Professional Documents

Culture Documents

RCC Folded Plates Short

RCC Folded Plates Short

Uploaded by

deepshikhaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RCC Folded Plates Short

RCC Folded Plates Short

Uploaded by

deepshikhaCopyright:

Available Formats

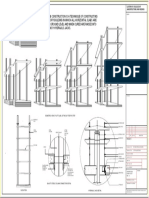

Q. Explain in detail (with neat sketches and reference) – RCC Folded Plates.

Ans: Folded structures are three-dimensional structures - spatial structures formed by the

elements in the plane, different in form and materialization and they belong to the structural systems.

Folded structures differ in: geometric form, the form of a base over which they are performed, the

manner of performance, methods of forming stiffness, function and position in the building, and the

material they are made of. The term folded structure defines a folded form of construction, including

structures derived from elements which form a folded structure by their mutual relationship in space.

For very long time this type of construction has been realized in practice only in of reinforced concrete

and made on site, which conditioned the use of a very complicated shell. Development of

prefabricated building led to improvements of this type of construction so that the folded structures

could be derived by assembly of prefabricated elements and their relationship – monolithization on

site.

Interest in folded plates first developed for folded plates of reinforced concrete as it had for concrete

shells because of the ease with which concrete can be adapted.

The folded-plate concept offers an almost unlimited range of possible cross-sectional arrangements

for structures. The simplest form consists of inclined plates in a series of connected V-shapes.

However, this cross-section has one disadvantage in that the area of concrete may be inadequate to

resist the longitudinal compressive flexural force or to permit placement of reinforcing steel to resist

longitudinal tension.

Formwork for folded plates is far simpler than that for curved thin shells. Pre-casting has also been a

simpler process to save formwork, permit mass-production construction, and achieve sharp lines for

exposed top corners (vees cast upside down) to satisfy aesthetic requirements. For very long spans,

posttensioned, draped tendons have been used to reduce the total depth, deflection, and reinforcing-

steel requirements. The tendons may be placed in the inclined plates or, more conveniently, in small

thickened edge beams. For cast-in-place, folded-plate construction, double forming can usually be

avoided if the slopes are less than 35 to 40°.

General Specifications

• On site during the formation of folded it is necessary to connect joints of plates.

• Thickness affects the way of monolithization in such a way that thin plates have more

complicated monolithization of the joints as a result of a lack of space for their mutual

connection.

• Folded structures can also be formed if we get one plane of the folds by joining several smaller

elements, including a larger number of compounds by monolithization. In some cases, in

addition to monolithization of the compounds, it is also necessary to pre-stress.

• For all concrete folded plates, the slope angle is

usually 45° or less in order to facilitate the

placing of the concrete without top forms.

• In general, the thickness of individual plates

should be kept at the minimum as governed by

the criteria for steel reinforcement protection. In

turn, this will affect the width of the plate, which

is generally not over 10 to 12 feet wide.

Construction Details of Folded structures made of reinforced concrete

ROCKER JOINT

You might also like

- Folded PlatesDocument20 pagesFolded Platestwinkle4545No ratings yet

- El-Guadual Early Youth Development CenterDocument24 pagesEl-Guadual Early Youth Development Centerjaz100% (1)

- Virtual Case StudyDocument28 pagesVirtual Case Studytanu kukreja100% (1)

- Chowdiah Memorial HallDocument4 pagesChowdiah Memorial HallAkash NKNo ratings yet

- Long Span Case StudyDocument1 pageLong Span Case StudyAishwarya AwcharNo ratings yet

- Aditi Goel 1SI18AT002 LIBRARY STUDYDocument22 pagesAditi Goel 1SI18AT002 LIBRARY STUDYAditi Goel100% (1)

- Sydney Opera House - Concert Hall Case StudyDocument18 pagesSydney Opera House - Concert Hall Case Studyradde madhavanNo ratings yet

- World Trade Park JaipurDocument3 pagesWorld Trade Park JaipurDevendra SharmaNo ratings yet

- SANNDocument1 pageSANNSanchita Jha100% (1)

- Sudha HouseDocument6 pagesSudha HouseAarshia Punavia JainNo ratings yet

- Finite-Element Analysis of Felix Candela's Chapel of Lomas de Cuernavaca.Document7 pagesFinite-Element Analysis of Felix Candela's Chapel of Lomas de Cuernavaca.Marco Antonio MalvaezNo ratings yet

- Natrani AmphitheaterDocument10 pagesNatrani AmphitheaterA-07 MIHIR BHUVANo ratings yet

- MG Road 01Document17 pagesMG Road 01MEKHIKA G MOHANNo ratings yet

- DOMESDocument23 pagesDOMESMukthesh ErukullaNo ratings yet

- Tubular Steel Monitor Roof Truss - Large Span Constructions - Civil Engineering ProjectsDocument3 pagesTubular Steel Monitor Roof Truss - Large Span Constructions - Civil Engineering ProjectsKranthi Kumar Chowdary ManamNo ratings yet

- Library Study ON Commercial Building: Presented by Aditya Gupta Aryo Das Aman Kumar Sanyam JainDocument36 pagesLibrary Study ON Commercial Building: Presented by Aditya Gupta Aryo Das Aman Kumar Sanyam JainADITYA GUPTANo ratings yet

- Funicular ShellsDocument1 pageFunicular Shellsdavinciw2000100% (1)

- Desktop Study - International (Architectural College) - 1Document38 pagesDesktop Study - International (Architectural College) - 1lakshmi akshaya maddiNo ratings yet

- ANDUR LAKE HOUSE BY ARCHITECT SHIRISH BERIDocument6 pagesANDUR LAKE HOUSE BY ARCHITECT SHIRISH BERISheryl ShekinahNo ratings yet

- Critical Appraisal Jami MAsjidDocument13 pagesCritical Appraisal Jami MAsjidHashim Muhammed100% (1)

- Shanghai Ocean Aquarium, Shanghai, China: Entrance Gateway ComplexDocument1 pageShanghai Ocean Aquarium, Shanghai, China: Entrance Gateway ComplexTushar SharmaNo ratings yet

- Vidy-Laussane Folded Plate CasestudyDocument6 pagesVidy-Laussane Folded Plate CasestudyAjay KushwahaNo ratings yet

- HathigaonDocument3 pagesHathigaonShivani IyengarNo ratings yet

- Sanjay MoheDocument28 pagesSanjay Mohetharun100% (1)

- Ar. B S Bhooshan: Philosophy and WorksDocument30 pagesAr. B S Bhooshan: Philosophy and WorksLeelaprasad ChigurupalliNo ratings yet

- Castellated GirderDocument14 pagesCastellated Girderpriyesh jainNo ratings yet

- Review-1 Case StudyDocument5 pagesReview-1 Case StudyArnav DasaurNo ratings yet

- Funicular Shells Part-1Document2 pagesFunicular Shells Part-1yadavshemant0% (1)

- Case Study About Thane, VardahDocument33 pagesCase Study About Thane, Vardahmeena raghunathNo ratings yet

- Goa Institute of Management.Document30 pagesGoa Institute of Management.sheethal sasikumar100% (1)

- Curtain Wall: Case Study: Nitesh Hub, Koregaon ParkDocument10 pagesCurtain Wall: Case Study: Nitesh Hub, Koregaon ParkAakansha DNo ratings yet

- Case Study ShravyaDocument3 pagesCase Study ShravyasuniiNo ratings yet

- Architectural Design - Viii Library Study: District Administrative and Judicial Complex Design Assignment 1Document35 pagesArchitectural Design - Viii Library Study: District Administrative and Judicial Complex Design Assignment 1Ishita BhardwajNo ratings yet

- Report On Folded Plates & Space FrameDocument12 pagesReport On Folded Plates & Space FrameShez ZyNo ratings yet

- Site Analysis 2Document25 pagesSite Analysis 2Jyothi HiremathNo ratings yet

- Case StudiesDocument10 pagesCase StudiesSuthar VinodNo ratings yet

- Ashol Lall: Beacon of Sustainable Architecture: IRRAD Gurgaon by Ashok B Lall ArchitectsDocument2 pagesAshol Lall: Beacon of Sustainable Architecture: IRRAD Gurgaon by Ashok B Lall ArchitectsMonisha100% (1)

- False Ceiling: Integrated Market Survey and Theoretical PresentationDocument29 pagesFalse Ceiling: Integrated Market Survey and Theoretical PresentationShruti TareNo ratings yet

- Smart Cum Luxury Group Housing: Sunderdeep College of Architecture Nh-24, Dasna, GhaziabadDocument71 pagesSmart Cum Luxury Group Housing: Sunderdeep College of Architecture Nh-24, Dasna, GhaziabadPrajapati Ankit100% (1)

- 23 MarinaDocument14 pages23 MarinaShivangi KocharNo ratings yet

- Birkha BawiriDocument14 pagesBirkha BawiribhargavaNo ratings yet

- Barrier Free ArchitectureDocument14 pagesBarrier Free Architecturewog jimNo ratings yet

- Ad 5 Case StudyDocument11 pagesAd 5 Case StudyPushkarani NNo ratings yet

- 01 Omkar Pilankar 5thb Folded Plates A.B.C.MDocument20 pages01 Omkar Pilankar 5thb Folded Plates A.B.C.MHeramb MaratheNo ratings yet

- Basement Sheet 1Document1 pageBasement Sheet 1Nazeeha NazneenNo ratings yet

- Site Analysis: Done By-1. S. Ibrahim Rizvi - RA1811201020013 2.sivasurya - RA1811201020019 3. Hema Kumar - RA1811201020045Document29 pagesSite Analysis: Done By-1. S. Ibrahim Rizvi - RA1811201020013 2.sivasurya - RA1811201020019 3. Hema Kumar - RA1811201020045Siva SuryaNo ratings yet

- Twa Structural AnalysisDocument24 pagesTwa Structural Analysisvishnu kapadiaNo ratings yet

- Design 8TH Sem FinalDocument78 pagesDesign 8TH Sem FinalSunidhi VermaNo ratings yet

- Location:: Basant Lok Community Centre, New DelhiDocument3 pagesLocation:: Basant Lok Community Centre, New DelhiKartik KhannaNo ratings yet

- Shelled StructureDocument10 pagesShelled Structurenandu shahNo ratings yet

- Evolution of Tombs in IndiaDocument25 pagesEvolution of Tombs in IndiaSumit Sharma100% (1)

- Concept Sheet PDFDocument1 pageConcept Sheet PDFAman SinghNo ratings yet

- Architectural Design-Iii: Submitted By:-Abhishek GoelDocument12 pagesArchitectural Design-Iii: Submitted By:-Abhishek GoelAbhishek GoelNo ratings yet

- Transition SpacesDocument22 pagesTransition SpacessagrikakhandkaNo ratings yet

- KhyahDocument74 pagesKhyahShashi Kant SinghNo ratings yet

- Wave One TowerDocument6 pagesWave One TowerAmar NeethiNo ratings yet

- Climate of AhmedabadDocument20 pagesClimate of AhmedabadAnas KhanNo ratings yet

- Composite BeamsDocument37 pagesComposite BeamsAbdallahNo ratings yet

- Expansion and Construction JointsDocument46 pagesExpansion and Construction Jointscricket review100% (1)

- Reinforced Cement Concrete Slab: Columns BeamsDocument9 pagesReinforced Cement Concrete Slab: Columns BeamsPeter SmithNo ratings yet

- 14 Gypsum Block ArticleDocument2 pages14 Gypsum Block Articledeepshikha100% (1)

- Complete HeriDocument44 pagesComplete HerideepshikhaNo ratings yet

- Heri ConservationDocument7 pagesHeri ConservationdeepshikhaNo ratings yet

- Sylva: Q. 11 Give A Brief History of Conservation? Early HistoryDocument4 pagesSylva: Q. 11 Give A Brief History of Conservation? Early HistorydeepshikhaNo ratings yet

- Heritage: Cultural Heitage Natural HeritageDocument4 pagesHeritage: Cultural Heitage Natural Heritagedeepshikha100% (3)

- Archi V YearDocument27 pagesArchi V YeardeepshikhaNo ratings yet

- Mayoor Chopasni School: J.Kcadk JKBKSM+Document1 pageMayoor Chopasni School: J.Kcadk JKBKSM+deepshikhaNo ratings yet

- Jaipur Metro (Phase-II) Sitapura To Ambabari: Detailed Project ReportDocument343 pagesJaipur Metro (Phase-II) Sitapura To Ambabari: Detailed Project ReportdeepshikhaNo ratings yet

- Moscow City Street DevelopmentDocument16 pagesMoscow City Street DevelopmentdeepshikhaNo ratings yet

- Elective PPT GROUP 2Document5 pagesElective PPT GROUP 2deepshikhaNo ratings yet

- Folded Plates - Building Materials & Construction - Group 2Document9 pagesFolded Plates - Building Materials & Construction - Group 2deepshikhaNo ratings yet

- Greek Lentil and Spinach SoupDocument3 pagesGreek Lentil and Spinach SouppudroNo ratings yet

- CVAsikin (Project Engineer)Document13 pagesCVAsikin (Project Engineer)Anonymous j6AXjDKNo ratings yet

- Specifications For Lime Slurry Injection For Ground ImprovementDocument5 pagesSpecifications For Lime Slurry Injection For Ground ImprovementSrini BaskaranNo ratings yet

- Effective Learning StrategiesDocument5 pagesEffective Learning StrategiesRossy Milena JarabaNo ratings yet

- General Specification For PaintingDocument15 pagesGeneral Specification For PaintingDeddy PratamaNo ratings yet

- En 300 330-1 V1.8.1Document68 pagesEn 300 330-1 V1.8.1SosialNo ratings yet

- Prototype TutorialDocument451 pagesPrototype TutorialMariela DemarkNo ratings yet

- Heermm ToolDocument18 pagesHeermm ToolJuan PabloNo ratings yet

- RAN1#NR - AH - 03: AgreementsDocument20 pagesRAN1#NR - AH - 03: AgreementssmequixuNo ratings yet

- Appliacation LetterDocument7 pagesAppliacation LetterTriantoNo ratings yet

- Fire Awareness PresentationDocument37 pagesFire Awareness Presentationshailu178No ratings yet

- Dhaval J. Pathak: Experience Warehouse ExecutiveDocument4 pagesDhaval J. Pathak: Experience Warehouse ExecutiveDhaval PathakNo ratings yet

- The 7 Levels of Wealth ManualDocument215 pagesThe 7 Levels of Wealth Manualawakejoy89% (18)

- Commentary With Worked Examples FOR IRC:6-2017: Indian Association of Structural EngineersDocument3 pagesCommentary With Worked Examples FOR IRC:6-2017: Indian Association of Structural EngineersNarayanan Jayachandran100% (3)

- Senfter Ernste Gedanken PDFDocument8 pagesSenfter Ernste Gedanken PDFthieves11No ratings yet

- LSS BB Body of KnowledgeDocument5 pagesLSS BB Body of KnowledgeVigneshNo ratings yet

- MarketingDocument110 pagesMarketingriddhi0% (1)

- Chemetall - PT - MSDS - LD7 - Liquid Developer AerosolDocument17 pagesChemetall - PT - MSDS - LD7 - Liquid Developer AerosolPhu Zar AungNo ratings yet

- Notes Industrial Security ConceptsDocument40 pagesNotes Industrial Security ConceptsAC GonzagaNo ratings yet

- Training Staff IDDocument14 pagesTraining Staff IDRS DulayNo ratings yet

- Market Development ReportDocument121 pagesMarket Development ReportSrivinayaga XNo ratings yet

- ELEN 3018 - Macro Test - 2013 - ADocument1 pageELEN 3018 - Macro Test - 2013 - AsirlordbookwormNo ratings yet

- PDF File Rites of The Lock-Picking With Surgat Lapaca by AftahhDocument7 pagesPDF File Rites of The Lock-Picking With Surgat Lapaca by AftahhvrsNo ratings yet

- ValeoDocument4 pagesValeographmashNo ratings yet

- Hostel RulesDocument15 pagesHostel RulesalogpgNo ratings yet

- BRSM Class Test ExamDocument3 pagesBRSM Class Test ExamFernando SidikNo ratings yet

- T14 CalculatorDocument5 pagesT14 CalculatorUsamaNo ratings yet

- CS Dec 2018-Jan 2019 PDFDocument78 pagesCS Dec 2018-Jan 2019 PDFPavanNo ratings yet

- Brain Teasers: GMAT: Problem SolvingDocument5 pagesBrain Teasers: GMAT: Problem SolvingHarsh MalhotraNo ratings yet