Professional Documents

Culture Documents

Laser Welding of The New Generation Gade of HSS Domex 960

Laser Welding of The New Generation Gade of HSS Domex 960

Uploaded by

Agnieszka Kurc-LisieckaCopyright:

Available Formats

You might also like

- CPHFD 011Document7 pagesCPHFD 011Napoleon DasNo ratings yet

- Ogre MiniaturesDocument86 pagesOgre MiniaturesEdward Holzman86% (7)

- Manual Xerox 252Document50 pagesManual Xerox 252elmismo1821No ratings yet

- DOI: 10.1515/amm-2016-0198Document8 pagesDOI: 10.1515/amm-2016-0198BHARANINo ratings yet

- Tekken en Acero Weldonx 1300Document8 pagesTekken en Acero Weldonx 1300nestor leonardonNo ratings yet

- Rehabilitation of Steel Structures C1Document37 pagesRehabilitation of Steel Structures C1Alina CiuraruNo ratings yet

- Ductile Iron Research PapersDocument8 pagesDuctile Iron Research Papersxkcwaaqlg100% (1)

- The Use of Heavy Rolled Sections in High-Rise Buildings Current Practice and Future Innovation by Riccardo ZANON, Georges AXMANN, Jean-Claude GERARDY, André PLUMIERDocument17 pagesThe Use of Heavy Rolled Sections in High-Rise Buildings Current Practice and Future Innovation by Riccardo ZANON, Georges AXMANN, Jean-Claude GERARDY, André PLUMIERgulilero_yoNo ratings yet

- Mmscience - 2016 11 - Welded Joint of High Strength Steels Weldox 700 and Common Grade Steel S 355Document4 pagesMmscience - 2016 11 - Welded Joint of High Strength Steels Weldox 700 and Common Grade Steel S 355Said ElhamydyNo ratings yet

- 113 14Document8 pages113 14rahul srivastavaNo ratings yet

- Review of Creep Resistant SteelsDocument4 pagesReview of Creep Resistant SteelsAleš NagodeNo ratings yet

- Investigation and Application of High Strength Low Alloy Wear Resistant Cast SteelDocument4 pagesInvestigation and Application of High Strength Low Alloy Wear Resistant Cast Steelz2aliNo ratings yet

- Lesson2 STEEL PROPERTIES CDocument87 pagesLesson2 STEEL PROPERTIES CMaqMaikNo ratings yet

- Metals 10 00099 v2 PDFDocument23 pagesMetals 10 00099 v2 PDFarjun prajapatiNo ratings yet

- Steels For Oil - Gas - ExplorationDocument16 pagesSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىNo ratings yet

- Steels For Cryogenic and Low-Temperature Service - KEY To METALS ArticleDocument3 pagesSteels For Cryogenic and Low-Temperature Service - KEY To METALS Articlekumarpankaj030No ratings yet

- High Strength SteelDocument19 pagesHigh Strength SteelBHARANINo ratings yet

- Poletskov 2020 IOP Conf. Ser. Mater. Sci.Document8 pagesPoletskov 2020 IOP Conf. Ser. Mater. Sci.Александр ТиньгаевNo ratings yet

- Materials Science & Engineering A: Ludmila Ku Cerov A, Karolina Burdov A, ST Ep An Jení Cek, Iveta ChenaDocument15 pagesMaterials Science & Engineering A: Ludmila Ku Cerov A, Karolina Burdov A, ST Ep An Jení Cek, Iveta ChenaJimmy the ReverendNo ratings yet

- UM ASDG Lesson1 STRUCTURAL STEEL REVIEW PDFDocument94 pagesUM ASDG Lesson1 STRUCTURAL STEEL REVIEW PDFjuan carlos montañezNo ratings yet

- 3225 HARDOX 450 Prilog OcjenDocument6 pages3225 HARDOX 450 Prilog OcjenGoran SpasojevicNo ratings yet

- 421 - Domex 700 MCDocument2 pages421 - Domex 700 MClalamed21No ratings yet

- HSLA-100 Steels: Influence of Aging Heat Treatment On Microstructure and PropertiesDocument11 pagesHSLA-100 Steels: Influence of Aging Heat Treatment On Microstructure and PropertiesEdgar HornusNo ratings yet

- Newly Designed High-Strength ToolDocument15 pagesNewly Designed High-Strength ToolMd Ibrahim KhalilNo ratings yet

- P91 MaterialDocument15 pagesP91 MaterialelrajilNo ratings yet

- Heat TreatmentDocument20 pagesHeat Treatmentعزت عبد المنعمNo ratings yet

- Application of Stainless SteelDocument13 pagesApplication of Stainless Steelsweety1188No ratings yet

- The Mechanical Properties of SteelDocument13 pagesThe Mechanical Properties of SteelAddrien DanielNo ratings yet

- 10 1016@j JCSR 2019 03 017 PDFDocument13 pages10 1016@j JCSR 2019 03 017 PDFDeni JaelaniNo ratings yet

- Weld Cons SojamDocument7 pagesWeld Cons SojamAsad Bin Ala QatariNo ratings yet

- Steel Making PracticesDocument32 pagesSteel Making PracticesSiva SubramaniNo ratings yet

- Journal Pre-Proof: Unda G, Sergej Gook, Andrey Gumenyuk, MichaelDocument34 pagesJournal Pre-Proof: Unda G, Sergej Gook, Andrey Gumenyuk, MichaelAgus WidyiantoNo ratings yet

- Creep ResistanceDocument16 pagesCreep Resistancefernandosimic96No ratings yet

- Electron Microscopy and Microanalysis of Steel Weld Joints After Long Time Exposures at High TemperaturesDocument10 pagesElectron Microscopy and Microanalysis of Steel Weld Joints After Long Time Exposures at High TemperaturesJEANNINA BULEJE CASTILLONo ratings yet

- Análisis de Las Propiedades de Desgaste Del Acero Pulvimetalúrgico enDocument18 pagesAnálisis de Las Propiedades de Desgaste Del Acero Pulvimetalúrgico enJazminNo ratings yet

- Effect of Tempering Temperatures On The Mechanical Properties and Microstructures of HSLA-100 Type Copper-Bearing SteelsDocument14 pagesEffect of Tempering Temperatures On The Mechanical Properties and Microstructures of HSLA-100 Type Copper-Bearing Steelsbharani dharanNo ratings yet

- Comparative Study About The Results of HAZ Physical Simulations On Different High-Strength Steel GradesDocument16 pagesComparative Study About The Results of HAZ Physical Simulations On Different High-Strength Steel GradesafabNo ratings yet

- Modern High Strength Niobium Microallyed Structural SteelsDocument26 pagesModern High Strength Niobium Microallyed Structural SteelsimetallurgyNo ratings yet

- Double Aust. AssgnmntDocument15 pagesDouble Aust. Assgnmntmaurya21No ratings yet

- Journal of Constructional Steel Research: Xia Yan, Yu Xia, Hannah B. Blum, Thomas GernayDocument12 pagesJournal of Constructional Steel Research: Xia Yan, Yu Xia, Hannah B. Blum, Thomas GernayAswini JhaNo ratings yet

- Metals: Heat Input Influence On The Fatigue Life of Welds From Steel S460MCDocument14 pagesMetals: Heat Input Influence On The Fatigue Life of Welds From Steel S460MCArab WeldersNo ratings yet

- Jurnal PengelasanDocument10 pagesJurnal Pengelasanyudha mamotsNo ratings yet

- Maisuradze-Björk2021 Article MicrostructureAndMechanicalProDocument10 pagesMaisuradze-Björk2021 Article MicrostructureAndMechanicalProsaifbenNo ratings yet

- Niobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener ApplicationsDocument7 pagesNiobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener Applicationsnvc_vishwanathanNo ratings yet

- Antifriction AlloysDocument5 pagesAntifriction AlloysMădălina ConstantinescuNo ratings yet

- Metalurgia Física ModernaDocument20 pagesMetalurgia Física ModernaMariliaFrancoNo ratings yet

- SMS Steel-Making-Practices PDFDocument32 pagesSMS Steel-Making-Practices PDFkalai0% (1)

- Propiedades AISI 410Document25 pagesPropiedades AISI 410alvaroyepezNo ratings yet

- Mechanical Properties of High Strength S690 Steel Welded Sections Through Tensile Tests On Heat-Treated Coupons - ScienceDirectDocument41 pagesMechanical Properties of High Strength S690 Steel Welded Sections Through Tensile Tests On Heat-Treated Coupons - ScienceDirectEhsan HaratiNo ratings yet

- Creep and Creep Damage Assessment in P91 Weld JointsDocument12 pagesCreep and Creep Damage Assessment in P91 Weld JointsDeepakNo ratings yet

- Materials and Examples of Preparing Damascus Type Blade SteelDocument8 pagesMaterials and Examples of Preparing Damascus Type Blade SteelrobertNo ratings yet

- Hardness X20CrMoV12 1Document8 pagesHardness X20CrMoV12 1misapera35No ratings yet

- RESID. STRESS - Effect of Residual Stresses in The ZTA of Welds of S700MCDocument14 pagesRESID. STRESS - Effect of Residual Stresses in The ZTA of Welds of S700MCGabriel PaesNo ratings yet

- (Welding) s7Document113 pages(Welding) s7Popo YuppyNo ratings yet

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingFrom EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingRating: 5 out of 5 stars5/5 (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingFrom EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingRating: 1 out of 5 stars1/5 (1)

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- GPR - Making It EasyDocument28 pagesGPR - Making It Easyishtiaque_anwarNo ratings yet

- Measurement of The Glucose Concentration in Human Urine With Optical RefractometerDocument7 pagesMeasurement of The Glucose Concentration in Human Urine With Optical RefractometerMuhammad AbduhNo ratings yet

- Orafol Wrapping Films: Product Summary SheetDocument4 pagesOrafol Wrapping Films: Product Summary SheetAgung SetiawanNo ratings yet

- KARIXA Dentolaser KA 45-01 DLDocument1 pageKARIXA Dentolaser KA 45-01 DLrochmandrg dokter gigiNo ratings yet

- Chapter 3 Optical Fiber CablesDocument132 pagesChapter 3 Optical Fiber CablesAhmed AmrNo ratings yet

- Laser CommunicationDocument3 pagesLaser CommunicationVishal KumarNo ratings yet

- ND-3300-Brochure - New - 2009Document2 pagesND-3300-Brochure - New - 2009ambuja_kumar5993No ratings yet

- Seminar On Wireless Charging of Mobile DevicesDocument24 pagesSeminar On Wireless Charging of Mobile DevicesGourish Amonkar100% (1)

- TCRT1000 PDFDocument7 pagesTCRT1000 PDFBalya SubarkahNo ratings yet

- Boring MachineDocument25 pagesBoring MachineSreedhar PugalendhiNo ratings yet

- Photodiode - WikipediaDocument15 pagesPhotodiode - WikipediaIKENNANo ratings yet

- BD Accuri C6Flow Cyto Instrument ManualDocument31 pagesBD Accuri C6Flow Cyto Instrument ManualWilna100% (1)

- Semiconductors 170506180045Document42 pagesSemiconductors 170506180045EdamEdamNo ratings yet

- 40k+rf Cavitation Ultrasound Rf+bipolar+quadrupole+sextupolar Rf+vacuum RF SlimDocument4 pages40k+rf Cavitation Ultrasound Rf+bipolar+quadrupole+sextupolar Rf+vacuum RF SlimErvin AmannNo ratings yet

- 10.energy Band Gap Behavior of Binary OxidesDocument24 pages10.energy Band Gap Behavior of Binary OxidesWan HafizaNo ratings yet

- Sharp AR-122E - 157E ServiceDocument130 pagesSharp AR-122E - 157E Serviceatookme100% (2)

- Nature of LightDocument2 pagesNature of LightDhanBahadurNo ratings yet

- Presentation ICU-2023 Levin v. M.Document25 pagesPresentation ICU-2023 Levin v. M.Vadim LevinNo ratings yet

- Dissertation Laser DiodeDocument5 pagesDissertation Laser DiodeFindSomeoneToWriteMyCollegePaperDesMoines100% (1)

- 4.01 Petrochemical and Offshore - ASTM D 1500 ColorDocument2 pages4.01 Petrochemical and Offshore - ASTM D 1500 Colorsetiawanaji407No ratings yet

- 5522-Central Loose Tube Armoured Outdoor CableDocument2 pages5522-Central Loose Tube Armoured Outdoor CableasifaliabidNo ratings yet

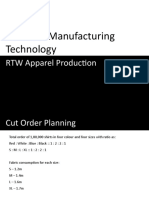

- Garment Manufacturing Technology: RTW Apparel ProductionDocument12 pagesGarment Manufacturing Technology: RTW Apparel Productionnalinkumar944No ratings yet

- ICF 7 - Q2 - Week5Document2 pagesICF 7 - Q2 - Week5Efren TabuadaNo ratings yet

- Uncertainty of Atomic Absorption SpectrometerDocument7 pagesUncertainty of Atomic Absorption SpectrometerbelazouzboualemNo ratings yet

- Nano Assesment-1 Question PaperDocument3 pagesNano Assesment-1 Question Paperdineshkumarbaskaran100% (3)

- I Port Ex3Document2 pagesI Port Ex3SlimeSlimeNo ratings yet

- Tutorial Chapter 4: Electronics: A. B. C. D. EDocument8 pagesTutorial Chapter 4: Electronics: A. B. C. D. EMohamad Rizal MukhtarNo ratings yet

- VeroVision Product SheetDocument2 pagesVeroVision Product SheetclurichaunNo ratings yet

Laser Welding of The New Generation Gade of HSS Domex 960

Laser Welding of The New Generation Gade of HSS Domex 960

Uploaded by

Agnieszka Kurc-LisieckaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laser Welding of The New Generation Gade of HSS Domex 960

Laser Welding of The New Generation Gade of HSS Domex 960

Uploaded by

Agnieszka Kurc-LisieckaCopyright:

Available Formats

MATERIALI IN TEHNOLOGIJE/MATERIALS AND TECHNOLOGY (1967–2017) – 50 LET/50 YEARS

UDK 621.791.725:669.14.018.291:621.791.053 ISSN 1580-2949

Original scientific article/Izvirni znanstveni ~lanek MTAEC9, 51(2)199(2017)

A. KURC-LISIECKA, A. LISIECKI: LASER WELDING OF THE NEW GRADE OF ADVANCED HIGH-STRENGTH STEEL ...

199–204

LASER WELDING OF THE NEW GRADE OF ADVANCED

HIGH-STRENGTH STEEL DOMEX 960

LASERSKO VARJENJE DOMEX 960 NOVEGA NAPREDNEGA

JEKLA Z VISOKO TRDNOSTJO

Agnieszka Kurc-Lisiecka1, Aleksander Lisiecki2

1University of D¹browa Górnicza, Rail Transport Department, Cieplaka 1C, 41-300 D¹browa Górnicza, Poland

2Silesian University of Technology, Faculty of Mechanical Engineering, Welding Department, Konarskiego 18A, 44-100 Gliwice, Poland

a.kurc@wp.pl, aleksander.lisiecki@polsl.pl

Prejem rokopisa – received: 2015-07-01; sprejem za objavo – accepted for publication: 2016-02-09

doi:10.17222/mit.2015.158

The article presents the results of investigations on autogenous laser welding of the new-generation advanced high-strength

steels (AHSS) Domex 960, classified as thermomechanically rolled steel by the manufacturer. There is little information about

welding this steel grade, relating only to arc-welding methods. Therefore, a modern disk laser was used for the butt-joint weld-

ing of 5.0 mm steel sheets. The results of a microstructure study, tensile tests, technological bending tests, impact-toughness

tests and also microhardness measurements showed that a low heat input during the laser welding of the new Domex 960 grade

steel is advantageous. A low heat input and thus a high cooling rate of the weld metal and the heat-affected zone (HAZ) led to

the formation of a favourable fine-grained microstructure, providing also high mechanical properties of butt joints, comparable

to the properties of the base metal. Despite the high cooling rates, there was no significant increase in the microhardness

measured across the butt joints. Moreover, a slight decrease in the microhardness was observed in the HAZ.

Keywords: laserlaser welding, disk laser, thermomechanically rolled steel, advanced high-strength steel, fine-grained steel, pro-

perties of welded joints

^lanek predstavlja rezultate preiskav avtogenega laserskega varjenja nove generacije naprednih visokotrdnostnih jekel (AHSS),

jekla Domex 960, ki so ga proizvajalci opredeljujejo kot termomehansko valjano jeklo. Malo je informacij o varjenju te vrste

jekla, nekaj le za metode oblo~nega varjenja. Za sole`no varjenje 5 mm debelih plo~evin je bil uporabljen modern diskasti laser.

Rezultati {tudija mikrostrukture, nateznih preizkusov, tehnolo{kih upogibnih preizkusov, preizkusov udarne `ilavosti in tudi

meritev mikrotrdote, so pokazali, da je ugoden majhen vnos toplote med laserskim varjenjem nove vrste jekla Domex 960.

Majhen vnos toplote in zato velika hitrost ohlajanja kovine v zvaru in v toplotno vplivani coni (HAZ), povzro~i nastanek `eljene

drobno zrnate mikrostrukture in tudi zagotavlja visoke mehanske lastnosti sole`nega zvara, v primerjavi z lastnostmi osnovne

kovine. Kljub velikim hitrostim ohlajanja, ni bilo ob~utnega pove~anja mikrotrdote, izmerjene preko sole`nega zvara. Poleg tega

je bilo v HAZ opa`eno rahlo zmanj{anje mikrotrdote.

Klju~ne besede: lasersko varjenje, diskasti laser, termomehansko valjano jeklo, napredna visokotrdnostna jekla, drobno zrnato

jeklo, lastnosti zvarjenih spojev

1 INTRODUCTION advanced and ultra-high-strength steels (AHSS and

UHSS), characterized by an extremely high yield point

The constant trend to increase production efficiency, and tensile strength over 1000 MPa.1–8 Steels of this type

reduce energy consumption and material consumption, achieve high mechanical properties thanks to a very

improve the durability and reliability has lead to an fine-grained structure and/or a sophisticated phase com-

increasing use of advanced high-strength materials.1–8 position like in the case of dual-phase (DP), complex-

Depending on the application, working conditions and phase (CP) and transformation-induced plasticity (TRIP)

the type of load and wear, different metallic, bimetallic steels.2,6,7

or composite materials are used.9–12

A significant group of the modern structural steels

In the case of the manufacturing of building struc-

currently used in the industry includes thermomechani-

tures such as bridges, towers, industrial buildings and

cally rolled fine-grained microalloyed steel classified by

vehicles, particularly heavy vehicles such as trucks,

trailers, semi-trailers, rail vehicles such wagons and the EN 10149-2 standard and also the quenched and

tramcars, and also other utility vehicles and machines tempered low-alloy steel classified by the EN 10025-6

such as cranes, loaders, excavators, etc., the primary standard. The EN 10149-2 standard covers the thermo-

group of materials is structural steel.13–18 The reason for mechanically rolled fine-grained microalloyed steel with

this is the ease of forming and joining steel pieces, a yield point of up to 700 MPa (e.g., S700MC). An

usually with welding technologies. Moreover, the use of example of the commercial name of this type of steel is

high-strength steel (HSS) has been growing in the Domex 700, manufactured by a Swedish company. On

industry for many years. The dynamic development of the contrary, the EN 10025-6 standard covers the

high-strength steels has led to the introduction of modern low-alloy quenched and tempered steel with a yield point

Materiali in tehnologije / Materials and technology 51 (2017) 2, 199–204 199

MATERIALI IN TEHNOLOGIJE/MATERIALS AND TECHNOLOGY (1967–2017) – 50 LET/50 YEARS

A. KURC-LISIECKA, A. LISIECKI: LASER WELDING OF THE NEW GRADE OF ADVANCED HIGH-STRENGTH STEEL ...

of up to 960 MPa (e.g., S960QL). An example of the the case of low-alloy quenched and tempered steel, the

commercial name in this case is Weldox 960. heat input must be within a specific range. Too high a

Steels of the above groups differ in the chemical heat input causes a drop in the toughness, like in the case

composition and manufacturing procedure, even if they of the fine-grained microalloyed steel. On the other

have similar mechanical properties, as shown in Table 1. hand, too low a heat input can lead to cold cracking of a

Differences in the chemical composition affect the car- joint. Therefore, according to the manufacturer’s instruc-

bon equivalent Ce, thus the hardenability and the asso- tions, the recommended cooling time t8/5 between tempe-

ciated susceptibility to cold cracking (hydrogen crack- rature ranges from 800 °C to 500 °C is 5 s to 15 s for

ing).15,20–22 Beside the chemical composition, structural Weldox 900 to 1300. As laser welding is of an increasing

constituents, especially the strengthening precipitations importance in the industry and the conditions of laser

like carbides, borides or nitrides, also influence the welding are radically different from arc welding, a

requirements and specification of the welding procedure. research of the laser welding of new steel grade Domex

960 was undertaken in this work.24,25

Table 1: Chemical composition of S700MC steel according to EN

10149-2

Tabela 1: Kemijska sestava jekla S700MC, skladno z EN 10149-2 2 EXPERIMENTAL PART

C Si Mn Al Nb V Ti Mo B

The steel chosen for the investigation was the new

0.12 0.6 2.1 0.015 0.09 0.2 0.22 0.5 0.005

generation of advanced high-strength steel (AHSS)

CEV max = 0.38, CET max = 0.25 Domex 960, recently introduced to the industry by a

Swedish company. The new grade of steel Domex 960 is

As a result of an intensive research and a dynamic included, by the manufacturer, in the group of thermo-

development of modern steel grades, the world’s largest mechanically rolled fine-grained microalloyed steels

steel manufacturers now offer steels with properties that covered by the EN 10149-2 standard. However, the me-

go beyond the standards. Examples are steel grades chanical properties of steel Domex 960 go far beyond the

Weldox 1100 or Weldox 1300 classified as quenched and steels specified in this standard. Additionally, details of

tempered steel, suitable for welding. Additionally, new the manufacturing process for the new steel grade are

steel grades, such as Domex 960, are available in the undisclosed. The investigated steel with the nominal che-

market. The Domex 960 steel grade is classified by the mical composition of 0.18 %C, 0.5 %Si, 2.1 %Mn and

manufacturer as a thermomechanically rolled steel even 0.018 %Al in % of mass fractions and balanced Fe has

though the properties of this steel are at the level of the minimum yield strength of 960 MPa and the mini-

quenched and tempered Weldox 960. mum tensile strength of 980 MPa.

Thus, with the introduction of new grades of steel, Specimens for the test involving laser welding were

the classification becomes more difficult. cut from a 5.0 mm steel plate into coupons with dimen-

The reason for this is a very sophisticated chemical sions of 100.0 × 100.0 mm, using a 2D laser cutting

composition, the combination of individual elements and machine with a CO2 generator. Surfaces to be welded

also the sophisticated manufacturing process. It should were sandblasted and then cleaned with acetone. The

also be noted that the chemical composition of these trials of welding were performed by means of a solid-

steels depends on their thickness. In addition, there are state Yb:YAG disk laser emitted in the continuous-wave

also significant differences between individual melts of mode at a wavelength of 1.03 μm with the maximum

steel. Moreover, the manufactures continue the research output power of 3.3 kW. The laser beam was focused to a

of how to modify the chemical composition in terms of diameter of 200 μm.

the optimum combination of mechanical properties and First, the bead-on-plate welds were produced at the

weldability. maximum output laser power of 3.3 kW and welding

Such sophisticated steels also require sophisticated speeds of (0.5, 1.0, 1.5 and 2.0) m/min. The bead-on-

welding procedures and welding technologies.19,23 Un- plate welds were produced to simulate the process of

fortunately, the manufactures provide only limited infor- butt-joint welding and to investigate the influence of

mation about the welding, relating only to conventional welding parameters on the penetration depth and weld

arc-welding processes such gas metal arc (GMA), gas shape. Based on the bead-on-plate welding trials, the

tungsten arc (GTA) or submerged-arc welding (SMAW). optimum parameters for butt joints were chosen. Butt

At the same time, general guidelines for welding joints were single-side autogenously laser welded at the

thermomechanically rolled fine-grained microalloyed maximum laser power of 3.3 kW and welding speeds of

steel grade such as Domex and low-alloy quenched and 1.0 m/min and 1.5 m/min, respectively. The specimens to

tempered steel such as Weldox are different. Generally, be welded were mounted to a clamping device to be

in the case of thermomechanically rolled fine-grained protect against distortions. The weld pool was protected

microalloyed steel, it is recommended not to exceed a by an argon flow via four cylindrical nozzles of 8.0 mm

certain heat input because it causes a drop in mechanical in diameter and set at an angle of 45° to the joint surface.

properties and impact toughness. On the other hand, in The flow of argon was kept at 15 L/min. The laser beam

200 Materiali in tehnologije / Materials and technology 51 (2017) 2, 199–204

MATERIALI IN TEHNOLOGIJE/MATERIALS AND TECHNOLOGY (1967–2017) – 50 LET/50 YEARS

A. KURC-LISIECKA, A. LISIECKI: LASER WELDING OF THE NEW GRADE OF ADVANCED HIGH-STRENGTH STEEL ...

was focused on the top surface of the specimens to be J/mm, at a laser output power of 3.3 kW and a welding

welded. When the laser-welding tests were completed, speed of 2.0 m/min. The width of a weld face produced

the first the visual inspections (VT) were performed at the minimum welding heat input is 2.15 mm, while the

according to the procedure of quality control in welding. root width is 0.8–1.27 mm. In this case the depth/width

Next, the metallographic and also mechanical examina- ratio is over 2.3, indicating that the laser welding mode

tions were done. The examination of the structure was was the keyhole mode. Additionally, the shape of the

carried out by means of optical microscopes (OM) and a fusion zone (FZ) in a columnar or hour-glass configura-

scanning electron microscope (SEM). The chemical tion (X shape) is characteristic for keyhole laser welding

composition of the base metal was determined with a at a high power density of the laser beam. An increase in

glow discharge spectrometer (GDS). On the other hand, the heat input of laser welding, by lowering the welding

mechanical tests included a technological bending test, a speed at a constant laser power, increases the width of a

static tensile test and a Charpy V-notch test. single bead-on-plate weld and the width of the heat

affected zone (HAZ).

3 RESULTS AND DISCUSSION The visual inspections (VT) of the test butt joints

revealed a proper shape of the welds, and proper rein-

The trials of bead-on-plate welding with a disk laser forcement of weld faces and roots. Macrographs of the

showed that the heat input required for a full penetration test joints showed a proper shape of the fusion lines and

of a 5.0 mm plate of the Domex 960 steel is at least 100 no internal imperfections (Figure 1a). A high quality of

the test joints was also confirmed with microscopic

observations (Figure 1b) and mechanical tests. The tech-

nological bending test revealed no tendency to cracking

of the welded joints, both in the weld and in the HAZ,

even at the maximum angle of bending. On the other

hand, the static tensile tests showed high strength of

laser-welded joints at the level of the base metal (BM).

Figure 1: a) Macrostructure of the butt joint produced at the welding

speed of 1.5 m/min, thus the heat input of 132 J/mm, b) and the

microstructure of the weld metal (FZ)

BM – base metal, FZ – fusion zone, HAZ – heat-affected zone, HAZCG –

coarse-grained region, HAZFG – fine-grained region, HAZPT – partially

transformed region, B – bainite, M – martensite, apf – polygonal ferrite, aaf –

allotriomorphic ferrite

Slika 1: a) Makrostruktura sole`nega zvara, izdelanega s hitrostjo

varjenja 1,5 m/min, vnos toplote 132 J/mm in b) mikrostruktura

zvarjene kovine (FZ) Figure 2: SEM micrographs of the fracture surface of the test joint

BM – osnovna kovina, FZ – podro~je taljenja, HAZ – toplotno vplivana cona,

produced at: a) the heat input of 198 J/mm and b) the heat input of 132

HAZCG – podro~je velikih zrn, HAZFG – podro~je drobnih zrn, HAZPT – delno J/mm

transformirano podro~je, B – bainit, M – martenzit, apf – poligonalni ferit, aaf – Slika 2: SEM-posnetek povr{ine preloma preizkusnega spoja izdela-

alotriomorfni ferit nega z vnosom toplote: a) 198 J/mm in b) vnosom toplote 132 J/mm

Materiali in tehnologije / Materials and technology 51 (2017) 2, 199–204 201

MATERIALI IN TEHNOLOGIJE/MATERIALS AND TECHNOLOGY (1967–2017) – 50 LET/50 YEARS

A. KURC-LISIECKA, A. LISIECKI: LASER WELDING OF THE NEW GRADE OF ADVANCED HIGH-STRENGTH STEEL ...

Table 2: Chemical composition of S690QL steel according to EN 10025-6

Tabela 2: Kemijska sestava jekla S690QL, skladno z EN 10025-6

C Si Mn B Cr Cu Mo N Nb Ni Ti V Zr

0.12 0.8 1.7 0.005 1.5 0.5 0.7 0.015 0.06 2.0 0.05 0.12 0.15

CEV max = 0.65, CET standard = 0.29

All of the tested samples broke out of the joint area in was 1.299 s. However, the cooling time in the case of a

the base metal at a tensile strength of 1093MPa – 1017 lower heat input of 132 J/mm was just 0.577 s. For com-

MPa. The Charpy V-notch test, performed at room tem- parison, in both cases, cooling times t8/5 are significantly

perature, showed that the impact toughness of the test lower than recommended for the quenched and tempered

butt joints is clearly lower compared to the base metal. Weldox grade steel, being in the range of 5s –15 s. How-

The results of the impact toughness determined for the ever, despite such short cooling times there was no

base metal were very consistent, ranging from 128 J/cm2 tendency to cold (hydrogen) cracking of the test joints

to 134 J/cm2. The average value was 131.3 J/cm2. The (Figure 1).

impact toughness of the test joint welded at a heat input The microhardness profiles determined on the

of 198 J/mm was in a range of 82 J/cm2 – 98 J/cm2, at the cross-sections of the welded butt joints show a clear

average value of 90 J/cm2. So, the impact toughness of increase in the microhardness values in the region of the

this joint is as low as 68 % of the base-metal toughness. weld metal, i.e., the fusion zone, compared to the micro-

On the contrary, the impact toughness of the second test hardness of the base metal, which is about 370 HV0.2

joint welded at a low heat input of 132 J/mm is 70.7 (Figure 3). The microhardness distribution across the FZ

J/cm2, so just 53 % of the base-metal toughness. is stable and maintained in a range of 360–440, while the

SEM micrographs of the fracture surfaces of the test mean value of microhardness in the FZ region is about

joints are presented in Figure 2. As can be seen, the frac- 404 HV0.2. On the other hand, the distribution of micro-

ture surfaces indicate a typical ductile dimple fracture hardness in the HAZ is more complex, so the HAZ can

mode in both cases. So, although the impact toughness be divided into at least two areas: the inner HAZ

of the test joints is clearly lower compared to the base adjacent to the FZ and the outer HAZ adjacent to the

metal, the fracture mode is ductile. The results indicate BM. From the side of the base metal, roughly in the

that the impact toughness of the test butt joints depends middle of the HAZ, the microhardness decreases

directly on the heat input of autogenous laser welding gradually from 370 to the minimum value of 290–300

within the investigated range of parameters, i.e., thermal HV0.2 and then it rises sharply up to over 400 HV0.2 in

conditions, cooling rates and the structures of the weld the inner HAZ.

metal and the HAZ. The microhardness in individual regions depends

The cooling times t8/5 between 800 °C and 500 °C directly on the microstructure and this, in turn, depends

were calculated for different heat inputs of laser welding on the chemical composition and the tendency to hard-

by means of an equation adopted for the conditions of ening. The GDS analysis showed that the investigated

keyhole laser welding, as described in details in 4. For steel contains 0.161 % C, 0.31 % Si, 1.32 % Mn, 0.15 %

the heat input of 198 J/mm for the butt laser welding of Cr, 0.05 % Ni, 0.41 % Mo, 0.043 % Al, 0.01 % of V, Ti,

the 5.0 mm steel plates, the calculated cooling time t8/5 Cu and 0.001 % Nb. Based on the determined compo-

Figure 3: Microhardness distribution on the cross-section of the butt Figure 4: SEM micrograph showing the structure of the base metal of

joint produced at the heat input of 132 J/mm Domex 960 steel at a magnification of 5000×

Slika 3: Razporeditev mikrotrdote po preseku sole`nega spoja, izdela- Slika 4: SEM-posnetek strukture osnovne kovine jekla Domex 960 pri

nega pri vnosu toplote 132 J/mm pove~avi 5000×

202 Materiali in tehnologije / Materials and technology 51 (2017) 2, 199–204

MATERIALI IN TEHNOLOGIJE/MATERIALS AND TECHNOLOGY (1967–2017) – 50 LET/50 YEARS

A. KURC-LISIECKA, A. LISIECKI: LASER WELDING OF THE NEW GRADE OF ADVANCED HIGH-STRENGTH STEEL ...

The structure of the base metal of the Domex 960

steel is shown in Figure 4. In general, the investigated

steel has a fine-grained bainitic-martensitic structure. A

closer view at the structure exhibits quite a complex

arrangement of different phases. The dominant structural

constituent is bainite with a significant amount of

needle-shaped low-carbon martensite. Beside the main

structural constituents, ferrite and also traces of retained

austenite can be identified. Additionally, small carbides

with a high dispersion can be identified in the structure.

The structure of the HAZ depends on the distance

from the fusion line and thus the thermal cycle and the

related cooling rate. The thermal conditions during the

liquid-metal solidification, especially in the HAZ, may

be estimated on the basis of calculated cooling times t8/5.

The calculated cooling times in the range of 0.6–1.3 are

very short and indicate that the solidification as well as

the cooling rates were very high under the laser-welding

conditions. The HAZ may be divided into three dis-

tinguishable regions with different structures (Figure 1a).

The first characteristic region of the HAZ is adjacent to

the fusion line. In this region, due to high temperatures, a

slight grain growth occurs. In this region, the structure is

bainitic with a higher share of ferrite compared to the

BM (Figures 1a, 5b). Next, a recrystallized fine-grained

region with fine-grained bainite as the dominant

structural constituent may be distinguished, cha-

racterized by a microhardness in the range of 380–420

HV0.2, Figure 3. Finally, a partially transformed and

tempered region with a bainitic-ferritic structure may be

distinguished (Figure 5c). A relatively high share of

ferrite in this region is responsible for a gradual

microhardness decrease to 280–310 HV0.2, as shown in

Figure 3.

The structure of the weld metal of the butt joint pro-

duced at a heat input of 132 J/mm is presented in Fig-

ures 1b and 5a. The structure consists mainly of bainite,

a smaller amount of fine martensitic islands and also of

ferrite, mainly polygonal (apf) and allotriomorphic ferrite

(aaf), as shown in Figures 1b and 5a.

Figure 5: SEM micrographs showing the structure of the weld metal

of the butt joint produced at the heat input of: a) 132 J/mm, b) the

HAZ region adjacent to the fusion zone and c) the recrystallized fine- 4 CONCLUSIONS

grained region of the HAZ

Slika 5: SEM-posnetek structure zvara sole`nega spoja izdelanega z The investigated new steel grade Domex 960 is

vnosom toplote: a) 132 J/mm, b) podro~je HAZ v bli`ini podro~ja pre- characterized by a low content of alloying elements

taljevanja in c) rekristalizirano drobnozrnato podro~je HAZ (microalloyed steel), thus the low carbon equivalent

(CET) is 0.343 and the relatively high temperature of

sition, the martensitic transformation temperature was martensitic transformation (Ms) is about 429 °C. Despite

calculated according to the following equation: Ms (°C) the low carbon equivalent, the base metal has a fine-

= 561 – 474 (% C) – 33 (% Mn) – 17 (% Ni) – 17(% Cr) grained bainitic-martensitic structure with a microhard-

– 21 (% Mo). The calculated Ms temperature is 429.1 °C. ness of 370–380 HV0.2. The calculated cooling times t8/5

Additionally, the carbon equivalent (CET) was deter- under the investigated laser-welding conditions are very

mined according to the following equation: CET = C + short, being in a range of 0.6s –1.3 s, so significantly

(Mn + Mo)/10 + (Cr + Cu)/20 + Ni/40. The value of the shorter than the recommended values for the quenched

calculated CET is 0.343. Both the high Ms temperature and tempered steel grades such as Weldox. Despite a

and the relatively low carbon equivalent indicate that the very rapid solidification of the weld metal and cooling,

hardenability of the investigated steel is not very high. the test joints exhibit a high tensile strength, being at the

Materiali in tehnologije / Materials and technology 51 (2017) 2, 199–204 203

MATERIALI IN TEHNOLOGIJE/MATERIALS AND TECHNOLOGY (1967–2017) – 50 LET/50 YEARS

A. KURC-LISIECKA, A. LISIECKI: LASER WELDING OF THE NEW GRADE OF ADVANCED HIGH-STRENGTH STEEL ...

10

level of the BM. The impact toughness of the test joints M. Bonek, The investigation of microstructures and properties of

high speed steel HS6-5-2-5 after laser alloying, Arch. Metall. Mater.,

clearly depends on the welding conditions (heat inputs).

59 (2014), 1647–1651, doi:10.2478/amm-2014-0280

Although the impact toughness is lower compared to the 11

G. Moskal, A. Grabowski, A. Lisiecki, Laser remelting of silicide

BM, the fracture mode is ductile. coatings on Mo and TZM alloy, Sol. St. Phenom., 226 (2015),

121–126, doi:10.4028/www.scientific.net/SSP.226.121

12

D. Janicki, High Power Diode Laser Cladding of Wear Resistant

Acknowledgements Metal Matrix Composite Coatings, Sol. St. Phenom., 199 (2013)

587–592, doi:10.4028/www.scientific.net/SSP.199.587

13

The article was financed by the University of A. Lisiecki, Titanium matrix composite Ti/TiN produced by diode

laser gas nitriding, Metals, 5 (2015), 54–69, doi:10.3390/

D¹browa Górnicza in Poland. Special thanks are met5010054

extended to Rafa³ Lis, a welding engineer from the 14

A. Lisiecki, Welding of thermomechanically rolled fine-grain steel

WIELTON Company for providing the new steel grade by different types of lasers, Arch. Metall. Mater., 59 (2014),

and also to dr. Wojciech Pakie³a for the experimental 1625–1631, doi:10.2478/amm-2014-0276

15

support. A. Kurc-Lisiecka, W. Ozgowicz, W. Ratuszek, J. Kowalska, Analysis

of deformation texture in AISI 304 steel sheets, Sol. St. Phenom.,

203–204 (2013), 105–110, doi:10.4028/www.scientific.net/SSP.

203-204.105

5 REFERENCES 16

R. Burdzik, £.Konieczny, Z. Stanik, P. Folêga, A. Smalcerz, A.

1 Lisiecki, Analysis of impact of chosen parameters on the wear of

J. Górka, Weldability of thermomechanically treated steels having a

camshaft, Arch. Metall. Mater., 59 (2014), 957–963, doi:10.2478/

high yield point, Arch. Metall. Mater., 60 (2015), 469–475,

amm-2014-0161

doi:10.1515/amm-2015-0076,

2

17

R. Burdzik, T. Wêgrzyn, £. Konieczny, A. Lisiecki, Research on

A. Grajcar, M. Ró¿añski, S. Stano, A. Kowalski, Microstructure

influence of fatigue metal damage of the inner race of bearing on

characterization of laser-welded Nb-microalloyed silicon-aluminum

vibration in different frequencies, Arch. Metall. Mater., 59 (2014),

TRIP steel, J. Mater. Eng. Perform., 23 (2014), 3400–3406,

1275–1281, doi:10.2478/amm-2014-0218

doi:10.1007/s11665-014-1118-1 18

3 J. Kusiñski, S. Kac, A. Kopia, A. Radziszewska, M. Rozmus-Gór-

J. Górka, Changes in the structure and properties of the steel

nikowska, B. Major, L. Major, J. Marczak, A. Lisiecki, Laser

S700MC by heat treatment, Adv. Mat. Res., 1036 (2014), 111–116,

doi:10.4028/www.scientific.net/AMR.1036.11 modification of the materials surface layer – a review paper, Bull.

4 Pol. Acad. Sci. Tech. Sci., 60 (2012), 711–728, doi:10.2478/

A. Lisiecki, Welding of thermomechanically rolled fine-grain steel

v10175-012-0083-9

by different types of lasers, Arch. Metall. Mater., 59 (2014), 19

1625–1631, doi:10.2478/amm-2014-0276 T. Wêgrzyn, J. Piwnik, D. Hadryœ, R. Wiesza³a, Car body welding

5

W. A. Swiatnicki, Modern steels: design-technologies-properties- with micro-jet cooling, J.Arch. Mater. Sci. Eng., 49 (2011), 90–94

20

applications (Guest Editorial), Mater. Sci. Technol., 31 (2015) J. Slania, Influence of phase transformations in the temperature

755–757, doi:10.1179/0267083615Z.000000000928 ranges of 1250-1000 °C and 650-350 °C on the ferrite content in

6

A. Grajcar, M.Ró¿añski, M.Kaminska, B.Grzegorczyk, Study on austenitic welds made with T 23 12 LRM3 tubular electrode, Arch.

non-metallic inclusions in laser-welded TRIP-adied Nb-microalloyed Metall. Mater., 50 (2005), 757–767

21

steel, Arch. Metall. Mater., 59 (2014), 1163–1169, doi:10.2478/ B. Slazak, J. S³ania, T. Wêgrzyn, A.P. Silva, Process stability

amm-2014-0203 evaluation of manual metal arc welding using digital signals, Mater.

7

A. Grajcar, M. Ró¿añski, S. Stano, A. Kowalski, B. Grzegorczyk, Sci. Forum, 730–732 (2013), 847–852, doi:10.4028/www.scien-

Effect of heat input on microstructure and hardness distribution of tific.net/MSF.730-732.847

22

laser welded Si-Al TRIP-type steel, Adv. Mater. Sci. Eng., 2014 K. Janerka, M. Pawlyta, J. Jezierski, J. Szajnar, D. Bartocha, Car-

(2014), doi:10.1155/2014/658947 buriser properties transfer into the structure of melted cast iron, J.

8

A. Lisiecki: Diode laser welding of high yield steel, Proc. of SPIE Mat. Proc. Tech., 214(4) (2014), 794–801, doi:10.1016/j.jmatprotec.

Vol. 8703, Laser Technology 2012: Applications of Lasers, 87030S 2013.11.027

23

(January 22, 2013), doi:10.1117/12.2013429 D. Janicki, Disk laser welding of Armor steel, Arch. Metall. Mater.,

9

L.A. Dobrzanski, M. Bonek, A. Klimpel, A. Lisiecki, Surface layer’s 59 (2014), 1641–1646, doi:10.2478/amm-2014-0279

24

structure of X40CrMoV5-1 steel remelted and/or WC alloyed with J. Bodzenta, A. KaŸmierczak, T. Kruczek, Analysis of thermograms

HPDL laser, Mater. Sci. Forum, 437-4 (2003), 69–72, based on FFT algorithm, J. Phys. IV, 129 (2005), 201–206,

doi:10.4028/www.scientific.net/MSF.437-438.69 doi:10.1051/jp4:2005129042

204 Materiali in tehnologije / Materials and technology 51 (2017) 2, 199–204

You might also like

- CPHFD 011Document7 pagesCPHFD 011Napoleon DasNo ratings yet

- Ogre MiniaturesDocument86 pagesOgre MiniaturesEdward Holzman86% (7)

- Manual Xerox 252Document50 pagesManual Xerox 252elmismo1821No ratings yet

- DOI: 10.1515/amm-2016-0198Document8 pagesDOI: 10.1515/amm-2016-0198BHARANINo ratings yet

- Tekken en Acero Weldonx 1300Document8 pagesTekken en Acero Weldonx 1300nestor leonardonNo ratings yet

- Rehabilitation of Steel Structures C1Document37 pagesRehabilitation of Steel Structures C1Alina CiuraruNo ratings yet

- Ductile Iron Research PapersDocument8 pagesDuctile Iron Research Papersxkcwaaqlg100% (1)

- The Use of Heavy Rolled Sections in High-Rise Buildings Current Practice and Future Innovation by Riccardo ZANON, Georges AXMANN, Jean-Claude GERARDY, André PLUMIERDocument17 pagesThe Use of Heavy Rolled Sections in High-Rise Buildings Current Practice and Future Innovation by Riccardo ZANON, Georges AXMANN, Jean-Claude GERARDY, André PLUMIERgulilero_yoNo ratings yet

- Mmscience - 2016 11 - Welded Joint of High Strength Steels Weldox 700 and Common Grade Steel S 355Document4 pagesMmscience - 2016 11 - Welded Joint of High Strength Steels Weldox 700 and Common Grade Steel S 355Said ElhamydyNo ratings yet

- 113 14Document8 pages113 14rahul srivastavaNo ratings yet

- Review of Creep Resistant SteelsDocument4 pagesReview of Creep Resistant SteelsAleš NagodeNo ratings yet

- Investigation and Application of High Strength Low Alloy Wear Resistant Cast SteelDocument4 pagesInvestigation and Application of High Strength Low Alloy Wear Resistant Cast Steelz2aliNo ratings yet

- Lesson2 STEEL PROPERTIES CDocument87 pagesLesson2 STEEL PROPERTIES CMaqMaikNo ratings yet

- Metals 10 00099 v2 PDFDocument23 pagesMetals 10 00099 v2 PDFarjun prajapatiNo ratings yet

- Steels For Oil - Gas - ExplorationDocument16 pagesSteels For Oil - Gas - Explorationدكتور مهندس جمال الشربينىNo ratings yet

- Steels For Cryogenic and Low-Temperature Service - KEY To METALS ArticleDocument3 pagesSteels For Cryogenic and Low-Temperature Service - KEY To METALS Articlekumarpankaj030No ratings yet

- High Strength SteelDocument19 pagesHigh Strength SteelBHARANINo ratings yet

- Poletskov 2020 IOP Conf. Ser. Mater. Sci.Document8 pagesPoletskov 2020 IOP Conf. Ser. Mater. Sci.Александр ТиньгаевNo ratings yet

- Materials Science & Engineering A: Ludmila Ku Cerov A, Karolina Burdov A, ST Ep An Jení Cek, Iveta ChenaDocument15 pagesMaterials Science & Engineering A: Ludmila Ku Cerov A, Karolina Burdov A, ST Ep An Jení Cek, Iveta ChenaJimmy the ReverendNo ratings yet

- UM ASDG Lesson1 STRUCTURAL STEEL REVIEW PDFDocument94 pagesUM ASDG Lesson1 STRUCTURAL STEEL REVIEW PDFjuan carlos montañezNo ratings yet

- 3225 HARDOX 450 Prilog OcjenDocument6 pages3225 HARDOX 450 Prilog OcjenGoran SpasojevicNo ratings yet

- 421 - Domex 700 MCDocument2 pages421 - Domex 700 MClalamed21No ratings yet

- HSLA-100 Steels: Influence of Aging Heat Treatment On Microstructure and PropertiesDocument11 pagesHSLA-100 Steels: Influence of Aging Heat Treatment On Microstructure and PropertiesEdgar HornusNo ratings yet

- Newly Designed High-Strength ToolDocument15 pagesNewly Designed High-Strength ToolMd Ibrahim KhalilNo ratings yet

- P91 MaterialDocument15 pagesP91 MaterialelrajilNo ratings yet

- Heat TreatmentDocument20 pagesHeat Treatmentعزت عبد المنعمNo ratings yet

- Application of Stainless SteelDocument13 pagesApplication of Stainless Steelsweety1188No ratings yet

- The Mechanical Properties of SteelDocument13 pagesThe Mechanical Properties of SteelAddrien DanielNo ratings yet

- 10 1016@j JCSR 2019 03 017 PDFDocument13 pages10 1016@j JCSR 2019 03 017 PDFDeni JaelaniNo ratings yet

- Weld Cons SojamDocument7 pagesWeld Cons SojamAsad Bin Ala QatariNo ratings yet

- Steel Making PracticesDocument32 pagesSteel Making PracticesSiva SubramaniNo ratings yet

- Journal Pre-Proof: Unda G, Sergej Gook, Andrey Gumenyuk, MichaelDocument34 pagesJournal Pre-Proof: Unda G, Sergej Gook, Andrey Gumenyuk, MichaelAgus WidyiantoNo ratings yet

- Creep ResistanceDocument16 pagesCreep Resistancefernandosimic96No ratings yet

- Electron Microscopy and Microanalysis of Steel Weld Joints After Long Time Exposures at High TemperaturesDocument10 pagesElectron Microscopy and Microanalysis of Steel Weld Joints After Long Time Exposures at High TemperaturesJEANNINA BULEJE CASTILLONo ratings yet

- Análisis de Las Propiedades de Desgaste Del Acero Pulvimetalúrgico enDocument18 pagesAnálisis de Las Propiedades de Desgaste Del Acero Pulvimetalúrgico enJazminNo ratings yet

- Effect of Tempering Temperatures On The Mechanical Properties and Microstructures of HSLA-100 Type Copper-Bearing SteelsDocument14 pagesEffect of Tempering Temperatures On The Mechanical Properties and Microstructures of HSLA-100 Type Copper-Bearing Steelsbharani dharanNo ratings yet

- Comparative Study About The Results of HAZ Physical Simulations On Different High-Strength Steel GradesDocument16 pagesComparative Study About The Results of HAZ Physical Simulations On Different High-Strength Steel GradesafabNo ratings yet

- Modern High Strength Niobium Microallyed Structural SteelsDocument26 pagesModern High Strength Niobium Microallyed Structural SteelsimetallurgyNo ratings yet

- Double Aust. AssgnmntDocument15 pagesDouble Aust. Assgnmntmaurya21No ratings yet

- Journal of Constructional Steel Research: Xia Yan, Yu Xia, Hannah B. Blum, Thomas GernayDocument12 pagesJournal of Constructional Steel Research: Xia Yan, Yu Xia, Hannah B. Blum, Thomas GernayAswini JhaNo ratings yet

- Metals: Heat Input Influence On The Fatigue Life of Welds From Steel S460MCDocument14 pagesMetals: Heat Input Influence On The Fatigue Life of Welds From Steel S460MCArab WeldersNo ratings yet

- Jurnal PengelasanDocument10 pagesJurnal Pengelasanyudha mamotsNo ratings yet

- Maisuradze-Björk2021 Article MicrostructureAndMechanicalProDocument10 pagesMaisuradze-Björk2021 Article MicrostructureAndMechanicalProsaifbenNo ratings yet

- Niobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener ApplicationsDocument7 pagesNiobium Microalloyed Cold Heading Steel Wire Rods Without Heat Treatment For Fastener Applicationsnvc_vishwanathanNo ratings yet

- Antifriction AlloysDocument5 pagesAntifriction AlloysMădălina ConstantinescuNo ratings yet

- Metalurgia Física ModernaDocument20 pagesMetalurgia Física ModernaMariliaFrancoNo ratings yet

- SMS Steel-Making-Practices PDFDocument32 pagesSMS Steel-Making-Practices PDFkalai0% (1)

- Propiedades AISI 410Document25 pagesPropiedades AISI 410alvaroyepezNo ratings yet

- Mechanical Properties of High Strength S690 Steel Welded Sections Through Tensile Tests On Heat-Treated Coupons - ScienceDirectDocument41 pagesMechanical Properties of High Strength S690 Steel Welded Sections Through Tensile Tests On Heat-Treated Coupons - ScienceDirectEhsan HaratiNo ratings yet

- Creep and Creep Damage Assessment in P91 Weld JointsDocument12 pagesCreep and Creep Damage Assessment in P91 Weld JointsDeepakNo ratings yet

- Materials and Examples of Preparing Damascus Type Blade SteelDocument8 pagesMaterials and Examples of Preparing Damascus Type Blade SteelrobertNo ratings yet

- Hardness X20CrMoV12 1Document8 pagesHardness X20CrMoV12 1misapera35No ratings yet

- RESID. STRESS - Effect of Residual Stresses in The ZTA of Welds of S700MCDocument14 pagesRESID. STRESS - Effect of Residual Stresses in The ZTA of Welds of S700MCGabriel PaesNo ratings yet

- (Welding) s7Document113 pages(Welding) s7Popo YuppyNo ratings yet

- Forging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingFrom EverandForging - Manual of Practical Instruction in Hand Forging of Wrought Iron, Machine Steel and Tool Steel; Drop Forging; and Heat Treatment of Steel, Including Annealing, Hardening and TemperingRating: 5 out of 5 stars5/5 (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Heat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingFrom EverandHeat-Treatment of Steel: A Comprehensive Treatise on the Hardening, Tempering, Annealing and Casehardening of Various Kinds of Steel: Including High-speed, High-Carbon, Alloy and Low Carbon Steels, Together with Chapters on Heat-Treating Furnaces and on Hardness TestingRating: 1 out of 5 stars1/5 (1)

- Standard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsFrom EverandStandard Blacksmithing, Horseshoeing and Wagon Making: Containing: Twelve Lessons in Elementary Blacksmithing Adapted to the Demand of Schools and Colleges of Mechanic Arts: Tables, Rules and Receipts Useful to Manufactures, Machinists, Engineers and BlacksmithsNo ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- GPR - Making It EasyDocument28 pagesGPR - Making It Easyishtiaque_anwarNo ratings yet

- Measurement of The Glucose Concentration in Human Urine With Optical RefractometerDocument7 pagesMeasurement of The Glucose Concentration in Human Urine With Optical RefractometerMuhammad AbduhNo ratings yet

- Orafol Wrapping Films: Product Summary SheetDocument4 pagesOrafol Wrapping Films: Product Summary SheetAgung SetiawanNo ratings yet

- KARIXA Dentolaser KA 45-01 DLDocument1 pageKARIXA Dentolaser KA 45-01 DLrochmandrg dokter gigiNo ratings yet

- Chapter 3 Optical Fiber CablesDocument132 pagesChapter 3 Optical Fiber CablesAhmed AmrNo ratings yet

- Laser CommunicationDocument3 pagesLaser CommunicationVishal KumarNo ratings yet

- ND-3300-Brochure - New - 2009Document2 pagesND-3300-Brochure - New - 2009ambuja_kumar5993No ratings yet

- Seminar On Wireless Charging of Mobile DevicesDocument24 pagesSeminar On Wireless Charging of Mobile DevicesGourish Amonkar100% (1)

- TCRT1000 PDFDocument7 pagesTCRT1000 PDFBalya SubarkahNo ratings yet

- Boring MachineDocument25 pagesBoring MachineSreedhar PugalendhiNo ratings yet

- Photodiode - WikipediaDocument15 pagesPhotodiode - WikipediaIKENNANo ratings yet

- BD Accuri C6Flow Cyto Instrument ManualDocument31 pagesBD Accuri C6Flow Cyto Instrument ManualWilna100% (1)

- Semiconductors 170506180045Document42 pagesSemiconductors 170506180045EdamEdamNo ratings yet

- 40k+rf Cavitation Ultrasound Rf+bipolar+quadrupole+sextupolar Rf+vacuum RF SlimDocument4 pages40k+rf Cavitation Ultrasound Rf+bipolar+quadrupole+sextupolar Rf+vacuum RF SlimErvin AmannNo ratings yet

- 10.energy Band Gap Behavior of Binary OxidesDocument24 pages10.energy Band Gap Behavior of Binary OxidesWan HafizaNo ratings yet

- Sharp AR-122E - 157E ServiceDocument130 pagesSharp AR-122E - 157E Serviceatookme100% (2)

- Nature of LightDocument2 pagesNature of LightDhanBahadurNo ratings yet

- Presentation ICU-2023 Levin v. M.Document25 pagesPresentation ICU-2023 Levin v. M.Vadim LevinNo ratings yet

- Dissertation Laser DiodeDocument5 pagesDissertation Laser DiodeFindSomeoneToWriteMyCollegePaperDesMoines100% (1)

- 4.01 Petrochemical and Offshore - ASTM D 1500 ColorDocument2 pages4.01 Petrochemical and Offshore - ASTM D 1500 Colorsetiawanaji407No ratings yet

- 5522-Central Loose Tube Armoured Outdoor CableDocument2 pages5522-Central Loose Tube Armoured Outdoor CableasifaliabidNo ratings yet

- Garment Manufacturing Technology: RTW Apparel ProductionDocument12 pagesGarment Manufacturing Technology: RTW Apparel Productionnalinkumar944No ratings yet

- ICF 7 - Q2 - Week5Document2 pagesICF 7 - Q2 - Week5Efren TabuadaNo ratings yet

- Uncertainty of Atomic Absorption SpectrometerDocument7 pagesUncertainty of Atomic Absorption SpectrometerbelazouzboualemNo ratings yet

- Nano Assesment-1 Question PaperDocument3 pagesNano Assesment-1 Question Paperdineshkumarbaskaran100% (3)

- I Port Ex3Document2 pagesI Port Ex3SlimeSlimeNo ratings yet

- Tutorial Chapter 4: Electronics: A. B. C. D. EDocument8 pagesTutorial Chapter 4: Electronics: A. B. C. D. EMohamad Rizal MukhtarNo ratings yet

- VeroVision Product SheetDocument2 pagesVeroVision Product SheetclurichaunNo ratings yet