Professional Documents

Culture Documents

Danfoss VLT 2800 (FC Protocol) Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User Manual

Danfoss VLT 2800 (FC Protocol) Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User Manual

Uploaded by

ryoCopyright:

Available Formats

You might also like

- Coa Da1Document31 pagesCoa Da1Aishwarya Tapadiya0% (1)

- RISH EM 2340 1320-30-40 Interface Definition1Document39 pagesRISH EM 2340 1320-30-40 Interface Definition1Ravi Negi100% (1)

- Coslight 48 VBMS MODBUS Communication Protocol Simplified VersionDocument14 pagesCoslight 48 VBMS MODBUS Communication Protocol Simplified VersionHoàng Hiếu100% (1)

- Sinusoidal Wave Controller KLS Broadcast CAN ProtocolDocument5 pagesSinusoidal Wave Controller KLS Broadcast CAN Protocolhpfuturetek CorpNo ratings yet

- MINI Cooper Service Manual: 2002-2006 - Table of ContentsDocument2 pagesMINI Cooper Service Manual: 2002-2006 - Table of ContentsBentley Publishers40% (5)

- How I Cured My Eye FloatersDocument6 pagesHow I Cured My Eye Floaters54321anon100% (2)

- Credit Policy Sample: Accounts Receivable AnalysisDocument3 pagesCredit Policy Sample: Accounts Receivable AnalysisAlinaNo ratings yet

- Electromagnetic Lab Write-UpDocument5 pagesElectromagnetic Lab Write-Upapi-375748727No ratings yet

- Character CreationDocument36 pagesCharacter CreationGracia Gagah100% (2)

- DELTA - IA-HMI - Danfoss VLT 2800 - FC Protocol - CM - EN - 20111122Document4 pagesDELTA - IA-HMI - Danfoss VLT 2800 - FC Protocol - CM - EN - 20111122Ronnie Ayala SandovalNo ratings yet

- Jetter Nano Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesJetter Nano Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Hust CNC Controller Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument1 pageHust CNC Controller Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Keyence KV/KZ Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument3 pagesKeyence KV/KZ Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Delta DVPDocument3 pagesDelta DVPKerolos MekhaelNo ratings yet

- Mks Ct150 Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMks Ct150 Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Facon FB Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesFacon FB Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Mitsubishi A2A/A2AS/A2USH A1SH/A3N/A2ASH (CPU-S1) CPU Port Delta A. HMI Factory SettingsDocument3 pagesMitsubishi A2A/A2AS/A2USH A1SH/A3N/A2ASH (CPU-S1) CPU Port Delta A. HMI Factory SettingsryoNo ratings yet

- Jetter Nano Series PLC - ENGDocument3 pagesJetter Nano Series PLC - ENGMiguel Gonzalez TrujilloNo ratings yet

- Load Cell Input Module: 1 Specifications of FBS-PLC Load Cell Measurement ModulesDocument8 pagesLoad Cell Input Module: 1 Specifications of FBS-PLC Load Cell Measurement ModulesNelson GilNo ratings yet

- Mitsubish Fx/Fx2N PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMitsubish Fx/Fx2N PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Koyo K-Sequence Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument3 pagesKoyo K-Sequence Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- LG Master K120S/200S Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLG Master K120S/200S Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Delta Ia-Hmi Mks By125 Low Cost Synchrocontroller CM en 20111122Document3 pagesDelta Ia-Hmi Mks By125 Low Cost Synchrocontroller CM en 20111122kaushal kumarNo ratings yet

- Liyan Lyplc Ex Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLiyan Lyplc Ex Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- DPS5005 Communication Protocol - English Google Translate Version V1.2Document7 pagesDPS5005 Communication Protocol - English Google Translate Version V1.2Giordano De StefanisNo ratings yet

- Sigma2 Modbus - Jan 2016Document19 pagesSigma2 Modbus - Jan 2016Dave PotterNo ratings yet

- Bluetooth 5 Smart RS232 Adapter S2B5232EDocument8 pagesBluetooth 5 Smart RS232 Adapter S2B5232EBender RodriguezNo ratings yet

- Delta DVPDocument2 pagesDelta DVPyahia abdelliNo ratings yet

- Norika WM Communication Quick ReferenceDocument1 pageNorika WM Communication Quick ReferencePhyo Phyo ZawNo ratings yet

- MITSUBISHI QJ71 Driver For Q00/Q01 CPU Port: HMI SettingDocument3 pagesMITSUBISHI QJ71 Driver For Q00/Q01 CPU Port: HMI SettingHamid KharazmiNo ratings yet

- Lab 01 RS - 232 SolvedDocument12 pagesLab 01 RS - 232 SolvedCarolina0% (1)

- Jetter JC Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesJetter JC Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- ModbusDocument6 pagesModbusCésar YagüeNo ratings yet

- Belimo Modbus RegisterDocument13 pagesBelimo Modbus RegisterJonny GloverNo ratings yet

- Technical Reference Options and Adapters Volume 2 3of3Document243 pagesTechnical Reference Options and Adapters Volume 2 3of3kgrhoadsNo ratings yet

- Experiment 1 UART and RS232C Standard: ObjectivesDocument8 pagesExperiment 1 UART and RS232C Standard: ObjectivesJay PatelNo ratings yet

- Mitsubishi A Series AJ71UC24 Communication Module Delta A. HMI Factory SettingsDocument2 pagesMitsubishi A Series AJ71UC24 Communication Module Delta A. HMI Factory SettingsryoNo ratings yet

- Modbus - Protocol - Hybrid - ARM205 - V1.7 - ETEHBTBH - ReadDataOnlyDocument19 pagesModbus - Protocol - Hybrid - ARM205 - V1.7 - ETEHBTBH - ReadDataOnlyJosef KonecnyNo ratings yet

- Pmac735 Modbus Register ListDocument31 pagesPmac735 Modbus Register ListjesankingNo ratings yet

- Danfoss Modbus2Document4 pagesDanfoss Modbus2erick paredesNo ratings yet

- Matsushita FP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMatsushita FP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Siemens S7 300 - Direct MPI - ENGDocument5 pagesSiemens S7 300 - Direct MPI - ENGDanilo MalanchinoNo ratings yet

- DAM-E3039F User's Manual H (V6.13)Document18 pagesDAM-E3039F User's Manual H (V6.13)ClaudiuMaxmiucNo ratings yet

- SAJ Modbus Communication Protocol: Document NumberDocument20 pagesSAJ Modbus Communication Protocol: Document NumberMarcos GomesNo ratings yet

- Community Monitoring MODBUS RTU Protocol Description: 1. Agreement ContentDocument2 pagesCommunity Monitoring MODBUS RTU Protocol Description: 1. Agreement ContentCreate thisNo ratings yet

- Manual Communication DigiRail-4C EnglishDocument5 pagesManual Communication DigiRail-4C Englishmetanoia88No ratings yet

- The Concise LCD Data Sheet.: RS T TDocument1 pageThe Concise LCD Data Sheet.: RS T TgcbilalNo ratings yet

- Gdm0802bflytw 19063127781Document18 pagesGdm0802bflytw 19063127781aristonrafaelNo ratings yet

- Mitsubishi FX5UDocument6 pagesMitsubishi FX5UVu MinhNo ratings yet

- Embedded System - Interfacing With 8051Document69 pagesEmbedded System - Interfacing With 8051DevashishNo ratings yet

- Es35 SW User Manual enDocument18 pagesEs35 SW User Manual enThái Trung TàiNo ratings yet

- WT60 Modbus Protocol Manual ENDocument24 pagesWT60 Modbus Protocol Manual ENvuong buiNo ratings yet

- 12.12.2 Storage of Data 12.13 Danfoss FC Control Profile 12.13.1 Control Word According To FC Profile (8-10 Control Profile FC Profile)Document3 pages12.12.2 Storage of Data 12.13 Danfoss FC Control Profile 12.13.1 Control Word According To FC Profile (8-10 Control Profile FC Profile)ARGENIS GOMEZNo ratings yet

- Setting BRAKE Wiring Digital Output CN1Document5 pagesSetting BRAKE Wiring Digital Output CN1Imam SyaefudinNo ratings yet

- Serial PortDocument31 pagesSerial Porttariq7868100% (2)

- An Introduction To Serial Port InterfacingDocument31 pagesAn Introduction To Serial Port InterfacingVeerendra SimplyMeNo ratings yet

- LCD Sharp Compaq Lq9d011Document15 pagesLCD Sharp Compaq Lq9d011Domingo SiguenzaNo ratings yet

- #Tutorialspoint Programmable Peripheral Interface 8255: Block DiagramDocument26 pages#Tutorialspoint Programmable Peripheral Interface 8255: Block DiagramHasib PeyalNo ratings yet

- Serial Communication: Communication Protocol V10x ADocument2 pagesSerial Communication: Communication Protocol V10x AAdonay HenriquezNo ratings yet

- H8/500 Series Programming Manual: Catalog No. ADE-602-021Document187 pagesH8/500 Series Programming Manual: Catalog No. ADE-602-021JuniorTNo ratings yet

- LG Master-K Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLG Master-K Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Mirle Fama SC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument1 pageMirle Fama SC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- 1550402978050 growatt pv inverter modbus rs485 rtu protocol v3.05 客户版Document15 pages1550402978050 growatt pv inverter modbus rs485 rtu protocol v3.05 客户版JohanNo ratings yet

- Operating Instructions Rish CON VI HZ Without DisplayDocument32 pagesOperating Instructions Rish CON VI HZ Without DisplayRanjit Sahoo0% (1)

- Mitsubish Fx/Fx2N PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMitsubish Fx/Fx2N PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Modbus Hexadecimal Address (Master) - RTU / ASCII Mode Delta A. HMI Factory SettingsDocument2 pagesModbus Hexadecimal Address (Master) - RTU / ASCII Mode Delta A. HMI Factory SettingsryoNo ratings yet

- Modbus NW (Master) - RTU / ASCII Mode Delta A. HMI Factory SettingsDocument1 pageModbus NW (Master) - RTU / ASCII Mode Delta A. HMI Factory SettingsryoNo ratings yet

- LG Glofa Gm6 Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLG Glofa Gm6 Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Modbus (Master) - 984 RTU / ASCII Mode Delta A. HMI Factory SettingsDocument1 pageModbus (Master) - 984 RTU / ASCII Mode Delta A. HMI Factory SettingsryoNo ratings yet

- Mitsubishi Q Series Cpu Port Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument3 pagesMitsubishi Q Series Cpu Port Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Mitsubishi A Series AJ71UC24 Communication Module Delta A. HMI Factory SettingsDocument2 pagesMitsubishi A Series AJ71UC24 Communication Module Delta A. HMI Factory SettingsryoNo ratings yet

- Mks Ct150 Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMks Ct150 Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Mitsubishi A2A/A2AS/A2USH A1SH/A3N/A2ASH (CPU-S1) CPU Port Delta A. HMI Factory SettingsDocument3 pagesMitsubishi A2A/A2AS/A2USH A1SH/A3N/A2ASH (CPU-S1) CPU Port Delta A. HMI Factory SettingsryoNo ratings yet

- Koyo K-Sequence Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument3 pagesKoyo K-Sequence Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Matsushita FP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMatsushita FP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Liyan Lyplc Ex Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLiyan Lyplc Ex Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Mirle Fama SC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument1 pageMirle Fama SC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- LG Master K120S/200S Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLG Master K120S/200S Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Lenze Lecom-A/B Protocol Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument5 pagesLenze Lecom-A/B Protocol Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Keyence KV/KZ Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument3 pagesKeyence KV/KZ Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- LG Master-K Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLG Master-K Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Festo PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesFesto PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Jetter Nano Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesJetter Nano Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Facon FB Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesFacon FB Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Koyo Su/Dl Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesKoyo Su/Dl Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Hust CNC Controller Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument1 pageHust CNC Controller Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Ge Fanuc 90 Series SNP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesGe Fanuc 90 Series SNP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Delta DVP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesDelta DVP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Allenbradley Micrologix PLC Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User ManualDocument3 pagesAllenbradley Micrologix PLC Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Allenbradley Slc5 PLC Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User ManualDocument4 pagesAllenbradley Slc5 PLC Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- A.3 Profile: DOPA (E) 57G (C) (B) STDDocument2 pagesA.3 Profile: DOPA (E) 57G (C) (B) STDryoNo ratings yet

- RXD (2) (2) TX TXD (3) GND (5) (4) RX (1) GND: C. Connections (Connector Pinouts) Delta ServoDocument2 pagesRXD (2) (2) TX TXD (3) GND (5) (4) RX (1) GND: C. Connections (Connector Pinouts) Delta ServoryoNo ratings yet

- A.5 Installation: Appendix A Specifications and Installation - Scredit Software User ManualDocument2 pagesA.5 Installation: Appendix A Specifications and Installation - Scredit Software User ManualryoNo ratings yet

- App A4Document2 pagesApp A4ryoNo ratings yet

- Documentation FlutterDocument12 pagesDocumentation FlutterIvhan SalazarNo ratings yet

- Flyer 2nd Page 2019 2020Document3 pagesFlyer 2nd Page 2019 2020Sandra JalmascoNo ratings yet

- Manual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Document338 pagesManual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Joel Carvajal ArayaNo ratings yet

- Summary of VBA For Scientific Computing 9-25-2013 v1Document19 pagesSummary of VBA For Scientific Computing 9-25-2013 v1lionfierce123No ratings yet

- Owner Manual - Avh-A205bt - Avh-A105dvd RC AseanDocument140 pagesOwner Manual - Avh-A205bt - Avh-A105dvd RC AseanalejandrohukNo ratings yet

- VR-Research Paper: August 2021Document66 pagesVR-Research Paper: August 2021Shashank YadavNo ratings yet

- Mathematics Grade 10Document270 pagesMathematics Grade 10TammanurRaviNo ratings yet

- 09-Humble Homemade Hifi - PhleaDocument4 pages09-Humble Homemade Hifi - Phleajns0110No ratings yet

- Objective of ECO401 (1 22) Short NotesDocument11 pagesObjective of ECO401 (1 22) Short Notesmuhammad jamilNo ratings yet

- ESC Cardiomyopathy ClassificationDocument7 pagesESC Cardiomyopathy Classificationvalerius83No ratings yet

- In Company 3.0 Intermediate in Action Video Worksheet - Scenario Worksheet CDocument2 pagesIn Company 3.0 Intermediate in Action Video Worksheet - Scenario Worksheet CAma GavNo ratings yet

- Fesco Online BillDocument2 pagesFesco Online BillFaisal NaveedNo ratings yet

- Sports and Entertainment Marketing: Sample Role PlaysDocument36 pagesSports and Entertainment Marketing: Sample Role PlaysTAHA GABRNo ratings yet

- QuestionsDocument5 pagesQuestionsrajasamygopalNo ratings yet

- Cesc 10021 BomDocument91 pagesCesc 10021 Bomsitam_nitj4202No ratings yet

- Part Ii: A BC ACB ABC Ø XyzDocument2 pagesPart Ii: A BC ACB ABC Ø XyzHamza NagraNo ratings yet

- R Trader Trader's GuideDocument93 pagesR Trader Trader's Guidelearn2shareNo ratings yet

- IMC 151 - PAIR AssignmentDocument37 pagesIMC 151 - PAIR Assignmentfarishaemylia40No ratings yet

- Hypertensive Patients Knowledge, Self-Care ManagementDocument10 pagesHypertensive Patients Knowledge, Self-Care ManagementLilian ArthoNo ratings yet

- Ultrasound in Obstretics PDFDocument40 pagesUltrasound in Obstretics PDFcarcobe3436100% (1)

- PCTG R11Document47 pagesPCTG R11Aron SaquilabonNo ratings yet

- New TIP Course 1 DepEd Teacher PDFDocument89 pagesNew TIP Course 1 DepEd Teacher PDFLenie TejadaNo ratings yet

- Wolfram Von Eschenbach - ParzivalDocument324 pagesWolfram Von Eschenbach - ParzivalStanley Castro100% (1)

- Genesis g16Document2 pagesGenesis g16Krist UtamaNo ratings yet

- Doctor Kekalo Pinto Bean Whole Supplier: 1. Executive SummaryDocument12 pagesDoctor Kekalo Pinto Bean Whole Supplier: 1. Executive Summaryalemayehu tarikuNo ratings yet

Danfoss VLT 2800 (FC Protocol) Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User Manual

Danfoss VLT 2800 (FC Protocol) Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User Manual

Uploaded by

ryoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Danfoss VLT 2800 (FC Protocol) Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User Manual

Danfoss VLT 2800 (FC Protocol) Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User Manual

Uploaded by

ryoCopyright:

Available Formats

Appendix B Communication|ScrEdit Software User Manual

Danfoss VLT 2800 (FC Protocol) DELTA

A. HMI factory setting

Baud rate: 9600, 8, Even, 1, RS-485.

PLC station number: 1.

Control area/state area: None / None.

NOTE

1) Delta HMI can be connected to for VLT-2800, 5000, 6000, 7000 controllers.

2) Each data length format of Danfoss AC drive parameter is not fixed, therefore, “Multiple Duplicate”

function is not provided.

3) Max. supported alarm number is 16. If the alarm number is over 16, a fault will occur.

4) Not support “optimum read/write” characteristic.

5) If the selected element is a string, the minimum data length should be more than 2.

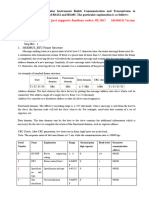

B. Definition of controller Read/Write address

Registers

Read/Write Range

Bit No.

Register Type Format

Word No. Low Byte High Byte

Index No.

Parameter Pn:I n: 0 ~ 999 0 I: 0 ~ 31

Control Word CTRWD 0 N/A N/A

Status Word STAWD 0 N/A N/A

¾ Index No : If the index No. is not used, its default setting will be 0. The default setting of index No. for

parameter P606 ~ P617 is 1.

¾ Please notice that it is necessary to input the index No. when using some parameters of Danfoss

controllers. At this time, please pay close attention on the setting range of index number. If the setting

range is not started from 0, the parameter read & write failure will occur. For example, the index No.

setting range of the parameter P615 is from 1 to 20, if the users do not input the index No., the system

will assume the index number is 0 (default setting) and the a fault will occur when the users read or write

the parameter.

¾ CTRWD: Write-only. (Can not be used on the devices which can display the value or input value. It is

recommended to be used on the setting value/setting constant (button), or marco function.)

¾ STAWD: Read-only.

¾ Control & Status Word: Please refer to the explanation on the next page (page B-20).

Revision 05/30/2006, EH00 B-19

Appendix B Communication|ScrEdit Software User Manual

Contacts

Read/Write Range

Word No. Bit No.

Contact Type Format

Low Byte High Byte

Element No.

Bits Index No.

Parameter Pn:I.b n: 0 ~ 999 b: 0 ~ 31 I: 0 ~ 31

¾ Bit No : Low byte stores Bit address. High byte stores index number.

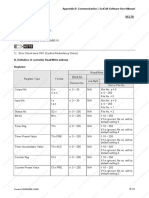

C. Connections (Connector Pinouts)

RS-485 Connection

DOP Series Controller

9 pin D-SUB male (RS-485) RS-485 cable connector

R XD + (2) 68 TX D /R XD +

TX D+ (3 )

R XD - (1 ) 69 TX D /R XD -

TX D- (4)

S hell S hell

Explanation of Control Word & Status Word

Control Word

Bit Bit = 0 Bit = 1

15 No Function Reversing

14 Choice of Setup 2 (msb)

13 Choice of Setup 1 (lsb)

12 No Function Relay 04 activated

11 No Function Relay 01 activated

10 Data Not Vaild Vaild

9 Ramp 1 Ramp2

8 Jog 1 OFF ON

7 No Function Reset

6 Ramp Stop Start

5 Hold Ramp Enable

4 Quick-Stop Ramp

3 Coasting Enable

2 DC Brake Ramp

1 Preset reference choice msb

0 Preset reference choice msb

¾ When Bit 10 = 1 (Data Valid), the Control Word is valid.

B-20 Revision 05/30/2006, EH00

Appendix B Communication|ScrEdit Software User Manual

Status Word

Bit Bit = 0 Bit = 1

15 Timer OK Above limit

14 Torque OK Above limit

13 Voltage OK Above limit

12 Temperature OK Over-Temp, auto-start pending

11 Not Running Running

10 Out of Range Frequency OK

9 Local Control Bus Control

8 Speed ≠ reference Speed = reference

7 No Warning Warning

6 Reserved

5 Reserved

4 Reserved

3 No Fault Trip

2 Coasting Enabled

1 VLT not ready Ready

0 Control not ready Ready

Revision 05/30/2006, EH00 B-21

You might also like

- Coa Da1Document31 pagesCoa Da1Aishwarya Tapadiya0% (1)

- RISH EM 2340 1320-30-40 Interface Definition1Document39 pagesRISH EM 2340 1320-30-40 Interface Definition1Ravi Negi100% (1)

- Coslight 48 VBMS MODBUS Communication Protocol Simplified VersionDocument14 pagesCoslight 48 VBMS MODBUS Communication Protocol Simplified VersionHoàng Hiếu100% (1)

- Sinusoidal Wave Controller KLS Broadcast CAN ProtocolDocument5 pagesSinusoidal Wave Controller KLS Broadcast CAN Protocolhpfuturetek CorpNo ratings yet

- MINI Cooper Service Manual: 2002-2006 - Table of ContentsDocument2 pagesMINI Cooper Service Manual: 2002-2006 - Table of ContentsBentley Publishers40% (5)

- How I Cured My Eye FloatersDocument6 pagesHow I Cured My Eye Floaters54321anon100% (2)

- Credit Policy Sample: Accounts Receivable AnalysisDocument3 pagesCredit Policy Sample: Accounts Receivable AnalysisAlinaNo ratings yet

- Electromagnetic Lab Write-UpDocument5 pagesElectromagnetic Lab Write-Upapi-375748727No ratings yet

- Character CreationDocument36 pagesCharacter CreationGracia Gagah100% (2)

- DELTA - IA-HMI - Danfoss VLT 2800 - FC Protocol - CM - EN - 20111122Document4 pagesDELTA - IA-HMI - Danfoss VLT 2800 - FC Protocol - CM - EN - 20111122Ronnie Ayala SandovalNo ratings yet

- Jetter Nano Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesJetter Nano Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Hust CNC Controller Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument1 pageHust CNC Controller Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Keyence KV/KZ Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument3 pagesKeyence KV/KZ Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Delta DVPDocument3 pagesDelta DVPKerolos MekhaelNo ratings yet

- Mks Ct150 Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMks Ct150 Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Facon FB Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesFacon FB Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Mitsubishi A2A/A2AS/A2USH A1SH/A3N/A2ASH (CPU-S1) CPU Port Delta A. HMI Factory SettingsDocument3 pagesMitsubishi A2A/A2AS/A2USH A1SH/A3N/A2ASH (CPU-S1) CPU Port Delta A. HMI Factory SettingsryoNo ratings yet

- Jetter Nano Series PLC - ENGDocument3 pagesJetter Nano Series PLC - ENGMiguel Gonzalez TrujilloNo ratings yet

- Load Cell Input Module: 1 Specifications of FBS-PLC Load Cell Measurement ModulesDocument8 pagesLoad Cell Input Module: 1 Specifications of FBS-PLC Load Cell Measurement ModulesNelson GilNo ratings yet

- Mitsubish Fx/Fx2N PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMitsubish Fx/Fx2N PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Koyo K-Sequence Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument3 pagesKoyo K-Sequence Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- LG Master K120S/200S Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLG Master K120S/200S Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Delta Ia-Hmi Mks By125 Low Cost Synchrocontroller CM en 20111122Document3 pagesDelta Ia-Hmi Mks By125 Low Cost Synchrocontroller CM en 20111122kaushal kumarNo ratings yet

- Liyan Lyplc Ex Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLiyan Lyplc Ex Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- DPS5005 Communication Protocol - English Google Translate Version V1.2Document7 pagesDPS5005 Communication Protocol - English Google Translate Version V1.2Giordano De StefanisNo ratings yet

- Sigma2 Modbus - Jan 2016Document19 pagesSigma2 Modbus - Jan 2016Dave PotterNo ratings yet

- Bluetooth 5 Smart RS232 Adapter S2B5232EDocument8 pagesBluetooth 5 Smart RS232 Adapter S2B5232EBender RodriguezNo ratings yet

- Delta DVPDocument2 pagesDelta DVPyahia abdelliNo ratings yet

- Norika WM Communication Quick ReferenceDocument1 pageNorika WM Communication Quick ReferencePhyo Phyo ZawNo ratings yet

- MITSUBISHI QJ71 Driver For Q00/Q01 CPU Port: HMI SettingDocument3 pagesMITSUBISHI QJ71 Driver For Q00/Q01 CPU Port: HMI SettingHamid KharazmiNo ratings yet

- Lab 01 RS - 232 SolvedDocument12 pagesLab 01 RS - 232 SolvedCarolina0% (1)

- Jetter JC Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesJetter JC Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- ModbusDocument6 pagesModbusCésar YagüeNo ratings yet

- Belimo Modbus RegisterDocument13 pagesBelimo Modbus RegisterJonny GloverNo ratings yet

- Technical Reference Options and Adapters Volume 2 3of3Document243 pagesTechnical Reference Options and Adapters Volume 2 3of3kgrhoadsNo ratings yet

- Experiment 1 UART and RS232C Standard: ObjectivesDocument8 pagesExperiment 1 UART and RS232C Standard: ObjectivesJay PatelNo ratings yet

- Mitsubishi A Series AJ71UC24 Communication Module Delta A. HMI Factory SettingsDocument2 pagesMitsubishi A Series AJ71UC24 Communication Module Delta A. HMI Factory SettingsryoNo ratings yet

- Modbus - Protocol - Hybrid - ARM205 - V1.7 - ETEHBTBH - ReadDataOnlyDocument19 pagesModbus - Protocol - Hybrid - ARM205 - V1.7 - ETEHBTBH - ReadDataOnlyJosef KonecnyNo ratings yet

- Pmac735 Modbus Register ListDocument31 pagesPmac735 Modbus Register ListjesankingNo ratings yet

- Danfoss Modbus2Document4 pagesDanfoss Modbus2erick paredesNo ratings yet

- Matsushita FP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMatsushita FP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Siemens S7 300 - Direct MPI - ENGDocument5 pagesSiemens S7 300 - Direct MPI - ENGDanilo MalanchinoNo ratings yet

- DAM-E3039F User's Manual H (V6.13)Document18 pagesDAM-E3039F User's Manual H (V6.13)ClaudiuMaxmiucNo ratings yet

- SAJ Modbus Communication Protocol: Document NumberDocument20 pagesSAJ Modbus Communication Protocol: Document NumberMarcos GomesNo ratings yet

- Community Monitoring MODBUS RTU Protocol Description: 1. Agreement ContentDocument2 pagesCommunity Monitoring MODBUS RTU Protocol Description: 1. Agreement ContentCreate thisNo ratings yet

- Manual Communication DigiRail-4C EnglishDocument5 pagesManual Communication DigiRail-4C Englishmetanoia88No ratings yet

- The Concise LCD Data Sheet.: RS T TDocument1 pageThe Concise LCD Data Sheet.: RS T TgcbilalNo ratings yet

- Gdm0802bflytw 19063127781Document18 pagesGdm0802bflytw 19063127781aristonrafaelNo ratings yet

- Mitsubishi FX5UDocument6 pagesMitsubishi FX5UVu MinhNo ratings yet

- Embedded System - Interfacing With 8051Document69 pagesEmbedded System - Interfacing With 8051DevashishNo ratings yet

- Es35 SW User Manual enDocument18 pagesEs35 SW User Manual enThái Trung TàiNo ratings yet

- WT60 Modbus Protocol Manual ENDocument24 pagesWT60 Modbus Protocol Manual ENvuong buiNo ratings yet

- 12.12.2 Storage of Data 12.13 Danfoss FC Control Profile 12.13.1 Control Word According To FC Profile (8-10 Control Profile FC Profile)Document3 pages12.12.2 Storage of Data 12.13 Danfoss FC Control Profile 12.13.1 Control Word According To FC Profile (8-10 Control Profile FC Profile)ARGENIS GOMEZNo ratings yet

- Setting BRAKE Wiring Digital Output CN1Document5 pagesSetting BRAKE Wiring Digital Output CN1Imam SyaefudinNo ratings yet

- Serial PortDocument31 pagesSerial Porttariq7868100% (2)

- An Introduction To Serial Port InterfacingDocument31 pagesAn Introduction To Serial Port InterfacingVeerendra SimplyMeNo ratings yet

- LCD Sharp Compaq Lq9d011Document15 pagesLCD Sharp Compaq Lq9d011Domingo SiguenzaNo ratings yet

- #Tutorialspoint Programmable Peripheral Interface 8255: Block DiagramDocument26 pages#Tutorialspoint Programmable Peripheral Interface 8255: Block DiagramHasib PeyalNo ratings yet

- Serial Communication: Communication Protocol V10x ADocument2 pagesSerial Communication: Communication Protocol V10x AAdonay HenriquezNo ratings yet

- H8/500 Series Programming Manual: Catalog No. ADE-602-021Document187 pagesH8/500 Series Programming Manual: Catalog No. ADE-602-021JuniorTNo ratings yet

- LG Master-K Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLG Master-K Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Mirle Fama SC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument1 pageMirle Fama SC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- 1550402978050 growatt pv inverter modbus rs485 rtu protocol v3.05 客户版Document15 pages1550402978050 growatt pv inverter modbus rs485 rtu protocol v3.05 客户版JohanNo ratings yet

- Operating Instructions Rish CON VI HZ Without DisplayDocument32 pagesOperating Instructions Rish CON VI HZ Without DisplayRanjit Sahoo0% (1)

- Mitsubish Fx/Fx2N PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMitsubish Fx/Fx2N PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Modbus Hexadecimal Address (Master) - RTU / ASCII Mode Delta A. HMI Factory SettingsDocument2 pagesModbus Hexadecimal Address (Master) - RTU / ASCII Mode Delta A. HMI Factory SettingsryoNo ratings yet

- Modbus NW (Master) - RTU / ASCII Mode Delta A. HMI Factory SettingsDocument1 pageModbus NW (Master) - RTU / ASCII Mode Delta A. HMI Factory SettingsryoNo ratings yet

- LG Glofa Gm6 Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLG Glofa Gm6 Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Modbus (Master) - 984 RTU / ASCII Mode Delta A. HMI Factory SettingsDocument1 pageModbus (Master) - 984 RTU / ASCII Mode Delta A. HMI Factory SettingsryoNo ratings yet

- Mitsubishi Q Series Cpu Port Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument3 pagesMitsubishi Q Series Cpu Port Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Mitsubishi A Series AJ71UC24 Communication Module Delta A. HMI Factory SettingsDocument2 pagesMitsubishi A Series AJ71UC24 Communication Module Delta A. HMI Factory SettingsryoNo ratings yet

- Mks Ct150 Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMks Ct150 Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Mitsubishi A2A/A2AS/A2USH A1SH/A3N/A2ASH (CPU-S1) CPU Port Delta A. HMI Factory SettingsDocument3 pagesMitsubishi A2A/A2AS/A2USH A1SH/A3N/A2ASH (CPU-S1) CPU Port Delta A. HMI Factory SettingsryoNo ratings yet

- Koyo K-Sequence Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument3 pagesKoyo K-Sequence Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Matsushita FP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesMatsushita FP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Liyan Lyplc Ex Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLiyan Lyplc Ex Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Mirle Fama SC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument1 pageMirle Fama SC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- LG Master K120S/200S Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLG Master K120S/200S Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Lenze Lecom-A/B Protocol Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument5 pagesLenze Lecom-A/B Protocol Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Keyence KV/KZ Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument3 pagesKeyence KV/KZ Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- LG Master-K Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesLG Master-K Cnet Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Festo PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesFesto PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Jetter Nano Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesJetter Nano Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Facon FB Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesFacon FB Series PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Koyo Su/Dl Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesKoyo Su/Dl Series Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Hust CNC Controller Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument1 pageHust CNC Controller Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Ge Fanuc 90 Series SNP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesGe Fanuc 90 Series SNP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Delta DVP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualDocument2 pagesDelta DVP PLC Delta A. Hmi Factory Settings: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Allenbradley Micrologix PLC Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User ManualDocument3 pagesAllenbradley Micrologix PLC Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- Allenbradley Slc5 PLC Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User ManualDocument4 pagesAllenbradley Slc5 PLC Delta A. Hmi Factory Setting: Appendix B Communication - Scredit Software User ManualryoNo ratings yet

- A.3 Profile: DOPA (E) 57G (C) (B) STDDocument2 pagesA.3 Profile: DOPA (E) 57G (C) (B) STDryoNo ratings yet

- RXD (2) (2) TX TXD (3) GND (5) (4) RX (1) GND: C. Connections (Connector Pinouts) Delta ServoDocument2 pagesRXD (2) (2) TX TXD (3) GND (5) (4) RX (1) GND: C. Connections (Connector Pinouts) Delta ServoryoNo ratings yet

- A.5 Installation: Appendix A Specifications and Installation - Scredit Software User ManualDocument2 pagesA.5 Installation: Appendix A Specifications and Installation - Scredit Software User ManualryoNo ratings yet

- App A4Document2 pagesApp A4ryoNo ratings yet

- Documentation FlutterDocument12 pagesDocumentation FlutterIvhan SalazarNo ratings yet

- Flyer 2nd Page 2019 2020Document3 pagesFlyer 2nd Page 2019 2020Sandra JalmascoNo ratings yet

- Manual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Document338 pagesManual Armado 960E-1 Serial Number A30003-A30024 CEAW005502Joel Carvajal ArayaNo ratings yet

- Summary of VBA For Scientific Computing 9-25-2013 v1Document19 pagesSummary of VBA For Scientific Computing 9-25-2013 v1lionfierce123No ratings yet

- Owner Manual - Avh-A205bt - Avh-A105dvd RC AseanDocument140 pagesOwner Manual - Avh-A205bt - Avh-A105dvd RC AseanalejandrohukNo ratings yet

- VR-Research Paper: August 2021Document66 pagesVR-Research Paper: August 2021Shashank YadavNo ratings yet

- Mathematics Grade 10Document270 pagesMathematics Grade 10TammanurRaviNo ratings yet

- 09-Humble Homemade Hifi - PhleaDocument4 pages09-Humble Homemade Hifi - Phleajns0110No ratings yet

- Objective of ECO401 (1 22) Short NotesDocument11 pagesObjective of ECO401 (1 22) Short Notesmuhammad jamilNo ratings yet

- ESC Cardiomyopathy ClassificationDocument7 pagesESC Cardiomyopathy Classificationvalerius83No ratings yet

- In Company 3.0 Intermediate in Action Video Worksheet - Scenario Worksheet CDocument2 pagesIn Company 3.0 Intermediate in Action Video Worksheet - Scenario Worksheet CAma GavNo ratings yet

- Fesco Online BillDocument2 pagesFesco Online BillFaisal NaveedNo ratings yet

- Sports and Entertainment Marketing: Sample Role PlaysDocument36 pagesSports and Entertainment Marketing: Sample Role PlaysTAHA GABRNo ratings yet

- QuestionsDocument5 pagesQuestionsrajasamygopalNo ratings yet

- Cesc 10021 BomDocument91 pagesCesc 10021 Bomsitam_nitj4202No ratings yet

- Part Ii: A BC ACB ABC Ø XyzDocument2 pagesPart Ii: A BC ACB ABC Ø XyzHamza NagraNo ratings yet

- R Trader Trader's GuideDocument93 pagesR Trader Trader's Guidelearn2shareNo ratings yet

- IMC 151 - PAIR AssignmentDocument37 pagesIMC 151 - PAIR Assignmentfarishaemylia40No ratings yet

- Hypertensive Patients Knowledge, Self-Care ManagementDocument10 pagesHypertensive Patients Knowledge, Self-Care ManagementLilian ArthoNo ratings yet

- Ultrasound in Obstretics PDFDocument40 pagesUltrasound in Obstretics PDFcarcobe3436100% (1)

- PCTG R11Document47 pagesPCTG R11Aron SaquilabonNo ratings yet

- New TIP Course 1 DepEd Teacher PDFDocument89 pagesNew TIP Course 1 DepEd Teacher PDFLenie TejadaNo ratings yet

- Wolfram Von Eschenbach - ParzivalDocument324 pagesWolfram Von Eschenbach - ParzivalStanley Castro100% (1)

- Genesis g16Document2 pagesGenesis g16Krist UtamaNo ratings yet

- Doctor Kekalo Pinto Bean Whole Supplier: 1. Executive SummaryDocument12 pagesDoctor Kekalo Pinto Bean Whole Supplier: 1. Executive Summaryalemayehu tarikuNo ratings yet