Professional Documents

Culture Documents

Mahmoud Khairy Process Engineer Certified Lean Six Sigma Green Belt

Mahmoud Khairy Process Engineer Certified Lean Six Sigma Green Belt

Uploaded by

mahmoud khairy0 ratings0% found this document useful (0 votes)

19 views1 page- Mahmoud Khairy has 3 years of experience as a shift engineer in the metal industry leading 60 employees and working as an industrial engineer to improve machine performance, overall equipment effectiveness, and cost savings.

- He currently works as a Continuous Improvement Engineer where he conducts time and motion studies, analyzes quality costs, monitors key performance indicators, and has increased overall equipment effectiveness by 4%.

- Previous experience includes work as an Operations Engineer where he led 60 employees and improved safety, increased material handling efficiency, and reduced costs.

Original Description:

Original Title

MahmoudKhairy_CV

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document- Mahmoud Khairy has 3 years of experience as a shift engineer in the metal industry leading 60 employees and working as an industrial engineer to improve machine performance, overall equipment effectiveness, and cost savings.

- He currently works as a Continuous Improvement Engineer where he conducts time and motion studies, analyzes quality costs, monitors key performance indicators, and has increased overall equipment effectiveness by 4%.

- Previous experience includes work as an Operations Engineer where he led 60 employees and improved safety, increased material handling efficiency, and reduced costs.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

19 views1 pageMahmoud Khairy Process Engineer Certified Lean Six Sigma Green Belt

Mahmoud Khairy Process Engineer Certified Lean Six Sigma Green Belt

Uploaded by

mahmoud khairy- Mahmoud Khairy has 3 years of experience as a shift engineer in the metal industry leading 60 employees and working as an industrial engineer to improve machine performance, overall equipment effectiveness, and cost savings.

- He currently works as a Continuous Improvement Engineer where he conducts time and motion studies, analyzes quality costs, monitors key performance indicators, and has increased overall equipment effectiveness by 4%.

- Previous experience includes work as an Operations Engineer where he led 60 employees and improved safety, increased material handling efficiency, and reduced costs.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 1

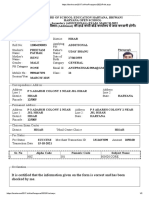

Mahmoud Khairy

SUMMARY Process Engineer

Certified Lean Six Sigma Green Belt

• I have 3 years’ experience in EDUCATION

metal industry as shift

engineer leading 60 employee Faculty of Engineering

and working as industrial Sep 2011 – August 2016

engineer to improve machines Bachelor’s degree in Production Engineering, Alexandria University,

OEE and cost savings. Grade: Good (73.03 %)

Military Service: Completed in Dec 2017

CONTACT WORK EXPERIENCE

PHONE: ABCO United for plastics and chemicals.

Continuous improvement Engineer Oct 2020 - present

+201066313741

• Time & motion study for labor utilization.

ADDRESS: • Follow up on TPM implementation during machine restoration

through an action plan

Seyouf Square, Alexandria.

•Analyzing monthly quality loss costs and prioritize the possible

WEBSITE: projects to reduce the highest costs.

• Monthly analysis for OEE, unplanned breakdowns, rework,

linkedin.com/in/mahmoud- defectives and scrap to get the vital few problems and machines

khairy0399b293 • Follow up operation losses during daily kaizen meeting, discuss

Email: corrective actions with operation team and action due dates.

• Make control charts to ensure production lines stability.

Mahmoudkhairy492@gmail.com ACHIEVEMENTS

• Reduce the required labors headcount by 50 %.

CERTIFICATIONS • Reoptimize the technicians’ headcount.

• Design a management system in TPM project for machine breakdowns and

• CSSGB -Certified Six Sigma improvements to facilitate actions coordination and implementation.

Green Belt from Six Sigma • Increase the overall OEE of the factory by 4 % compared to last year OEE.

Institute Harsco Environmental Sep 2018 - Oct 2020

• Lean manufacturing from Operations Engineer

TUM (Techniche Universität • leading 60 operative employees during the shift

München) • Identifying the activities risks and hazards and recommend and implement

the corrective actions to improve the operations safety.

• Material Handling Safety

from OSHA Academy. • Analyzing the material tonnage transported per equipment hours, fuel

• Mechanical Behavior of consumption and workforce used.

Materials from MIT ACHIEVEMENTS

SKILLS • Achieved the highest material tonnages transported to the client.

• Lean Manufacturing: Good • Reduce the Cost per Ton (CPT) in cutting section by 30%.

• Six Sigma Green belt: Good • Increasing the Labor working hours per ton by increasing labors

• Process cost analysis: Good productivity.

• Reduce the overtime cost by 40% by eliminating NVA

• MS office : Excellent

INTERNSHIPS

• Solidworks : Intermediate • Summer Trainee at Egyptian Petrochemical company (2015).

Voluntary Work • Summer Trainee at Zahran group (Seb venture) and lord company (2014)

Marketing member at ASME

AlexSS (2015-2016)

You might also like

- Pedh 122 Week 20 ExamDocument43 pagesPedh 122 Week 20 ExamLymenson Boongaling100% (1)

- Digital Marketing Best Practices GuideDocument16 pagesDigital Marketing Best Practices GuideDemand MetricNo ratings yet

- Bassam Mohamed C.VDocument16 pagesBassam Mohamed C.VAnas NagyNo ratings yet

- Resume SampleDocument2 pagesResume Sample18TUEC119 Kiran SeshiNo ratings yet

- Ashish Mishra - CV - 2Document3 pagesAshish Mishra - CV - 2Ashish MishraNo ratings yet

- CV Update of Feb. 2024-1Document3 pagesCV Update of Feb. 2024-1mohamed hamedNo ratings yet

- IE (Resume)Document2 pagesIE (Resume)Ahmed RehmanNo ratings yet

- Himansu Sekhar Mohapatra: Professional SummaryDocument5 pagesHimansu Sekhar Mohapatra: Professional SummaryHimansu MohapatraNo ratings yet

- Abhikul Kumar Singh: Mechanical EngineerDocument2 pagesAbhikul Kumar Singh: Mechanical EngineerBrent M GeorgeNo ratings yet

- Engineering Project LeaderDocument3 pagesEngineering Project LeaderPhelep MounirNo ratings yet

- Industrial Engineer Quality LEAN MES 1564069816Document1 pageIndustrial Engineer Quality LEAN MES 1564069816Sondos EuchiNo ratings yet

- CV of Muhammad Adeel RajputDocument4 pagesCV of Muhammad Adeel RajputFarhan SaghirNo ratings yet

- Rawad HilalDocument2 pagesRawad Hilalmaroun machaalanyNo ratings yet

- Armando MoralesDocument2 pagesArmando MoralesArmandoNo ratings yet

- Zeeshan Pathan Mechanical EngineerDocument4 pagesZeeshan Pathan Mechanical EngineerZeeshan PathanNo ratings yet

- Mark Knofler: Career OverviewDocument2 pagesMark Knofler: Career OverviewknoflerNo ratings yet

- MunendraSharma 13453974 - 05 06 - 1Document6 pagesMunendraSharma 13453974 - 05 06 - 1Mayur ShindeNo ratings yet

- My Resume PDFDocument3 pagesMy Resume PDFAbdullah SheikhNo ratings yet

- Nitin Kumar: Contact: 8793014824, 9420369645Document2 pagesNitin Kumar: Contact: 8793014824, 9420369645NitinKumarNo ratings yet

- Devansh Resume TATA STeelDocument1 pageDevansh Resume TATA STeelDevansh SrivastavaNo ratings yet

- Curriculum Vitae - Alaa Osman HL PDFDocument2 pagesCurriculum Vitae - Alaa Osman HL PDFAlaaNo ratings yet

- Resume MurnieMadlanDocument2 pagesResume MurnieMadlanWAN AHMAD HANISNo ratings yet

- CV Mhammed Lahlaba En-4Document5 pagesCV Mhammed Lahlaba En-4lahlabaNo ratings yet

- Mechanical EngineerDocument4 pagesMechanical EngineerKhalid MahmoudNo ratings yet

- Resume SabiqAzmiDocument2 pagesResume SabiqAzmiAcab AimiNo ratings yet

- Abdelrahman Helal - AERODocument4 pagesAbdelrahman Helal - AEROAbdelRahman Helal AhmedNo ratings yet

- Muhammad Khaleel C.V - Senior Process Operation Engineer PDFDocument4 pagesMuhammad Khaleel C.V - Senior Process Operation Engineer PDFMuhammad KhaleelNo ratings yet

- R. Sundar: Career ObjectiveDocument5 pagesR. Sundar: Career ObjectiveBalachandar SNo ratings yet

- Saad Bin Sadaqat VisualCV ResumeDocument3 pagesSaad Bin Sadaqat VisualCV Resumesaad bin sadaqatNo ratings yet

- Guhan Mahalingam: Assembly EngineerDocument2 pagesGuhan Mahalingam: Assembly EngineerGuhan MNo ratings yet

- Varun 4.9 YOEDocument3 pagesVarun 4.9 YOEVarun SharmaNo ratings yet

- A Brief Career SummaryDocument2 pagesA Brief Career SummaryRajinNo ratings yet

- Abdelrahman Helal - Updated CVDocument4 pagesAbdelrahman Helal - Updated CVAbdelRahman Helal AhmedNo ratings yet

- CV Kareem Mohamed 0623deDocument2 pagesCV Kareem Mohamed 0623deKareem MohamedNo ratings yet

- Saad Bin Sadaqat: Industrial & Manufacturing EngineerDocument3 pagesSaad Bin Sadaqat: Industrial & Manufacturing EngineerSaad Bin SadaqatNo ratings yet

- Resume-M. AsadDocument1 pageResume-M. AsadAsad QureshiNo ratings yet

- Srilekha G.Industrial Engineer-1Document4 pagesSrilekha G.Industrial Engineer-1prabu cNo ratings yet

- ALSayed HashimDocument4 pagesALSayed HashimAya AbdoNo ratings yet

- Mohamed Seddik ZRAFI: Mechanical Manufacturing EngineerDocument2 pagesMohamed Seddik ZRAFI: Mechanical Manufacturing EngineerseddikNo ratings yet

- OssamaBoHmadResume PDFDocument2 pagesOssamaBoHmadResume PDFOssama bohamdNo ratings yet

- Muhammad Anas Resume - Muhammad AnasDocument2 pagesMuhammad Anas Resume - Muhammad Anaskoi naiNo ratings yet

- AngloGold Ashanti (Ghana) Limited Is Hiring Staff - 221030 - 133951Document46 pagesAngloGold Ashanti (Ghana) Limited Is Hiring Staff - 221030 - 133951Marc WrldNo ratings yet

- CV Ingenieur Ensem Casablanca Iliass BoumzebraDocument2 pagesCV Ingenieur Ensem Casablanca Iliass BoumzebraIlyassBoumzebraNo ratings yet

- Athar Abbas Resume - 2019 PDFDocument1 pageAthar Abbas Resume - 2019 PDFAli RazaNo ratings yet

- Mechatronics Engineer D MabasaDocument3 pagesMechatronics Engineer D MabasaDirector lennox mabasaNo ratings yet

- Resume-B N RautDocument6 pagesResume-B N RautBalaji RautNo ratings yet

- Ahmed Saad Qureshi Supply Chain ResumeDocument3 pagesAhmed Saad Qureshi Supply Chain ResumeAhmed NomanNo ratings yet

- Naukri AbhishekFaujdar 15326740 - 04 10 - 1Document3 pagesNaukri AbhishekFaujdar 15326740 - 04 10 - 1Mayur ShindeNo ratings yet

- Alan Jason Correa: Senior Engineer - Technology Development & IndustrializationDocument2 pagesAlan Jason Correa: Senior Engineer - Technology Development & IndustrializationAnonymous 1U2FukcNo ratings yet

- Process Design Engineering ProgramDocument6 pagesProcess Design Engineering Programdeeptemptation02222No ratings yet

- Case StudiesDocument7 pagesCase StudiesJerome DalisayNo ratings yet

- Project Report On For The Course Industrial Engineering &quality Control (Mechanical Engineering) by 2200440226 2200440225 Under The Guidance ofDocument13 pagesProject Report On For The Course Industrial Engineering &quality Control (Mechanical Engineering) by 2200440226 2200440225 Under The Guidance ofAfaque KhatriNo ratings yet

- Aman Panse - LeanDocument3 pagesAman Panse - LeanMayur ShindeNo ratings yet

- Khaled Emad Alrutroot CVDocument1 pageKhaled Emad Alrutroot CVJomana JomanaNo ratings yet

- My CVDocument3 pagesMy CVUsman KhanNo ratings yet

- Rufus Short ResumeDocument3 pagesRufus Short ResumeStacy ElliottNo ratings yet

- Asad AliDocument5 pagesAsad AliMisbhasaeedaNo ratings yet

- 15 Fa 8 F 4 Bfade 1 B 43Document14 pages15 Fa 8 F 4 Bfade 1 B 43shairabartolome32No ratings yet

- Industrial Engineering: Võ Minh KhúcDocument3 pagesIndustrial Engineering: Võ Minh KhúcPeter SonNo ratings yet

- Abhishek Singh Rathore2024.1Document4 pagesAbhishek Singh Rathore2024.1Rathore ABhishek singhNo ratings yet

- Ashish Mishra - CVDocument5 pagesAshish Mishra - CVAshish MishraNo ratings yet

- Fishbone-Cause-And-Effect-Diagram GiveawayDocument2 pagesFishbone-Cause-And-Effect-Diagram Giveawaymahmoud khairyNo ratings yet

- Scrap ProjectDocument27 pagesScrap Projectmahmoud khairyNo ratings yet

- Quality Inspectors Machines DistributionDocument3 pagesQuality Inspectors Machines Distributionmahmoud khairyNo ratings yet

- Case Study ABCODocument15 pagesCase Study ABCOmahmoud khairyNo ratings yet

- Solution To Reduce Production Date ProblemsDocument10 pagesSolution To Reduce Production Date Problemsmahmoud khairyNo ratings yet

- FG Cartons Balances Machines DistributionDocument4 pagesFG Cartons Balances Machines Distributionmahmoud khairyNo ratings yet

- Sachet Balances Machines DistributionDocument4 pagesSachet Balances Machines Distributionmahmoud khairyNo ratings yet

- OEE Improvement Project: Eng. Ehab Abo Elkhier Eng. Ahmed Shawky Eng. Mohamed Ramadan Eng. Hamdy Saber Mahmoud KhairyDocument23 pagesOEE Improvement Project: Eng. Ehab Abo Elkhier Eng. Ahmed Shawky Eng. Mohamed Ramadan Eng. Hamdy Saber Mahmoud Khairymahmoud khairyNo ratings yet

- Oct Defect RateDocument14 pagesOct Defect Ratemahmoud khairyNo ratings yet

- Nov Defect RateDocument14 pagesNov Defect Ratemahmoud khairyNo ratings yet

- KAI-04070 2048 (H) X 2048 (V) Interline CCD Image Sensor: DescriptionDocument50 pagesKAI-04070 2048 (H) X 2048 (V) Interline CCD Image Sensor: Descriptionmahmoud khairyNo ratings yet

- Tiger: CCD 4 MPDocument2 pagesTiger: CCD 4 MPmahmoud khairyNo ratings yet

- Customer Saticfaction For The First Half of 2020 (Local)Document3 pagesCustomer Saticfaction For The First Half of 2020 (Local)mahmoud khairyNo ratings yet

- Assignment Brief MODocument5 pagesAssignment Brief MOAlamzeb Khan100% (1)

- Promotion MixDocument4 pagesPromotion MixAtia KhalidNo ratings yet

- Mariam Abdulla Observation 3Document2 pagesMariam Abdulla Observation 3api-456760133No ratings yet

- Calleja TransformationinPhilippinelocalgovernment PDFDocument27 pagesCalleja TransformationinPhilippinelocalgovernment PDFJacky GalvezNo ratings yet

- Compatibility or Restraint? The Effects of Sexual Timing On Marriage RelationshipsDocument9 pagesCompatibility or Restraint? The Effects of Sexual Timing On Marriage Relationshipsniespamowi1No ratings yet

- Call For New Volunteers Upper AustriaDocument3 pagesCall For New Volunteers Upper AustriathejazzpoliceNo ratings yet

- Listening Comprehension SectionDocument41 pagesListening Comprehension SectionKhoirul AnasNo ratings yet

- A Comparative Clinical Study of Ushna Manda As Pathya Ahara Kalpana and Yogic Procedures in Management of Sthaulya W.S.R. ObesityDocument2 pagesA Comparative Clinical Study of Ushna Manda As Pathya Ahara Kalpana and Yogic Procedures in Management of Sthaulya W.S.R. ObesityArunKumarNo ratings yet

- Question Paper Code:: Reg. No.Document12 pagesQuestion Paper Code:: Reg. No.Jona CanoNo ratings yet

- MUET SPEAKING BookletDocument5 pagesMUET SPEAKING BookletFaizul Hisham100% (1)

- Narrative Report - TalaDocument3 pagesNarrative Report - TalaRichmond Lloyd Menguito JavierNo ratings yet

- Technology Entrepreneurship: BTMW 4012Document16 pagesTechnology Entrepreneurship: BTMW 4012MK ChuaNo ratings yet

- Learning Plan in T.L.E 9: St. Francis Xavier Academy of Kapatagan Inc. Kapatagan, Lanao Del Norte S.Y 2019-2020Document15 pagesLearning Plan in T.L.E 9: St. Francis Xavier Academy of Kapatagan Inc. Kapatagan, Lanao Del Norte S.Y 2019-2020Anicadlien Ellipaw Inin100% (1)

- 08!09!1993 DoPT MemorandumDocument6 pages08!09!1993 DoPT MemorandumDeepak SinghNo ratings yet

- 10.1007@978 3 030 15032 7 PDFDocument1,396 pages10.1007@978 3 030 15032 7 PDFClara JustinoNo ratings yet

- MScCityDesignHandbook 2010-2011Document28 pagesMScCityDesignHandbook 2010-2011Luisa Urrejola DavanzoNo ratings yet

- Detailed ResumeDocument3 pagesDetailed Resumevscs.198293% (15)

- Flight Link Helicopter Flight Simulator ControlsDocument2 pagesFlight Link Helicopter Flight Simulator ControlsAnonymous mfgFBX9XNo ratings yet

- A Brief History of M&S : My Favourite BrandDocument3 pagesA Brief History of M&S : My Favourite BrandabdulwahabNo ratings yet

- Telecommunications #Warren Hioki: WWW - bit.ly/1yU1RJUDocument12 pagesTelecommunications #Warren Hioki: WWW - bit.ly/1yU1RJULet's Go TlmNo ratings yet

- Company Profile PDFDocument21 pagesCompany Profile PDFNilay GandhiNo ratings yet

- DukeDocument52 pagesDukedtyutyjghvghgNo ratings yet

- Student Print Form: It Is Certified That The Information Given On The Form Is Correct and Has Been Checked by MeDocument2 pagesStudent Print Form: It Is Certified That The Information Given On The Form Is Correct and Has Been Checked by MeTesting Lab (JSHL-QUALITY)No ratings yet

- Ontex 2019-Full ReportDocument168 pagesOntex 2019-Full ReportZak ElmkdNo ratings yet

- New Business Certificate PDFDocument1 pageNew Business Certificate PDFAnonymous l6Jd1sQRNo ratings yet

- Liverpool School of Tropical Medicine: Application FormDocument7 pagesLiverpool School of Tropical Medicine: Application FormDenis IsaiahNo ratings yet

- Student Workbook: Advance 1Document26 pagesStudent Workbook: Advance 1Damaris Vega100% (1)

- Answering Interview QuestionsDocument11 pagesAnswering Interview QuestionsPhu Cong LeNo ratings yet