Professional Documents

Culture Documents

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory

Uploaded by

gangshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory

Uploaded by

gangshCopyright:

Available Formats

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 1

Equivalent Circuit of Armature Controlled DC Motor

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 2

EX.NO: TRANSFER FUNCTION OF ARMATURE CONTROLLED DC MOTOR

DATE:

AIM:

To derive the transfer function of armature controlled DC motor.

APPARATUS REQUIRED:

S. No Name of the Apparatus Range Type Quantity

(0 – 2) Amps MC 1

1 Ammeter

(0 – 10) Amps MC 1

2 Voltmeter (0 – 300) Volts MC 1

3 Rheostat 50,5A Wire Wound 2

4 Rheostat 360,1.4A Wire Wound 1

5 Tachometer - Digital 1

6 Connecting wires - - few

THEORY:

In armature controlled DC motor, the desired speed is obtained by varying armature

voltage and keeping field current is constant.

We know that,

Eb = PZN / 60*A

From above equation DC motor speed is directly proportional to the armature voltage.

Let,

Ra= Armature Resistance

La= Armature Inductance

Eb= Back emf

Ia =Armature current

T=Torque developed in the motor

J =Moment of inertia

B=Dashpot

=Angular Displacement

Kt=Torque constant

Kb=Back emf constant

From equivalent circuit,

Differential equation of equivalent circuit can be written as

Ra ia +La dia/dt + eb = Va ……………………………………... 1

Differential equation of mechanical system can be written as

J d2 /dt2 + B d/dt = T………………………………… 2

Torque is directly proportional to the armature current

T Ia , T Ia

T = Kt Ia……………………………. 3

Motor back emf is directly proportional to the speed (Angular velocity)

Eb = Kb d / dt ………………….. ……………………... 4

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 3

TABULATION:

(I) To find Eb:

Armature Armature

Speed Eb =Va - IaRa =2N/60

S. No Current Voltage

(N) (Volts) (Radians/Sec)

( Ia) ( Va)

(II) To find Ta:

Radius = 0.075 m

Armature Armature Torque

S1 S2 S1-S2

Sl.No Current Voltage (Ta)=9.81*(S1-S2)* r

(Kg) (Kg) (Kg)

( Ia) ( Va) (N-M)

MODEL GRAPH:

(i) Measurement of Back Emf(kb):

Eb

Eb

(radians/sec)

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 4

Taking Laplace transform for equation (1), (2) & (3)

RaIa(s) + LasIa(s) + Eb(s) = Va(s) …………………….. 5

Js2(s) + Bs(s) = T(s)…………………………………. 6

T(s) = KtsIa(s)…………………………………………… 7

Eb(s) = Kbs(s)…………………………………... ……… 8

Equating equation (6) & (7)

KtsIa(s) = Js2(s) + Bs(s)

Ia(s) = Js2(s) + Bs(s) / Kts ………………. 9

Equation 8 & 9 values substitute in equation 5

( Ra + sLa)Ia(s) + Eb(s) = Va(s)

( Ra + sLa) Js2(s) + Bs(s) / sKt+ Kbs(s) = Va(s)

(s )( Ra + sLa) Js2) + Bs + Kbs / Kts = Va(s)

(s ) sKt

=

Va(s) ( Ra + sLa) Js2) + (B + Kbs

Procedure For Calculating Back Emf (Eb):

1. Initially keep all switches in off position.

2. Initially keep voltage adjustment POT (variac) in minimum position.

3. Initially keep armature and field voltage adjustment POT (variac) in minimum position.

4. Connect the kit armature output A and AA to motor armature terminal A and AA

respectively.

5. Connect the kit field output F and FF to motor field terminal F and FF respectively.

6. Switch on the power switch and SPST switch S1 and S2.

7. Set the field voltage at rated value. Adjust the Va and note down Ia and Speed for various

Va.Plot the graph.

Procedure For Calculating Armature Torque constant:

1. Apply the Va till the motor run at rated speed and apply load by tightening.

2. Note down the Va, Ia and spring balance reading and plot the graph and calculate torque

constant from the graph.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 5

(ii)Torque Vs Armature current(Ia):

T

(Nm) T

Ia

Ia

MODEL CALCULATION:

Kb = Eb /

Kt = T/ Ia

m =Jm/Bm

a =La/Ra

DC Motor Specifications:

DC motor: 0.5HP/ 180V / 1500 rpm with loading arrangement

Armature Resistance, Ra = 18 Ω

Armature Inductance, La =135mH

Moment of Inertia, Jm = 0.024 kg-m2

Coefficient of viscous Friction, B = 0.8 N-m/(rad/sec)

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 6

BLOCK DIAGRAM REPRESENTATION:

Km 1

SBm(1+mS)

Va(S) Ra(1+Sa) m(S)

sKb

RESULT:

Thus the transfer function of armature controlled DC motor is obtained.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 7

Circuit Diagram

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 8

EX.NO: TRANSFER FUNCTION OF FIELD CONTROLLED DC MOTOR

DATE:

AIM:

To derive the transfer function of field controlled DC motor.

APPARATUS REQUIRED:

Name of the

S. No Range Type Quantity

Apparatus

(0 – 2) Amps MC 1

1 Ammeter

(0 – 10) Amps MC 1

2 Voltmeter (0 – 300) Volts MC 1

3 Rheostat 50,5A Wire Wound 2

4 Rheostat 360,1.4A Wire Wound 1

5 Tachometer - Digital 1

6 Connecting wires - - few

THEORY:

In Field controlled DC motor, the desired speed is obtained by varying field current and

keeping armature is constant.

We know that,

Eb = PZN / 60*A

From above equation DC motor speed is inversely proportional to the field current.

Let,

Rf = Field Resistance

Lf = Field Inductance

Ra = Armature Resistance

La = Armature Inductance

If = Field current

T = Torque developed in the motor

J = Moment of inertia

B = Dashpot

= Angular Displacement

Kt = Torque constant

Kb = Back emf constant

From equivalent circuit,

Differential equation of equivalent circuit can be written as

Rf ia +La dia/dt +Eb = Vf …………………………………….. 1

Differential equation of mechanical system can be written as

J d2 /dt2 + B d / dt = T……………………….. 2

Torque is directly propotional to the armature current

T Ia ,

T Ia, T = Kt Ia……………………. 3

Taking laplace transform for equation 1, 2 & 3

RaIa(s) + LsIa(s) = Va(s) ………………. ………. 4

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 9

TABULATION:

( I) To find Eb:

Field Field

Speed Eb =Vf – IfRf =2N/60

S. No Current Voltage

(N) (Volts) (Radians/Sec)

( If) ( Vf)

II) To find Tf:

Radius = 0.075 m

Field Field Torque

S1 S2 S1-S2

S. No Current Voltage (Tf)=9.81*(S1-S2)* r

(Kg) (Kg) (Kg)

( If) ( Vf) (N-M)

MODEL GRAPH:

(i) Measurement of Back Emf (Eb):

Eb

Eb

(radians/sec)

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 10

Js2(s) + Bs(s) = T(s)………………………… 5

T(s) = KtsIa(s)……………………………………. 6

Equating equation (6) & (7)

KtsIa(s) = Js2(s) + Bs(s)

Ia(s) = Js2(s) + Bs(s) / Kts ………………. 7

Equation (7) values substitute in equation (4)

(Ra+ Ls)If(s) + Eb(s) = Va(s)

(Ra+ Ls) Js2(s) + Bs(s) / Kts) = Va(s)

(s)( Ra + Ls) Js2) + Bs / Kts = Va(s)

(s) Kt s

=

Va(s) ( Rf + Ls) ( Js2 + Bs)

Procedure for Calculating Back Emf (Eb):

1. Initially keep all switches in off position.

2. Initially keep voltage adjustment POT (variac) in minimum position.

3. Initially keep armature and field voltage adjustment POT (variac) in minimum position.

4. Connect the kit armature output A and AA to motor armature terminal A and AA

respectively.

5. Connect the kit field output F and FF to motor field terminal F and FF respectively.

6. Switch on the power switch and SPST switch S1 and S2.

7. Set the field voltage at rated value. Adjust the Vf and note down If and Speed for various

Vf., Plot the graph.

Procedure for Calculating Field Torque constant:

1. Apply the Vf till the motor run 50 % at rated speed and apply load by tightening.

2. Note down the Vf, If and spring balance reading and plot the graph and calculate torque

constant from the graph.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 11

(ii)Torque Vs Field current(If):

T

(Nm) T

If

If

MODEL CALCULATION:

Kb = Eb /

Kt = Tf/ If

m =Jm/Bm

f =Lf/Rf

DC Motor Specifications

DC motor: 0.5HP/ 180V / 1500 rpm with loading arrangement

Armature Resistance, Ra = 18 Ω

Armature Inductance, La =135mH

Moment of Inertia, Jm = 0.024 kg-m2

Coefficient of viscous Friction, B = 0.8 N-m/(rad/sec)

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 12

BLOCK DIAGRAM REPRESENTATION:

Km 1

SBm(1+mS)

Vf(S) Rf(1+Sf) m(S)

SKb

RESULT:

Thus the transfer function of field controlled DC motor was obtained.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 13

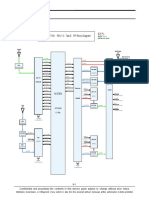

S2

S1

R1

S2

R1 R2

S3

R2

S1 S3

SYNCHRO TRANSMITTERR

S2

Vo

S3 S1

SYNCHRO CONTROL TRANSFORMER

S S

2 2

1Ø Eθ α sin (θXT -

SUPPLY θCT)

S S S S

3 1 3 1

θX θC

T T

SYNCHRO ERROR DETECTOR

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 14

EXP. NO.:

DATE: STUDY OF SYNCHROS

AIM:

(i) To measure the stator output voltage with respect to rotor position & plot the

variation of stator output voltage with respect to rotor position

(ii) To study synchros as AC position control system.

THEORY:

The term synchro is a generic name for a family of inductive devices which work on the

principle of a rotating transformer. The trade names for synchros are selsyn, autosyn and telesyn.

Basically they are electro mechanical devices or electromagnetic transducers which produce an

output voltage depending upon angular position of the rotor.

A synchro system is formed by interconnection of the device called synchro transmitter

& synchro control transformer. It is also called synchro pair. The synchro pair measures and

compares two angular displacements and its output voltage is approximately linear with angular

difference at the axes of both the shafts. They can be used in the following two ways.

1. To control the angular position of the load from a remote place/long distance.

2. For automatic correction of changes due to disturbances in the angular position of theload.

SYNCHRO TRANSMITTER:

Two major parts of synchro transmitter are stator and rotor. The stator is identical to the stator of

a three phase alternator. It is made of laminated silicon steel and slotted on the inner periphery to

accommodate a balanced three phase winding. The stator winding is star connected with winding

axes of the three coils electrically 120 degrees apart.

The rotor is of dumb bell construction with single winding. The ends of the rotor

windings are terminated on two slip rings. A single phase AC excitation voltage is applied to the

rotor through the slip rings.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 15

SYNCHRO CONTROL TRANSFORMER:

Stator winding consists of many turns of fine wire. Its impedance is higher compared to

that of synchro transmitter stator. This is due to the fact synchro control transformer should not

load synchro transmitter.

Rotor of control transformer is cylindrically shaped so that air gap flux is uniformly

distributed around the rotor.

Synchro control transformer is never used alone. It is used in conjunction with synchro

transmitter. Synchro control transformer and Synchro transmitter are used as error detector.

S2 S2

T T

X R

1Ø

1Ø

SUPPLY

SUPPLY

S3 S1 S3 S1

θR θC

SYNCHRO POSITION SYSTEM

S1 S1

S1

1 phase S2 S2 S2

supply

S3

S3 S3

TX1 TDR TX2

DIFFERENTIAL SYNCHROS

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 16

Vo = VXT – VCT

This is the error voltage available across rotor of control transformer. This output voltage

is amplitude modulated to a suppressed carrier signal.

Synchro Error Detector:

Zeroing of both synchros is done. Rotor of Control transformer is turned through 90º and

this position is taken as its electrical zero position.

Synchro Position System:

Zeroing of synchro transmitter and synchro receiver rotor is made. Connections are made

as shown in diagram. Both rotors are supplied from same single-phase supply. If rotor of XT is

turned clockwise through vº, rotor of XR will also rotate clockwise through same vº; usually rotor

of XR drives the pointer.

If two rotor positions are identical, voltages that are induced in both stators are identical

and there is no circulating current between two stators. But if two rotor positions are different,

circulating current flows in stator winding. This produces torque on rotor of XR and it is rotated

such that rotor of XT is equal to rotor position of XR. This system is electrical gearing because

asvx changes, vR also changes. There is no mechanical coupling between two shafts. Still it is

possible to acheive this gearing electrically.

Differential Synchros:

They have three phase stator winding and three phase rotor winding.

Types:

a) Differential Synchro Transmitter TDX

b) Differential Synchro Receiver TDR

TDX is used where correction must be inserted in angular information being transmitted

or sum or difference between two angles must be transmitted.

If rotor of TX is turned clockwise through Aº and if rotor of TDX is turned clockwise

through Bº, then rotor of TR will rotate through (A-B)º. Differential synchro receiver indicates to

remote point, sum or difference of two shaft positions of synchro transmitters. If rotor of TX1 is

rotated clockwise through Aº and if rotor of TX2 is rotated clockwise through Bº, either rotor of

TDR will rotate through (A-B)º.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 17

TABULATION:

S.NO. TRANSMITTER POSITION RECEIVER POSITION

(Degrees) (Degrees)

Rotor Voltage = V

S.NO. ROTOR STATOR OUTPUT VOLTAGE (V)

POSITION VS1S2(V) VS2S3(V) VS3S1(V)

(Degrees)

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 18

WORKING PRINCIPLE OF SYNCHROS:

When the rotor is excited by AC voltage, the rotor current flows and a magnetic field is

produced. The rotor magnetic field induces an emf in the stator coil by transformer action. The

effective voltage induced in any stator coil depends upon the angular position of the coil axis

with respect to rotor axis.

The generated emf of the synchro transmitter is applied as input to the stator coils of

control transformer. The rotor shaft is connected to the desired angular value. Depending on the

current position of the rotor and the applied emf on the stator, an emf is induced on the rotor

winding. This emf can be measured and used to drive a motor so that the position of the load is

corrected.

Let an ac voltage Vr(t) = Vrsin wct be supplied to the rotor of synchro transmitter. This

voltage causes a flow of magnetic current in the rotor coil, which produces a sinusoidal time

varying flux directed along its axis and distributed nearly sinusoidally in the air gap along stator

periphery. Because of transformer action, voltages are induced in each of the stator coils. As the

air gap flux is sinusoidally distributed, the flux linking any stator coil is proportional to the

cosine of angle between rotor and stator coil axes and so is the voltage induced in each stator coil

The stator coil voltages are of course in time phase with each other. Thus, it is seen that

the synchro transmitter acts like a single-phase transformer in which the rotor coil is the primary

and the stator coils form the three secondaries. Let VS1N, VS2N and VS3N respectively be the

voltage induced in the stator coils S1, S2, S3 with respect to the neutral. Then, for the rotor

position of the synchro transmitter where rotor axis makes an angle θ with axis of stator coil S2,

VS1N = KVr sin wct cos(θ+120o)

VS2N = KVr sin wct cosθ

VS3N = KVr sin wct cos (θ +240o)

The three terminal voltages of stator are,

VS1S2 = VS1N – VS2N

= 3 KVr sin (θ + 240o) sin wct

VS2S3 = VS2N –VS3N = 3 KVr sin (θ +120o) sin wct

VS3S1 = VS3N – VS1 = 3 KVr sin θ sin wct

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 19

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 20

When θ =0o, it is seen that maximum voltage is induced in the stator coil S2 while it follows that

the terminal voltage VS3S1 is zero. This position of rotor is defined as electrical zero of the

transmitter and is used as the reference for specifying angular position of the rotor.

Thus it is seen that the synchro transmitter is the angular position of its rotor shaft and the

output is a set of three single-phase voltages. The magnitudes of these voltages are functions of

the shaft position.

PROCEDURE:

Initial adjustments:

1. Digital voltmeter terminals are connected to S1 and S2 of stator coils.

2. Transmitter coil terminals S1, S2, S3 are connected to receiver coil terminals S11, S21, S31.

3. Power supply to the synchro kit is switched on and SPDT switch is closed.

4. Output voltage is checked for 0V at 0 degrees. If it is not 0V, then the pointer of both the

transmitter and receiver are adjusted to read 0V at 0 degrees.

To measure stator voltage with respect to rotor position:

1. After performing the initial adjustments, stator coil connections are disconnected.

2. Power supply to the synchro kit is switched on and SPDT switch is closed.

3. Digital voltmeter terminals are connected to S1 and S2 of stator coils.

4. Rotor position is adjusted and the corresponding stator output voltage is noted.

5. The same procedure is repeated for measurement of voltages across stator coils S1S3 and

S2S3 also.

To study the operation of Synchro pair:

1. Transmitter coil terminals S1, S2, S3 are connected to receiver coil terminals S11, S21, S31.

2. Power supply to the synchro kit is switched on and SPDT switch is closed.

3. Transmitter position is varied and corresponding receiver position is noted.

RESULT:

(i) Stator output voltage with respect to the rotor position was measured and the variation of

stator output voltage with respect to rotor position was plotted.

(ii) Synchro was studied as AC position control system.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 21

Source coding for Step Response of a first order system:

num=[1];

den=[1 0.1];

t=tf(num,den);

step(t);

Step Response of a first order system

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 22

EXP. NO.: DIGITAL SIMULATION OF FIRST ORDER SYSTEM

DATE:

AIM:

To write a MATLAB program to obtain the impulse and step response characteristics of

the given first order system.

APPARATUS REQUIRED:

1. PC with 2.93 GHz clock speed, 2 GB of RAM

2. MATLAB software

THEORY:

INTRODUCTION TO MATLAB & SIMULINK

MATLAB® is a high-performance language for technical computing. It integrates

computation, visualization, and programming in an easy-to-use environment where problems and

solutions are expressed in familiar mathematical notation. Typical uses include

Math and computation

Algorithm development

Data acquisition

Modeling, simulation, and prototyping

Data analysis, exploration, and visualization

Scientific and engineering graphics

Application development, including graphical user interface building

MATLAB is an interactive system whose basic data element is an array that does not

require dimensioning. This allows you to solve many technical computing problems, especially

those with matrix and vector formulations, in a fraction of the time it would take to write a

program in a scalar no interactive language such as C or FORTRAN. The name MATLAB

stands for matrix laboratory. MATLAB was originally written to provide easy access to matrix

software developed by the LINPACK and EISPACK projects. Today, MATLAB engines

incorporate the LAPACK and BLAS libraries, embedding the state of the art in software for

matrix computation.

MATLAB has evolved over a period of years with input from many users. In university

environments, it is the standard instructional tool for introductory and advanced courses in

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 23

Source coding for Impulse Response of a first order system:

num=[1];

den=[1 0.1];

t=tf(num,den);

impulse(t);

Impulse Response of a first order system

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 24

PROCEDURE:

1. Enter the command window of MATLAB.

2. Create a New M-File by selecting File New M-File.

3. Type and save the program.

4. Execute the program by pressing F5

5. View the results.

6. Analyze the Results.

FORMULA USED:

For step input,

−𝑡

𝐶 𝑡 = 𝐴 1−𝑒 𝑇 ; 𝑡≥0

For impulse input,

𝐾 −𝑡

𝐶 𝑡 = 𝑒 𝜏 ;𝑡 ≥ 0

𝜏

RESULT:

Thus the MATLAB program was written to obtain the time response characteristics for

impulse and step input of the given first order system.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 25

Source coding for Step Response of a second order system:

num1=[0.1];

den1=[1 0.1];

t1=tf(num1,den1);

num2=[0.2];

den2=[1 0.2];

t2=tf(num2,den2);

step(t1,t2);

MODEL CALCULATION:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 26

EXP. NO.: DIGITAL SIMULATION OF SECOND ORDER SYSTEM

DATE:

AIM:

To write a MATLAB program to obtain the impulse and step response characteristics of

the given first order system.

APPARATUS REQUIRED:

1. PC with 2.93 GHz clock speed, 2 GB of RAM

2. MATLAB software

PROCEDURE:

1. Enter the command window of MATLAB.

2. Create a New M-File by selecting File New M-File.

3. Type and save the program.

4. Execute the program by pressing F5

5. View the results.

6. Analyze the Results.

FORMULA USED:

𝜋−𝜃

𝑅𝑖𝑠𝑒 𝑡𝑖𝑚𝑒 𝑡𝑟 =

𝜔𝑑

𝜋

𝑃𝑒𝑎𝑘 𝑡𝑖𝑚𝑒 𝑡𝑝 =

𝜔𝑑

4

𝑆𝑒𝑡𝑡𝑙𝑖𝑛𝑔 𝑡𝑖𝑚𝑒 𝑡𝑠 = 𝑓𝑜𝑟 2% 𝑒𝑟𝑟𝑜𝑟

𝜀𝜔𝑛

3

𝑆𝑒𝑡𝑡𝑙𝑖𝑛𝑔 𝑡𝑖𝑚𝑒 𝑡𝑠 = 𝑓𝑜𝑟 5% 𝑒𝑟𝑟𝑜𝑟

𝜀𝜔𝑛

−𝜀 𝜋

% 𝑃𝑒𝑎𝑘𝑜𝑣𝑒𝑟𝑠𝑜𝑜𝑡 𝑡𝑖𝑚𝑒 𝑀𝑝 = 𝑒 1−𝜀 2

1 − 𝜀2

𝑤𝑒𝑟𝑒 𝜃 = tan−1 ( )

𝜀

𝜔𝑑= 𝜔𝑛 1 − 𝜀 2

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 27

Source coding for Impulse Response of a Second order system:

num1=[0.1];

den1=[1 0.1];

t1=tf(num1,den1);

num2=[0.2];

den2=[1 0.2];

t2=tf(num2,den2);

impulse(t1,t2);

TABULATION:

S. No. Parameters Theoretical Values Practical Values

1. Rise time

2. Peak time

3. Peak overshoot

4. Settling time

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 28

RESULT:

Thus the MATLAB program was written to obtain the time response characteristics for

step input of the given second order system.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 29

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 30

EXP. NO.:

STABILITY ANALYSIS OF LINEAR SYSTEM

DATE:

AIM:

To write a program (or using SIMULINK) to analyze the stability of linear system using

Bode plot and Root locus.

APPARATUS REQUIRED

1. PC with 2.93 GHz clock speed, 2GB RAM

2. MATLAB Software.

PROCEDURE:

DESIGN PROCEDURE OF BODE PLOT:

For magnitude plot,

1. Convert the open loop transfer function into bode form or time constant form. The bode

form of the transfer function is

Replace s by jω

2. List the corner frequencies in the increasing order and prepare a table as shown in below.

Term Corner frequency(𝝎)in Slope in Change in slope

rad/sec db/dec in db/dec

3. Choose an arbitrary frequency 𝜔𝑙 which is less than the lowest corner frequency and 𝜔 is

greater than highest corner frequency

4. Find Magnitude at all corner frequency

At 𝜔𝑐𝑙 𝑎𝑛𝑑 𝜔𝑐1 Gain A =20 log [G(jω)]

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 31

TRANSFER FUNCTION

G(S) = 25 / (S2+ 4S + 25)

Source Code

% Bode Plot

% Enter the Numerator and Denominator

num=[0 25];

den=[1 4 25];

ω=logspace(-2,3,100);

sys=tf(num,den);

[mag,phase,ω]=bode(sys, ω);

bode(sys,ω);

margin(mag,phase,ω);

xlabel(„frequency‟);

ylabel(„phase(deg);magnitude(db)‟);

title(„bode plot‟);

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 32

5. Find the change in slope at every corner frequency

𝜔 𝑐2

Gain at 𝜔𝑐2 = [𝑠𝑙𝑜𝑝𝑒 𝑓𝑟𝑜𝑚 𝜔𝑐1 𝑡𝑜 𝜔𝑐2 × log 𝜔 𝑐1

+ 𝑔𝑎𝑖𝑛 𝜔𝑐1 ]

6. In a semi log graph sheet mark the required the range of frequency in x-axis and range of

db in y-axis after choosing proper scale.

7. Mark all the points on the graph sheet and join the points by straight line.

For phase plot,

1. Convert the open loop transfer function into bode form or time constant form. The bode

form of the transfer function is

Replace s by jω

2. Find the phase angle of G(jω) for various values of ω and tabulate it.

Ф in deg = tan-1(img/real)

ω in rad/sec Ф in deg

3. In a semi-log graph sheet mark the required the range of frequency in x-axis and range of

degree in y-axis after choosing proper scale.

4. Mark all the points on the graph sheet and join the points.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 33

TRANSFER FUNCTION:

G(S) H(S) = k(S + 1) / S(S + 2)(S + 3)

This transfer function can be rewritten as

G(S) H(S) = kS + k / (S3 + 5S2 + 6S + 10)

Assuming k = 1

Source Code

% Root locus

num=[0 0 1 1]

den=[1 5 6 0]

subplot(2,1,1)

title(„Root locus‟)

rlocus(num,den)

xlabel(„Real axis‟)

ylabel(„Imaginary axis‟)

subplot(2,1,2)

title(„Root locus‟)

r = rlocus(num,den)

plot(r,„o‟)

v = [-6 6 -6 6]

axis (v)

xlabel(„Real axis‟)

ylabel(„Imaginary axis‟)

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 34

Determination Gain margin and phase margin,

1. Find gain cross over frequency(ωgc) from magnitude plot (plot crossing at 0 db line)

2. Find the phase cross over frequency(ωpc) from phase plot (plot crossing at -1800 line)

3. The gain margin in db is measured by negative of db of G(jω) at the phase cross-over

frequency(ωpc)

4. The phase margin in degree is given by γ=1800+Фgc

Where Фgc is the phase angle of G(jω) at gain cross over frequency (ωgc)

DESIGN PROCEDURE OF ROOT LOCUS:

1. The root locus is symmetrical about the real axis and the number of branches is equal to

the order of the characteristic polynomial (No. of poles of the OLTF)

2. All branches of root locus at open loop poles (when K=0) and ends at either open loop

zero or infinity (K=∞). The number of branches terminating at infinity equals to the

difference between the number of poles and number of zeros of G(s) H(s).

3. A point on the real axis lies on the root locus if the sum of the poles and zeros on the real

axis to the right of the point is an odd number

4. The (n-m) root locus branches that proceed to infinity do so along the asymptotes with

angles

(2𝑞+1)

∅𝐴 = ± 180° ; q=0,1,2…..n-m-1.

(𝑛−𝑚 )

5. The centroid of intersection of the asymptotes with real axis at 𝜎𝐴 is given by

𝑠𝑢𝑚 𝑜𝑓 𝑟𝑒𝑎𝑙 𝑝𝑎𝑟𝑡𝑠 𝑜𝑓 𝑝𝑜𝑙𝑒𝑠 − 𝑠𝑢𝑚 𝑜𝑓 𝑟𝑒𝑎𝑙 𝑝𝑎𝑟𝑡𝑠 𝑜𝑓 𝑧𝑒𝑟𝑜𝑠

𝜎𝐴 =

𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑝𝑜𝑙𝑒𝑠 − 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑧𝑒𝑟𝑜𝑠

𝑑𝑘

6. The breakaway points of the root locus are the solution of 𝑑𝑠

=0

7. The angle of departure from a complex open loop pole is given by

∅𝑃 = ±180° 2𝑞 + 1 + ∅ q=0, 1, 2……

Where Ф is net angle contribution to this pole by all other open loop poles and zeros.

Similarly the angle of arrival at open loop zero is given by

∅𝑍 = ±180° 2𝑞 + 1 − ∅ q=0,1,2……

Where Ф is net angle contribution to the zero under consideration by all other open loop poles

and zeros.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 35

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 36

Note: For a complex pole

Angle of departure=180◦ - sum of angle of vector to the + sum of angle of vector to the

complex pole from other poles complex pole from other zeros

Note: For a complex zero

Angle of departure=180◦ - sum of angle of vector to the + sum of angle of vector to the

complex zero from other zeros complex zero from other poles

8. The intersection of root locus with imaginary axis can be determined using the Routh

criterion

9. The open loop gain K at any point S=S0 on the root locus is given by

𝑛

𝑖=1 |(𝑆0 + 𝑝𝑖 )|

𝐾= 𝑛

𝑖=1 |(𝑆0 + 𝑍𝑖 )|

𝑝𝑟𝑜𝑑𝑢𝑐𝑡 𝑜𝑓 𝑝𝑎𝑠𝑜𝑟 𝑙𝑒𝑛𝑔𝑡𝑠 𝑓𝑟𝑜𝑚 𝑆𝑜 𝑡𝑜 𝑜𝑝𝑒𝑛 𝑙𝑜𝑜𝑝 𝑝𝑜𝑙𝑒𝑠

𝑘=

𝑝𝑟𝑜𝑑𝑢𝑐𝑡 𝑜𝑓 𝑝𝑎𝑠𝑜𝑟 𝑙𝑒𝑛𝑔𝑡𝑠 𝑓𝑟𝑜𝑚 𝑆𝑜 𝑡𝑜 𝑜𝑝𝑒𝑛 𝑙𝑜𝑜𝑝 𝑍𝑒𝑟𝑜𝑠

RESULT

Thus the stability of linear systems using bode plot and root locus were analyzed.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 37

SCHEMATIC DIAGRAM OF AC POSITION CONTROL SYSTEM

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 38

EXP. NO.:

STUDY OF AC POSITION CONTROL SYSTEM

DATE:

AIM:

To control the position of loading system using AC servomotor.

APPARATUS REQUIRED:

S. No. APPARATUS SPECIFICATION QUANTITY

1. AC Position / Speed Control Trainer Kit - 1

2. Two phase AC motor 12 V, 90 RPM 1

3 Digital Storage Oscilloscope (DSO) - 1

4 Patch cords - As required

AC SERVOMOTOR POSITION CONTROL:

It is attempted to position the shaft of a AC Motor‟s (Receiver) shaft at any angle in the

range of 100 to 3500 as set by the Transmitter‟s angular position transducer (potentiometer), in

the range of 100 to 3500. This trainer is intended to study angular position between two

mechanical components (potentiometers), a Transmitter Pot and Receiver pot. The relation

between these two parameters must be studied.

Any servo system has three blocks namely Command, Control and Monitor.

(a) The command is responsible for determining what angular position is desired. This is

corresponds to a Transmitter‟s angular position (Set Point- Sp) set by a potentiometer.

(b) The Control (servo) is an action, in accordance with the command issued and a control is

initiated (Control Variable -Cv) which causes a change in the Motor‟s angular position. This

corresponds to the receiver‟s angular position using a mechanically ganged potentiometer.

(c) Monitor is to identify whether the intended controlled action is executed properly or not. This

is similar to feedback. This corresponds to Process Variable Pv. All the three actions together

form a closed loop system.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 39

TABULATION:

Set Angle in degrees Measured angle in

S. No Error in degrees(Өs- Өm)

( Өs) degrees(Өm)

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 40

FORMULA USED:

Error in degree =θs - θm

Error in percentage = ((θs - θm) / θs)* 100

PROCEDURE:

1. Connections are patched for AC position control system in the trainer kit.

2. Set and actual positions of the motor are noted.

3. Proportional Gain KP, derivative time Td and integral time Ti are set using the

respective potentiometers.

4. AC supply is switched on. DSO is used to observe the transient response of the actual

position of the system once the motor starts to rotate. Two phase AC motor stops at a

particular position.

5. Error between actual and set positions is noted. Steps 3, 4 and 5 are repeated for

different values of KP, Td and Ti.

6. When Proportional Control action is maximum, the system responds quickly to reach

the steady state (i.e. Actual position reaches the desired position very quickly). When

Proportional Control action is minimum, the system responds slowly to reach the

steady state (i.e. Actual position reaches the desired position very quickly).

7. When Integral Control action is maximum, the system response is more oscillatory.

When Integral Control action is minimum, the system response is less oscillatory.

8. When Derivative Control action is maximum, the system response settles down and

reaches the set position with less overshoot. When derivative Control action is

minimum, the system response settles down and reaches the set position with more

overshoot.

RESULT:

Thus the DC Position control system is studied and effect of Proportional and Integral

Control actions on the system response is studied.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 41

MATLAB OUTPUT:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 42

EXP. NO.: DESIGN OF LAG, LEAD & LEAD-LAG COMPENSATOR BY

DATE: MATLAB SIMULATION

AIM:

To design a lag, lead & lead-lag compensator for a unity feedback system (whose open

loop transfer function is specified) in order to meet the desired specifications.

APPARATUS REQUIRED

1. PC with 2.93 GHz clock speed, 2GB RAM

2. MATLAB Software.

THEORY:

The nature of compensation depends upon the given plant, the compensator may be an

electrical, mechanical, hydraulic, pneumatic or other type of devices are network usually an

electric network serves as compensator in many control systems. The compensator transfer

function may be placed in cascade with the plant transfer function (cascade or series

compensation) or in the feedback path (feed back or parallel compensation). The compensators

are of three types

a) Lead compensator: The compensator having transfer function of the form given below is

known as lead compensator. GC (s)= (s+zc)/(s+pc) = (s+ 1/W)/(s+1/DW); D= zc/pc0 D< 1

ensures that the pole is located to the left of the zero. Lead compensator speeds up the transient

response and increases the margin of stability of a system. It also helps to increase the system

error constant though to limited extent.

b) Lag Compensator: The Compensator having transfer function of the form given below is

known as lag compensator. GC (s)= (s+zc)/(s+pc) = (s+ 1/W)/(s+1/EW); E = zc/pc>1, D>0 E>1

ensures that pole is to the right of Zero, that is nearer the origin than Zero. Lag compensator

improves the steady state behaving a system, while nearly preserving its transient response.

c) Lag – Lead Compensator: When both the transient and steady state response require

improvement a Lag –Lead compensator is required. This is basically a Lag and Lead

compensator connected in series.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 43

Lag compensator

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 44

PROCEDURE:

1. Open the MATLAB software and create a blank Model file.

2. Develop the block diagrams for lag, lead and lead-lag compensator using the simulink

function.

3. Simulate the MATLAB model and obtain the phase angle Vs frequency and gain Vs

Frequency for lag, lead and lag – lead networks.

RESULT:

Thus a lag, lead & lead-lag compensator for the unity feedback system is designed and

the improvement in the output response after compensation is studied.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 45

Source coding of P controller

kp=300;

num=[kp];

den=[1 10 20+kp];

t=0:0.01:2;

step(num,den,t);

Source coding of PI controller

kp=300;

ki=10

num=[ki kp];

den=[1 10+ki 20+kp];

108

t=0:0.01:2;

step(num,den,t);

Source coding of PID controller

kp=350;

ki=300

kd=50;

num=[kd kp ki];

den=[1 10+kd 20+kp ki];

t=0:0.01:2;

step(num,den,t);

MODEL GRAPH:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 46

EXP. NO.: STUDY THE EFFECT OF P, PI, PID CONTROLLERS

DATE: USING MATLAB

AIM:

To study the effect of Proportional, Proportional –Integral, Proportional –Integral-

Derivative controller using MATLAB

APPARATUS REQUIRED

1. PC with 2.93 GHz clock speed, 2GB RAM

2. MATLAB Software.

THEORY:

In order to get a good output response from an existing closed-loop system (plant), a

controller can be introduced. The controller can be a proportional controller (P), proportional

plus integral controller (PI), or proportional plus integral plus derivative controller (PID). The

type of controller required for the system is chosen based on its open-loop response or closed

loop response from which the performance parameters can be known. In order to improve the

overall response, it is required to choose a PID controller.

The input to the plant consists of three components: 1. KpE, which is proportional to

error. This component increases the loop gain of the system, thereby reducing its sensitivity to

plant parameter variations. 2. KiE/s, which is proportional to the integral of the error. This

component increases the order of the system and reduces the steady state error of the system by

adding a pole at the origin in the s plane. 3. KdsE, which is proportional to the derivative of the

error. This component tends to stabilize the system by introducing the derivative of the error.

P CONTROLLER:

P controller is mostly used in first order processes with single energy storage to stabilize

the unstable process. The main usage of the P controller is to decrease the steady state error of

the system. As the proportional gain factor K increases, the steady state error of the

system decreases. However, despite the reduction, P control can never manage to eliminate the

steady state error of the system. As we increase the proportional gain, it provides smaller

amplitude and phase margin, faster dynamics satisfying wider frequency band and larger

sensitivity to the noise. We can use this controller only when our system is tolerable to a

constant steady state error. In addition, it can be easily concluded that applying P controller

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 47

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 48

decreases the rise time and after a certain value of reduction on the steady state error, increasing

K only leads to overshoot of the system response. P control also causes oscillation if sufficiently

aggressive in the presence of lags and/or dead time. The more lags (higher order), the more

problem it leads. Plus, it directly amplifies process noise.

P-I CONTROLLER:

P-I controller is mainly used to eliminate the steady state error resulting from P

controller. However, in terms of the speed of the response and overall stability of the system, it

has a negative impact. This controller is mostly used in areas where speed of the system is not

an issue. Since P-I controller has no ability to predict the future errors of the system it cannot

decrease the rise time and eliminate the oscillations. If applied, any amount of I guarantees set

point overshoot.

P-I-D CONTROLLER:

P-I-D controller has the optimum control dynamics including zero steady state error,

fast response (short rise time), no oscillations and higher stability. The necessity of using a

derivative gain component in addition to the PI controller is to eliminate the overshoot and the

oscillations occurring in the output response of the system. One of the main advantages of the P-

I-D controller is that it can be used with higher order processes including more than single

energy storage.

PROCEDURE:

1. Open the MATLAB software and create a blank M- file.

2. Write the Program for P, PI and PID Controller in MATLAB.

3. Simulate the MATLAB program and obtain the response of the transfer function of higher

order system.

RESULT:

Thus the response of P, PI and PID controller were studied and verified using MATLAB.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 49

CIRCUIT DIAGRAM:

PANEL DIAGRAM

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 50

EX. NO.:

WHEATSTONE BRIDGE

DATE:

AIM:

To determine the value of unknown medium resistance using Wheatstone bridge.

APPARATUS REQUIRED:

S. No Apparatus Quantity

1 Wheat stone bridge trainer kit 1

2 Digital Multi-meter 1

3 Unknown resistor specimen 5

4 (or) unknown

Patch Cords resistances As Required

THEORY:

DC bridges are used to measure the resistance of any resistive element. Wheatstone

bridge is used to measure the medium resistance (1 to 10k). The Wheatstone bridge is an

accurate and reliable instrument, which is extensively used in industries. The Wheatstone bridge

is an instrument for making comparison measurement and operates upon a null indication

principle. This means that the indication is independent of the calibration of the null indicating

instrument or any of the characteristics. For this reason, very high degree of accuracy can be

achieved using Wheatstone bridge.

The Wheatstone bridge has four resistive arms consisting of resistances R1, R2, R3 and Rx

together with a source of an emf and a null detector, usually a galvanometer or any other sensitive

current meter. The current through the galvanometer depends on the potential difference between

points „C‟ and „D‟. The bridge is said to be balanced when there is no current through the

galvanometer or when the potential difference across the galvanometer is zero. This occurs when

the voltage from point „A‟ to point „C‟ equals the voltage from point „ A „ to point „ D „ and vice

versa. At balance,

Rx R2 R1 R3

R3

Rx R1 (1)

R2

Where, Rx - Unknown resistance

R1, R2, R3 – Variable resistors

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 51

TABULATION:

Multiplier Unknown

Sl. Actual resistance Variable resistance resistance, resistance,

No R2 ()

RM (or) R3() Rx ()

MODEL CALCULATION:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 52

PROCEDURE

1. The connections are made as per circuit diagram shown.

2. The unknown resistance is connected across at Rx terminals.

3. The trainer kit is switched ON.

4. R2 is varied to get exact point of balance.

5. The Kit is switched off and patching at R2is removed.

6. The resistance across R2 is measured using multi-meter.

7. The readings are tabulated and the value of unknown resistance is estimated.

RESULT:

Thus the unknown medium resistance value was estimated using Wheatstone bridge.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 53

CIRCUIT DIAGRAM:

PANEL DIAGRAM

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 54

EX. NO.: KELVIN’S DOUBLE BRIDGE

DATE:

AIM:

To estimate the value of unknown low resistance using Kelvin‟s Double Bridge.

APPARATUS REQUIRED:

S. No Apparatus Quantity

1 Kelvin‟s double bridge trainer kit 1

2 Digital Multi-meter 1

3 Unknown Resistor specimen As Required

(or)

4 Patchunknown

Cords resistances As Required

FORMULA USED:

The unknown resistance Rx = (P / Q)* S

Where,

P, Q – Ratio arm resistances

S – Variable Resistance

THEORY:

Kelvin‟s Double Bridge is a modification of Whetstone‟s bridge. It provides increased

accuracy in the measurement of low resistance. It incorporates two sets of ratio arms ‟P‟ & ‟Q‟

and „p‟ & „q‟. A Galvanometer is connected between the mid points of two ratio arms. The ratio

P/Q is made equal to the ratio p/q. Under balanced condition, no current flows through the

galvanometer i.e. the deflection in galvanometer is zero. This implies that the voltage drop across

the two ratio arms is zero.

The unknown resistance Rx is connected at one end of the arm and the decade resistance box is

connected at the other. The decade resistance box is used for balancing the unknown resistance.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 55

TABULATION

Rx (Ω) Rx (Ω)

S. No P (Ω) Q (Ω) S (Ω) Actual Observed

MODEL CALCULATION

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 56

PROCEDURE

1. Connections are made as per the connection diagram.

2. The unknown resistance is connected at Rx terminal.

.

3. The unit is switched ON.

4. The range selection switch is selected at the point where the multi-meter reads least possible

value of voltage.

5. The potentiometer (P1) is varied to obtain null balance.

6. The unit is switched off and the resistance is estimated using multi-meter across P1.

RESULT:

Thus the unknown low resistance value was estimated using Kelvin double bridge.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 57

CIRCUIT DIAGRAM:

C3 = Unknown Capacitance,

C3 = R1*C2/R2

PANEL DIAGRAM

C1 =0.001µF, C2 =0.1 µF, R2 = RM (Multiplier Resistance)

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 58

EXP. NO.:

SCHERING BRIDGE

DATE:

AIM:

To estimate the unknown value of capacitance using Schering Bridge.

APPARATUS REQUIRED:

S. No Apparatus Quantity

1 Schering Bridge trainer kit 1

2 Decade Capacitance Box 1

3 Digital Multi-meter 1

4 CRO 1

5 Patch cords As required

FORMULA USED:

Unknown capacitance, Cx = R1*C2/R2

Unknown resistance, R3 = C1*R2/C2

THEORY:

The Schering Bridge is basically a four-arm AC bridge circuit and its measurement idea

is based on balancing the loads on its arms. The figure below shows a circuit diagram of the

Schering Bridge. In this figure, R1 and R2 are known, while R3 (Series resistance of the test

capacitor) is unknown. C1 and C2 are also known, while C3 is the value being measured. To

measure R3 and C3, the values of C2 and R2 are fixed, while the values of R1 and C1 are

adjusted until the current through the ammeter between points A and B becomes zero. This

happens when the voltages at points A and B are equal, in which case the bridge is said to be

"balanced". In this state, the followings hold:

R3 = C1*R2/C2 and C3 = R1*C2/R2.

Note that the balancing of a Schering Bridge is frequency-independent. Because of the

inductance of the resistances, we forced to put a capacitance in parallel with the resistances to

compensate their inherent inductances. Also, for accurate measurement in high voltage tests,

shielding of the circuit components is of crucial importance.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 59

TABULATION:

S. No. Variable resistance Multiplier resistance, Cx

Cx(Practical)

R1 (Ω) RM (or) R2 (Ω) (Theoretical)

1 0.01 μF

2 0.1 μF

3 0.22 μF

4 0.47 μF

5 10 μF

MODEL CALCULATION:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 60

PROCEDURE:

1. Connections are made as per the circuit diagram.

2. The power supply is switched ON.

3. The unknown capacitance CX is connected.

4. Connect a digital multi-meter across the socket marked “To detector”

5. The bridge is balanced by varying the values of R1 and connect the suitable multiplier

resistance(RM).

5. The power supply is switched off and the resistances R1 and RM are measured by using multi-

meter.

6. The value of unknown capacitance CX is calculated by using the given formula and tabulated.

7. The steps 2 to 6 are repeated for different values of capacitances.

RESULT:

Thus the unknown capacitance value was estimated using Schering bridge kit.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 61

CIRCUIT DIAGRAM:

PANEL DIAGRAM

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 62

EXP. NO.: MAXWELL’S INDUCTANCE CAPACITANCE BRIDGE

DATE:

AIM:

To estimate the value of unknown inductance using Maxwell‟s inductance capacitance bridge.

APPARATUS REQUIRED:

S. No Apparatus Qty

1 Maxwell Inductance Bridge kit 1

2 Unknown Inductance specimen 1

3 Digital Multi-meter 1

4 Patch Cords As required

5 Headphone/CRO 1

FORMULA USED:

Unknown Inductance, Lx = R2RM C1

Quality Factor, Q = ω R1 C1

THEORY

Maxwell‟s Inductance – Capacitance Bridge is used to measure unknown inductance in

terms of calibrated resistance and capacitance. Calibration-grade inductors are more difficult to

manufacture than capacitors of similar precision, and so the use of a simple "symmetrical"

inductance bridge is not always practical. Because the phase shifts of inductors and capacitors

are exactly opposite to each other, capacitive impedance can balance out inductive impedance if

they are located in opposite legs of a bridge.

Another advantage of using a Maxwell bridge to measure inductance rather than a

symmetrical inductance bridge is the elimination of measurement error due to mutual inductance

between two inductors. Magnetic fields can be difficult to shield, and even a small amount of

coupling between coils in a bridge can introduce substantial errors in certain conditions. With no

second inductor to react with in the Maxwell Bridge, this problem is eliminated.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 63

TABULATION:

Variable Variable Multiplier Calculated Actual Value

S. No. resistance, R1 resistance, R2 Resistance, Value, Lx(mH) Q Factor

(Ω) (Ω) RM(Ω) Lx (mH)

MODEL CALCULATION:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 64

PROCEDURE:

i) Connections are made as per the circuit diagram.

ii) The unknown inductance is connected at the Lx (unknown) point.

iii) The power supply is switched ON.

iv) By selecting the multiplier resistance to successive higher or lower values for

minimum unbalance, vary the resistance R2 to obtain the final balance point.

v) Further balancing is done by varying the Resistance R1, till the unbalance drops close to

zero.

vi) Using Digital Multi-meter, measure variable resistance(R1 and R2 )

vii) Patching is removed; the readings are noted and the value of unknown inductance is

calculated using the formula.

RESULT:

Thus the unknown inductance value was estimated using Maxwell‟s inductance capacitance

bridge.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 65

CIRCUIT DIAGRAM:

PANEL DIAGRAM:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 66

EX. NO.: TEMPERATURE MEASUREMENT

DATE:

AIM:

To obtain the temperature - resistance characteristics of the given thermistor.

APPARATUS REQUIRED:

S. No APPARATUS RANGE QUANTITY

1. Temperature measurement trainer kit - 1

2. Multi-meter - 1

3. Thermistor sensor 2 Wire NTC (5K) 1

4. Thermometer (0-110) °C 1

5. Water bath 1.8 litre 1

PRECAUTION:

1. Water level in the water bath should be maintained above the heating filament.

Otherwise, heater will be spoiled.

2. Thermistor and thermometer should not touch the body of the heater.

PROCEDURE:

1. The thermistor is connected across T1 and T2 & the ITB-06A unit is switched ON.

2. For resistance measurement, SW1 should be kept in resistance mode.

3. The multi-meter (in resistance mode) is connected across T3 & T4.

4. During zero calibration, SW2 should be in EXT mode.

5. The offset potentiometer is adjusted to 5V. Because, thermistor is NTC type.

6. Before conducting the experiment, SW2 should be in INT mode.

7. Thermometer is inserted into the water bath and the water bath is switched ON.

8. The temperature in thermometer is noted and corresponding resistance output of the

thermistor is measured.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 67

TABULATION:

Thermometer Temperature °C Resistance (Ω)

Model Graph:

Resistance

Temperature 0C

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 68

THEORY:

Thermistors are semi-conductor type resistance thermometers. Thermistor is the short

form for „Thermal Resistor‟. Thermistors are composed of sintered mixture of metallic oxides

such as manganese, nickel, cobalt, copper, iron and uranium. Thermistor may be in the form of

beads, probes, rods and discs. The device consists of the bulk semiconductor device that acts as a

resistor with a high and negative temperature co-efficient of resistance, sometimes as high as –

6% per degree Celsius rise in temperature. Due to this property of high sensitivity thermistor is

mainly applicable in precision temperature measurement, temperature control and temperature

compensation, especially in a lower temperature range of -1000 C to +3000 C. A typical

thermistor has a base resistance of about 16.3 kΩ at 00, decreasing to about 340Ω at 1000 C

RESULT:

Thus the temperature - resistance characteristics of the thermistor was obtained.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 69

TRAINER SCHEMATIC DIAGRAM:

CONSTRUCTION DIAGRAM

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 70

EXP. NO.:

STUDY OF PRESSURE TRANSDUCER

DATE:

AIM:

To obtain the characteristic curve for the given bourdon tube pressure transducer.

APPARATUS REQUIRED:

S. No Equipment Quantity

1 Bourdon pressure transducer kit 1 No

2 Foot pump 1 No

3 Multi-meter 1 No

4 Power Cord As required

FORMULA USED:

Applied pressure – Displayed pressure

% Error = ------------------------------------------------------------ x 100

Displayed pressure

THEORY

Pressure measuring devices use elastic members for sensing pressure at the primary

stage. These elastic members convert pressure into mechanical displacement which is later

converted into an electrical form using a secondary member.

The commonly used pressure sensitive device is Bourdon tube. The Bourdon tubes are

made out of an elliptically flattened tube bent in such a way as to produce C type shape. One end

of the tube is sealed and the other end is open for the fluid or air to enter. When the fluid or air

whose pressure is measured enters the tube, the tube tends to straighten out on account of the

pressure applied.

The displacement of the free end is used to move a pointer on a scale calibrated in terms

of pressure or may be applied to an electrical displacement transducer whose output may be

calibrated in terms of the pressure applied. Bourdon tube has several advantages which includes

simple construction, low cost, high pressure range, and good accuracy except at low pressures.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 71

TABULATION

Applied Pressure, Displayed Pressure,

S. No. Error (%)

Pa (PSI) Pd (PSI)

MODEL GRAPH:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 72

PROCEDURE

1. The air inside the cylinder is released by opening the valve and the power supply is

switched ON.

2. The opened air release valve is closed and it is to be checked that the pressure gauge

indicates „0‟ position.

3. The air is gradually pumped into the cylinder so that the pressure increases.

4. The bridge output and the displayed pressure are noted.

5. The above steps are repeated for different values of pressures.

6. The readings are tabulated and the following curves are plotted.

i) Applied pressure Vs displayed pressure

RESULT:

Thus the characteristic curves for a given Bourdon tube were obtained.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 73

Circuit Diagram

Trainer Schematic Diagram

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 74

EXP. NO.:

STUDY OF DISPLACEMENT TRANSDUCER – LVDT

DATE:

AIM:

To study LVDT and obtain its characteristic curve.

APPARATUSREQUIRED:

S. No Equipment Quantity

1 LVDT Trainer kit 1

2 Digital multi-meter 1

3 3Patch cords As required

FORMULA USED:

Actual displacement – Displayed displacement

% Error = ----------------------------------------------------------- x100

Displayed displacement

THEORY:

Differential transformers, based on a variable inductance principle are also used to

measure displacement. The most popular variable inductance transducer for measurement of

linear displacement is the Linear Variable Differential Transformer (LVDT). The transformer

consists of a single primary winding and two secondary windings wound on a cylindrical former.

The secondary windings have equal number of turns and are identically placed on either side of

the primary winding. The primary winding is connected to an alternating current source. A

movable soft iron core is placed inside the former. The displacement to be measured is applied to

the arm attached to the soft iron core. This magnetic core provides a path for magnetic flux

linkage between the coils. The position of the magnetic core controls the mutual inductance

between the centre of primary coil and two secondary coils.

When the core is centered between, the two secondary coils are equal but out of phase by

o

180 . The voltage in the two coils cancels and the output voltage will be zero. When the core is

moved from the center position, an imbalance in mutual inductance between the primary coil and

secondary coil occurs and an output voltage develops. The output voltage of an LVDT is a linear

function of the core displacement.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 75

TABULATION

Positive Displacement

Screw Gauge Digital output

S. No Setting (mm) % Error

Negative Displacement

Screw Gauge Digital output

S. No Setting (mm) % Error

Model Graph:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 76

LVDTs have a very high range for measurement of displacement. It is a frictionless

device and can tolerate high degree of shock and vibrations. It shows low hysteresis and

consumes less power. These advantages make LVDTs most popular for measurement of

displacement.

PROCEDURE:

1. The LVDT kit is switched ON.

2. The Screw gauge is rotated till it reads 10.0. mm.

3. The ZERO potentiometer is adjusted at the front panel so that the display reads 0.0 mm.

4. The core of micrometer is rotated till the micrometer‟s display reads “10.0 mm”.

Otherwise the gain knob is adjusted until the display reads “10.0 mm”.

5. The instrument is calibrated for +/-10.0 mm range. As the core of LVDT moves, the

display reads the displacement in mm.

6. The core of the micrometer is rotated in steps of 1 mm and the readings are tabulated.

The micrometer will show the exact displacement given to the LVDT core and the

display will read the displacement sensed by the LVDT.

7. The readings are tabulated and the graph of displacement Vs output voltage is plotted.

8. The characteristic curve between actual displacement and displayed displacement is

plotted.

RESULT:

Thus the residual voltage was determined and the characteristic curve for a given LVDT

was obtained.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 77

PANEL DIAGRAM:

SYMBOL:

Light Dependent Resistor Photodiode Phototransistor

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 78

EXP. NO.:

OPTICAL SENSOR

DATE:

AIM:

To study the voltage characteristics of Light Dependent Resistor (LDR), Photodiode,

Phototransistor.

APPARATUS REQUIRED:

1. LDR/Photo Diode/Photo Transistor Characteristics Trainer

2. Multi-meter

3. Patch cords

4. Power cords

PROCEDURE:

1. The pointer at 0 light intensity level on the scale is positioned, when the bulb is away

from the sensors.

2. The supply to the unit is switched ON.

3. The 1V across T1, T2 terminals is set by adjusting the (0-12) V DC potentiometer.

4. The voltage output across T5, T6 terminals is measured at that time when the switch is in

V position.

5. The bulb is moved towards the sensor in steps of 5th light intensity level distance and the

corresponding voltage is noted.

6. The steps 4 and 5 are repeated for 10V and 12V adjustments.

7. The readings are tabulated and the graph between distance and voltage is plotted.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 79

TABULATION:

Light Intensity Level Sensor Output Voltage ( V )

(cm) LDR Photo Diode Photo Transistor

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 80

THEORY:

This system consists of a variable voltage source, LDR, Photo diode and a photo

transistor. The intensity of the bulb can be increased or decreased by varying the voltage source.

When the light emitted by the bulb falls on the LDR, the resistance changes and a current flows

through the circuit. The current flowing through the circuit can be measured at T2 and T3. The

voltage drop across the load R1 can be measured at T4, T5.

The working of photo diode is similar to LDR circuit. When light falls on photodiode,

current flows through the circuit. The current flowing through the circuit can be measured at T7,

T8. The voltage drop across the load R2 can be measured at T9, T10. When the light falls on the

photo transistor, current flows through the circuit. The voltage drop across the load R4 can be

measured at T12, T13.

RESULT:

Thus the voltage characteristics of Light Dependent Resistor (LDR), Photodiode, and

Phototransistor were studied.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 81

CIRCUIT DIAGRAM:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 82

EXP. NO.:

STRAIN MEASUREMENT

DATE:

AIM:

To study the characteristics between strain applied to the cantilever beam strain sensor

and the bridge voltage.

APPARATUS REQUIRED:

1. ITB-17-CE Trainer kit

2. Multi-meter (mV)

3. Cantilever beam strain sensor setup

4. Weights (100 gram x 10 No‟s)

5. Power cord

FORMULA:

Theoretical strain= 6PL / (Bt2Y)

Where,

P=Applied load to the beam in kg

t=Thickness of the beam in cm = 0.25 cm

B=Breath of the beam in cm = 3 cm

L=Length of the beam in cm = 18.7 cm

Y=Young's modulus of the beam = 2 x 106 Kg /cm2

THEORY:

Strain gauges are sensing devices used in a variety of physical test and measurement

applications. They change resistance at their output terminals when stretched or compressed.

Because of this characteristic, the gages are typically bonded to the surface of a solid material

and measure its minute dimensional changes when put in compression or tension. Strain gages

and strain gage principles are often used in devices for measuring acceleration, pressure, tension,

and force. Strain is a dimensionless unit, defined as a change in length per unit length. For

example, if a 1-m long bar stretches to 1.000002 m, the strain is defined as 2 micro-strains.

Strain gauges have a characteristic gage factor, defined as the fractional change in resistance

divided by the strain.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 83

TABULATION:

Applied Load(gram) Theoretical strain(mm) Bridge voltage (mV)

MODEL GRAPH:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 84

To make an accurate strain measurement, extremely small resistance changes must be

measured. The Wheatstone bridge circuit is widely used to convert the gauge‟s micro-strain into

a voltage change that can be fed to the input of the ADC. When all four resistors in the bridge are

absolutely equal, the bridge is perfectly balanced and Vout = 0. But when any one or more of the

resistors change value by only a fractional amount, the bridge produces a significant, measurable

voltage. When used with an instrument, a strain gauge replaces one or more of the resistors in the

bridge, and as the strain gage undergoes dimensional changes (because it is bonded to a test

specimen), it unbalances the bridge and produces an output voltage proportional to the strain.

PROCEDURE:

1. The cantilever strain sensor setup is installed and the 9 pin D connector is interfaced with

ITB-17-CE kit.

2. The multi-meter is connected in milli-volts mode across T2 and T3 for bridge voltage

measurement and the module is switched ON.

3. Initially, the beam is unloaded and the bridge voltage is nullified by using zero

adjustment POT.

4. The load is applied to the beam; the strain will develop on the beam and the bridge

voltage (mV) is measured across T2 and T3.

5. The load is gradually increased on the beam, the applied load and the bridge voltage

(mV) are noted.

6. The values of applied load, theoretical stain and the bridge voltage (mV) are tabulated.

7. The graph between theoretical strain versus bridge voltage (mV) is plotted.

RESULT:

Thus the characteristic of cantilever beam strain sensor was plotted and the bridge

voltage was studied.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 85

CIRCUIT DIAGRAM

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 86

EXP. NO.:

DATE: MEASUREMENT OF POWER AND ENERGY

AIM:

To measure the power and energy in single phase AC supply.

APPARATUS REQUIRED:

S. No Name of the Equipment Range Type Quantity

1. Ammeter (0-10A) MI 1

2. Voltmeter 0-300V MI 1

3. Energy meter Single phase Analog 1

4. Stopwatch - Analog 1

5. Connecting wires - - As Required

6 Wattmeter 300V, 10A UPF 1

FORMULA USED:

Power = Voltage in Volts * Current in Amps

True Energy = Number of revolutions / Energy meter constant

Actual Energy = [(Power * Time taken for „n‟ revolutions) / (3600 *1000)]

% of Absolute error = (True Energy – Actual Energy / True Energy) *100

THEORY:

The energy meter is an integrated type instrument where the speed of rotation of

aluminium disc is directly proportional to the amount of power consumed by the load and the no

of revs/min is proportional to the amount of energy consumed by the load. In energy meter the

angular displacement offered by the driving system is connected to the gearing arrangement to

provide the rotation of energy meter visually. The ratings associated with an energy meter are

1. Voltage Rating. 2. Current Rating. 3. Frequency Rating

4. Meter Constants.

Based on the amount of energy consumption, the driving system provides rotational torque for

the moving system which in turn activates the energy registering system for reading the real

energy consumption. The energy meter is operated based on induction principle in which the

eddy current produced by the induction of eddy emf in the portion of the aluminium disc which

creates the driving torque by the interaction of 2 eddy current fluxes.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 87

TABULATION:

S. Voltage Current Power Time No. of Actual True %

No. energy Error

(V) (A) (W) (sec) Revolutions Energy

kWh

kWh

MODEL CALCULATION:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 88

PROCEDURE:

1. Connections are given as per the circuit diagram.

2. Single phase AC supply is switched ON by closing the SPSTS.

3. By increasing the load in steps, the voltmeter, ammeter and wattmeter readings are noted. Also

the time taken for the energy meter disc to rotate for „n‟ revolutions is noted down.

4. Using the formula energy is measured; the percentage error is calculated for each set of

readings.

RESULT:

Thus the power and energy were measured in single phase supply and the absolute error

was calculated.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 89

CIRCUIT DIAGRAM:

R1 = 10K

R2 = 47K

R3 = 10K

R4 = 1K or 10K or 100K ohms

Formula:

Gain = R4 / R3 (1+ (2R2/R1))

Output Voltage = = R4 / R3 [(1+ (2R2/R1)).(V2-V1)]

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 90

EXP. NO.: INSTRUMENTATION AMPLIFIER

DATE:

AIM:

To measure the output voltage of an instrumentation amplifier for various input voltages.

APPARATUS REQUIRED:

S. No Name of the Equipment Range Quantity

1. Trainer Kit - 1

2. Multi-meter - 1

3 Patch Cords - As required

THEORY:

Instrumentation amplifiers are used in monitoring and controlling of the physical

quantities in the industrial processes for measurement and control of temperature, humidity and

light intensity. These physical quantities are usually measured with the help of transducers. The

output of transducer has to be amplified so that it can drive the indicator or display system. The

major function of instrumentation amplifier is precise amplification of low level output signal of

the transducer, and it is widely used in applications where low noise, low thermal drifts, high

input impedance and accurate closed-loop gains are required. Important features of

instrumentation amplifier includes: high gain accuracy, high CMRR, high gain stability, low dc

offset.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 91

TABULATION:

Input voltage Differential input

Output voltage,

S. No voltage (V1-V2) Gain

Vo(V)

V1 mV V2 mV mV

MODEL GRAPH:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 92

PROCEDURE:

1. Connections are given as per the circuit diagram.

2. The input voltage from 0-1200mV is applied from the signal generator.

3. The output voltage (Vo) was measured using multi-meter.

4. The gain (Vo/Vin) is calculated and verified with theoretical value.

RESULT:

Thus the output voltage of an instrumentation amplifier for various input voltages was

measured.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 93

CIRCUIT DIAGRAM:

TABULATION:

S. No Analog Input Digital Output

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 94

EXP. NO.:

ANALOG TO DIGITAL CONVERTER

DATE:

AIM:

To study the working of an Analog to Digital converter.

APPARATUS REQUIRED:

S. No Name of the Equipment Range Quantity

1. A/D converter trainer kit - 1

2. Digital Multi-meter - 1

3. Patch Cords - As required

THEORY

Most of the real world physical quantities such as voltage, current, temperature, pressure

and time etc. are available in analog form. Therefore, for processing, transmission and storage

purposes, it is often convenient to express these variables in digital form. Analog to digital

converter (ADC) is a device that converts analog information into digital form. Successive

approximation type is an ADC which completes an n-bit conversion in n-clock periods. The

converter uses a digital control register with gated binary inputs of 1 and 0, a D/A converter with

a reference voltage supply, a comparison circuit, a control timing loop, and a distribution

register. The distribution register is a ring counter. At the start of conversion cycle, both the

control register and the distribution register are set with a 1 in the MSB and a 0 in all bits of less

significance. It causes an output voltage at the D/A converter and it is compared with the

comparator analog input. Depending on the comparator output, the MSB remains in the state 1 or

it is reset to 0. The procedure repeats itself until the final approximation has been corrected and

the distribution register indicates the end of the conversion.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 95

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 96

PROCEDURE:

1. The ADC trainer kit is switched ON.

2. Reset the counter by pressing RESET push switch to read digital outputs of 0 0 0 0.

3. Connections are made as per the circuit diagram.

4. Enable the clock pulse into the counter by bringing the toggle switch to low level.

5. The start of conversion (SOC) button(SERIAL INPUT) is pressed once to start the

conversion from analog signal to digital signal form.(QA LED will glow)

6. The digital output for the corresponding analog input is displayed on the LEDs viz. D0

through D7

7. The potentiometer is varied for different values of analog inputs and the corresponding

digital output is noted down

RESULT:

Thus the working of an 8-bit analog to digital converter was studied.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 97

CIRCUIT DIAGRAM:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 98

EXP. NO.:

DIGITAL TO ANALOG CONVERTER

DATE:

AIM:

To study the working of Digital to Analog converter.

APPARATUS REQUIRED:

S. No Name of the Equipment Range Quantity

1. D/A converter trainer kit - 1

2. Digital Multi-meter - 1

3. Patch Cords - As required

THEORY:

Weighted resistor type DAC uses a summing amplifier with a binary weighted resistor

network. It has n-electronic switches d1, d2, d3 …… dn, controlled by binary input word. If the

binary input to a particular switch is 1, it connects the resistance to the reference voltage (VR).

and if the input bit is 0, the switch connects the resistor to the ground. The output voltage is

given by

Output Voltage = Total Current * Feedback Resistance

Total current = (V/R)* Multiplication factor

Where,

Input voltage, V= 5V

Resistance, R= 1KΩ

Feedback resistance, Rf=540Ω

Multiplying factor = (d3/1)+(d2/2)+(d1/4)+(d0/8)

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 99

TABULATION:

S. No Digital Input Analog Output Theoretical output

MODELGRAPH:

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 100

PROCEDURE:

1. Connections are given as per the circuit diagram.

2. The digital input data is set and the output voltage is measured.

3. The graph of binary input Vs output voltage is plotted.

4. The theoretical output is also calculated.

RESULT:

Thus the working of digital to analog converter was studied.

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 101

SVSCE/EEE/EE8511 Control and Instrumentation Laboratory Page 102

EXP. NO.: ANALOG SIMULATION OF TYPE-0 & TYPE-1 SYSTEM

DATE:

AIM:

To study the time response of first and second order type –0 and type- 1 systems.

APPARATUS REQUIRED:

1. Linear system simulator kit

2. Cathode Ray Oscilloscope (CRO)

3. Patch Cords

FORMULAE USED:

The type number of the system is obtained from the number of poles located at origin in a given