Professional Documents

Culture Documents

Electrical Safety Precautions: For Electrical Heat Tracing

Electrical Safety Precautions: For Electrical Heat Tracing

Uploaded by

Amila BalasooriyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Safety Precautions: For Electrical Heat Tracing

Electrical Safety Precautions: For Electrical Heat Tracing

Uploaded by

Amila BalasooriyaCopyright:

Available Formats

Site Practice . . .

1. Provide protective clothing, personal protective equipment, and other protective

equipment needed to protect employees from potential arc flash and shock haz-

ards identified in the analysis.

2. Provide training to create qualified employees capable of understanding the pur- Electrical Safety Precautions

pose/function of the electrical heat tracing, its electrical power supply/control

equipment, and how to recognize and avoid the hazards associated with its op- FOR ELECTRICAL HEAT TRACING

eration and maintenance.

3. Treat all electrical conductors and circuit parts as though they are energized until Prepared for Thermon Industries, Inc. by:

they are placed in an electrically safe work condition by doing the following: Ray A. Jones, P.E. and L. Bruce McClung, P.E.

• Identify the circuit or equipment to be de-energized and all possible sources of Electrical Safety Consulting Service, Inc.

electrical energy supplies to the specific circuit or equipment.

• Interrupt the load currents appropriately, and then open the circuit disconnect-

ing device(s).

• Visually verify, where possible, that the appropriated circuit disconnecting de-

vice is indeed open.

• Apply lockout/tagout devices according to a documented and established

procedure.

• Test for absence of voltage with an approved voltmeter (where the voltmeter is

tested on a known circuit voltage prior to and immediately following application).

• Ground the phase conductors or circuit parts before touching them where the

possibility of induced voltages or stored electrical energy exists.

• Apply ground-connecting devices rated for the available fault duty where the

conductors or circuit parts being de-energized could possible contact other ex-

posed energized conductors or circuit parts.

THERMON . . . The Heat Tracing Specialists®

100 Thermon Dr. •PO Box 609 •San Marcos, TX 78667-0609

Phone: 512-396-5801 •

Facsimile: 512-396-3627 • 800-820-HEAT

www.thermon.com

Form TMP0006-0901 Printed in U.S.A.

Electrical Safety Precautions FOR ELECTRICAL HEAT TRACING

Avoiding electrical hazards associated with electrical heat tracing requires protective Analysis . . .

measures in several different areas. A designer/installer must pay attention to circuit 1. Determine the amount of electrical energy available at the source of electrical

and equipment identification, analysis of hazards and exposure to those hazards, power used to supply electric heating circuits. (NOTE: The amount of available

warnings, listing, and labeling. The designer/installer must also consider the me- energy is dependent upon the design of the circuit supplying energy.)

chanics of establishing an electrically safe work condition.

2. Analyze the overall electrical arc-flash and shock hazards associated with the volt-

In designing, installing, or maintaining electrical heat tracing systems, the following age, short-circuit current available, and circuit-protective device clearing time. Con-

actions should be considered. sider each point in the electrical system/facility where personnel may be exposed.

Identification . . . 3. With engineering supervision, establish the flash protection boundary by doing

the following:

1. Clearly label the outer surface of thermal insulation (after final dressing is in-

stalled). Labels should be installed on piping, vessels, pumps and similar equip- • Identify the voltage level and its associated limited/re-

ment. The label should indicate that stricted/prohibited approach boundaries. Define the

electrical heating conductors are in- distance from any potential exposed energized electri-

stalled under the insulation. At least cal conductor or circuit part where the incident en-

one label should be visible from any ergy exceeds 1.2 cal/square cm.

location. On insulated pipe lines, la- • If available energy is less than 16 kA, establish the

bels should be installed at intervals flash protection boundary using the formula in NFPA

no greater that 10 feet (3 meters) 70E, Part II, Paragraph 2-1.3.3.2 or in Appendix B-

and on alternating sides of the pipe. 2.3.2 or B-2.3.3.

If insulation is removed or replaced, • If available energy is at least 16 kA but less than 50

make sure that the label is replaced. kA, establish the flash protection boundary using the

formula in NFPA 70E, Appendix B-5.1 or B-5.2.

2. Clearly label any controller used to supply and/or protect electrical heat tracing

circuits and/or products. Information on the label should contain the circuit be- 4. Clearly label the electrical equipment enclosures (front, back, and ends) to show

ing controlled/protected by the controller. the approach boundaries determined in the analysis. If employee is to approach

any live part closer than the Prohibited Space shown in NFPA 70E, Part II, Table

3. Clearly label any power supply panel and/or circuit protective device used to

2-1.3.4, he/she must be insulated or guarded from the live parts.

supply and/or protect electrical heat tracing circuits. The label should indicate

the circuit being supplied or protected. If the protective device serves as the 5. Clearly label the electrical equipment enclosures (front/back, ends) to show the

circuit isolation device for lockout purposes, the label should indicate this infor- incident energy at 18 inches (46 cm) and at 36 inches (91 cm) from the arc-

mation. flash hazard source.

4. Clearly label any power transformers, power circuits, raceways, and cable trays Design/Installation . . .

or other routing methods used for providing electric power to heat tracing. The

label should indicate that the equipment/raceway supplies heating circuits. 1. Provide/install only electrical heat tracing and electrical power supply or control

equipment that has been evaluated, tested, and listed by a nationally recognized

testing laboratory (NRTL).

2. Install listed electrical equipment according to any directions from the listing

agency.

3. Apply electrical heat tracing and its electrical power supply and control equip-

ment according to the National Electrical Code® (NEC®).

4. Provide necessary equipment or circuit disconnecting devices (for lockout) for

each circuit or item of equipment.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Service Manual Electrical Diagrams 2003B: Maskin: U AC Manual NR: 005973Document61 pagesService Manual Electrical Diagrams 2003B: Maskin: U AC Manual NR: 005973Дмитро СелютинNo ratings yet

- Advanced Engineering Mathematics 10th EditionDocument134 pagesAdvanced Engineering Mathematics 10th EditionAyan0% (1)

- Datasheet KT5W-2P1116 1018044 enDocument8 pagesDatasheet KT5W-2P1116 1018044 enAmila BalasooriyaNo ratings yet

- Datasheet CS81-P1112 1028224 enDocument7 pagesDatasheet CS81-P1112 1028224 enAmila BalasooriyaNo ratings yet

- City Tour of Dubai With English Speaking GuideDocument3 pagesCity Tour of Dubai With English Speaking GuideAmila BalasooriyaNo ratings yet

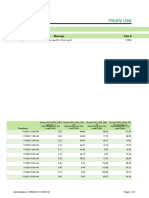

- Hourly Usage ReportDocument36 pagesHourly Usage ReportAmila BalasooriyaNo ratings yet

- Dynamic Weight Estimation Using An Artificial Neural NetworkDocument5 pagesDynamic Weight Estimation Using An Artificial Neural NetworkAmila BalasooriyaNo ratings yet

- DTR LXM52 enDocument158 pagesDTR LXM52 enAmila BalasooriyaNo ratings yet

- Datasheet - DT50-P2113 - 1047314 - en - SickDocument6 pagesDatasheet - DT50-P2113 - 1047314 - en - SickAmila BalasooriyaNo ratings yet

- SDR 480 Spec PDFDocument3 pagesSDR 480 Spec PDFAmila BalasooriyaNo ratings yet

- Datasheet - DT50-P2113 - 1047314 - en - SickDocument6 pagesDatasheet - DT50-P2113 - 1047314 - en - SickAmila BalasooriyaNo ratings yet

- Datasheet DT20-P224B 1040405 En-SickDocument7 pagesDatasheet DT20-P224B 1040405 En-SickAmila BalasooriyaNo ratings yet

- Fiber Optic Cable Sensor: Available As PDF Only Status: 10.10.2016Document16 pagesFiber Optic Cable Sensor: Available As PDF Only Status: 10.10.2016Amila BalasooriyaNo ratings yet

- Reflex Sensor: With Background SuppressionDocument2 pagesReflex Sensor: With Background SuppressionAmila BalasooriyaNo ratings yet

- Retro-Reflex Sensor: Technical DataDocument2 pagesRetro-Reflex Sensor: Technical DataAmila BalasooriyaNo ratings yet

- DampingDocument24 pagesDampingKarthiik88No ratings yet

- LK89PA7: Retro-Reflex SensorDocument2 pagesLK89PA7: Retro-Reflex SensorAmila BalasooriyaNo ratings yet

- KCGGDocument16 pagesKCGGFarwa KhanNo ratings yet

- Economical Comparison of Different Power Systems: Practical Assignment 1Document8 pagesEconomical Comparison of Different Power Systems: Practical Assignment 1Amila BalasooriyaNo ratings yet

- Practical 03 Speed Control of DC Machines: Conducted By: Ms G.N.T SilvaDocument7 pagesPractical 03 Speed Control of DC Machines: Conducted By: Ms G.N.T SilvaAmila BalasooriyaNo ratings yet

- ABB Special Report 2008-02 38-42Document5 pagesABB Special Report 2008-02 38-42iskandarn_el5735No ratings yet

- Cores DatasheetDocument45 pagesCores DatasheetGigi KentNo ratings yet

- Engineering AssistantDocument9 pagesEngineering AssistantKrishna ChaitanyaNo ratings yet

- General Wave Properties 1 MSDocument4 pagesGeneral Wave Properties 1 MSherawatiNo ratings yet

- Well FoundationDocument119 pagesWell FoundationRaviteja Murala100% (1)

- CHAPTER 2. Physics f5Document45 pagesCHAPTER 2. Physics f5Normawarni HasanNo ratings yet

- HSC Chem NotesDocument118 pagesHSC Chem NotesAidan Chan100% (1)

- Com Varistoren Von Epcos 3 1576 PDFDocument36 pagesCom Varistoren Von Epcos 3 1576 PDFAwadhNo ratings yet

- PATRICK MULCAHY Divine Measure of Time and SpaceDocument95 pagesPATRICK MULCAHY Divine Measure of Time and SpacePash R100% (2)

- Short-Circuit Calculation According To IEC 60909 Comparison ReportDocument21 pagesShort-Circuit Calculation According To IEC 60909 Comparison ReportMax SteeleNo ratings yet

- Sensor de Ca Con Arduino lm358Document4 pagesSensor de Ca Con Arduino lm358Wilfredo CindetNo ratings yet

- Plano Electrico 994F PDFDocument4 pagesPlano Electrico 994F PDFChristianM.CarrascoNo ratings yet

- Catalogmicom 10 20 Nrjed112402enDocument196 pagesCatalogmicom 10 20 Nrjed112402enganesamoorthy1987No ratings yet

- 9709 w15 QP 53Document4 pages9709 w15 QP 53yuke kristinaNo ratings yet

- Moments QuestionsDocument12 pagesMoments Questionsmuxadey100% (1)

- FEM Based No-Load Loss Calculation of Triangular W Ound Core TransformerDocument4 pagesFEM Based No-Load Loss Calculation of Triangular W Ound Core TransformerVictor Julián Fernández CarrazanaNo ratings yet

- IEEE Guide For AC Generator ProtectionDocument76 pagesIEEE Guide For AC Generator ProtectionOmar Chayña VelásquezNo ratings yet

- 1.0 FUNDAMENTALS of VIBRATION 1.1 What Is Vibration? Mechanical VibrationDocument56 pages1.0 FUNDAMENTALS of VIBRATION 1.1 What Is Vibration? Mechanical VibrationLuis Balducci100% (1)

- Lect 4Document37 pagesLect 4eba yohannesNo ratings yet

- Delhi Public School Bangalore - East Physics Force and Pressure (Answer Key) Class: Viii Sec: DateDocument6 pagesDelhi Public School Bangalore - East Physics Force and Pressure (Answer Key) Class: Viii Sec: DateSaket TNo ratings yet

- Two Step Impedance Matching Using Quarter Wave Transformers For Resistive and Non-Resistive LoadsDocument19 pagesTwo Step Impedance Matching Using Quarter Wave Transformers For Resistive and Non-Resistive LoadsJ SanyalNo ratings yet

- Warm Up Exam # 2 QuestionerDocument6 pagesWarm Up Exam # 2 QuestionerJimmy GutierrezNo ratings yet

- R9 1934 10 PDFDocument36 pagesR9 1934 10 PDFAlaa MaNo ratings yet

- AC Transmission Line LossesDocument8 pagesAC Transmission Line LossesThakur YogendraNo ratings yet

- Equivalent Circuit Model Analysis ExampleDocument4 pagesEquivalent Circuit Model Analysis ExampleGiray SenerginNo ratings yet

- R250 RegulatorDocument12 pagesR250 Regulatoremerson212121100% (2)

- Assignment 5Document5 pagesAssignment 5maha saeedNo ratings yet

- LOCG-GEN-Guideline-003 Rev 0 - Marine Lifting PDFDocument28 pagesLOCG-GEN-Guideline-003 Rev 0 - Marine Lifting PDFJohn PetterNo ratings yet