Professional Documents

Culture Documents

Water and Its Treatment-5,6

Water and Its Treatment-5,6

Uploaded by

Tushar SharmaCopyright:

Available Formats

You might also like

- Enel 3112Document8 pagesEnel 3112waqasNo ratings yet

- EE1000 Problem Single Phase AC CircuitsDocument4 pagesEE1000 Problem Single Phase AC CircuitsAmit DipankarNo ratings yet

- Economic Load Dispatch (Optimal Power Flow) : by Adisu TeshaleDocument26 pagesEconomic Load Dispatch (Optimal Power Flow) : by Adisu TeshaleAdisuNo ratings yet

- LAB REPORT NO 12 (Electrical Engineering)Document8 pagesLAB REPORT NO 12 (Electrical Engineering)Malik Hassaan SangraalNo ratings yet

- Attachment No.2 CECA Technical Proposal Unit 104ADocument2 pagesAttachment No.2 CECA Technical Proposal Unit 104Aghasem_726990287No ratings yet

- EE321 LAb6Document18 pagesEE321 LAb6Brown Tukalou100% (1)

- Index: Bandel Thermal Power Station Project Report 2009-2010Document46 pagesIndex: Bandel Thermal Power Station Project Report 2009-2010Debaditya Nath100% (1)

- Feedback Amplifiers-EDC PDFDocument45 pagesFeedback Amplifiers-EDC PDFanjanaNo ratings yet

- Special - Electrical - Machines QBDocument25 pagesSpecial - Electrical - Machines QBVel MuruganNo ratings yet

- Module 1 Measurement of Inductance and CapacitanceDocument15 pagesModule 1 Measurement of Inductance and CapacitancemanjulabiradarNo ratings yet

- Steady-State Analysis of DC MotorsDocument24 pagesSteady-State Analysis of DC MotorsUsama RaoNo ratings yet

- Net Length of Iron (Unit-2 DC Machines)Document3 pagesNet Length of Iron (Unit-2 DC Machines)Ramesh BabuNo ratings yet

- Communication Engineering Cycle Test 1 AnDocument2 pagesCommunication Engineering Cycle Test 1 AnsamNo ratings yet

- Part BDocument10 pagesPart BVenkat ManiNo ratings yet

- DCMTDocument37 pagesDCMTGloria HolcombNo ratings yet

- Tutorial Ans 1Document13 pagesTutorial Ans 1anirbansingha345No ratings yet

- R7210206-Electrical Machines - IDocument4 pagesR7210206-Electrical Machines - IsivabharathamurthyNo ratings yet

- Chapter 10 Single Phase Motors EE 342Document32 pagesChapter 10 Single Phase Motors EE 342Umar AftabNo ratings yet

- Sns College of Technology Department of Eee: SVC-SVC InteractionDocument7 pagesSns College of Technology Department of Eee: SVC-SVC InteractionDejene BirileNo ratings yet

- SyncroDocument5 pagesSyncroRajat MittalNo ratings yet

- Brushless DC MotorDocument3 pagesBrushless DC MotorSourav KumarNo ratings yet

- Transformers and Induction Machines PDFDocument156 pagesTransformers and Induction Machines PDFJagadeesh sm0% (2)

- Lec # 021 Thermal Time ConstantDocument16 pagesLec # 021 Thermal Time ConstantAyeshaNo ratings yet

- Single Phasing of Three Phase Induction MotorDocument33 pagesSingle Phasing of Three Phase Induction MotorOsama RashaydaNo ratings yet

- Electrical Engineering Laboratory V Course Code: Epo662: Simulation of Three-Phase Inverter With A PWM Control EPO662Document5 pagesElectrical Engineering Laboratory V Course Code: Epo662: Simulation of Three-Phase Inverter With A PWM Control EPO662Danial AkramNo ratings yet

- Problems Chapter 5 1Document7 pagesProblems Chapter 5 1Siva KumarNo ratings yet

- Marks: 0.00 User Answer Sheet Rank: 7: Report QuestionDocument17 pagesMarks: 0.00 User Answer Sheet Rank: 7: Report Questionchandrachurom5538100% (1)

- Excitation Phenomena in Transformers Excitation Phenomena With Out HysteresisDocument2 pagesExcitation Phenomena in Transformers Excitation Phenomena With Out Hysteresism_mustaqeem100% (1)

- Use The Information Below To Answer Questions 1 and 2:: A) 8 - 0 (Cos 55 - 4Document9 pagesUse The Information Below To Answer Questions 1 and 2:: A) 8 - 0 (Cos 55 - 4Samuel Kafui KwawukumeNo ratings yet

- DC Load FlowDocument14 pagesDC Load FlowSolomon ManayeNo ratings yet

- Part - 3Document9 pagesPart - 3Keerthee MadhuriNo ratings yet

- DC Motor BrakingDocument15 pagesDC Motor BrakingSusmita DasNo ratings yet

- Nano Fluid Volume PercentageDocument35 pagesNano Fluid Volume PercentageMuthiah Chidambaram Muthiah100% (1)

- Transformers Practice Problems Set IDocument2 pagesTransformers Practice Problems Set ISuryansh Singh RawatNo ratings yet

- Conductometric TitrationDocument2 pagesConductometric TitrationDelin Shaji JohnNo ratings yet

- Chapter21 TransformerDocument25 pagesChapter21 TransformerChin Chee FeeNo ratings yet

- Pse Problems Group AssignmentDocument14 pagesPse Problems Group AssignmentSajid KhanNo ratings yet

- Auto TransformerDocument5 pagesAuto TransformerAugy HaerudyNo ratings yet

- Energy Audit-SYLLABUS: ReferencesDocument4 pagesEnergy Audit-SYLLABUS: ReferencesHariprasath SelvakumarNo ratings yet

- HV Engineering: Generation of High Frequency Ac High Voltage Using Tesla CoilDocument6 pagesHV Engineering: Generation of High Frequency Ac High Voltage Using Tesla CoilAdnan AliNo ratings yet

- Unit 1 Ee2355 Machine DesignDocument21 pagesUnit 1 Ee2355 Machine DesignRamesh BabuNo ratings yet

- Tutorial On Single Phase Induction MotorDocument1 pageTutorial On Single Phase Induction MotorHimanshu Saini0% (1)

- Power Electronics 2 MarkDocument5 pagesPower Electronics 2 MarkPrakash Mahendran100% (2)

- Questions 1Document11 pagesQuestions 1anvithaNo ratings yet

- EE6501 DecDocument148 pagesEE6501 DecPrassath AnandNo ratings yet

- Introduction To Power Systems (Eceg-3176) : Addis Ababa University Addis Ababa Institute of Technology (Aait)Document38 pagesIntroduction To Power Systems (Eceg-3176) : Addis Ababa University Addis Ababa Institute of Technology (Aait)DANIEL ABERANo ratings yet

- Services Design Midsem - Docx AbDocument5 pagesServices Design Midsem - Docx AbMichael Adu-boahenNo ratings yet

- PTDU Lab No. 10 Study of Real Time Operation of Bus Bars Abdul Wahab Nasir (02) Bsee 16-20Document2 pagesPTDU Lab No. 10 Study of Real Time Operation of Bus Bars Abdul Wahab Nasir (02) Bsee 16-20Ali ArshadNo ratings yet

- Module3 Numericals ADocument11 pagesModule3 Numericals ASomil GuptaNo ratings yet

- Tut - PsocDocument2 pagesTut - Psocfews100% (1)

- Characteristics of DC MotorsDocument40 pagesCharacteristics of DC MotorsRamu ThommandruNo ratings yet

- EEE267 DCMotor Math ProblemsDocument5 pagesEEE267 DCMotor Math ProblemsmaakbdNo ratings yet

- TransformerDocument25 pagesTransformerJerald SagusayNo ratings yet

- ExamAut LWD2022BDocument6 pagesExamAut LWD2022BAyman100% (1)

- Lecture Objectives: Working Principle of Alternator OR Synchronous Generator StatorDocument5 pagesLecture Objectives: Working Principle of Alternator OR Synchronous Generator StatorZ_JahangeerNo ratings yet

- Zeolite or Permutit Process:: Na O - Al O - Xsio - Yh ODocument11 pagesZeolite or Permutit Process:: Na O - Al O - Xsio - Yh O056 Jatin GavelNo ratings yet

- Zeolite 160429161158Document11 pagesZeolite 160429161158Muhammad Azman AseriNo ratings yet

- Chemistry Materials - QuestionsDocument11 pagesChemistry Materials - QuestionsSanthosh kannaNo ratings yet

- Water SofteningDocument20 pagesWater SofteningHassan AliNo ratings yet

- Lecture 13 - Numerical Practice On Superposition, Norton and Thevenin TheoremsDocument15 pagesLecture 13 - Numerical Practice On Superposition, Norton and Thevenin TheoremsTushar SharmaNo ratings yet

- Lecture 12 - Thevenins Theorem and Nortons TheoremDocument15 pagesLecture 12 - Thevenins Theorem and Nortons TheoremTushar SharmaNo ratings yet

- Lecture 11 (B) - Superposition TheoremDocument11 pagesLecture 11 (B) - Superposition TheoremTushar SharmaNo ratings yet

- Lecture 10 - Star - Delta Transformation and NumericalDocument16 pagesLecture 10 - Star - Delta Transformation and NumericalTushar SharmaNo ratings yet

- Water Chemistry 1Document2 pagesWater Chemistry 1Tushar SharmaNo ratings yet

- Lecture 4 - Analysis of Voltage, Current Sources and Resistances in Series and ParallelDocument11 pagesLecture 4 - Analysis of Voltage, Current Sources and Resistances in Series and ParallelTushar SharmaNo ratings yet

- Lecture 0 - Introduction To The CourseDocument4 pagesLecture 0 - Introduction To The CourseTushar SharmaNo ratings yet

- Water and Its Treatment-7,8Document4 pagesWater and Its Treatment-7,8Tushar SharmaNo ratings yet

- Water and Its Treatment 3,4Document4 pagesWater and Its Treatment 3,4Tushar SharmaNo ratings yet

- An XRD Study of The Effect of The SiO2-Na2O Ratio On The Alkali Activation of Fly AshDocument9 pagesAn XRD Study of The Effect of The SiO2-Na2O Ratio On The Alkali Activation of Fly AshReshmita PallaNo ratings yet

- Towards The Rational Synthesis of ZeolitesDocument0 pagesTowards The Rational Synthesis of ZeoliteslsueyinNo ratings yet

- Hydroconversion of Waste Cooking Oil Into Bio Jet Fuel Over A Hierarchical NiMo-USY Al SBA 15 ZeoliteDocument8 pagesHydroconversion of Waste Cooking Oil Into Bio Jet Fuel Over A Hierarchical NiMo-USY Al SBA 15 ZeoliteNisarg SonaniNo ratings yet

- ZeoliteDocument23 pagesZeoliterajankthomas100% (1)

- Namma Kalvi 12th Chemistry Pta Question Papers 217338 PDFDocument68 pagesNamma Kalvi 12th Chemistry Pta Question Papers 217338 PDFmnareshg007No ratings yet

- BENTONE - Hectorite Clay Grades - Part 1 Mineralogy-Cesare EditsDocument7 pagesBENTONE - Hectorite Clay Grades - Part 1 Mineralogy-Cesare EditsHelene Di marcantonioNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- Hydrogen Shobhit NirwanDocument26 pagesHydrogen Shobhit NirwanANMOL SHREYAMNo ratings yet

- 02 - 21 - 2018 - ChE Plant Design - Synthetic Zeolite From Coal Fly Ash (CFA)Document130 pages02 - 21 - 2018 - ChE Plant Design - Synthetic Zeolite From Coal Fly Ash (CFA)Juhlian V. SantosNo ratings yet

- Us 5874659Document9 pagesUs 5874659prasad_vjtiNo ratings yet

- NSEC 2023 Set 31Document15 pagesNSEC 2023 Set 31Vishnu SinhaNo ratings yet

- MSDS Zeolite 25 JAN 2019Document4 pagesMSDS Zeolite 25 JAN 2019marraezNo ratings yet

- Natural Aggregates Used For Light Weight Concrete A Review2020IOP Conference Series Materials Science and EngineeringDocument10 pagesNatural Aggregates Used For Light Weight Concrete A Review2020IOP Conference Series Materials Science and EngineeringJoe Alcantara RomeroNo ratings yet

- 4113 9 PDFDocument64 pages4113 9 PDFsimonwonghksar1No ratings yet

- Polyethylene Catalytic Cracking by Thermogravimetric AnalysisDocument13 pagesPolyethylene Catalytic Cracking by Thermogravimetric AnalysisMohamed FateemNo ratings yet

- Cpo To Fatty Alcohol Catalyst Ni-Cu zsm5 PDFDocument18 pagesCpo To Fatty Alcohol Catalyst Ni-Cu zsm5 PDFHelmi BaharNo ratings yet

- Geolite Modifier 210Document4 pagesGeolite Modifier 210Izziddeen AhmedNo ratings yet

- Síntesis y Caracterización de Zeolite 4a Con Swat KaolinDocument6 pagesSíntesis y Caracterización de Zeolite 4a Con Swat KaolinJohan Brand GalvisNo ratings yet

- United States Patent: (10) Patent No.: US 8,084,655 B2Document11 pagesUnited States Patent: (10) Patent No.: US 8,084,655 B2AdhityaEkoBagusNo ratings yet

- Solar HydrogenDocument8 pagesSolar Hydrogenapi-3834013100% (2)

- Microporous and Mesoporous MaterialsDocument10 pagesMicroporous and Mesoporous MaterialsYonatan AdiNo ratings yet

- Porous Materials For Oil Spill Cleanup: A Review of Synthesis and Absorbing PropertiesDocument12 pagesPorous Materials For Oil Spill Cleanup: A Review of Synthesis and Absorbing PropertiesAJAY KUMAR MAHAKUDNo ratings yet

- Synthesis and Characterization of Zeolite A by Hydrothermal Transformation of Natural Jordanian KaolinDocument8 pagesSynthesis and Characterization of Zeolite A by Hydrothermal Transformation of Natural Jordanian Kaolinbkpadhi815No ratings yet

- ZeoliteDocument28 pagesZeoliteDan Stefan100% (1)

- Experimental Leaching of Atacamite, Chrysocolla and Malachite - Relationship Between Copper Retention and Cation Exchange CapacityDocument7 pagesExperimental Leaching of Atacamite, Chrysocolla and Malachite - Relationship Between Copper Retention and Cation Exchange CapacityFrancisco GarcíaNo ratings yet

- The Bioethanol-to-Ethylene (B.E.T.E.) Processa: Applied Catalysis, 48 265Document13 pagesThe Bioethanol-to-Ethylene (B.E.T.E.) Processa: Applied Catalysis, 48 265Eduardo Ruiz VelezNo ratings yet

- Unit - I: Water TreatmentDocument127 pagesUnit - I: Water TreatmentAnu ShanthanNo ratings yet

- Review of H2S Sorbents at Low-Temperature Desulfurization of BiogasDocument7 pagesReview of H2S Sorbents at Low-Temperature Desulfurization of BiogasHamed HpNo ratings yet

- Adsorption of Methylene Blue and Orange II Onto Unmodified and Surfactant-Modified ZeoliteDocument5 pagesAdsorption of Methylene Blue and Orange II Onto Unmodified and Surfactant-Modified ZeoliteBrahma Hakim Yuanda HutabaratNo ratings yet

Water and Its Treatment-5,6

Water and Its Treatment-5,6

Uploaded by

Tushar SharmaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water and Its Treatment-5,6

Water and Its Treatment-5,6

Uploaded by

Tushar SharmaCopyright:

Available Formats

Unit-1b Water and its treatment

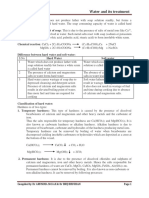

Zeolite or permutite process:

Zeolites are naturally occurring hydrated sodium alumino silicate minerals

capable of exchanging reversibly its sodium ions for the ions present and

responsible of formation of hard water.

Permutite-is the trade name given to sodium zeolites.

Chemical formula of zeolite is Na2O Al2O3 ySiO2 x H2O. y=2-10, x= 2-6

When y = 2, we get Na2OAI2Si2O8.xH2O.

For simplicity, we can write zeolites as Na2Z Where Z = OAl2Si2O8.xH2O

Zeolites are of two types: Natural zeolites and synthetic zeolites.

Process involved:

In this method, hard water is passed through a bed of permutite contained in a

cylindrical vessel. The water percolates at a specified rate through the bed. The loose

sodium ions of the zeolite are exchanged for Ca2- and Mg2+ ions of hard water. Thus

calcium and magnesium salts get removed in the form of the insoluble zeolites and soft

water is collected.

This process removes both temporary and permanent hardness. After long use, the zeolite

bed gets exhausted. It can be regenerated by using chemicals, such as brine solution,

NaCI or sodium nitrate or sodium sulphate. However, NaCl is preferred on account of its

Compiled by Dr ARUNIMA NAYAK & Dr BRIJ BHUSHAN Page 1

Unit-1b Water and its treatment

cheapness, easy availability and low molecular weight. The products ‘calcium chloride

and magnesium chloride are highly soluble in water and can be easily washed out. The

softening and regeneration process can be represented as follows:

Merits of Zeolite Process

1. The equipment used is compact. So time saving process.

2. No impurities are precipitated. So no sludge formation occurs.

3. Requires less time for softening

4. Requires less skill for maintenance.

5. Process helps to remove hardness upto a level of 10ppm

Demerits

a. Treated water contains a greater number of Na ions; This method leaves ions

(HCO3- and CO3-- ions) in soft water which if enters a boiler, generates CO2

which leads to corrosion and caustic embrittlement

b. Turbid water can’t be made soft by this process because it leads to clogging of the

holes of zeolite bed.

Compiled by Dr ARUNIMA NAYAK & Dr BRIJ BHUSHAN Page 2

Unit-1b Water and its treatment

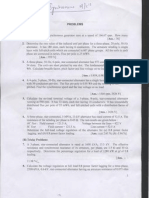

Numericals on Zeolite process

Q1. The hardness of 1000L of a sample of water was removed by passing it through a

zeolite softener. The zeolite softener required 30L of NaCl containing 1.5g/L of NaCl for

regeneration. Find the hardness of water sample.

Ans:

Quantity of NaCl in 30L of NaCl solution = 1.5g/L x 30L = 45g

CaCO3 equivalent of NaCl = 45x [(100/2)/(58.5/1)] = 45x50/58.5 = 38.46gm equiv.

1000L of water sample is contains 38.46gm equiv of CaCO3 equiv.

1L of water sample contains 38.46x1000mg/1000L = 38.46 ppm

Hardness of water sample = 38.46ppm

Q2. An exhausted zeolite softener was regenerated by passing 150L of NaCl solution having

strength of 1.5g/L of NaCl. Find the total volume of water that can be softened by this

zeolite softener, if the hardness of water is 600 ppm.

Ans:

Quantity of NaCl in 150L of NaCl solution = 1.5g/L x 150L = 225g

CaCO3 equivalent of NaCl = 225x [(100/2)/(58.5/1)] = 2255x50/58.5 = 192.308g equiv.

Hardness of water = 600ppm

i.e 600mg of CaCO3 equiv is present in 1L of water

192.308x1000 mg of CaCO3 is present in 192308/600 = 320.5 L

Q3. A zeolite softener was 90% exhausted by removing the hardness completely when

10,000L of hard water sample was passed through it. The exhausted zeolite bed required

200L of 3% NaCl solution for its complete regeneration. Calculate the hardness of water

solution.

Ans:

Quantity of NaCl in 200L of 3% NaCl solution = 3/100x1000x200L = 6000g

CaCO3 equivalent of NaCl = 6000x [(100/2)/(58.5/1)] = 6000x50/58.5 = 5128g equiv.

90% of 10000 L of water = 5128g equiv = 5128x1000mg equiv

1L of water = [5128x1000]/[90/100x10000] = 569.8 mg/L = 569.8 ppm

Hardness = 569.8 ppm

Compiled by Dr ARUNIMA NAYAK & Dr BRIJ BHUSHAN Page 3

You might also like

- Enel 3112Document8 pagesEnel 3112waqasNo ratings yet

- EE1000 Problem Single Phase AC CircuitsDocument4 pagesEE1000 Problem Single Phase AC CircuitsAmit DipankarNo ratings yet

- Economic Load Dispatch (Optimal Power Flow) : by Adisu TeshaleDocument26 pagesEconomic Load Dispatch (Optimal Power Flow) : by Adisu TeshaleAdisuNo ratings yet

- LAB REPORT NO 12 (Electrical Engineering)Document8 pagesLAB REPORT NO 12 (Electrical Engineering)Malik Hassaan SangraalNo ratings yet

- Attachment No.2 CECA Technical Proposal Unit 104ADocument2 pagesAttachment No.2 CECA Technical Proposal Unit 104Aghasem_726990287No ratings yet

- EE321 LAb6Document18 pagesEE321 LAb6Brown Tukalou100% (1)

- Index: Bandel Thermal Power Station Project Report 2009-2010Document46 pagesIndex: Bandel Thermal Power Station Project Report 2009-2010Debaditya Nath100% (1)

- Feedback Amplifiers-EDC PDFDocument45 pagesFeedback Amplifiers-EDC PDFanjanaNo ratings yet

- Special - Electrical - Machines QBDocument25 pagesSpecial - Electrical - Machines QBVel MuruganNo ratings yet

- Module 1 Measurement of Inductance and CapacitanceDocument15 pagesModule 1 Measurement of Inductance and CapacitancemanjulabiradarNo ratings yet

- Steady-State Analysis of DC MotorsDocument24 pagesSteady-State Analysis of DC MotorsUsama RaoNo ratings yet

- Net Length of Iron (Unit-2 DC Machines)Document3 pagesNet Length of Iron (Unit-2 DC Machines)Ramesh BabuNo ratings yet

- Communication Engineering Cycle Test 1 AnDocument2 pagesCommunication Engineering Cycle Test 1 AnsamNo ratings yet

- Part BDocument10 pagesPart BVenkat ManiNo ratings yet

- DCMTDocument37 pagesDCMTGloria HolcombNo ratings yet

- Tutorial Ans 1Document13 pagesTutorial Ans 1anirbansingha345No ratings yet

- R7210206-Electrical Machines - IDocument4 pagesR7210206-Electrical Machines - IsivabharathamurthyNo ratings yet

- Chapter 10 Single Phase Motors EE 342Document32 pagesChapter 10 Single Phase Motors EE 342Umar AftabNo ratings yet

- Sns College of Technology Department of Eee: SVC-SVC InteractionDocument7 pagesSns College of Technology Department of Eee: SVC-SVC InteractionDejene BirileNo ratings yet

- SyncroDocument5 pagesSyncroRajat MittalNo ratings yet

- Brushless DC MotorDocument3 pagesBrushless DC MotorSourav KumarNo ratings yet

- Transformers and Induction Machines PDFDocument156 pagesTransformers and Induction Machines PDFJagadeesh sm0% (2)

- Lec # 021 Thermal Time ConstantDocument16 pagesLec # 021 Thermal Time ConstantAyeshaNo ratings yet

- Single Phasing of Three Phase Induction MotorDocument33 pagesSingle Phasing of Three Phase Induction MotorOsama RashaydaNo ratings yet

- Electrical Engineering Laboratory V Course Code: Epo662: Simulation of Three-Phase Inverter With A PWM Control EPO662Document5 pagesElectrical Engineering Laboratory V Course Code: Epo662: Simulation of Three-Phase Inverter With A PWM Control EPO662Danial AkramNo ratings yet

- Problems Chapter 5 1Document7 pagesProblems Chapter 5 1Siva KumarNo ratings yet

- Marks: 0.00 User Answer Sheet Rank: 7: Report QuestionDocument17 pagesMarks: 0.00 User Answer Sheet Rank: 7: Report Questionchandrachurom5538100% (1)

- Excitation Phenomena in Transformers Excitation Phenomena With Out HysteresisDocument2 pagesExcitation Phenomena in Transformers Excitation Phenomena With Out Hysteresism_mustaqeem100% (1)

- Use The Information Below To Answer Questions 1 and 2:: A) 8 - 0 (Cos 55 - 4Document9 pagesUse The Information Below To Answer Questions 1 and 2:: A) 8 - 0 (Cos 55 - 4Samuel Kafui KwawukumeNo ratings yet

- DC Load FlowDocument14 pagesDC Load FlowSolomon ManayeNo ratings yet

- Part - 3Document9 pagesPart - 3Keerthee MadhuriNo ratings yet

- DC Motor BrakingDocument15 pagesDC Motor BrakingSusmita DasNo ratings yet

- Nano Fluid Volume PercentageDocument35 pagesNano Fluid Volume PercentageMuthiah Chidambaram Muthiah100% (1)

- Transformers Practice Problems Set IDocument2 pagesTransformers Practice Problems Set ISuryansh Singh RawatNo ratings yet

- Conductometric TitrationDocument2 pagesConductometric TitrationDelin Shaji JohnNo ratings yet

- Chapter21 TransformerDocument25 pagesChapter21 TransformerChin Chee FeeNo ratings yet

- Pse Problems Group AssignmentDocument14 pagesPse Problems Group AssignmentSajid KhanNo ratings yet

- Auto TransformerDocument5 pagesAuto TransformerAugy HaerudyNo ratings yet

- Energy Audit-SYLLABUS: ReferencesDocument4 pagesEnergy Audit-SYLLABUS: ReferencesHariprasath SelvakumarNo ratings yet

- HV Engineering: Generation of High Frequency Ac High Voltage Using Tesla CoilDocument6 pagesHV Engineering: Generation of High Frequency Ac High Voltage Using Tesla CoilAdnan AliNo ratings yet

- Unit 1 Ee2355 Machine DesignDocument21 pagesUnit 1 Ee2355 Machine DesignRamesh BabuNo ratings yet

- Tutorial On Single Phase Induction MotorDocument1 pageTutorial On Single Phase Induction MotorHimanshu Saini0% (1)

- Power Electronics 2 MarkDocument5 pagesPower Electronics 2 MarkPrakash Mahendran100% (2)

- Questions 1Document11 pagesQuestions 1anvithaNo ratings yet

- EE6501 DecDocument148 pagesEE6501 DecPrassath AnandNo ratings yet

- Introduction To Power Systems (Eceg-3176) : Addis Ababa University Addis Ababa Institute of Technology (Aait)Document38 pagesIntroduction To Power Systems (Eceg-3176) : Addis Ababa University Addis Ababa Institute of Technology (Aait)DANIEL ABERANo ratings yet

- Services Design Midsem - Docx AbDocument5 pagesServices Design Midsem - Docx AbMichael Adu-boahenNo ratings yet

- PTDU Lab No. 10 Study of Real Time Operation of Bus Bars Abdul Wahab Nasir (02) Bsee 16-20Document2 pagesPTDU Lab No. 10 Study of Real Time Operation of Bus Bars Abdul Wahab Nasir (02) Bsee 16-20Ali ArshadNo ratings yet

- Module3 Numericals ADocument11 pagesModule3 Numericals ASomil GuptaNo ratings yet

- Tut - PsocDocument2 pagesTut - Psocfews100% (1)

- Characteristics of DC MotorsDocument40 pagesCharacteristics of DC MotorsRamu ThommandruNo ratings yet

- EEE267 DCMotor Math ProblemsDocument5 pagesEEE267 DCMotor Math ProblemsmaakbdNo ratings yet

- TransformerDocument25 pagesTransformerJerald SagusayNo ratings yet

- ExamAut LWD2022BDocument6 pagesExamAut LWD2022BAyman100% (1)

- Lecture Objectives: Working Principle of Alternator OR Synchronous Generator StatorDocument5 pagesLecture Objectives: Working Principle of Alternator OR Synchronous Generator StatorZ_JahangeerNo ratings yet

- Zeolite or Permutit Process:: Na O - Al O - Xsio - Yh ODocument11 pagesZeolite or Permutit Process:: Na O - Al O - Xsio - Yh O056 Jatin GavelNo ratings yet

- Zeolite 160429161158Document11 pagesZeolite 160429161158Muhammad Azman AseriNo ratings yet

- Chemistry Materials - QuestionsDocument11 pagesChemistry Materials - QuestionsSanthosh kannaNo ratings yet

- Water SofteningDocument20 pagesWater SofteningHassan AliNo ratings yet

- Lecture 13 - Numerical Practice On Superposition, Norton and Thevenin TheoremsDocument15 pagesLecture 13 - Numerical Practice On Superposition, Norton and Thevenin TheoremsTushar SharmaNo ratings yet

- Lecture 12 - Thevenins Theorem and Nortons TheoremDocument15 pagesLecture 12 - Thevenins Theorem and Nortons TheoremTushar SharmaNo ratings yet

- Lecture 11 (B) - Superposition TheoremDocument11 pagesLecture 11 (B) - Superposition TheoremTushar SharmaNo ratings yet

- Lecture 10 - Star - Delta Transformation and NumericalDocument16 pagesLecture 10 - Star - Delta Transformation and NumericalTushar SharmaNo ratings yet

- Water Chemistry 1Document2 pagesWater Chemistry 1Tushar SharmaNo ratings yet

- Lecture 4 - Analysis of Voltage, Current Sources and Resistances in Series and ParallelDocument11 pagesLecture 4 - Analysis of Voltage, Current Sources and Resistances in Series and ParallelTushar SharmaNo ratings yet

- Lecture 0 - Introduction To The CourseDocument4 pagesLecture 0 - Introduction To The CourseTushar SharmaNo ratings yet

- Water and Its Treatment-7,8Document4 pagesWater and Its Treatment-7,8Tushar SharmaNo ratings yet

- Water and Its Treatment 3,4Document4 pagesWater and Its Treatment 3,4Tushar SharmaNo ratings yet

- An XRD Study of The Effect of The SiO2-Na2O Ratio On The Alkali Activation of Fly AshDocument9 pagesAn XRD Study of The Effect of The SiO2-Na2O Ratio On The Alkali Activation of Fly AshReshmita PallaNo ratings yet

- Towards The Rational Synthesis of ZeolitesDocument0 pagesTowards The Rational Synthesis of ZeoliteslsueyinNo ratings yet

- Hydroconversion of Waste Cooking Oil Into Bio Jet Fuel Over A Hierarchical NiMo-USY Al SBA 15 ZeoliteDocument8 pagesHydroconversion of Waste Cooking Oil Into Bio Jet Fuel Over A Hierarchical NiMo-USY Al SBA 15 ZeoliteNisarg SonaniNo ratings yet

- ZeoliteDocument23 pagesZeoliterajankthomas100% (1)

- Namma Kalvi 12th Chemistry Pta Question Papers 217338 PDFDocument68 pagesNamma Kalvi 12th Chemistry Pta Question Papers 217338 PDFmnareshg007No ratings yet

- BENTONE - Hectorite Clay Grades - Part 1 Mineralogy-Cesare EditsDocument7 pagesBENTONE - Hectorite Clay Grades - Part 1 Mineralogy-Cesare EditsHelene Di marcantonioNo ratings yet

- UntitledDocument2 pagesUntitledIssam LahlouNo ratings yet

- Hydrogen Shobhit NirwanDocument26 pagesHydrogen Shobhit NirwanANMOL SHREYAMNo ratings yet

- 02 - 21 - 2018 - ChE Plant Design - Synthetic Zeolite From Coal Fly Ash (CFA)Document130 pages02 - 21 - 2018 - ChE Plant Design - Synthetic Zeolite From Coal Fly Ash (CFA)Juhlian V. SantosNo ratings yet

- Us 5874659Document9 pagesUs 5874659prasad_vjtiNo ratings yet

- NSEC 2023 Set 31Document15 pagesNSEC 2023 Set 31Vishnu SinhaNo ratings yet

- MSDS Zeolite 25 JAN 2019Document4 pagesMSDS Zeolite 25 JAN 2019marraezNo ratings yet

- Natural Aggregates Used For Light Weight Concrete A Review2020IOP Conference Series Materials Science and EngineeringDocument10 pagesNatural Aggregates Used For Light Weight Concrete A Review2020IOP Conference Series Materials Science and EngineeringJoe Alcantara RomeroNo ratings yet

- 4113 9 PDFDocument64 pages4113 9 PDFsimonwonghksar1No ratings yet

- Polyethylene Catalytic Cracking by Thermogravimetric AnalysisDocument13 pagesPolyethylene Catalytic Cracking by Thermogravimetric AnalysisMohamed FateemNo ratings yet

- Cpo To Fatty Alcohol Catalyst Ni-Cu zsm5 PDFDocument18 pagesCpo To Fatty Alcohol Catalyst Ni-Cu zsm5 PDFHelmi BaharNo ratings yet

- Geolite Modifier 210Document4 pagesGeolite Modifier 210Izziddeen AhmedNo ratings yet

- Síntesis y Caracterización de Zeolite 4a Con Swat KaolinDocument6 pagesSíntesis y Caracterización de Zeolite 4a Con Swat KaolinJohan Brand GalvisNo ratings yet

- United States Patent: (10) Patent No.: US 8,084,655 B2Document11 pagesUnited States Patent: (10) Patent No.: US 8,084,655 B2AdhityaEkoBagusNo ratings yet

- Solar HydrogenDocument8 pagesSolar Hydrogenapi-3834013100% (2)

- Microporous and Mesoporous MaterialsDocument10 pagesMicroporous and Mesoporous MaterialsYonatan AdiNo ratings yet

- Porous Materials For Oil Spill Cleanup: A Review of Synthesis and Absorbing PropertiesDocument12 pagesPorous Materials For Oil Spill Cleanup: A Review of Synthesis and Absorbing PropertiesAJAY KUMAR MAHAKUDNo ratings yet

- Synthesis and Characterization of Zeolite A by Hydrothermal Transformation of Natural Jordanian KaolinDocument8 pagesSynthesis and Characterization of Zeolite A by Hydrothermal Transformation of Natural Jordanian Kaolinbkpadhi815No ratings yet

- ZeoliteDocument28 pagesZeoliteDan Stefan100% (1)

- Experimental Leaching of Atacamite, Chrysocolla and Malachite - Relationship Between Copper Retention and Cation Exchange CapacityDocument7 pagesExperimental Leaching of Atacamite, Chrysocolla and Malachite - Relationship Between Copper Retention and Cation Exchange CapacityFrancisco GarcíaNo ratings yet

- The Bioethanol-to-Ethylene (B.E.T.E.) Processa: Applied Catalysis, 48 265Document13 pagesThe Bioethanol-to-Ethylene (B.E.T.E.) Processa: Applied Catalysis, 48 265Eduardo Ruiz VelezNo ratings yet

- Unit - I: Water TreatmentDocument127 pagesUnit - I: Water TreatmentAnu ShanthanNo ratings yet

- Review of H2S Sorbents at Low-Temperature Desulfurization of BiogasDocument7 pagesReview of H2S Sorbents at Low-Temperature Desulfurization of BiogasHamed HpNo ratings yet

- Adsorption of Methylene Blue and Orange II Onto Unmodified and Surfactant-Modified ZeoliteDocument5 pagesAdsorption of Methylene Blue and Orange II Onto Unmodified and Surfactant-Modified ZeoliteBrahma Hakim Yuanda HutabaratNo ratings yet