Scroll Saw 40-100 16 1246Document8 pagesScroll Saw 40-100 16 1246Theodor EikeNo ratings yet

- 3 Types of PulleysDocument5 pages3 Types of PulleysJohn GarciaNo ratings yet

- Din 13-23Document21 pagesDin 13-23rajeskumarNo ratings yet

- SOW Annual Maintenance of Howden CompressorsDocument13 pagesSOW Annual Maintenance of Howden CompressorsMasroor RasoolNo ratings yet

- BMMM2333 Lecture 5 ValvesDocument18 pagesBMMM2333 Lecture 5 ValvesFgj JhgNo ratings yet