Professional Documents

Culture Documents

Mandatory Tests Required Details

Mandatory Tests Required Details

Uploaded by

Sourabh Pal0 ratings0% found this document useful (0 votes)

8 views8 pagesThe document outlines the minimum quality tests required versus the number of tests actually done at a construction site. It lists 6 items - water, cement, sand, stone aggregate, reinforced cement concrete, and steel - and details for each item: the description, minimum quality for testing, frequency of testing, quantity consumed, number of tests required, and number of tests actually done. For most items, the number of required tests exceeds the number actually performed.

Original Description:

Original Title

Mandatory Tests Required Details

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines the minimum quality tests required versus the number of tests actually done at a construction site. It lists 6 items - water, cement, sand, stone aggregate, reinforced cement concrete, and steel - and details for each item: the description, minimum quality for testing, frequency of testing, quantity consumed, number of tests required, and number of tests actually done. For most items, the number of required tests exceeds the number actually performed.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

8 views8 pagesMandatory Tests Required Details

Mandatory Tests Required Details

Uploaded by

Sourabh PalThe document outlines the minimum quality tests required versus the number of tests actually done at a construction site. It lists 6 items - water, cement, sand, stone aggregate, reinforced cement concrete, and steel - and details for each item: the description, minimum quality for testing, frequency of testing, quantity consumed, number of tests required, and number of tests actually done. For most items, the number of required tests exceeds the number actually performed.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 8

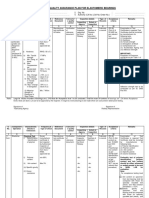

Statement for Mandatory Tests Required v/s Actually Done at Site

DATE: 20/5/2021

Minimum Quality of Qty. of Material No. of Tests

Sr. Description of Item of No. of Tests

Material Test Material for carrying Frequency of Testing consumed at Required to be

No. Work (in brief) Actually done

out the test site done

1. P.H. Value

Water from each source shall be

2. Limits of Acidity got tested before the

For Construction commencement of work and

1 WATER 3. Limits of Alkanity 2 liter NA 12 8

Purpose thereafter one in every three

4. Percentage of Solids months till the completion of the

a. Chlorides work.

b. Suspended matter

c. Sulphates

d. Inorganic Solids

e. Organic Solids

Physical Requirement 1 KG

Fineness Each Lot Every 50 tones or part thereof

Soundness Each Lot Every 50 tones or part thereof

C.C., R.C.C. Plaster

2 CEMENT 10425 10 5

&Masonry works etc. Setting time (Initial& Final) Each Lot Every 50 tones or part thereof

Compressive Strength Each Lot Every 50 tones or part thereof

Consistency of standard

Each Lot Every 50 tones or part thereof

cement paste

Fineness Each Lot Every 50 tones or part thereof

Every 20 Cum. Or part thereof or

Organic impurities 20 Cum. more frequently as decided by

Engineer-in-charge

Cement Concrete, Every 20 Cum. Or part thereof or

3 SAND Plaster &Masonry works Silt Content 20 Cum. more frequently as decided by 325 16 12

etc. Engineer-in-charge

Particle size distribution a,

40 Cum. Every 40 Cum. Or part thereof

b, c, d & e

Bulking of Sand 20 Cum. Every 20 Cum. Or part thereof

SUB HEAD : 4.0 CONCRETE WORK

a) Percentage of soft or

One test for each source For all quantities

deleterious materials

For every 45 Cum or part of

thereof for RCC work only for rest

a) Particle size distribution

of items as decided by Engineer-

In-charge

Estimation of organic

For every 40 cum or part there of

impurities

Surface Moisture For every 40 cum or part there of

4 Stone Aggregate 80 2 5

Determination of 10% fine

For every 40 cum or part there of

value

Specific Gravity For every 40 cum or part there of

Bulk Density For every 40 cum or part there of

Aggregate crushing strength For every 40 cum or part there of

Aggregate Impact Value For every 40 cum or part there of

SUB HEAD : 5.0 REINFORCED CEMENT CONCRETE WORK

Beams, Plinth Beams,

Girders, Bressumers, 50 Cum. For RCC work including

Cantilevers, Suspended in all other small location. RCC

5 Reinforced Cement Concrete floors, lintels roofs and Slump Test 10 cum done in a day less than 50 cum test 51553 cum 5155 5155

staircases including may be carried out as required by

spiral staircases shelves Engineer-in-charge

etc.

50 Cum. For RCC work including

in all other small location. RCC

Walls, Columns, Pillars,

Cube Test 10 cum or part thereof done in a day less than 50 cum test 51553 cum 1100 1100

Posts &Structs

may be carried out as required by

Engineer-in-charge

Physical Tests Retest,

Rebound Test, Nominal Each lot from each source

6 Steel for RCC Mass, Eligation, Proof for each dia, as per

Stress, Tensile Strength, CPWD, 2009 frequency

Bend Test

8mm dia 25tonneor part thereof 558 19 14

10mm dia 35tonneor part thereof 1665 47 49

12mm dia 35tonneor part thereof 875 25 24

16mm dia 35tonneor part thereof 904 25 25

20mm dia 45tonneor part thereof 729 16 17

25mm dia 45tonneor part thereof 1834 40 37

28mm dia 45tonneor part thereof NA NA NA

32mm dia 45tonneor part thereof 1979 43 41

SUB HEAD: 6.0 BRICK WORK

Dimensions

7 Bricks Masonry Work Compressive Strength As per Table 6.3 & 6.4 50000 or part thereof 273480 6 13

Water Absorption

Efflorescence

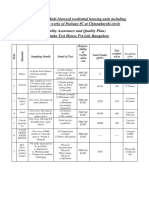

SUB HEAD: 7.0 STONE WORK

IS 1124 100 Sq.m./20 Cu.m. or part thereof

Water Absorption 90 Cu.m. or change of source as per

5500 Sq.m. direction of Engineer-in-charge.

100 Sq.m./20 Cu.m. or part thereof

Transverse strength IS 1121 Part II or change of source as per

direction of Engineer-in-charge.

8 Stone Stone Work 100 Sq.m./20 Cu.m. or part thereof 2241 4 LOT 1

Resistance to wear IS 1706 or change of source as per

direction of Engineer-in-charge.

100 Sq.m./20 Cu.m. or part thereof

Durability IS 1126 or change of source as per

direction of Engineer-in-charge.

SUB HEAD: 8.0 MARBLE WORK

Moisture Absorption IS 1124 100 Sq.m. of part thereof

9 Marble Marble Work Hardness Test Mho's Scale 101 Sq.m. of part thereof 667 2 LOT 1

Specific Gravity IS 1122 102 Sq.m. of part thereof

Moisture IS 1124 103 Sq.m. of part thereof

10 Granite 421 4 LOT 2

Specific Gravity IS 1122 104 Sq.m. of part thereof

11 Timber Moisture Content Appendix 'C' Every 1 Cu.m. or part thereof NA NA NA

End immersion Test knife IS 2202 As per sampling & testing

12 Flush Door NA NA NA

test, Adhesion Test Appendix 'F' specified in clause 9.7.11

IS 2209

Mortice locks Testing of Spring Appendix 'G' 100 or part thereof NA NA NA

SUB HEAD: 10.0 STEEL WORK

a) Tensile Strength

13 Steel, if arranged by Contractor Steel Work IS 1599 Every 20 tons or part thereof NA NA NA

b) Bend Test

a) Tensile Strength IS 1608

14 Steel Tubular Pipes b) Bend Test IS 2329 Every 8 tons or part thereof 395 49 20

c)Flattering Test IS 2328

SUB HEAD: 11.0 FLOORING

a) Transverse Strength to be done even if the no. of

terrazo tiles of any type and size

15 Terrazo Tiles Flooring b) Water Absorption IS 1237 NA NA NA

from a single manufacturer is less

c) Abrasion Test than 5000 nos provided the total

a) Dimensions & Surface

Pressed Ceramic tiles (for Floor quality

16 IS 13630 3000 Nos. or part thereof NA NA NA

&Wall) b) Physical properties

c)Chemical Properties

ROAD WORK

IS 2386

17 Coarse Aggregate a) Los Angeles per 200 Cu.m. NA NA NA

Part IV

IS 2386

b) Abrasion value or

NA NA NA

Aggregate Impact value

b) Abrasion value or

Part IV & NA NA NA

Aggregate Impact value

IS 5640

IS 2386

c) Flakiness Index NA NA NA

Part I

IS 2386

d)Grading Requirement per 100 Cu.m. NA NA NA

Part I

IS 2386

18 Fine Aggregate Deleterious Materials As required by Engineer-in-charge NA NA NA

Part I Before approval of the quarry and

Cement Concrete Pavement under Coarse Aggregate IS 2386 every subsequent change in source

19 NA NA NA

controlled conditions a) Flakiness Index Part I of supply and one test per 100

Cu.m.

Before approval of the quarry and

every subsequent change in source

b) Impact value 400 Cu.m. NA NA NA

of supply and one test per 100

Cu.m.

Before approval of the quarry and

c) Los Angeles Abration every subsequent change in source

400 Cu.m. NA NA NA

Value of supply and one test per 100

Cu.m.

Before approval of the quarry and

every subsequent change in source

d) Deleterious Materials 400 Cu.m. NA NA NA

of supply and one test per 100

Cu.m.

Before approval of the quarry and

every subsequent change in source

e) Moisture Content 400 Cu.m. NA NA NA

of supply and one test per 100

Cu.m.

Fine Aggregate NA NA NA

a) Silt Content 200 Cu.m. One test per 15 Cu.m. NA NA NA

b) Gradation of Sand 200 Cu.m. One test per 15 Cu.m. NA NA NA

Before approval of the quarry and

c) Deleterious material 200 Cu.m. every subsequent change in source NA NA NA

of supply

Regularly as required subject to

d) moisture Content 200 Cu.m. NA NA NA

minimum of two tests per day

Remarks

All RCC WORK DONE BY RMC.

All RCC WORK DONE BY RMC.

All RCC WORK DONE BY RMC.

28mm dia is not used this project

WORK/METERIALNOT START YET

WORK/METERIAL NOT START YET

WORK/MATERIAL NOT START YET

NOT ARRANGED BY ANY

CONTRACTOR

WORK/METERIAL NOT START YET

WORK/METERIAL NOT START YET

ROAD WORK NOT STARTED YET

You might also like

- Standard QA Plan (Elastomeric Bearings)Document8 pagesStandard QA Plan (Elastomeric Bearings)ghaghra bridgeNo ratings yet

- QC For Building WorksDocument20 pagesQC For Building WorksNagaVenkat ChNo ratings yet

- QAP Overall ProjectDocument2 pagesQAP Overall ProjectGangadhar GangaNo ratings yet

- Testing of MaterialDocument1 pageTesting of Materialshakil nagoriNo ratings yet

- Speci FactionsDocument280 pagesSpeci FactionsNivetha VNo ratings yet

- Excel Sheet For Indian Standard Concrete Mix Design (Without Fly Ash)Document16 pagesExcel Sheet For Indian Standard Concrete Mix Design (Without Fly Ash)SOURAV RANJAN KHANRANo ratings yet

- Filled-Summary of Third Party Test-March-2022Document3 pagesFilled-Summary of Third Party Test-March-2022shameerkasalaNo ratings yet

- Test Requirement & Frequancy of Test For Quality Assurance of Works Based On BOQDocument5 pagesTest Requirement & Frequancy of Test For Quality Assurance of Works Based On BOQSujan MalbulNo ratings yet

- Indicates User Defined Values Indicates Final ValuesDocument16 pagesIndicates User Defined Values Indicates Final ValuesCos ConsultancyNo ratings yet

- Test Frequency: (As Per Mort&H 5Th Revision)Document6 pagesTest Frequency: (As Per Mort&H 5Th Revision)jitendra dixitNo ratings yet

- Std. QAP of Expension Joints (March 16)Document6 pagesStd. QAP of Expension Joints (March 16)ghaghra bridgeNo ratings yet

- QAP WRTW Banke-05Document1 pageQAP WRTW Banke-05Jaljala NirmanNo ratings yet

- Luyos Design MixDocument18 pagesLuyos Design MixRennee Son Bancud100% (1)

- The Frequency of Various TestsDocument3 pagesThe Frequency of Various TestsNaveed Ahmed Get-InfoNo ratings yet

- He Frequency of Various TestsDocument3 pagesHe Frequency of Various TestsNaveed Ahmed Get-InfoNo ratings yet

- HUDAGDADDocument6 pagesHUDAGDADR.K. CONSULTANCY AND CONTRACTORNo ratings yet

- HUDAGDADDocument6 pagesHUDAGDADR.K. CONSULTANCY AND CONTRACTORNo ratings yet

- Here Are The Frequency of Tests For Soil.: S/N Description Area Test Frequency Qty. of TestDocument2 pagesHere Are The Frequency of Tests For Soil.: S/N Description Area Test Frequency Qty. of TestM iqbalNo ratings yet

- Quality Control Test Frequency For Road and BuildingsDocument34 pagesQuality Control Test Frequency For Road and BuildingsShashank VermaNo ratings yet

- 03 Initial and Final SettingDocument1 page03 Initial and Final SettingjitendraNo ratings yet

- Tendernotice 3Document9 pagesTendernotice 3rxrahul9334No ratings yet

- 2CE-C - BAUTISTA, DARLENE JOY C. - ExperimentDocument5 pages2CE-C - BAUTISTA, DARLENE JOY C. - ExperimentDARLENE JOY C. BAUTISTANo ratings yet

- Civil Engineering Laboratory Equipment ListDocument4 pagesCivil Engineering Laboratory Equipment ListHasan KamalNo ratings yet

- Unconsolidated-Undrained Triaxial Compression Test On Cohesive Soils (Quick Undrained)Document2 pagesUnconsolidated-Undrained Triaxial Compression Test On Cohesive Soils (Quick Undrained)FANNYNo ratings yet

- Susmita PatiDocument27 pagesSusmita PatiSusmitaNo ratings yet

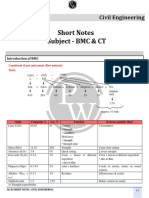

- BMC & CT - Short NotesDocument68 pagesBMC & CT - Short NotesPhoenix Gaming -An Official CommunityNo ratings yet

- Frequency of Test / Checks Sr. No - Title Doc. No. Frequency of Test / Check Relevant IS Codes 1. SoilDocument5 pagesFrequency of Test / Checks Sr. No - Title Doc. No. Frequency of Test / Check Relevant IS Codes 1. SoilAV ChavdaNo ratings yet

- Presentasi Hatti 2017-11-07 08. Prof. Paulus P. Rahardjo - Insitu Test CPT-HATTIDocument77 pagesPresentasi Hatti 2017-11-07 08. Prof. Paulus P. Rahardjo - Insitu Test CPT-HATTIemail robbi dot shobri2 at gmail dot comNo ratings yet

- One Dimensional Consolidation Properties: (Oedometer)Document2 pagesOne Dimensional Consolidation Properties: (Oedometer)Siti MaimunahNo ratings yet

- MC InjectionDocument3 pagesMC InjectionMordo GordoNo ratings yet

- Sub-Annexure B8 ASPHALT (Specification 245)Document1 pageSub-Annexure B8 ASPHALT (Specification 245)Tanmay VegadNo ratings yet

- QC Frequency Test Plan (5th Revision)Document42 pagesQC Frequency Test Plan (5th Revision)Deven PatleNo ratings yet

- Monthly Quality Assurance Report For August-13, Elf RVNL DankuniDocument14 pagesMonthly Quality Assurance Report For August-13, Elf RVNL DankuniPrasanta ParidaNo ratings yet

- Material Specification & TestDocument3 pagesMaterial Specification & TestmunimiutNo ratings yet

- MoRTH Quality Control Tests - Comparision TableDocument5 pagesMoRTH Quality Control Tests - Comparision TableAbdullah RafeekNo ratings yet

- Quality TestDocument22 pagesQuality TestUmair Shaikh100% (1)

- BMCT Merged InvertDocument2,069 pagesBMCT Merged Invertnikhilprajapat80968No ratings yet

- Annex 1: (RA Bill 1)Document3 pagesAnnex 1: (RA Bill 1)Sandip PaulNo ratings yet

- Transformer TestDocument104 pagesTransformer TestMahfuz HasanNo ratings yet

- STANDARD QUALITY ASSURANCE XXXDocument4 pagesSTANDARD QUALITY ASSURANCE XXXsanNo ratings yet

- Methodology For Bitumen MasticDocument6 pagesMethodology For Bitumen MasticSudip MukhopadhyayNo ratings yet

- Unconsolidated-Undrained Triaxial Compression Test On Cohesive Soils (Quick Undrained)Document2 pagesUnconsolidated-Undrained Triaxial Compression Test On Cohesive Soils (Quick Undrained)FANNYNo ratings yet

- Draft SORDocument12 pagesDraft SORArpit ParikhNo ratings yet

- Test For Material As Per Indian StandardDocument1 pageTest For Material As Per Indian StandardEspn SachinNo ratings yet

- Mix Design of Class C-24 (3500psi) ConcreteDocument3 pagesMix Design of Class C-24 (3500psi) ConcreteMd. Mahmudle HassanNo ratings yet

- Concrete Mix DesignDocument6 pagesConcrete Mix Designlewis kalataNo ratings yet

- Type Test: Power TransformerDocument4 pagesType Test: Power TransformerAdrianus PramudhitaNo ratings yet

- Tata Consulting Engineers Limited: Testing of Quality of Bricks / Solid BlocksDocument1 pageTata Consulting Engineers Limited: Testing of Quality of Bricks / Solid BlocksSandip PaulNo ratings yet

- Brickwork PDFDocument114 pagesBrickwork PDFfluretNo ratings yet

- Analysis of RatesDocument1,986 pagesAnalysis of RatesMuhammad Ali DaanishNo ratings yet

- Lab Test Quantity & FrequencyDocument20 pagesLab Test Quantity & FrequencyMadhav ReddyNo ratings yet

- Report of Technology Materials Testing of Portland CementDocument20 pagesReport of Technology Materials Testing of Portland CementAnara BhismaNo ratings yet

- Material Testing Summary: Soil Compaction Test (8m X 5m)Document1 pageMaterial Testing Summary: Soil Compaction Test (8m X 5m)KamalNo ratings yet

- Contreras Grout in Paper Geotechnical News Part 2Document4 pagesContreras Grout in Paper Geotechnical News Part 2Ghulam Kibria KhanNo ratings yet

- Material Testing TemplateDocument12 pagesMaterial Testing TemplateLibaginNo ratings yet

- LN03Document20 pagesLN03alismart1382No ratings yet

- Some Basic Concepts Related To Fuel Cells With A Focus On Microbial and Enzymatic Fuel CellsDocument30 pagesSome Basic Concepts Related To Fuel Cells With A Focus On Microbial and Enzymatic Fuel CellsAjay GmNo ratings yet

- Unconsolidated-Undrained Triaxial Compression Test On Cohesive Soils (Quick Undrained)Document2 pagesUnconsolidated-Undrained Triaxial Compression Test On Cohesive Soils (Quick Undrained)FANNYNo ratings yet

- FMM - Unit I QBDocument43 pagesFMM - Unit I QBThiruvasagamoorthy KaNo ratings yet

- Gprs Attach PDP Sequence DiagramDocument4 pagesGprs Attach PDP Sequence Diagramapi-3838344100% (1)

- C4 Digital TransmissionDocument42 pagesC4 Digital Transmissionaditya_polepeddiNo ratings yet

- Limit States Design of Crane Runway GirdersDocument7 pagesLimit States Design of Crane Runway GirdersRatna YanuarNo ratings yet

- Anonymous and Traceable Group Data Sharing in Cloud ComputingDocument84 pagesAnonymous and Traceable Group Data Sharing in Cloud Computingvikas guptaNo ratings yet

- Shan Zhong, Student Member, IEEE, and Ali Abur, Senior Member, IEEEDocument5 pagesShan Zhong, Student Member, IEEE, and Ali Abur, Senior Member, IEEEAhmadinijadNo ratings yet

- Latihan Soal Pat Bahasa InggrisDocument8 pagesLatihan Soal Pat Bahasa InggrisDragNo ratings yet

- EE ProblemsDocument33 pagesEE ProblemsSaied Aly SalamahNo ratings yet

- Buoyance FactorDocument20 pagesBuoyance FactormanibabuNo ratings yet

- RF Controlled Robotic Vehicle With Metal Detection ProjectDocument4 pagesRF Controlled Robotic Vehicle With Metal Detection Projectvijay4vlrNo ratings yet

- CT S&P-Avr13-THGT-SélectionDocument78 pagesCT S&P-Avr13-THGT-Sélectionkasztakatika100% (1)

- One Dimensional FlowDocument11 pagesOne Dimensional FlowmechgokulNo ratings yet

- AQA Physics: Determining UncertaintyDocument6 pagesAQA Physics: Determining UncertaintyboobooNo ratings yet

- Liebherr Hs 855 With Hydraulic Slurry Wall Grab EnglishDocument12 pagesLiebherr Hs 855 With Hydraulic Slurry Wall Grab EnglishMary JeanNo ratings yet

- Magnetism & Matter CH5Document24 pagesMagnetism & Matter CH5Rishab SharmaNo ratings yet

- Gross Tonnage CalculatorDocument3 pagesGross Tonnage CalculatorSanderNo ratings yet

- Math Kangaroo Competition: Test PaperDocument10 pagesMath Kangaroo Competition: Test PaperKhaing Phyu0% (1)

- 2Q Budget of Work Math IVDocument2 pages2Q Budget of Work Math IVEurika LimNo ratings yet

- DbmspaperDocument9 pagesDbmspaperRajiv GuptaNo ratings yet

- Continuous Estimate of CEC From Log DataDocument15 pagesContinuous Estimate of CEC From Log DatalakhanmukhtiarNo ratings yet

- Note! Correctness or Validity of Reasoning Does Not Necessarily Mean The TruthDocument4 pagesNote! Correctness or Validity of Reasoning Does Not Necessarily Mean The TruthFMMNo ratings yet

- Define Load PatternDocument4 pagesDefine Load PatternsovannchhoemNo ratings yet

- Taxonomy v101Document67 pagesTaxonomy v101Angela BernalNo ratings yet

- Multi Product Brochure 2023 HiResDocument51 pagesMulti Product Brochure 2023 HiResikhwan.138986No ratings yet

- Soal UTS Bahasa Inggris SD Semester Genap Kelas 5Document5 pagesSoal UTS Bahasa Inggris SD Semester Genap Kelas 5Yusuf HamdaniNo ratings yet

- Large-Break Loss-Of-Coolant Accident PDFDocument11 pagesLarge-Break Loss-Of-Coolant Accident PDFThiago RobertoNo ratings yet

- Week 5 Take Home Assignment Questions-Semester 1 2024-3 Jaime DurkinDocument13 pagesWeek 5 Take Home Assignment Questions-Semester 1 2024-3 Jaime DurkinMr Christ101No ratings yet

- Materi IT EnglishDocument19 pagesMateri IT EnglishMohammad MaudiawanNo ratings yet

- Opposite Hypotenuse Adjacent Hypotenuse Sin ! Cos ! Opposite AdjacentDocument43 pagesOpposite Hypotenuse Adjacent Hypotenuse Sin ! Cos ! Opposite AdjacentFerry YutamaNo ratings yet

- MSC NASTRAN Patran Progressive Failure and Delam 021712Document53 pagesMSC NASTRAN Patran Progressive Failure and Delam 021712alitariq90No ratings yet