Professional Documents

Culture Documents

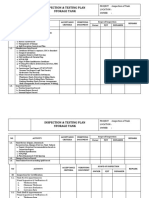

Copy of in Service Storage Tank Inspection and Verification Checklist

Copy of in Service Storage Tank Inspection and Verification Checklist

Uploaded by

Zohaib AlamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Copy of in Service Storage Tank Inspection and Verification Checklist

Copy of in Service Storage Tank Inspection and Verification Checklist

Uploaded by

Zohaib AlamCopyright:

Available Formats

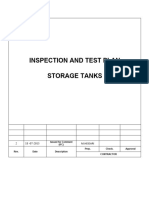

STORAGE TANK IN SERVICE

INSPECTION CHECK LIST

Project Description

Client / End User Manufacture

Code / Standard API 653 Item / Tag No.

Completion result Comments

No Inspected Item Satis Remark

Good Poor Bad Accept Reject

factory

1 Foundation

Measure foundation levelness and bottom elevations (see Appendix B API 653

for extent of measurements).

1.1 Concrete Ring

a. Inspect for broken concrete, spalling, and cracks, particularly under backup bars

used in welding butt-welded annular rings under the shell.

b. Inspect drain openings in ring, back of draw basins and top surface of ring

for indications of bottom leakage.

c. Inspect for cavities under foundation and vegetation against bottom of tank.

d. Check that runoff rain water from the shell drains away from tank.

e. Check for settlement around perimeter of tank.

1.2 Asphalt

a. Check for setting of tank into asphalt base which would direct runoff rain water

under the tank instead of away from it.

b. Look for areas where leaching of oil has left rock filler exposed, which indicates

hydrocarbon leakage.

1.3 Oiled Dirt or Sand

Check for settlement into the base which would direct runoff rain water under the

tank rather than away from it.

1.4 Rock

Presence of crushed rock under the steel bottom usually results in severe underside corrosion.

Make a note to do additional bottom plate examination (Ultrasonic, hammer testing, or turning of

coupons) when the tank is out of service.

1.5 Site Drainage

a. Check site for drainage away from the tank and associated piping and manifolds.

b. Check operating condition of the dike drains.

1.5 Housekeeping

Inspect the area for buildup of trash, vegetation, and other inflammables buildup.

611-F-005 Rev. 0 In-Service Storage Tank Inspection and Verification Checklist

STORAGE TANK IN SERVICE

INSPECTION CHECK LIST

Project Description

Client / End User Manufacture

Code / Standard API 653 Item / Tag No.

Completion result Comments

No Inspected Item Satis Remark

Good Poor Bad Accept Reject

factory

2 SHELLS

2.1 External Visual Inspection

a. Visually inspect for paint failures, pitting, and corrosion.

b. Clean off bottom angle area and inspect for corrosion and thinning on plate and weld

c. Inspect the bottom-to-foundation seal, if any.

2.2 Internal (Floating Roof Tank)

Visually inspect for grooving, corrosion, pitting, and coating failures.

2.3 Riveted Shell Inspection

a. Inspect external surface for rivet and seam leaks.

b. Locate leaks by sketch or photo (location will be lost when shell is abrasive

cleaned for painting)

c. Inspect rivets for corrosion loss and wear.

d. Inspect vertical seams to see if they have been full fillet lap-welded to increase

joint efficiency.

e. If no record exists of vertical riveted seams, dimension and sketch(or photograph) the rivet

pattern: number of rows, rivet size, pitch length, and note whether the joint is

butt-riveted or lap-riveted.

2.4 Wind Girder(Floating Roof Tanks)

a. Inspect wind girder and handrail for corrosion damage (paint failure, pitting, corrosion

product buildup), especially where it occurs at tack-welded junction, and for broken welds.

b. Check support welds to shell for pitting, especially on shell plates.

c. Note whether supports have reinforcing pads welded to shell.

3 SHELL APPURTENANCES

3.1 Manways and Nozzles

a. Inspect for cracks or signs of leakage on weld joint at nozzles, manways, and reinforcing

plates.

b. Inspect for shell plate dimpling around nozzles, caused by excessive pipe deflection.

c. Inspect for flange leaks and leaks around bolting.

611-F-005 Rev. 0 In-Service Storage Tank Inspection and Verification Checklist

STORAGE TANK IN SERVICE

INSPECTION CHECK LIST

Project Description

Client / End User Manufacture

Code / Standard API 653 Item / Tag No.

Completion result Comments

No Inspected Item Satis Remark

Good Poor Bad Accept Reject

factory

3 SHELL APPURTENANCES (Continue)

d. Inspect sealing of insulation around manways and nozzles.

e. Check for inadequate manway flange and cover thickness on mixer manways.

3.2 Tank Piping Manifolds

a. Inspect manifold piping, flanges, and valves for leaks.

b. Inspect fire fighting system components.

c. Check for anchored piping which would be hazardous to the tank shell or bottom

connections during earth movement.

d. Check for adequate thermal pressure relief of piping to the tank.

e. Check operation of regulators for tanks with purge gas systems.

f. Check sample connections for leaks and for proper valve operation.

g. Check for damage and test the accuracy of temperature indicators.

h. Check welds on shell-mounted davit clips above valves 6 inches and larger.

3.3 Autogauge System

a. Inspect autogauge tape guide and lower sheave housing (floating swings) for leaks.

b. Inspect autogauge head for damage.

c. Bump the checker on autogauge head for proper movement of tape.

d. Identify size and construction material of autogauge tape guide (floating roof tanks).

e. Ask operator if tape tends to hang up during tank roof movement (floating roof tanks).

f. Compare actual product level to the reading on the autogauge

(maximum variation is 2 inches).

g. On floating roof tanks, when the roof is in the lowest position, check that no more

than two feet of tape are exposed at the end of the tape guide.

h. Inspect condition of board and legibility of board-type autogauges.

i. Test freedom of movement of marker and float.

3.4 Shell-Mounted Sample Station

a. Inspect sample lines for function of valves and plugging of lines, including drain or

return to tank line.

b. Check circulation pump for leaks and operating problems.

c. Test bracing and supports for sample lines and equipment.

611-F-005 Rev. 0 In-Service Storage Tank Inspection and Verification Checklist

STORAGE TANK IN SERVICE

INSPECTION CHECK LIST

Project Description

Client / End User Manufacture

Code / Standard API 653 Item / Tag No.

Completion result Comments

No Inspected Item Satis Remark

Good Poor Bad Accept Reject

factory

3 SHELL APPURTENANCES (Continue)

3.5 Heater

Inspect condensate drain for presence of oil indicating leakage.

3.6 Mixer

a. Inspect for proper mounting flange and support.

b. Inspect for leakage.

c. Inspect condition of power lines and connections to mixer.

3.7 Swing Lines:Winch Operation

a. Nonfloating, Raise, then lower the swing line with the winch, and check

for cable tightness to confirm that swing line lowered properly.

b. Floating. With tank half full or more, lower the swing line with the swing line,

then let out cable and check if swing has pulled cable tight, indicating that the winch is

operating properly.

c. Indicator. Check that the indicator moves in the proper direction:Floating swing

line indicators show a lower level as cable is wound up on the winch. Non-floating show

swing line indicators the opposite.

3.8 Swing Lines: External Guide System

Check for leaks at threaded and flanged joints.

3.9 Swing Lines: Identify Ballast Varying Need

Check for significant difference in stock specific gravity.

3.10 Swing Lines: Cable Material and Condition

a. For nonstainless steel cable, check for corrosion over entire length.

b. All cable: check for wear or fraying.

3.11 Swing Lines: Product Sample Comparison

Check for water or gravity differences that would indicate a leaking swing joint.

3.12 Swing Lines: Target

Target should indicate direction of swing opening (up or down) and height above

bottom where suction will be lost with swing on bottom support.

611-F-005 Rev. 0 In-Service Storage Tank Inspection and Verification Checklist

STORAGE TANK IN SERVICE

INSPECTION CHECK LIST

Project Description

Client / End User Manufacture

Code / Standard API 653 Item / Tag No.

Completion result Comments

No Inspected Item Satis Remark

Good Poor Bad Accept Reject

factory

4 ROOFS

4.1 Deck Plate Internal Corrosion

For safety, before accessing the roof, check with ultrasonic instrument or lightly use a ball

peen hammer to test the deck plate near the edge of the roof for thinning. (Corrosion normally

attacks the deck plate at the edge of a fixed roof and at the rafters in the center

of the roof first).

4.2 Deck Plate External Corrosion

Visually inspect for paint failure, holes, pitting, and corrosion product on the roof deck.

4.3 Roof Deck Drainage

Look for indication of standing water. (Significant sagging of fixed roof deck indicates

potential rafter failure. Large standing water areas on a floating roof indicate inadequate

drainage design or, if to one side, a nonlevel roof with possible leaking pontoons).

4.4 Level of Floating Roof

At several locations, measure distance from roof rim to a horizontal weld seam above

the roof. A Variance in the reading indicates a nonlevel roof with possible shell out-of-round,

out-of-plumb, leaking pontoons, or hang-up. On small diameter tanks, an unleveled condition

can indicate unequal loading at that level.

4.5 Gas Test Internal Floating Roof

Test for explosive gas on top of the internal floating roof. Readings could indicate a leaking

roof, leaking seal system, or inadequate ventilation of the area above the internal floating roof.

4.6 Roof Insulation

a. Visually inspect for cracks or leaks in the insulation weather coat where runoff

rain water could penetrate the insulation.

b. Inspect for wet insulation under the weather coat.

c. Remove small test sections of insulation and check roof deck for corrosion and holes

near the edge of the insulated area.

4.7 Floating Roof Seal systems

a. Measure and record maximum seal-to-shell gaps at :

1. Low pump out.

2. Mid-shell.

611-F-005 Rev. 0 In-Service Storage Tank Inspection and Verification Checklist

STORAGE TANK IN SERVICE

INSPECTION CHECK LIST

Project Description

Client / End User Manufacture

Code / Standard API 653 Item / Tag No.

Completion result Comments

No Inspected Item Satis Remark

Good Poor Bad Accept Reject

factory

4 ROOFS (Continue)

3. High liquid level.

b. Measure and record annular space at 30 foot spacing (minimum of four quadrants)

around roof and record. Measurements should be taken in directly opposite pairs.

1. --------- ---------- Opposite pair 1.

2. --------- ---------- Opposite pair 2.

c. Check if seal fabric on primary shoe seals is pulling shoes away from shell

(fabric not wide enough).

d. Inspect fabric on deterioration, holes, tears, and cracks.

e. Inspect visible metallic parts for corrosion and wear.

f. Inspect for openings in seals that would permit vapor emissions.

g. inspect for protruding bolt or rivet heads against the shell.

h. Pull both primary and secondary seal systems back all around the shell

to check their operation.

i. Inspect secondary seals for signs of buckling or indications that their angle with

the shell is too shallow.

j. inspect wedge-type wiper seals for flexibility, cracks, and tears.

5 ROOF APPURTENANCES

5.1 Sample Hatch

a. Inspect condition and functioning of sample hatch cover.

b. On tanks governed by Air Quality Monitoring District rules, check for the condition

of seal inside hatch cover.

c. Check for corrosion and plugging on thief and gauge hatch cover.

d. Where sample hatch is used to reel gauge stock level, check for marker and tab stating

hold-off distance.

e. Check for reinforcing pad where sample hatch pipe penetrates the roof deck.

f. On floating root sample hatch and recoil systems, inspect operation of recoil reel

and condition of rope.

g. Test operation of system.

611-F-005 Rev. 0 In-Service Storage Tank Inspection and Verification Checklist

STORAGE TANK IN SERVICE

INSPECTION CHECK LIST

Project Description

Client / End User Manufacture

Code / Standard API 653 Item / Tag No.

Completion result Comments

No Inspected Item Satis Remark

Good Poor Bad Accept Reject

factory

5 ROOF APPURTENANCES (Continue)

h. On ultra clean stock such as JP4, check for presence and condition of protective coating

or liner inside sample hatch (preventing rust from pipe getting into sample).

5.2 Gauge Well

a. Inspect visible portion of the gauge well for thinning, size of slots, and cover condition.

b. Check for hold-off distance marker and tab with hold-off distance (legible)

c. On floating roofs, inspect condition of roof guide for gauge well, particularly the condition

of the rollers for grooving.

d. If accessible, check the distance from the gauge well pipe to the tank shell

at different levels.

e. If tank has a gauge well washer, check valve for leakage and for presence of

a bull plug or blind flange.

5.3 Fixed Roof Scaffold Support

Inspect scaffold support for corrosion, wear, and structural soundness.

5.4 Autogauge : Inspection Hatch and Guides (Fixed Roof)

a. Check the hatch for corrosion and missing bolts.

b. Look for corrosion on the tape guide's and float guide's wire anchors.

5.5 Autogauge : Float Well Cover

a. Inspect for corrosion.

b. Check tape cable for wear or fraying caused by rubbing on the cover.

5.6 Sample Hatch (Internal Floating Roof)

a. Check overall condition.

b. When equipped with a fabric seal, check for automatic sealing after sampling.

c. When equipped with a recoil reel opening device, check for proper operations.

5.7 Roof-Mounted Vents (Internal Floating Roof)

Check condition of screens, locking and pivot pins.

5.8 Gauging Platform Drip Ring

On fixed roof tanks with drip rings under the gauging platform or sampling area,

inspect for plugged drain return to the tank.

611-F-005 Rev. 0 In-Service Storage Tank Inspection and Verification Checklist

STORAGE TANK IN SERVICE

INSPECTION CHECK LIST

Project Description

Client / End User Manufacture

Code / Standard API 653 Item / Tag No.

Completion result Comments

No Inspected Item Satis Remark

Good Poor Bad Accept Reject

factory

5 ROOF APPURTENANCES (Continue)

5.9 Emergency Roof Drains

Inspect vapor plugs for emergency drain : that seal fabric discs are slightly smaller

than the pipe ID and that fabric seal is above the liquid level.

5.10 Removable Roof Leg Racks

Check for leg racks on roof.

5.11 Vacuum Breakers

Report size, number, and type of vacuum breakers, inspect vacuum breakers,

if high legs are set, check for setting of mechanical breaker in high leg position.

5.12 Rim Vents

a. Check condition of the screen on the rim vent cover.

b. Check for plating off or removal of rim vents where jurisdictional rules do not permit removal.

611-F-005 Rev. 0 In-Service Storage Tank Inspection and Verification Checklist

STORAGE TANK IN SERVICE

INSPECTION CHECK LIST

Project Description

Client / End User Manufacture

Code / Standard API 653 Item / Tag No.

Completion result Comments

No Inspected Item Satis Remark

Good Poor Bad Accept Reject

factory

COMMENT and RECOMMENDATION :

Name Date Sign

611-F-005 Rev. 0 In-Service Storage Tank Inspection and Verification Checklist

You might also like

- Checklist For Testing Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing Commissioning of Sprinkler SystemMuhammad Fathullah bin SuhailiNo ratings yet

- In-Service Storage Tank Inspection and Verification ChecklistDocument9 pagesIn-Service Storage Tank Inspection and Verification ChecklistAshif Khan100% (1)

- Annexure 3 External Inspection ChecklistDocument5 pagesAnnexure 3 External Inspection Checklistankur100% (1)

- Logbook KoDocument13 pagesLogbook KoMarkmar AnchetaNo ratings yet

- Checklist For Testing & Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing & Commissioning of Sprinkler Systembeho2000100% (6)

- Checklist For Under Ground Water Piping InstallationDocument1 pageChecklist For Under Ground Water Piping InstallationBelal Alrwadieh100% (1)

- Piping Field Inspection Checklist DikonversiDocument3 pagesPiping Field Inspection Checklist DikonversiJo Francesc100% (2)

- Procedure D'inspectionDocument9 pagesProcedure D'inspectionsalahjallali100% (2)

- Inspection Report For TANK 102-Rev.0Document41 pagesInspection Report For TANK 102-Rev.0walid100% (1)

- SOP Overhead Crane-Rev.1Document5 pagesSOP Overhead Crane-Rev.1RonniNo ratings yet

- Scope of WorkDocument7 pagesScope of WorkKriengsak Ruangdech100% (3)

- Of in Service Storage Tank Inspection and Verification ChecklistDocument14 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- Of in Service Storage Tank Inspection and Verification ChecklistDocument16 pagesOf in Service Storage Tank Inspection and Verification Checklistkevin RichNo ratings yet

- Checklist For Installation of Underground Checmical Waste TanksDocument1 pageChecklist For Installation of Underground Checmical Waste TanksDiana Abu Hassan HatoumNo ratings yet

- T48. Annexure - 11 RFT Check SheetDocument11 pagesT48. Annexure - 11 RFT Check SheetarissaNo ratings yet

- Jash Engineering LTD.: Quality Assurance PlanDocument3 pagesJash Engineering LTD.: Quality Assurance PlanShree ConstructionNo ratings yet

- API 653 Tank InspectionDocument53 pagesAPI 653 Tank InspectionWàhränî Là Cläşş100% (3)

- Visit Report - 312Document4 pagesVisit Report - 312Vinay YadavNo ratings yet

- Weld Visual Report Rev.0Document1 pageWeld Visual Report Rev.0John TerryNo ratings yet

- List of InspectionDocument17 pagesList of InspectionNQTNo ratings yet

- LegendDocument6 pagesLegendDheska AgungwNo ratings yet

- Formwork ChecklistDocument1 pageFormwork Checklistdeonstuurman777No ratings yet

- Checklist For T&C of Chemical Fire Suppression SystemDocument2 pagesChecklist For T&C of Chemical Fire Suppression Systembeho2000No ratings yet

- Inspection Plan For Pipe LineDocument4 pagesInspection Plan For Pipe LineArfanAliNo ratings yet

- Form ITP Storage TankDocument4 pagesForm ITP Storage Tanksuratno 25No ratings yet

- Verif EPI GRIGRI Procedure enDocument3 pagesVerif EPI GRIGRI Procedure eninternetNo ratings yet

- Verif EPI Poulies Procedure ENDocument3 pagesVerif EPI Poulies Procedure ENaliya azharNo ratings yet

- Fabrication & Erection of Steel Works ChecklistDocument1 pageFabrication & Erection of Steel Works ChecklisttaghlubNo ratings yet

- Oqc Check Sheet - 12Document5 pagesOqc Check Sheet - 12prabu cNo ratings yet

- Pressure Vessel Inspection Procedure: 1. ScopeDocument9 pagesPressure Vessel Inspection Procedure: 1. ScopeZeno PaulNo ratings yet

- Tank Erection Itp Org ChartDocument34 pagesTank Erection Itp Org Chartvasantha kumar100% (1)

- Saudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEDocument2 pagesSaudi Aramco Test Report: Vaccum Box Leak Test Report 15-Dec-09 MECH-NDEWaleed MedhatNo ratings yet

- Sample Report-2Document35 pagesSample Report-2raulNo ratings yet

- MonitoringDocument1 pageMonitoringRey GeraldinoNo ratings yet

- Sample - Cda ChecklistDocument2 pagesSample - Cda ChecklistVicevar PerezNo ratings yet

- Chick List CivilDocument12 pagesChick List CivilMohamed TaherNo ratings yet

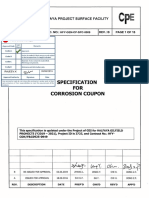

- HFY-GEN-CP-SPC-0009 - B Specification For Corrosion Coupon - Code-ADocument15 pagesHFY-GEN-CP-SPC-0009 - B Specification For Corrosion Coupon - Code-ATahir FadhilNo ratings yet

- Inspection and Test Plan-LIT Project - 3.1.2024Document11 pagesInspection and Test Plan-LIT Project - 3.1.2024rhannie garciaNo ratings yet

- QA&QC D4010.15160.05-FIre & Jockey Rev01Document3 pagesQA&QC D4010.15160.05-FIre & Jockey Rev01Non Etabas GadnatamNo ratings yet

- Tank Check List - Standard APIAS1940Document17 pagesTank Check List - Standard APIAS1940Dimitris NikouNo ratings yet

- SJV-EP-IA-011-VP-003 - DATA SHEET - 190117 - 최종Document15 pagesSJV-EP-IA-011-VP-003 - DATA SHEET - 190117 - 최종Jahangir AlamNo ratings yet

- Fbe-Coated ProcessDocument5 pagesFbe-Coated ProcessOmar WardehNo ratings yet

- SEPARATOR S22 Preliminary Revision 00Document17 pagesSEPARATOR S22 Preliminary Revision 00Ahmed MohammedNo ratings yet

- Pre-Shipment Inspection: Product PhotoDocument35 pagesPre-Shipment Inspection: Product Photo123456No ratings yet

- Form HRSBDocument9 pagesForm HRSBMehdi SoltaniNo ratings yet

- HookDocument5 pagesHookHarris ShehzadNo ratings yet

- Amc QapDocument8 pagesAmc QapSasanka SekharNo ratings yet

- QA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeDocument2 pagesQA/QC Inspection Checklist: Design Coordinates, Inc. CP No. - Vector ThreeNon Etabas GadnatamNo ratings yet

- QA&QC D2020.15100.05-Water Supply Pumps Rev01Document3 pagesQA&QC D2020.15100.05-Water Supply Pumps Rev01Non Etabas GadnatamNo ratings yet

- MPP & Itt - Internal Epoxy PaintDocument12 pagesMPP & Itt - Internal Epoxy PaintSiswo YuwonoNo ratings yet

- 653 231rev0Document16 pages653 231rev0Badiuzzama786No ratings yet

- Ray Itp For PaitingDocument18 pagesRay Itp For PaitingVinayaga MoorthiNo ratings yet

- Distribution PanelDocument5 pagesDistribution PanelSourav RanaNo ratings yet

- Sample Report-Handphone-电子电器-耳机Document19 pagesSample Report-Handphone-电子电器-耳机raulNo ratings yet

- FF Water Sprinkler Test ProcedureDocument2 pagesFF Water Sprinkler Test ProcedureSalim Bakhsh100% (1)

- GCP Sect5RB RB LineDocument25 pagesGCP Sect5RB RB Linelevanvui161No ratings yet

- Project Name Project No.: OOOO: General Cable Pulling WorksDocument8 pagesProject Name Project No.: OOOO: General Cable Pulling WorksReynante AlimNo ratings yet

- Verif Epi Protraxion Procedure enDocument4 pagesVerif Epi Protraxion Procedure eninternetNo ratings yet

- SOP Mobile Crane-Rev.1Document7 pagesSOP Mobile Crane-Rev.1RonniNo ratings yet

- Drilling String InspectionDocument7 pagesDrilling String Inspectionrais ridha100% (2)

- 400V LV Feeder ListDocument14 pages400V LV Feeder ListZohaib AlamNo ratings yet

- Energy Vs HydrologyDocument8 pagesEnergy Vs HydrologyZohaib AlamNo ratings yet

- Appendices: 13.1. Appendix 1: Project FeaturesDocument2 pagesAppendices: 13.1. Appendix 1: Project FeaturesZohaib AlamNo ratings yet

- Compensatory Duty:: KOEN AJ&K Branch OfficeDocument1 pageCompensatory Duty:: KOEN AJ&K Branch OfficeZohaib AlamNo ratings yet

- Incentive PolicyDocument1 pageIncentive PolicyZohaib AlamNo ratings yet

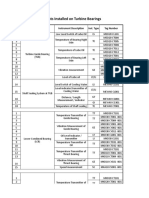

- Bearings Details & AuxDocument3 pagesBearings Details & AuxZohaib AlamNo ratings yet

- Permission Letter For KioskDocument3 pagesPermission Letter For KioskZohaib Alam100% (1)

- Gad AccomplishementxlsxDocument4 pagesGad AccomplishementxlsxDenielle DelosoNo ratings yet

- Effects of Grape Seed Oil Nanoemulsion On Physicochemical and Antibacterial Properties of Gelatin Sodium Alginate Film BlendsDocument12 pagesEffects of Grape Seed Oil Nanoemulsion On Physicochemical and Antibacterial Properties of Gelatin Sodium Alginate Film BlendsMohammad Hamayoon Norri100% (1)

- Deep Sea Mining PresentationDocument14 pagesDeep Sea Mining Presentationganesh100% (1)

- Jurnal Hubungan Kebisingan Dengan Tingkat Stress PekerjaDocument12 pagesJurnal Hubungan Kebisingan Dengan Tingkat Stress PekerjaKafi MuhammadNo ratings yet

- Basics of EKG InterpretationDocument132 pagesBasics of EKG InterpretationArif Imam HidayatNo ratings yet

- Relationship Between Quality of Life and Social SupportDocument9 pagesRelationship Between Quality of Life and Social SupportDragos IvanNo ratings yet

- TSKII Series: In-Line Centrifugal Duct FanDocument4 pagesTSKII Series: In-Line Centrifugal Duct FanKarin Aca Ovi100% (1)

- Flanges: Figure 71 Flange Adapter (ANSI Class 125/150)Document2 pagesFlanges: Figure 71 Flange Adapter (ANSI Class 125/150)Mina MagdyNo ratings yet

- X Vs State of NCT of Delhi On 20 November 2017Document13 pagesX Vs State of NCT of Delhi On 20 November 2017Arihant RoyNo ratings yet

- CARPER (Comprehensive Agrarian Reform Program Extension With Reforms) RA 9700Document1 pageCARPER (Comprehensive Agrarian Reform Program Extension With Reforms) RA 9700megawhat115No ratings yet

- Restaurant - McdonaldsDocument9 pagesRestaurant - McdonaldsGABRIELA ELVIRA OSORIO MENDOZANo ratings yet

- 014EBM Degracia DB EtallDocument17 pages014EBM Degracia DB EtallMarinel Piol MarasiganNo ratings yet

- Iso 27001 ChecklistDocument8 pagesIso 27001 ChecklistALEX COSTA CRUZNo ratings yet

- Franciscan ThePulseNewsletterDocument4 pagesFranciscan ThePulseNewsletterJill McDonoughNo ratings yet

- Technical Report PeDocument75 pagesTechnical Report Penur hidayatiNo ratings yet

- Aubert Et Al. 2018Document3 pagesAubert Et Al. 2018LhuissetNo ratings yet

- Isa Cem: Comparatives and SuperlativesDocument7 pagesIsa Cem: Comparatives and SuperlativesAnonymous 7xhhVAWCXNo ratings yet

- Ent Emergencies: DR Mohammad Almayouf Associat Consultant ENTDocument27 pagesEnt Emergencies: DR Mohammad Almayouf Associat Consultant ENTMuhammad ANo ratings yet

- Safety Standard For Horizontal Carousel Material Handling and Associated EquipmentDocument19 pagesSafety Standard For Horizontal Carousel Material Handling and Associated EquipmentIntegrated Systems DesignNo ratings yet

- Wages For ESICDocument10 pagesWages For ESICvai8havNo ratings yet

- 09-22-2021 Original Complaint by Austin ISD Against District Over Covid-19 PoliciesDocument278 pages09-22-2021 Original Complaint by Austin ISD Against District Over Covid-19 PoliciesCBS Austin WebteamNo ratings yet

- Diagnosis and Management of Intrahepatic Cholangiocarcinoma: A Comprehensive Update For The RadiologistDocument22 pagesDiagnosis and Management of Intrahepatic Cholangiocarcinoma: A Comprehensive Update For The RadiologistNadia HamdaniNo ratings yet

- Best Scented Candles in IndiaDocument9 pagesBest Scented Candles in IndiaBrandon JohnNo ratings yet

- Elpido Ines Jr. MD, Mha Medical Director Elpido Ines Jr. MD, Mha Medical DirectorDocument3 pagesElpido Ines Jr. MD, Mha Medical Director Elpido Ines Jr. MD, Mha Medical Directorcriselda desistoNo ratings yet

- Maquina Do Wando PDFDocument76 pagesMaquina Do Wando PDFGlauber AquinoNo ratings yet

- 2010 CM Engineering Manual Pefy-Nmsu-Nmau-NmhuDocument60 pages2010 CM Engineering Manual Pefy-Nmsu-Nmau-NmhuEli Montano VegaNo ratings yet

- Mens's 6-8 Minute WorkoutDocument3 pagesMens's 6-8 Minute WorkoutVictor WoodsNo ratings yet

- Clean Room DetailDocument40 pagesClean Room DetailAjay SastryNo ratings yet