Professional Documents

Culture Documents

Welding Procedure Specification: JOINTS (QW-402)

Welding Procedure Specification: JOINTS (QW-402)

Uploaded by

Nitin KurupCopyright:

Available Formats

You might also like

- Ford E-Series Electrical Wiring Diagrams PDFDocument28 pagesFord E-Series Electrical Wiring Diagrams PDFjgarfield42086% (7)

- Distillation Column Diameter Calculation - Reference TrybalDocument7 pagesDistillation Column Diameter Calculation - Reference TrybalNitin Kurup100% (1)

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Document12 pagesPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNo ratings yet

- Welding Procedure Specification - TemplateDocument2 pagesWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (4)

- Physics Cheat SheetDocument1 pagePhysics Cheat Sheetjlvmrbd7770% (1)

- Quiz 3Document8 pagesQuiz 3Dhruv Sahni100% (1)

- Prpposed Welding Procedure Specification (WPS) : Code: Asme Ix API 1104 AWS D1.1Document1 pagePrpposed Welding Procedure Specification (WPS) : Code: Asme Ix API 1104 AWS D1.1MohamedNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationHasan Ahmed100% (1)

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 pagesWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNo ratings yet

- Wps PQR A3620 PDFDocument5 pagesWps PQR A3620 PDFHamid MansouriNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- First: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesDocument3 pagesFirst: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesAhmed AbdoNo ratings yet

- Welding Procedure Specification: Backing MaterialDocument2 pagesWelding Procedure Specification: Backing MaterialDiki ArmandoNo ratings yet

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin Romero100% (2)

- 3-Actual Exams Last Edition (ASME IX)Document6 pages3-Actual Exams Last Edition (ASME IX)Hares SlalNo ratings yet

- (Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMDocument2 pages(Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMpraveesh qc2023No ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- KKJV WPS PP01Document2 pagesKKJV WPS PP01serbay tuncaNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- 1108-DES-005 Rev02Document1 page1108-DES-005 Rev02Omar TocmoNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- Ongc WPS 1 of 2Document4 pagesOngc WPS 1 of 2Kiran NikateNo ratings yet

- Asme PQRDocument4 pagesAsme PQRHong Dae Yoon100% (2)

- WPS-01 - FCAW-3G - (E250BR To E250BR-A36) - CSWIP - 03.10.2023 (Group-1) - Groove JointsDocument11 pagesWPS-01 - FCAW-3G - (E250BR To E250BR-A36) - CSWIP - 03.10.2023 (Group-1) - Groove JointsMohammad AdilNo ratings yet

- PWPS DonpyDocument1 pagePWPS DonpyANDINTA MUDA YUSUFNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- Asme Wps DemoDocument3 pagesAsme Wps Demoharis saleemNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNo ratings yet

- SILVER-WPS-GESA-07 8mm To 16mm SAW LW P1.2 TO P1.2 - PQR-0036-W-21Document2 pagesSILVER-WPS-GESA-07 8mm To 16mm SAW LW P1.2 TO P1.2 - PQR-0036-W-21Abdulmecit YetisNo ratings yet

- PWPS 102Document2 pagesPWPS 102Cyril J PadiyathNo ratings yet

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- SILVER-WPS-GESA-09 5mm To 28mm SAW BW P1.2 TO P1.2 - PQR-0052-W-18Document2 pagesSILVER-WPS-GESA-09 5mm To 28mm SAW BW P1.2 TO P1.2 - PQR-0052-W-18Abdulmecit YetisNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- WQT Form (AWS D1.1) 04-23Document1 pageWQT Form (AWS D1.1) 04-23hanz bermejoNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- WPS Tsila 012Document2 pagesWPS Tsila 012AslaouiNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- List WPS Piping New 2023Document1 pageList WPS Piping New 2023YUDI IRMAWANTONo ratings yet

- 6gr Smaw WQTR - F. Edilo (Sn-189)Document1 page6gr Smaw WQTR - F. Edilo (Sn-189)hanz bermejoNo ratings yet

- 001 WPS Cntim 2023Document10 pages001 WPS Cntim 2023shangyuan1079163.comNo ratings yet

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNo ratings yet

- Hfy2 E1890 CPF1WT WLD SPC 0008Document3 pagesHfy2 E1890 CPF1WT WLD SPC 0008Firas AlbaweiNo ratings yet

- Qw-482 Welding Procedure Specification (WPS) : (Automatic, Manual, Machine or Semi-Auto)Document2 pagesQw-482 Welding Procedure Specification (WPS) : (Automatic, Manual, Machine or Semi-Auto)BalasahebNo ratings yet

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- WPS 684 CS 012Document3 pagesWPS 684 CS 012siva8000100% (1)

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Computer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- Enmax Engineering (India) PVT - LTD Survey No.15, Suraram, Hyderabad - 500 055, IndiaDocument2 pagesEnmax Engineering (India) PVT - LTD Survey No.15, Suraram, Hyderabad - 500 055, IndiaSampath KumarNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Solvent Properties - NewDocument10 pagesSolvent Properties - NewNitin KurupNo ratings yet

- Fluid - Machinery Unit 4Document12 pagesFluid - Machinery Unit 4Nitin KurupNo ratings yet

- (Refer Page 5) HPLC - Access - Cat - 2013 - ValvesDocument6 pages(Refer Page 5) HPLC - Access - Cat - 2013 - ValvesNitin KurupNo ratings yet

- Kom LabDocument15 pagesKom LabNitin KurupNo ratings yet

- Valve CV Calculation Tool Liquid: Value UnitDocument11 pagesValve CV Calculation Tool Liquid: Value UnitNoureddine MerahNo ratings yet

- Pump Calc PranayDocument24 pagesPump Calc PranayNitin KurupNo ratings yet

- Booklet On Biomass Conversion Technologies 2021Document122 pagesBooklet On Biomass Conversion Technologies 2021Nitin KurupNo ratings yet

- Goa Waste Management ModelDocument48 pagesGoa Waste Management ModelNitin KurupNo ratings yet

- Control Valve CVDocument11 pagesControl Valve CVNitin KurupNo ratings yet

- High Precision Double Piston Pump (p3000)Document5 pagesHigh Precision Double Piston Pump (p3000)Nitin KurupNo ratings yet

- FB 1203 CalibrationDocument10 pagesFB 1203 CalibrationNitin KurupNo ratings yet

- Distillation Column SizingDocument12 pagesDistillation Column SizingNitin Kurup0% (1)

- 511-CP02 KPD 25-16QFDocument3 pages511-CP02 KPD 25-16QFNitin KurupNo ratings yet

- 0 0 01 Oct 2015 1127076201AdditionalInformationsugarmillLtdDocument33 pages0 0 01 Oct 2015 1127076201AdditionalInformationsugarmillLtdNitin KurupNo ratings yet

- Mechanical Vapour Compression MVC BrochureDocument6 pagesMechanical Vapour Compression MVC BrochureNitin KurupNo ratings yet

- 23 GorakhpurDocument4 pages23 GorakhpurNitin KurupNo ratings yet

- MT8 Datasheet 0821Document8 pagesMT8 Datasheet 0821Nitin KurupNo ratings yet

- Isgec Sugar Distilleries Leaflet English Oct21Document4 pagesIsgec Sugar Distilleries Leaflet English Oct21Nitin KurupNo ratings yet

- Environmental Feasibility of Rice StrawDocument88 pagesEnvironmental Feasibility of Rice StrawNitin KurupNo ratings yet

- Subodh Kumar IocDocument18 pagesSubodh Kumar IocNitin KurupNo ratings yet

- Product Information: Sic at Sheet Membranes and ModulesDocument29 pagesProduct Information: Sic at Sheet Membranes and ModulesNitin KurupNo ratings yet

- Verbio GB 2019 ENDocument132 pagesVerbio GB 2019 ENNitin KurupNo ratings yet

- Panda WV 4500 B: BoosterDocument3 pagesPanda WV 4500 B: BoosterNitin KurupNo ratings yet

- PUMA WY 2000/4500 C: BoosterDocument3 pagesPUMA WY 2000/4500 C: BoosterNitin KurupNo ratings yet

- PUMA WPA 040-075 A: BoosterDocument3 pagesPUMA WPA 040-075 A: BoosterNitin KurupNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument3 pagesPump Performance Datasheet: Operating Conditions LiquidNitin KurupNo ratings yet

- R2004-3-8 AnnualDocument1 pageR2004-3-8 Annualkarthik100% (1)

- Ee8002 - Dem - Question Bank - Unit 1Document8 pagesEe8002 - Dem - Question Bank - Unit 1DEVINo ratings yet

- Oracle.2passeasy.1Z0 051.study - Guide.v2017 Jul 09.by - Marian.283q.vceDocument25 pagesOracle.2passeasy.1Z0 051.study - Guide.v2017 Jul 09.by - Marian.283q.vcePraveen KumarNo ratings yet

- Steven Sasson - WikipediaDocument14 pagesSteven Sasson - WikipediaCube Film ProductionNo ratings yet

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- Solution Manual To Introduction To Fluid MechanicDocument3 pagesSolution Manual To Introduction To Fluid MechanicHadibayatNo ratings yet

- A Study On Roadside Noise Generated by Tricycles: Karl N. Vergel Frielly T. Cacho and Cheryl Lyne E. CapizDocument22 pagesA Study On Roadside Noise Generated by Tricycles: Karl N. Vergel Frielly T. Cacho and Cheryl Lyne E. CapizJerry EsquivelNo ratings yet

- Wood Work Check ListDocument11 pagesWood Work Check ListbkgboqdraftsmanNo ratings yet

- Documentation Checklist: FSAE and Baja SAE Tube Structures Sept 1 2017 Preparing and Submitting Documents To VR3 For Review and RFQDocument3 pagesDocumentation Checklist: FSAE and Baja SAE Tube Structures Sept 1 2017 Preparing and Submitting Documents To VR3 For Review and RFQpequeno_brotherNo ratings yet

- Housingless MillsDocument51 pagesHousingless MillsvaibhavkumarjainNo ratings yet

- Study The Notes Below and Use The Information To Complete The Text PhoneDocument8 pagesStudy The Notes Below and Use The Information To Complete The Text PhoneTAARANo ratings yet

- DIVISIO 2000 Series - SIMPLEX - Maintenance: Author: Thomas KeimDocument20 pagesDIVISIO 2000 Series - SIMPLEX - Maintenance: Author: Thomas KeimNader KortNo ratings yet

- 42wkn 1pdDocument16 pages42wkn 1pdClaudiaFerrioliNo ratings yet

- Two Types of FixationDocument7 pagesTwo Types of FixationPOOJANo ratings yet

- TK5P50D DatasheetDocument10 pagesTK5P50D DatasheetJosé BosaNo ratings yet

- Manual Ohaus NavigatorDocument72 pagesManual Ohaus NavigatorEmmanuel Mariano GómezNo ratings yet

- Philippines-Flood Forecasting WarningDocument43 pagesPhilippines-Flood Forecasting WarningKen VillanuevaNo ratings yet

- UserscriptDocument8 pagesUserscriptapi-289675854No ratings yet

- Supplement 1 - Interim View of An Interpreter's Guide For eTOM and ITIL Practitioners PDFDocument54 pagesSupplement 1 - Interim View of An Interpreter's Guide For eTOM and ITIL Practitioners PDFShantamNo ratings yet

- SolidCAM 2015 Milling Training Course 2.5D MillingDocument315 pagesSolidCAM 2015 Milling Training Course 2.5D MillingJhayro GT100% (2)

- Manual HP71BDocument303 pagesManual HP71BGundisalvo Vega SanabriaNo ratings yet

- Touch Pro ManualDocument98 pagesTouch Pro ManuallandwolfeNo ratings yet

- Ajr - 400-24 - (B) - TR-L (Weg)Document2 pagesAjr - 400-24 - (B) - TR-L (Weg)irfanNo ratings yet

- Computer System Architecture MCA - 301Document10 pagesComputer System Architecture MCA - 301Mangesh MalvankarNo ratings yet

- BS en 1011-1-2005Document15 pagesBS en 1011-1-2005reezmanNo ratings yet

- 2009 TEREX TA400 Articulated Truck Parts ManualDocument448 pages2009 TEREX TA400 Articulated Truck Parts ManualEmmanuel DiazNo ratings yet

- Credit Evaluation Process FlowDocument1 pageCredit Evaluation Process FlowAbby CifraNo ratings yet

Welding Procedure Specification: JOINTS (QW-402)

Welding Procedure Specification: JOINTS (QW-402)

Uploaded by

Nitin KurupOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification: JOINTS (QW-402)

Welding Procedure Specification: JOINTS (QW-402)

Uploaded by

Nitin KurupCopyright:

Available Formats

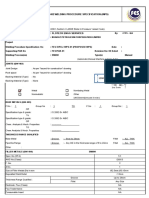

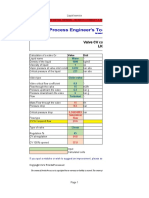

Doc No: CP-23-002

Rev: 01

WELDING PROCEDURE SPECIFICATION Date: 12-DEC-2015

Page: 1 of 3

Welding Procedure Specification no. RI-AMT-WPS-001 Revision No. 00 Date: 12-12-2015

Supporting PQR No.(s) TBA Date: 10-Dec-2015

Manufacturer: RISAL REDLAND INDUSTRIAL SERVICES (ARABIA) LTD.

Welding Process (es): GTAW+SMAW Type (s) * Manual

CODE: ASME IX ASME B31.3 AWS D1.1 OTHER SAES-W-11/W-12 ASME B31.4

* (Automatic, Manual, Machine or Semi-Auto)

JOINTS (QW-402) A= 60°~70°

Joint Design As per Drawing

Backing (Yes) N/A

Backing Material (Type) N/A

Base Matel (T) 12.7 mm T

Root Gap (G) 1.5~2.5 mm F

Root Face(F) 1~2 mm G

Angle of Bevel (A) 30°~35° *Refer to page no 3 for other application weld & weld joints

Bevel Preparation:- Flame cut, Machining / Grinding

BASE METALS (QW-403)

P.No. 1 Group No. 1 to P.No. 1 Group No. 1

OR

Specification type and grade API 5L Gr B or Equivalent

to specification type and grade API 5L Gr B or Equivalent

OR

Chem. Analysis and Mech. Prop. N/A

to Chem. Analysis and Mech. Prop. N.A

Thickness Range :

Base Metal : Groove 1.5 mm ~16.36 Fillet All

Pipe Dia Range: Groove All Fillet All

Other N/A

FILLER METALS (QW-404) Root Filling / Capping

Spec. No. (SFA) 5.18 5.1

AWS No. (Class) ER 70S-2 E 7018

F. No. 6 4

A.No. 1 1

Size of Electrode/Filler Wire 2.4 mm 2.5, 3.25, 4.00 mm

Filler Metal Product Type N/A N/A

Deposited Weld Metal: 4.0 mm 12.36 mm

Thickness Range :

Groove 1.5mm~4.0 mm upto 16.36 mm

Fillet All All

Flux --- ---

Electrode-Flux (Class) --- ---

Flux Trade Name --- ---

Consumable Insert --- ---

Other Brand ESAB, LINCLON ESAB / LINCLON

No single Pass is greater than 13 mm

Doc No: CP-23-002

Rev: 00

WELDING PROCEDURE SPECIFICATION Date: 12-DEC-2015

Page: 2 of 3

WPS No: RI-AMT-WPS-001

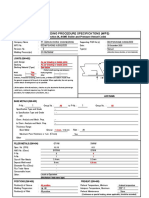

POSITIONS (QW-405) POST WELD HEAT TREATMENT (QW-407)

Position(s) of Groove All Temperature Range N/A

Welding Progression : Uphil Downhill SoakingTime N/A

Position(s) of Fillet All Rate of Heating N/A

Rate of Cooling N/A

PREHEAT (QW-406) GAS (QW-408)

Preheat Temp Min. 10°C Composition

* See table 3A & 3B of SAES-W-011 & SAES-W-012 Gas(es) Mixture % Flow rate(CFH)

Interpass Temp Max. 260 °C Shielding Argon 99.99% 25-30

Preheat Maintenance None Trailing

Backing

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC DC Polarity (SMAW ) Reverse + (GTAW) Straight

Amps (Range) 80~130 Amp Volts (Range) 10~25 V

(Amps and volts range should be recorded for each electrode size,

position, and thickness, etc. This information may be listed in a tabular

form similar to that shown below.)

Pulsing NO

Tungsten electrode Size and Type Ø 2.4 mm, Tungsten Electrode 2% Thoriated

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW N/A

(Spray arc, short circuiting arc, etc.)

TECHNIQUE (QW-410)

String or Weave bead Root: (String), Filling -Capping (Weaving 3ø of Electrode )

Orifice or Gas Cup Size 4~8 mm

Initial and Interpass Cleaning (Brushing, Grinding etc.) Wire brushing, Grinding

Method of Back Gouging Grinding

Oscillation N.A

Multiple or Single Pass (per side) Multiple

Multiple or Single Electrodes Single

Travel Speed (Range) 70~141 mm/min

Peening Not Allowed

Use of thermal Process N/A

Other N/A

Weld Filler Metal Current Volt Travel Speed Average Heat

Process Amp.

Layer (s) Class Dia. Mm DC Range Range(mm/min) Input(kj/mm)

Range

ROOT GTAW ER 70S-2 2.4 EN 100-105 10-12 70-75 0.93

HOT GTAW ER 70S-2 2.4 EN 122-127 11-12 122-127 0.69

FILL SMAW E 7018 3.2 EP 80-130 22-25 133-141 1.086

CAP SMAW E 7018 2.5 EP 89-94 21-23 112-117 1.056

PREPARED BY APPROVED BY REVIEWED BY

NAME. : WAQAS ALI NAME : _________________________ NAME : _________________________

SIGN : _________________ SIGN. : _________________________ SIGN.: _________________________

DATE : __________________ DATE : _________________________ DATE : _________________________

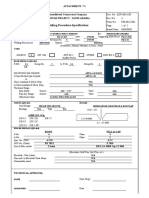

Doc No: CP-23-002

Rev: 00

WELDING PROCEDURE SPECIFICATION Date: 12-DEC-2015

Page: 3 of 3

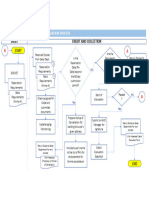

WELD & JOINT DETAILS WPS No: RI-AMT-WPS-001

You might also like

- Ford E-Series Electrical Wiring Diagrams PDFDocument28 pagesFord E-Series Electrical Wiring Diagrams PDFjgarfield42086% (7)

- Distillation Column Diameter Calculation - Reference TrybalDocument7 pagesDistillation Column Diameter Calculation - Reference TrybalNitin Kurup100% (1)

- PT. FAB: Proposed Welding Procedure Specification (PWPS)Document12 pagesPT. FAB: Proposed Welding Procedure Specification (PWPS)dharwinNo ratings yet

- Welding Procedure Specification - TemplateDocument2 pagesWelding Procedure Specification - TemplateDiosdado Mingi Jr.100% (4)

- Physics Cheat SheetDocument1 pagePhysics Cheat Sheetjlvmrbd7770% (1)

- Quiz 3Document8 pagesQuiz 3Dhruv Sahni100% (1)

- Prpposed Welding Procedure Specification (WPS) : Code: Asme Ix API 1104 AWS D1.1Document1 pagePrpposed Welding Procedure Specification (WPS) : Code: Asme Ix API 1104 AWS D1.1MohamedNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationHasan Ahmed100% (1)

- Welding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldDocument2 pagesWelding Procedure Specification (WPS) : Chip Back To The Sound Metal and Re-WeldAbdulmecit YetisNo ratings yet

- Wps PQR A3620 PDFDocument5 pagesWps PQR A3620 PDFHamid MansouriNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- First: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesDocument3 pagesFirst: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesAhmed AbdoNo ratings yet

- Welding Procedure Specification: Backing MaterialDocument2 pagesWelding Procedure Specification: Backing MaterialDiki ArmandoNo ratings yet

- Welding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Document2 pagesWelding Procedure Specification (WPS) : Asme Boiler and Pressure Vessel Code - Section Ix - Qw-482Edwin Romero100% (2)

- 3-Actual Exams Last Edition (ASME IX)Document6 pages3-Actual Exams Last Edition (ASME IX)Hares SlalNo ratings yet

- (Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMDocument2 pages(Automatic, Manual, Machine, or Semi-Auto) : 3-4 MM 1-5 MMpraveesh qc2023No ratings yet

- Astm 537 CL.1 WPSDocument2 pagesAstm 537 CL.1 WPSaudiihussain67% (3)

- KKJV WPS PP01Document2 pagesKKJV WPS PP01serbay tuncaNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- 1108-DES-005 Rev02Document1 page1108-DES-005 Rev02Omar TocmoNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- Ongc WPS 1 of 2Document4 pagesOngc WPS 1 of 2Kiran NikateNo ratings yet

- Asme PQRDocument4 pagesAsme PQRHong Dae Yoon100% (2)

- WPS-01 - FCAW-3G - (E250BR To E250BR-A36) - CSWIP - 03.10.2023 (Group-1) - Groove JointsDocument11 pagesWPS-01 - FCAW-3G - (E250BR To E250BR-A36) - CSWIP - 03.10.2023 (Group-1) - Groove JointsMohammad AdilNo ratings yet

- PWPS DonpyDocument1 pagePWPS DonpyANDINTA MUDA YUSUFNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- Asme Wps DemoDocument3 pagesAsme Wps Demoharis saleemNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 pagesNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidNo ratings yet

- SILVER-WPS-GESA-07 8mm To 16mm SAW LW P1.2 TO P1.2 - PQR-0036-W-21Document2 pagesSILVER-WPS-GESA-07 8mm To 16mm SAW LW P1.2 TO P1.2 - PQR-0036-W-21Abdulmecit YetisNo ratings yet

- PWPS 102Document2 pagesPWPS 102Cyril J PadiyathNo ratings yet

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- SILVER-WPS-GESA-09 5mm To 28mm SAW BW P1.2 TO P1.2 - PQR-0052-W-18Document2 pagesSILVER-WPS-GESA-09 5mm To 28mm SAW BW P1.2 TO P1.2 - PQR-0052-W-18Abdulmecit YetisNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Wps Ausa Gtaw Smaw 002 2018 Ok RDocument2 pagesWps Ausa Gtaw Smaw 002 2018 Ok RIvan Dario Carrillo Rubio0% (1)

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKDocument2 pagesWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaNo ratings yet

- WQT Form (AWS D1.1) 04-23Document1 pageWQT Form (AWS D1.1) 04-23hanz bermejoNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- WPS Tsila 012Document2 pagesWPS Tsila 012AslaouiNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- List WPS Piping New 2023Document1 pageList WPS Piping New 2023YUDI IRMAWANTONo ratings yet

- 6gr Smaw WQTR - F. Edilo (Sn-189)Document1 page6gr Smaw WQTR - F. Edilo (Sn-189)hanz bermejoNo ratings yet

- 001 WPS Cntim 2023Document10 pages001 WPS Cntim 2023shangyuan1079163.comNo ratings yet

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNo ratings yet

- Hfy2 E1890 CPF1WT WLD SPC 0008Document3 pagesHfy2 E1890 CPF1WT WLD SPC 0008Firas AlbaweiNo ratings yet

- Qw-482 Welding Procedure Specification (WPS) : (Automatic, Manual, Machine or Semi-Auto)Document2 pagesQw-482 Welding Procedure Specification (WPS) : (Automatic, Manual, Machine or Semi-Auto)BalasahebNo ratings yet

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- WPS 684 CS 012Document3 pagesWPS 684 CS 012siva8000100% (1)

- 004 Gtaw P5aDocument16 pages004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Computer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- Enmax Engineering (India) PVT - LTD Survey No.15, Suraram, Hyderabad - 500 055, IndiaDocument2 pagesEnmax Engineering (India) PVT - LTD Survey No.15, Suraram, Hyderabad - 500 055, IndiaSampath KumarNo ratings yet

- WPS Dissimilar 11.08 MM Max.Document4 pagesWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Solvent Properties - NewDocument10 pagesSolvent Properties - NewNitin KurupNo ratings yet

- Fluid - Machinery Unit 4Document12 pagesFluid - Machinery Unit 4Nitin KurupNo ratings yet

- (Refer Page 5) HPLC - Access - Cat - 2013 - ValvesDocument6 pages(Refer Page 5) HPLC - Access - Cat - 2013 - ValvesNitin KurupNo ratings yet

- Kom LabDocument15 pagesKom LabNitin KurupNo ratings yet

- Valve CV Calculation Tool Liquid: Value UnitDocument11 pagesValve CV Calculation Tool Liquid: Value UnitNoureddine MerahNo ratings yet

- Pump Calc PranayDocument24 pagesPump Calc PranayNitin KurupNo ratings yet

- Booklet On Biomass Conversion Technologies 2021Document122 pagesBooklet On Biomass Conversion Technologies 2021Nitin KurupNo ratings yet

- Goa Waste Management ModelDocument48 pagesGoa Waste Management ModelNitin KurupNo ratings yet

- Control Valve CVDocument11 pagesControl Valve CVNitin KurupNo ratings yet

- High Precision Double Piston Pump (p3000)Document5 pagesHigh Precision Double Piston Pump (p3000)Nitin KurupNo ratings yet

- FB 1203 CalibrationDocument10 pagesFB 1203 CalibrationNitin KurupNo ratings yet

- Distillation Column SizingDocument12 pagesDistillation Column SizingNitin Kurup0% (1)

- 511-CP02 KPD 25-16QFDocument3 pages511-CP02 KPD 25-16QFNitin KurupNo ratings yet

- 0 0 01 Oct 2015 1127076201AdditionalInformationsugarmillLtdDocument33 pages0 0 01 Oct 2015 1127076201AdditionalInformationsugarmillLtdNitin KurupNo ratings yet

- Mechanical Vapour Compression MVC BrochureDocument6 pagesMechanical Vapour Compression MVC BrochureNitin KurupNo ratings yet

- 23 GorakhpurDocument4 pages23 GorakhpurNitin KurupNo ratings yet

- MT8 Datasheet 0821Document8 pagesMT8 Datasheet 0821Nitin KurupNo ratings yet

- Isgec Sugar Distilleries Leaflet English Oct21Document4 pagesIsgec Sugar Distilleries Leaflet English Oct21Nitin KurupNo ratings yet

- Environmental Feasibility of Rice StrawDocument88 pagesEnvironmental Feasibility of Rice StrawNitin KurupNo ratings yet

- Subodh Kumar IocDocument18 pagesSubodh Kumar IocNitin KurupNo ratings yet

- Product Information: Sic at Sheet Membranes and ModulesDocument29 pagesProduct Information: Sic at Sheet Membranes and ModulesNitin KurupNo ratings yet

- Verbio GB 2019 ENDocument132 pagesVerbio GB 2019 ENNitin KurupNo ratings yet

- Panda WV 4500 B: BoosterDocument3 pagesPanda WV 4500 B: BoosterNitin KurupNo ratings yet

- PUMA WY 2000/4500 C: BoosterDocument3 pagesPUMA WY 2000/4500 C: BoosterNitin KurupNo ratings yet

- PUMA WPA 040-075 A: BoosterDocument3 pagesPUMA WPA 040-075 A: BoosterNitin KurupNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument3 pagesPump Performance Datasheet: Operating Conditions LiquidNitin KurupNo ratings yet

- R2004-3-8 AnnualDocument1 pageR2004-3-8 Annualkarthik100% (1)

- Ee8002 - Dem - Question Bank - Unit 1Document8 pagesEe8002 - Dem - Question Bank - Unit 1DEVINo ratings yet

- Oracle.2passeasy.1Z0 051.study - Guide.v2017 Jul 09.by - Marian.283q.vceDocument25 pagesOracle.2passeasy.1Z0 051.study - Guide.v2017 Jul 09.by - Marian.283q.vcePraveen KumarNo ratings yet

- Steven Sasson - WikipediaDocument14 pagesSteven Sasson - WikipediaCube Film ProductionNo ratings yet

- SAIC-W-2087 Post-Welding Visual Inspection PDFDocument2 pagesSAIC-W-2087 Post-Welding Visual Inspection PDFkarioke mohaNo ratings yet

- Solution Manual To Introduction To Fluid MechanicDocument3 pagesSolution Manual To Introduction To Fluid MechanicHadibayatNo ratings yet

- A Study On Roadside Noise Generated by Tricycles: Karl N. Vergel Frielly T. Cacho and Cheryl Lyne E. CapizDocument22 pagesA Study On Roadside Noise Generated by Tricycles: Karl N. Vergel Frielly T. Cacho and Cheryl Lyne E. CapizJerry EsquivelNo ratings yet

- Wood Work Check ListDocument11 pagesWood Work Check ListbkgboqdraftsmanNo ratings yet

- Documentation Checklist: FSAE and Baja SAE Tube Structures Sept 1 2017 Preparing and Submitting Documents To VR3 For Review and RFQDocument3 pagesDocumentation Checklist: FSAE and Baja SAE Tube Structures Sept 1 2017 Preparing and Submitting Documents To VR3 For Review and RFQpequeno_brotherNo ratings yet

- Housingless MillsDocument51 pagesHousingless MillsvaibhavkumarjainNo ratings yet

- Study The Notes Below and Use The Information To Complete The Text PhoneDocument8 pagesStudy The Notes Below and Use The Information To Complete The Text PhoneTAARANo ratings yet

- DIVISIO 2000 Series - SIMPLEX - Maintenance: Author: Thomas KeimDocument20 pagesDIVISIO 2000 Series - SIMPLEX - Maintenance: Author: Thomas KeimNader KortNo ratings yet

- 42wkn 1pdDocument16 pages42wkn 1pdClaudiaFerrioliNo ratings yet

- Two Types of FixationDocument7 pagesTwo Types of FixationPOOJANo ratings yet

- TK5P50D DatasheetDocument10 pagesTK5P50D DatasheetJosé BosaNo ratings yet

- Manual Ohaus NavigatorDocument72 pagesManual Ohaus NavigatorEmmanuel Mariano GómezNo ratings yet

- Philippines-Flood Forecasting WarningDocument43 pagesPhilippines-Flood Forecasting WarningKen VillanuevaNo ratings yet

- UserscriptDocument8 pagesUserscriptapi-289675854No ratings yet

- Supplement 1 - Interim View of An Interpreter's Guide For eTOM and ITIL Practitioners PDFDocument54 pagesSupplement 1 - Interim View of An Interpreter's Guide For eTOM and ITIL Practitioners PDFShantamNo ratings yet

- SolidCAM 2015 Milling Training Course 2.5D MillingDocument315 pagesSolidCAM 2015 Milling Training Course 2.5D MillingJhayro GT100% (2)

- Manual HP71BDocument303 pagesManual HP71BGundisalvo Vega SanabriaNo ratings yet

- Touch Pro ManualDocument98 pagesTouch Pro ManuallandwolfeNo ratings yet

- Ajr - 400-24 - (B) - TR-L (Weg)Document2 pagesAjr - 400-24 - (B) - TR-L (Weg)irfanNo ratings yet

- Computer System Architecture MCA - 301Document10 pagesComputer System Architecture MCA - 301Mangesh MalvankarNo ratings yet

- BS en 1011-1-2005Document15 pagesBS en 1011-1-2005reezmanNo ratings yet

- 2009 TEREX TA400 Articulated Truck Parts ManualDocument448 pages2009 TEREX TA400 Articulated Truck Parts ManualEmmanuel DiazNo ratings yet

- Credit Evaluation Process FlowDocument1 pageCredit Evaluation Process FlowAbby CifraNo ratings yet