Professional Documents

Culture Documents

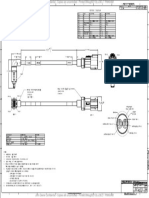

Prototype Print: 1 AT516772 1 Raw Weldment Painted Weldment, Lap Bar 2 T449786 1 Handlebar Lapbar Overmold

Prototype Print: 1 AT516772 1 Raw Weldment Painted Weldment, Lap Bar 2 T449786 1 Handlebar Lapbar Overmold

Uploaded by

Lilian ChangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prototype Print: 1 AT516772 1 Raw Weldment Painted Weldment, Lap Bar 2 T449786 1 Handlebar Lapbar Overmold

Prototype Print: 1 AT516772 1 Raw Weldment Painted Weldment, Lap Bar 2 T449786 1 Handlebar Lapbar Overmold

Uploaded by

Lilian ChangCopyright:

Available Formats

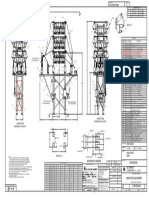

14 13 12 11 10 9 8 7 6 5 4 3 2 1

REV.

NOTIFICATION DATE BY CHANGE

8 7 6 5 4 3 1

PART NUMBER VERSION SHEET REV LET.

AT516773 JD90 1/1 B 0 * 04-20-21 AJW IMPORT

ZONE SYM DESCRIPTION CHANGE DOC

DATE (YYYY-MM-DD) APPROVED

CODY S.

B REDRAWN WITH CHANGES 569551YT 2021-02-19

DARLING

2

K K

D D

J J

(534.8)

478.9

INERSECTION OF INTERSECTION OF

2X 381.2 DATUMS A AND B

DATUMS A AND B

I I

C C

(⌀10.5 ±0.25)

VIEW FOR REFERENCE ONLY

SCALE 1:5

292.7

H B H

1 351.7

315.1

(703.4) A

2X 352.5

SEE DETAIL A

G G

B B

LOGO TO BE MOLDED

PART NUMBER

INTO INTEGRAL SKIN FOAM

AT516773

JD90

VERSION

F F

1/1

SHEET

REV

B

DETAIL A

SCALE ~13:20

1. THE PART SHOULD BE FREE FROM FLASHES

2 T449786 1 HANDLEBAR LAPBAR OVERMOLD

2. ALL OTHER DETAILS AS PER 3D CAD DATA

3. TEXTURE ON THE AESTHETIC SURFACE AS PER RAWAL RE-6465 1 AT516772 1 RAW WELDMENT PAINTED WELDMENT, LAP BAR

A 4. COLOR AS PER JDM F9TR MEDIUM GLOSS BLACK ITEM PART NUMBER QTY. PART NAME DESCRIPTION A

E 5. FOAM HARDNESS: 60 ± 10 (SHORE A) CONFIDENTIAL AND PROPRIETARY TO DEERE & COMPANY. ORIGINATOR E

6. A BOW OF 3mm IS ALLOWED ALONG THE LENGTH OF THE ARM PAD UNAUTHORIZED USE, DISCLOSURE, OR REPRODUCTION PROHIBITED.

COPYRIGHT Ⓒ DEERE & COMPANY. ALL RIGHTS RESERVED. INDRAJEET DESAI

ORIGINATION DATE REFERENCES: SCALE

7. MATERIAL: INTEGRAL SKIN FORM (POLYOL ISOCYANATE) MATERIAL 2020-01-10 JDS-G113 METRIC ~7:20

8. COMPONENTS MUST COMPLY WITH FMVSS-302/ISO-3795 ASSEMBLY MULTI MATERIAL

NAME

BAR SIZE

D

HORIZONTAL BURNING RATE LESS THAN OR EQUAL TO 100 MM/MIN LAP BAR CAGE CODE

9. TARGET DEPRESSION FORCE 20 ± 3Kg WITH ⌀ 80mm INDENTOR AT 12% COMPRESSION VERSION

10. UNLESS OTHERWISE SPECIFIED, ALL OUTER FEATURES DEERE & COMPANY JD90

⌓ 4 A B SIMULTANEOUS REQUIREMENT

SHEET

MOLINE, ILLINOIS 61265

1/1

PART NUMBER REVISION

AT516773 B

8 7 6 5 4 3 2 1

D D

C C

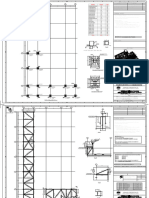

PROTOTYPE PRINT

THIS MODEL/DRAWING HAS NOT BEEN

RELEASED FOR PRODUCTION

JOHN DEERE P/N AT516773 METRIC DRAWING

FACILITIES AFFECTED NOTICE:

B B

SEARS DAVENPORT Yes THIS PART IS MODELED IN CREO. REVISIONS

SEARS EUROPE No TO THIS PART MUST BE MADE IN CREO.

SEARS BRAZIL No CREO PARAMETERS: PART No.: SA50775

SEARS SGA No REV.:0 LIFECYCLE STATE:Development

DESIGN CONTROL:NONE VERSION:0.0 DATE: May-13-21

SEE NOTES

FINISH: REF.

ENG. SPEC. SEE NOTES

NOTES: NOTE 1 The property hereon is the

1. USE SAME FOAM OVERMOLD TOOLING AS S28075 property of Sears Seating and/or

its subsidiaries. Without written

permissions, any copying,

transmittal to others and any use TITLE

except that for which it is

loaned, is prohibited. ASSY, LAP BAR, OVERMOLD

NOTE 2 Burrs and sharp edges to

UL 1439 or 10% maximum of material MATERIAL

A thickness not to exceed 0.25mm A

SEE NOTES

NOTE 3 Product chemical compliance

per ES0137

SCALE

TOLERANCES DRAWN

AJW 04-20-21 1.000

ANGLES 1

WHOLE NUMBERS 1.5

CHECKED

AJH XX-XX-XX

SHEET

1 OF 1

ONE PLACE DECIMAL 0.8 PART NO. DWG. SIZE REV. LTR

TWO PLACE DECIMAL 0.25 SA50775 E 0

(Unless otherwise specified the above will apply.)

14 13 12 11 10 9 8 7 6 5 4 3 2 1

You might also like

- 0417 - 118T3293 Cooling Sealing AirDocument6 pages0417 - 118T3293 Cooling Sealing AirfaisalnadimNo ratings yet

- Catalog VALSIR Canalizare PDFDocument60 pagesCatalog VALSIR Canalizare PDFAlexandru Ilioiu100% (1)

- Officially Released: July 23, 2008Document2 pagesOfficially Released: July 23, 2008eeyyee GsNo ratings yet

- Electrical Schematic E185 355 Fixed Speed Star DeltaDocument5 pagesElectrical Schematic E185 355 Fixed Speed Star DeltaRudy LashleyNo ratings yet

- 8410 SchematicsDocument19 pages8410 Schematicstolak anginNo ratings yet

- Checkprint 1808795 4E701Document1 pageCheckprint 1808795 4E701fangrui maiNo ratings yet

- Outline Drawing of Segment Lining (Basic Design) - V2Document51 pagesOutline Drawing of Segment Lining (Basic Design) - V2know netNo ratings yet

- Outline Drawing of Segment Lining (Basic Design) - V2Document51 pagesOutline Drawing of Segment Lining (Basic Design) - V2know netNo ratings yet

- AHIBA IR Pro Assembly Manual - REV BDocument13 pagesAHIBA IR Pro Assembly Manual - REV BAniceto Fernandez LimachiNo ratings yet

- Cost Estimation BundDocument81 pagesCost Estimation Bundmohan890No ratings yet

- Schematic, Electrical Wiring (Fs-Yd) 24276602 R: Detail ADocument3 pagesSchematic, Electrical Wiring (Fs-Yd) 24276602 R: Detail ArubenkolosovasNo ratings yet

- Raft Section A-A: 50 Thk. PCC 1:3:6 4 Thk. Water Proofing Membrane 100 Thk. PCC 1:4:8Document1 pageRaft Section A-A: 50 Thk. PCC 1:3:6 4 Thk. Water Proofing Membrane 100 Thk. PCC 1:4:8Omer HayatNo ratings yet

- Rev C MKR 37X Monopole Chain Installation DrawingDocument1 pageRev C MKR 37X Monopole Chain Installation Drawingudaykiranorange1986No ratings yet

- DRG-OT-561 - R02 - L-Clamp Assy (Vedang)Document7 pagesDRG-OT-561 - R02 - L-Clamp Assy (Vedang)Puneet SharmaNo ratings yet

- Rev1Document2 pagesRev1Deyvi Osmar Zegarra VillenaNo ratings yet

- 14 Wire 185344Document3 pages14 Wire 185344Anisa KumiNo ratings yet

- Montaje Plataforma Trabajo - 001209Document1 pageMontaje Plataforma Trabajo - 001209WilliamNo ratings yet

- Modulo CHM FTLDocument9 pagesModulo CHM FTLNestor Zela MamaniNo ratings yet

- IRN90-160k-Of AC-WC Electric SchematicDocument3 pagesIRN90-160k-Of AC-WC Electric Schematicsachin JoshiNo ratings yet

- Wiring Diagram: Ethernet Id Label EthernetDocument1 pageWiring Diagram: Ethernet Id Label EthernetRmz Rdz CarlosNo ratings yet

- Standard Machine (Sheet 1) : Diagram, Electro/Pneumatic Basic Regulation 22062608 EDocument2 pagesStandard Machine (Sheet 1) : Diagram, Electro/Pneumatic Basic Regulation 22062608 EJose Marie Asuncion100% (1)

- Standard Machine (Sheet 1) : Diagram, Electro/Pneumatic Basic Regulation 22062608 EDocument2 pagesStandard Machine (Sheet 1) : Diagram, Electro/Pneumatic Basic Regulation 22062608 EOscar ZavaletaNo ratings yet

- Diag, Schem Pp-Fire Protection 121T1290Document3 pagesDiag, Schem Pp-Fire Protection 121T1290Bounezra OussamaNo ratings yet

- Detail C-C Scale 2: 1: Cpu CardDocument1 pageDetail C-C Scale 2: 1: Cpu CardAhmed ShawkiNo ratings yet

- SD-9781 Rev 6Document13 pagesSD-9781 Rev 6Amresh KumarNo ratings yet

- G WatermarkedDocument5 pagesG WatermarkedRudy LashleyNo ratings yet

- View F-5 View F-3: REV ZoneDocument1 pageView F-5 View F-3: REV ZoneR- Md Masud Rana B-110No ratings yet

- Atlantic Version: Revisions CDocument4 pagesAtlantic Version: Revisions Cjuan lopezNo ratings yet

- Top Level Diagram: See Also CommunicationsDocument18 pagesTop Level Diagram: See Also CommunicationsSandra Yanira Vivas DiázNo ratings yet

- Electrical Schematic DiagramDocument3 pagesElectrical Schematic DiagramLeopoldo LiriosNo ratings yet

- CVT DP2 Typical Cable IntDocument25 pagesCVT DP2 Typical Cable IntAhmed El-FayoumyNo ratings yet

- 40 Ye - Edu Tre 101Document1 page40 Ye - Edu Tre 101Daniel F Paredes ManriqueNo ratings yet

- PB Waste Crane - PB Bunker Runway Beam - Waste Crane Mark UpDocument4 pagesPB Waste Crane - PB Bunker Runway Beam - Waste Crane Mark Upyip konglungNo ratings yet

- Grupo de Potência HidráulicaDocument24 pagesGrupo de Potência HidráulicaelizeuNo ratings yet

- Drawings r90 160 Vs Electrical SchematicDocument2 pagesDrawings r90 160 Vs Electrical Schematicingenieria4.0No ratings yet

- Elec Schematic 2658488584 - 015Document24 pagesElec Schematic 2658488584 - 015aidaluz achahui condoriNo ratings yet

- Reference Designator Symbol Legend: NotesDocument106 pagesReference Designator Symbol Legend: NotesVU ingenieriaNo ratings yet

- Ge Frame 9e DRY CLEAN SYSTEM PIDDocument2 pagesGe Frame 9e DRY CLEAN SYSTEM PIDAbbas AkbarNo ratings yet

- Pro Engineer: DescriptionDocument1 pagePro Engineer: DescriptionGonzalo GalvezNo ratings yet

- Rochester Civic Theatre's 72nd SeasonDocument1 pageRochester Civic Theatre's 72nd SeasoninforumdocsNo ratings yet

- Eep 000097 0102148005 3 ST Det 0669 R02Document1 pageEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalNo ratings yet

- Reference Drawings: General NotesDocument4 pagesReference Drawings: General NotesPrashant KhadtareNo ratings yet

- Window & Door Schedule: StudioDocument1 pageWindow & Door Schedule: StudioBatWing ZNo ratings yet

- GA - 24-50 Rev H: General Arrangement RXF 24 - 50 Screw Compressor PackageDocument1 pageGA - 24-50 Rev H: General Arrangement RXF 24 - 50 Screw Compressor Packagekemas biruNo ratings yet

- Preliminary - For Information Only Not For Design/ConstructionDocument4 pagesPreliminary - For Information Only Not For Design/ConstructionMarcoNo ratings yet

- Architectural 5Document1 pageArchitectural 5Cendrix PayaoNo ratings yet

- A D Section A-A: Lower Housing, R/A II, PB5X0Document7 pagesA D Section A-A: Lower Housing, R/A II, PB5X0zizouhicheNo ratings yet

- 536E4525 Gen Arr. RWF-II-222 Screw Compress.Document1 page536E4525 Gen Arr. RWF-II-222 Screw Compress.Jose TorrezNo ratings yet

- NOSE JACKING SA (TEB - Tool Equipment Bulletin)Document9 pagesNOSE JACKING SA (TEB - Tool Equipment Bulletin)Jivendra KumarNo ratings yet

- For Construction: 1 No Beam Required As Drawn MKD ' L0R0011Be110PDocument1 pageFor Construction: 1 No Beam Required As Drawn MKD ' L0R0011Be110PrajendraNo ratings yet

- FP202 FIRE PROTECTION PLAN - P3 Rev.8Document1 pageFP202 FIRE PROTECTION PLAN - P3 Rev.8Siddharth SoniNo ratings yet

- ASF DwgsDocument7 pagesASF DwgsAnis GharsellaouiNo ratings yet

- Diesel Engine Fire Pump Controller Negative Ground DC 24V:Gpd ModelDocument6 pagesDiesel Engine Fire Pump Controller Negative Ground DC 24V:Gpd ModelpochoNo ratings yet

- Clarkson Kga+ Dn1200 Nps48 HC RDC 08.ADocument1 pageClarkson Kga+ Dn1200 Nps48 HC RDC 08.AAlejandro Pupunovich RodriguezNo ratings yet

- 154D3502AA D: Elementary DiagramDocument1 page154D3502AA D: Elementary DiagramYas AlbNo ratings yet

- Construction Specs For Hvac Building WorksDocument77 pagesConstruction Specs For Hvac Building WorksSkylink Estimation TeamNo ratings yet

- Rev C MKR 370 DC Self Support Installation DrawingDocument1 pageRev C MKR 370 DC Self Support Installation DrawingPrasenjit DuttaNo ratings yet

- Tkis Elt 8353 LD 00008 - 000 - 00Document1 pageTkis Elt 8353 LD 00008 - 000 - 00Muhammed Abo-FandoodNo ratings yet

- Schematic, Electrical Wiring (Fixed Speed - Soft Starter) 23378540 FDocument2 pagesSchematic, Electrical Wiring (Fixed Speed - Soft Starter) 23378540 Fvalberto75No ratings yet

- Tolerance Map Models For Design and Manufacturing: MotivationDocument9 pagesTolerance Map Models For Design and Manufacturing: MotivationCahyono IriawanNo ratings yet

- 12th Imp Topics Chapter WiseDocument4 pages12th Imp Topics Chapter WiserampriyachinNo ratings yet

- IMOCSEA Infopack 900Document15 pagesIMOCSEA Infopack 900Ely SoemarniNo ratings yet

- Benevolence of IslamDocument9 pagesBenevolence of IslamfirdousNo ratings yet

- Unsteady Thermotopography in Non-Destructive Testing: January 1976Document6 pagesUnsteady Thermotopography in Non-Destructive Testing: January 1976Ciprian LupuNo ratings yet

- What Is Piezoelectric Sensor - Construction, Working & ApplicationsDocument4 pagesWhat Is Piezoelectric Sensor - Construction, Working & ApplicationsSam BelloNo ratings yet

- Chapter 7 Shell Tube Heat ExchangerDocument138 pagesChapter 7 Shell Tube Heat ExchangerPHƯƠNG ĐẶNG YẾNNo ratings yet

- FINGERPRINT - Price List - SOLUTION - July 2019Document4 pagesFINGERPRINT - Price List - SOLUTION - July 2019Nirmanamedia HRDNo ratings yet

- Bicenter Running ParametersDocument4 pagesBicenter Running ParametersJonathanNo ratings yet

- Civil Design That Puts You in The Passing LaneDocument4 pagesCivil Design That Puts You in The Passing Lanebbutros_317684077No ratings yet

- UG Demand Forecasting Revenue ManagementDocument16 pagesUG Demand Forecasting Revenue ManagementRadu BadoiuNo ratings yet

- Wittig ReactionDocument22 pagesWittig Reactionabubakar siddiqueNo ratings yet

- Aisi 1060Document3 pagesAisi 1060black_absynth0% (1)

- Autosar Products and Services (Maaz) : SoftwareDocument12 pagesAutosar Products and Services (Maaz) : Softwarethanhmaikmt123456No ratings yet

- Flex3D USER MANUAL EN V2.0Document33 pagesFlex3D USER MANUAL EN V2.0Hosmer ArrietaNo ratings yet

- FOC and DTCDocument69 pagesFOC and DTCRaed MohsenNo ratings yet

- Power Generation: Powered by Perkins Diesel Engine 50Hz, 380v, 415v, 3 Phase, 4 Wire, 1500rpmDocument2 pagesPower Generation: Powered by Perkins Diesel Engine 50Hz, 380v, 415v, 3 Phase, 4 Wire, 1500rpmTegas Shidik PermanaNo ratings yet

- ADocument51 pagesASayandip MondalNo ratings yet

- Module 1Document44 pagesModule 1bhara.r433No ratings yet

- ch-9 Well FoundationDocument27 pagesch-9 Well FoundationRJ JordanNo ratings yet

- Hora (Wealth) Chaturthamsha (Destiny) : Ranjeeta RanjeetaDocument19 pagesHora (Wealth) Chaturthamsha (Destiny) : Ranjeeta RanjeetaUtpal KumarNo ratings yet

- Resonant Converters-IIDocument68 pagesResonant Converters-IISONU KUMARNo ratings yet

- Groundfos SP 16015Document10 pagesGroundfos SP 16015suwono radukNo ratings yet

- BI 7 UpgradeDocument9 pagesBI 7 UpgradekaranNo ratings yet

- 21mab102t Model MCQ Unit I To VDocument16 pages21mab102t Model MCQ Unit I To Vsd9422No ratings yet

- L L L L L L: Answer The Following Questions. Answer The Following Questions. Answer The Following QuestionsDocument1 pageL L L L L L: Answer The Following Questions. Answer The Following Questions. Answer The Following QuestionsBasappaSarkarNo ratings yet

- Catalogue Bernecker - Pipe ClampsDocument15 pagesCatalogue Bernecker - Pipe ClampsJunior CorrêaNo ratings yet

- EA-10-18 BalanzasDocument94 pagesEA-10-18 BalanzasFrosan Adolfo Rodriguez GamboaNo ratings yet

- Wide Flange Beam ChartDocument16 pagesWide Flange Beam Chartrtrajan_mech5408No ratings yet