Professional Documents

Culture Documents

How To Prepare For An Inspection - Most Common GMP Deficiencies by T. Hecker

How To Prepare For An Inspection - Most Common GMP Deficiencies by T. Hecker

Uploaded by

furqan.malikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Prepare For An Inspection - Most Common GMP Deficiencies by T. Hecker

How To Prepare For An Inspection - Most Common GMP Deficiencies by T. Hecker

Uploaded by

furqan.malikCopyright:

Available Formats

THE EUROPEAN

DIRECTORATE FOR THE

QUALITY OF MEDICINES

& HEALTHCARE

(EDQM)

Module 8

The EDQM Inspection Programme

How to prepare for an Inspection

&

Most common GMP Deficiencies

Dr Thomas HECKER

GMP Inspector

Certification of Substances Department

2 © EDQM, Council of Europe, 2021. All rights reserved.

Agenda

AVOIDING DEFICIENCIES

or

or

GETTING PREPARED?

?

3 © EDQM, Council of Europe, 2021. All rights reserved.

Preparation - BEFORE

Product(s)

per Official

Workshop Document*

First Contact Second

2-3 months Contact Send via

Inspection = Countries ahead of

=

express

History supplied the mail/courier

Site Status inspection Notification of and email

Review* Inspection

Informs

Production

status about exact

(ongoing, dates, API

shutdowns and

inspectors

*Refusal may lead to

etc.)

*simplified regulatory actions

4 © EDQM, Council of Europe, 2021. All rights reserved.

BEFORE: The Company should

Prepare and provide Send Invitation Letters

requested documents

(e.g. SMF)

Provide support in

Hotel booking

Pay Travel Expenses &

Appoint skilled Inspection Fees

Interpreters

(if needed)

Organise lunch during

Organise transfers

the inspection

(hotel, airport, factory)

5 © EDQM, Council of Europe, 2021. All rights reserved.

BEFORE: The Company should not

Notify undeclared

Paint premises and

changes in the CEP Interrupt Production

equipment

dossier

Create, rewrite, Perform not scheduled Draft new or update

manipulate documents maintenance activities procedures (Except if already

foreseen)

Hire new staff

members (Except already

foreseen)

6 © EDQM, Council of Europe, 2021. All rights reserved.

Not yet over: BEFORE…

Some further points to be noted:

• EDQM informs local Inspectorate about the dates and scope of the inspection

• EDQM welcomes the presence of local inspectors as observers

• An inspection schedule is sent to the company about one week before

inspection starts

7 © EDQM, Council of Europe, 2021. All rights reserved.

DURING the inspection

General Points to consider:

• Ensure ability to retrieve any document:

• Documents to be provided as fast as possible

• Ensure that the “Inspection War Room” is close to the meeting room

• Even if requested documents are not embedded in the Company’s quality system, they

should be made available to the team as can provide valuable additional information

• Instruct the staff members to answer to inspectors’ questions straightforward, clearly and

honestly, in order to be able to maintain trust and confidence

8 © EDQM, Council of Europe, 2021. All rights reserved.

DURING: Plant Tour

9 © EDQM, Council of Europe, 2021. All rights reserved.

DURING: Plant Tour cont.

Inspectors may:

• Deviate from schedule and suggested directions

• Split during the plant tour

• Request access to any area if they feel that they can be related to the scope of

the inspection

• Ask questions directly to staff members involved in manufacturing operations

• Use digital cameras as auxiliary means (unless not permitted for safety

reasons)

• Call for a daily wrap-up meeting if serious observations were made

10 © EDQM, Council of Europe, 2021. All rights reserved.

INSPECTION: After

• Replies to be fully documented:

• Commitments, deadline, description of the corrective action; commitments

should reflect what has or will actually be done

• Copies of procedures (translated into English if needed)

• Pictures

• Replies to be provided in electronic format

• Pdf format

• Annexes should be bookmarked

• Discrepancies with the CEP dossier are specifically addressed and

managed by the revision process at EDQM

11 © EDQM, Council of Europe, 2021. All rights reserved.

GMP Deficiencies

12 © EDQM, Council of Europe, 2021. All rights reserved.

EDQM on-site inspections deficiencies

13 © EDQM, Council of Europe, 2021. All rights reserved.

800 Classification of deficiencies per GMP area 2017-2019

726

700

600

Critical

500

Major

400 379 Other

293

300

206

200

130

104

100

43 40

31 30

19

3 1 3 0 1 0 3

0

QUALITY BUILDINGS & PRODUCTION, MATERIAL LABORATORY COMPLIANCE TO

RELATED EQUIPMENT REJECTION, MANAGEMENT, CONTROLS CEP DOSSIER

MATTERS REUSE STORAGE ETC.

14 © EDQM, Council of Europe, 2021. All rights reserved.

Quality related GMP violations: QA Oversight

Failure to effectively

control documentation

(both paper and

electronic)

Underreporting

and/or

insufficient

Inadequate Insufficient investigation of

overview of oversight of quality events

production and (complaints,

laboratory quality unit deviations, out-

activities over GMP of-specification

activities results, change

controls)

15 © EDQM, Council of Europe, 2021. All rights reserved.

Quality related GMP violations - Documentation

Rewriting documents

in order to Unavailability

demonstrate of records

acceptable,

expected or

presentable results, Untimely

values or dates recording

of operations, e.g.

before (sic!)

or far to late

Use of loose sheets

instead of bound logbooks

16 © EDQM, Council of Europe, 2021. All rights reserved.

Quality related GMP violations: Miscellaneous

• Quality Risk Management not applied or inadequately implemented in areas such

as production activities, deviations, change control, etc.

• Insufficient validation, e.g.:

o processes such as use of recovered solvents, blending or micronisation not always addressed;

o lack of sound knowledge of different approaches regarding cleaning validation.

• Insufficient personnel training, e.g.:

o no training given to upper management with regard to GMP related matters;

o no assessment of training’s efficiency or with limited value

17 © EDQM, Council of Europe, 2021. All rights reserved.

GMP Violations related to Buildings and Facilities

• Risks of contamination and/or cross-contamination arising from:

• improper design of facilities;

• inadequate cleaning of equipment;

• insufficient maintenance of equipment.

• Lack of appropriate user requirement specifications concerning equipment

qualification

18 © EDQM, Council of Europe, 2021. All rights reserved.

GMP Violations: Computerised Systems (CS)

No or insufficient

Lack of appropriate user management of access

requirement specifications levels (risk of loss of

traceability)

Insufficient knowledge of No or insufficient review of

CS validation requirements audit trail

IT staff lacking or without

Insufficient controls to

knowledge of GMP

prevent data manipulation

requirements

19 © EDQM, Council of Europe, 2021. All rights reserved.

GMP Violations: Other areas

Production:

• Blending of batches without prior appropriate testing;

• Lack of control of solvent recovery.

Materials management:

• Insufficient approval and/or management of vendors of key starting materials or

intermediates (e.g. unreliable on-site audits);

• Risk of loss of traceability due to insufficient identification of containers;

• Improper storage conditions (temperature, humidity, non-controlled storage

facilities…).

Sub-contracted activities:

• Insufficient qualification of subcontractors (against GMP)

• Quality agreements without or poorly identified responsibilities

20 © EDQM, Council of Europe, 2021. All rights reserved.

GMP Violations: Quality Control

Fraudulent practices Unreliable microbiological results

regarding testing

activities, e.g.:

pretesting or “testing

into compliance”;

deleting OOS results;

unreliability of Issues with Chemical reference standards,

analytical results e.g. absence of the Ph. Eur. CRS;

insufficient establishment of secondary standards

21 © EDQM, Council of Europe, 2021. All rights reserved.

GMP Violations: Data Integrity

200 7

2015-2019 DI deficiencies Usual breaches of data integrity:

180 • documentation practices;

160 81 • laboratory controls;

140

120 3 Critical

• validation and controls on

100

Major

Other

computerised systems

4 57

80 24 (absence or gaps).

60 112

40 57 55

20

0

Total Paper Electronic

22 © EDQM, Council of Europe, 2021. All rights reserved.

Acknowledgements

• Dr Sotirios Paraschos, Inspector, EDQM

23 © EDQM, Council of Europe, 2021. All rights reserved.

Thank you for your attention

Stay connected with the EDQM

EDQM Newsletter: https://go.edqm.eu/Newsletter

LinkedIn: https://www.linkedin.com/company/edqm/

Twitter: @edqm_news

Facebook: @EDQMCouncilofEurope

© EDQM, Council of Europe, 2021. All rights reserved.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- White Paper My SAP ERP CGMPDocument44 pagesWhite Paper My SAP ERP CGMPfurqan.malik100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Assignment Academic Year 2021-22: BM565 Digital Business & New Technologies DR Muhammad HaqueDocument8 pagesAssignment Academic Year 2021-22: BM565 Digital Business & New Technologies DR Muhammad HaqueRahul SarkarNo ratings yet

- Standard Operating ProcedureDocument46 pagesStandard Operating Procedurefurqan.malikNo ratings yet

- 21CFR11 Assessment FAQ Metler Toledo STAREDocument51 pages21CFR11 Assessment FAQ Metler Toledo STAREfurqan.malikNo ratings yet

- The Big Five Personality Test (BFPT)Document6 pagesThe Big Five Personality Test (BFPT)furqan.malikNo ratings yet

- Information Security Requirements Checklist PDFDocument7 pagesInformation Security Requirements Checklist PDFfurqan.malikNo ratings yet

- Information Risk Assessment Handbook 0.05Document11 pagesInformation Risk Assessment Handbook 0.05furqan.malikNo ratings yet

- Information Security Requirements Checklist PDFDocument7 pagesInformation Security Requirements Checklist PDFfurqan.malikNo ratings yet

- Use The Linux Desktop: Section 2Document18 pagesUse The Linux Desktop: Section 2furqan.malikNo ratings yet

- Business Ethics 1Document15 pagesBusiness Ethics 1Nikita VithlaniNo ratings yet

- Ceha PDFDocument17 pagesCeha PDFMIGUELNo ratings yet

- The Use of Audiovisual Materials To Teach Pronunciation in The ESL:EFL ClassroomDocument14 pagesThe Use of Audiovisual Materials To Teach Pronunciation in The ESL:EFL ClassroomClaudia AntunesNo ratings yet

- LBR JWB Sesi 1 - Medika Adijaya - 2021Document11 pagesLBR JWB Sesi 1 - Medika Adijaya - 2021NahmaKidsNo ratings yet

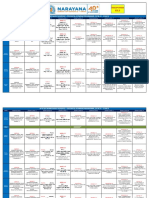

- AP X-SSC Board Micro Schedule - Etechno&Olympiad - 23.08.21-11.09.21Document3 pagesAP X-SSC Board Micro Schedule - Etechno&Olympiad - 23.08.21-11.09.21Raj RaoNo ratings yet

- 7 PFMDocument6 pages7 PFMSantosh ParvatikarNo ratings yet

- WEF Innovation and Cyber-Risk in Fin Serv 2017 12Document24 pagesWEF Innovation and Cyber-Risk in Fin Serv 2017 12Konstantin S. TrusevichNo ratings yet

- Hydraulics Calculations and Field Application of Radial Jet DrillingDocument11 pagesHydraulics Calculations and Field Application of Radial Jet DrillingAnonymous VNu3ODGavNo ratings yet

- Steel Futures April 09Document4 pagesSteel Futures April 09whwy99No ratings yet

- Unique and Common Traits in Mycorrhizal SymbiosesDocument12 pagesUnique and Common Traits in Mycorrhizal SymbiosesThắng Trần BảoNo ratings yet

- Concretemixdesign 150329082925 Conversion Gate01Document167 pagesConcretemixdesign 150329082925 Conversion Gate01PARASASRINIVASNo ratings yet

- JeopardyDocument51 pagesJeopardyapi-509133063No ratings yet

- DehDocument34 pagesDehAnand Swami100% (1)

- Instruction Manual: FVR-E11S-7EN FVR-E11S-4ENDocument116 pagesInstruction Manual: FVR-E11S-7EN FVR-E11S-4ENminh đạo nguyễnNo ratings yet

- Assessing The Effectiveness of Comic-Style Illustrations For Promoting Environmental SustainabilityDocument10 pagesAssessing The Effectiveness of Comic-Style Illustrations For Promoting Environmental SustainabilitymarikuzaNo ratings yet

- Rangeland SystemsDocument664 pagesRangeland Systemsalfonso lopez alquisirezNo ratings yet

- Affiliate Commission Report 202209241638Document224 pagesAffiliate Commission Report 202209241638Grupo AvancerNo ratings yet

- Driveline InformationDocument43 pagesDriveline InformationRodman7770% (1)

- Analogue and Digital RecordingDocument4 pagesAnalogue and Digital RecordingKavita koNo ratings yet

- Study Material: Free Master Class SeriesDocument21 pagesStudy Material: Free Master Class SeriesTinku SinglaNo ratings yet

- A Novel Neural Network Framework For The Prediction of Drilling Rate of PenetrationDocument11 pagesA Novel Neural Network Framework For The Prediction of Drilling Rate of PenetrationденисNo ratings yet

- MAN - CH - 2 - MCQsDocument6 pagesMAN - CH - 2 - MCQsSaquibh ShaikhNo ratings yet

- 01 Introduction KMDocument15 pages01 Introduction KMDiyana Sri WahyuNo ratings yet

- Class 10 Economics PDFDocument104 pagesClass 10 Economics PDFanirudhNo ratings yet

- Portland Slag Cement - Specification: Indian StandardDocument11 pagesPortland Slag Cement - Specification: Indian Standardদেবীসা দুর্গা সিনহাNo ratings yet

- Vacuum PumpDocument126 pagesVacuum PumpJessicalba Lou100% (3)

- Documentary: Mind Over Money: 1 2 3 4 5 6 7 8 9 10 A X X X B X X C X X X D X XDocument1 pageDocumentary: Mind Over Money: 1 2 3 4 5 6 7 8 9 10 A X X X B X X C X X X D X XCARLOTA MALDONADO MARTINNo ratings yet

- Voltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Document5 pagesVoltaic Cells: 1-Which of The Following Must Be True of A Salt Bridge?Moustafa NassarNo ratings yet

- Network Analysis of Chaotic Dynamics inDocument5 pagesNetwork Analysis of Chaotic Dynamics inansam.moh2016No ratings yet