Professional Documents

Culture Documents

K-Water Institute, K-Waterter, Yuseong-Gu, Daejeon 305-730, South Korea Korea Institute of Energy Research, Yuseong-Gu, Daejeon, 305-343, South Korea

K-Water Institute, K-Waterter, Yuseong-Gu, Daejeon 305-730, South Korea Korea Institute of Energy Research, Yuseong-Gu, Daejeon, 305-343, South Korea

Uploaded by

Nguyen AnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

K-Water Institute, K-Waterter, Yuseong-Gu, Daejeon 305-730, South Korea Korea Institute of Energy Research, Yuseong-Gu, Daejeon, 305-343, South Korea

K-Water Institute, K-Waterter, Yuseong-Gu, Daejeon 305-730, South Korea Korea Institute of Energy Research, Yuseong-Gu, Daejeon, 305-343, South Korea

Uploaded by

Nguyen AnCopyright:

Available Formats

Enhanced biological nitrogen and

phosphorus removal within a field-scale membrane

bioreactor by adding pre-treated sludge and alum

Byung-Goon Kim*, Jae-Hwan Cha**, Hong-Suk Kim*, Ji-Yeon Kim*

*K-water Institute, K-waterter, Yuseong-gu, Daejeon 305-730, South Korea

**Korea Institute of Energy Research, Yuseong-gu, Daejeon, 305-343 , South Korea

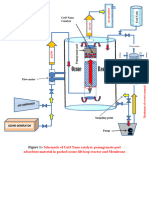

Introduction Field scale KSMBR combined with sludge solubilization process

• The conventional activated sludge process generally produces a considerable • A field-scale KSMBR combined process by incorporating sludge reduction process

amount of excess sludge, which must be safely disposed. into was run at Sari wastewater treatment plant (average influent flow rate was 160

m3/day) in South Korea.

• However, the disposal of sludge is very expensive, which may account for around

• This process is an innovative membrane bioreactor which consists of an anaerobic

20% of the total operating costs of domestic wastewater treatment plants in South

tank located before two interconnected biological tanks of equal volume and a

Korea.

submerged membrane bioreactor.

• Membrane bioreactor (MBR) is considered as a good solution for enhanced • The biological tanks (Aerobic/anaerobic switching tanks), which operated in three

wastewater treatment, because it has great advantages including a smaller phases of non-aeration, aeration and non-aeration, work in an alternating mode of

footprint, less sludge production and better effluent quality. operation.

Influent

• However, it is difficult for MBR employing a single reactor to remove nitrogen and

phosphorus simultaneously.

Pretreated

sludge

• Therefore, in this study, a field-scale MBR coupled with anaerobic tank and two Oxygen Anaerobic

Exhausting P-precipitating

interconnected biological tanks was investigated. Tank tank

Tank

Fermentation

Aerobic/ Aerobic/ Tank

Results & Discussion Anoxic

Switching Tank

Anoxic

Switching Tank

Ozone Oxidation

Coagulant Tank

Run #1 : Control

Membrane P-releasing

Run #2 : Adding pretreated sludge (C source) and Coagulant (Alum) Return sludge Bioreactor Excess sludge Tank

Run #3 : Adding pretreated sludge only

Run #1 Run #2 Run #3 Effleunt

200 18

COD removal efficiency (%)

Run #1

16 Run #2

100

150 14 Run #3

NH4+-N (mg/L)

CODCr (mg/L)

80 12

100 60 10

Influent 8

40

Effluent 6

50 Removal Efficiency

20 4

0 0 2

0

0 10 20 30 40 50 60 nt nk nk nk R nt

e a a a B ue

flu T T T M fl

Time (day) In

E xh bi c

in

g Ef

o h

xy

aer i tc

O Sw

An

50

14 Run #1

T-N removal efficiency (%)

Run #2

100

40 12 Run #3

NO3--N (mg/L)

80 10

T-N (mg/L)

30

60 8

20

40 6

10 4

20

Influent

Effluent 2

0 Removal Efficiency 0

0

t nk k nk t

0 10 20 30 40 50 60 ue

n a an a M BR ue

n

fl T c T T ffl

In E xh bi i ng E

Time (day) y ero

tc

h

Ox a i

An Sw

6 3.5

Run #1

T-P removal efficiency (%)

5 100 3.0 Run #2

Run #3

2.5

PO4--P (mg/L)

4 80

T-P (mg/L)

2.0

3 60

Influent

Effluent 1.5

2 40

Removal Efficiency

1.0

1 20

0.5

0 0

0.0

0 10 20 30 40 50 60 nt nk nk nk R nt

ue B e

fl Ta Ta Ta M flu

Time (day) In E xh bic

in

g Ef

o h

xy

aer itc

O Sw

An

Summary

• Even though, the COD removal efficiency was varied with the fluctuation of influent COD concentration, it reached a satisfying level of 80%.

• Compared at Run 1, the phosphorus removal efficiency during Run 2 greatly increased from 65 to 95% by adding the coagulant to the effluent of aerobic/anoxic switching tank.

• However, when the alum was stopped to add, the phosphorus removal efficiency decreased to 75%.

• To avoid the membrane bio-fouling by coagulant , coagulant should be injected into the effluent of aerobic/ anoxic switching tank.

You might also like

- Flexo Principles & Practices 940 PageDocument940 pagesFlexo Principles & Practices 940 PageWilmer Gonzalez70% (10)

- Organic Chemistry Class 11 Notes by Bharat PanchalDocument24 pagesOrganic Chemistry Class 11 Notes by Bharat Panchalsaurabh Kumar83% (12)

- Cswip 3.1 Welding Inspector - Multiple Choice Question, Dec 7, 2007Document43 pagesCswip 3.1 Welding Inspector - Multiple Choice Question, Dec 7, 2007claytoninf87% (30)

- CE 085 Wastewater Treatment III MBRDocument28 pagesCE 085 Wastewater Treatment III MBRNguyen An100% (1)

- AquaNereda Brochure 1017 WebDocument4 pagesAquaNereda Brochure 1017 WebdmnNo ratings yet

- Techno 2019 Nano Calcium CarbonateDocument1 pageTechno 2019 Nano Calcium CarbonateShermal FernandoNo ratings yet

- Dwnload Full Water and Wastewater Technology 7th Edition Hammer Solutions Manual PDFDocument35 pagesDwnload Full Water and Wastewater Technology 7th Edition Hammer Solutions Manual PDFamoeboid.amvis.uiem100% (8)

- Water and Wastewater Technology 7th Edition Hammer Solutions ManualDocument35 pagesWater and Wastewater Technology 7th Edition Hammer Solutions Manualbisterkeelvat.ydma3q100% (20)

- FYP Waste Water TreatmentDocument53 pagesFYP Waste Water TreatmentAgha SufyanNo ratings yet

- Cumene Factsheet EnpdfDocument2 pagesCumene Factsheet EnpdfSaidNo ratings yet

- Flow Diagram Instalasi Pengolahan Air Limbah By: Cv. Bangkit Maju JayaDocument1 pageFlow Diagram Instalasi Pengolahan Air Limbah By: Cv. Bangkit Maju JayaDenti Maressa MNo ratings yet

- SBR MMBR RBCDocument30 pagesSBR MMBR RBCbayu sinyoNo ratings yet

- Membranes 09 00172 PDFDocument14 pagesMembranes 09 00172 PDFMladen PopovNo ratings yet

- Water and Wastewater Technology 7th Edition Hammer Solutions ManualDocument21 pagesWater and Wastewater Technology 7th Edition Hammer Solutions ManualLaurenBateskqtre100% (15)

- Design, Installation, Operation and Experimentation of Septic Tank eDocument10 pagesDesign, Installation, Operation and Experimentation of Septic Tank eghasfa khalidNo ratings yet

- Session 4 SIZING PRINCIPLE FOR A GREEN AMMONIA PLANT - FinalDocument18 pagesSession 4 SIZING PRINCIPLE FOR A GREEN AMMONIA PLANT - FinalswapneelkhanangNo ratings yet

- WS Carbselector DSDocument2 pagesWS Carbselector DSdanielph15No ratings yet

- RSC Advances: PaperDocument9 pagesRSC Advances: PaperADevilSwordNo ratings yet

- Water Management: Typical ApplicationsDocument2 pagesWater Management: Typical ApplicationsHardik KhetaniNo ratings yet

- cumene_factsheet_enDocument2 pagescumene_factsheet_enAndrea JaenNo ratings yet

- Equation (G) Nitrogen: HydrogenDocument1 pageEquation (G) Nitrogen: HydrogenMUHAMMAD LUQMAN HAKIMI MOHD ZAMRINo ratings yet

- Ventsorb Ventsorb: Description Specifications Carbon Life EstimateDocument4 pagesVentsorb Ventsorb: Description Specifications Carbon Life EstimateEvert AlexNo ratings yet

- MABR Product Brochure Aug19Document4 pagesMABR Product Brochure Aug19e.mostafa.abdelhadyNo ratings yet

- Anaerobic ReactorsDocument21 pagesAnaerobic ReactorsManish Kumar GhoraNo ratings yet

- Chapter 5Document82 pagesChapter 5Anonymous IF81QDRylNo ratings yet

- ChE 3201 G7 Removal of Toxic ComponentsDocument18 pagesChE 3201 G7 Removal of Toxic ComponentsJohn Emmanuel Abel RamosNo ratings yet

- 09.advanced WWTDocument30 pages09.advanced WWTMuamar DhikriNo ratings yet

- Slides b3Document32 pagesSlides b3Jack nguyenNo ratings yet

- Proposal by MuizDocument9 pagesProposal by MuizOluwatobiloba IbrahimNo ratings yet

- Singh 1997Document6 pagesSingh 1997ThobiasNo ratings yet

- Aerobic and Anaerobic TreatmentDocument44 pagesAerobic and Anaerobic TreatmentJohn Carlo Abala100% (1)

- The Cleaner Production of Monosodium L-Glutamate by Resin-Filled Electro-Membrane ReactorDocument8 pagesThe Cleaner Production of Monosodium L-Glutamate by Resin-Filled Electro-Membrane ReactorFernando IzquierdoNo ratings yet

- Wwi MBR Reuse 2014Document2 pagesWwi MBR Reuse 2014qiaoxin136No ratings yet

- Jacobi Activated Carbon waterMP23Document2 pagesJacobi Activated Carbon waterMP23maryam javadiNo ratings yet

- MBBR Evaluation For Oil Refinery WW Treatment With Post-Ozonation and BAC For WW ReuseDocument6 pagesMBBR Evaluation For Oil Refinery WW Treatment With Post-Ozonation and BAC For WW ReusemonkeyjackcnNo ratings yet

- Ohio Biosolids Nereda Seminar 2017Document71 pagesOhio Biosolids Nereda Seminar 2017فؤاد مهندسNo ratings yet

- ES 200 - Module B - Lec - 3 - TNDocument23 pagesES 200 - Module B - Lec - 3 - TNdummy PavanNo ratings yet

- Septage Treatment OptionsDocument25 pagesSeptage Treatment OptionsDon Clerance Denzil Weerakkody50% (2)

- Brewery Wastewater TreatmentDocument7 pagesBrewery Wastewater TreatmentSithandiwe Sindiso MlalaziNo ratings yet

- To Scale Up Waste Water Treatment PlantDocument26 pagesTo Scale Up Waste Water Treatment PlantAgha SufyanNo ratings yet

- STP Comparision of ProcessDocument11 pagesSTP Comparision of Processwd100% (1)

- WWT 1Document33 pagesWWT 1Abhishek AdhikariNo ratings yet

- BioMOD AnMBR BrochureDocument4 pagesBioMOD AnMBR BrochureDouglas CostaNo ratings yet

- Membrane Bioreactors: State of The Art and Technology ExchangeDocument54 pagesMembrane Bioreactors: State of The Art and Technology ExchangeNermeen ElmelegaeNo ratings yet

- Pharmaceutical Manufacturing: Filtration SolutionsDocument6 pagesPharmaceutical Manufacturing: Filtration SolutionsApril TejadaNo ratings yet

- MBR Process: Membrane Bioreactors MBR PlantsDocument1 pageMBR Process: Membrane Bioreactors MBR Plantsprem_k_sNo ratings yet

- UASBDocument10 pagesUASBkritizasharmaNo ratings yet

- MAK WATER - PDS Membrane Bioreactor (MBR) PDFDocument2 pagesMAK WATER - PDS Membrane Bioreactor (MBR) PDFmeisam100% (1)

- 3.2 17566 Product Leaflet MBR LowresDocument2 pages3.2 17566 Product Leaflet MBR LowresRahul Damodar100% (1)

- A Novel Binary Flooding System of A BiobasedDocument5 pagesA Novel Binary Flooding System of A Biobasedarif setiawanNo ratings yet

- Process For Solvent Extraction of Bitumen From Oil Sand: Jiangying Wu and Tadeusz DabrosDocument7 pagesProcess For Solvent Extraction of Bitumen From Oil Sand: Jiangying Wu and Tadeusz DabrosbuyitnotregretitNo ratings yet

- Coway Water Purifier Catalog - 0320 PDFDocument10 pagesCoway Water Purifier Catalog - 0320 PDFSyida NaufalNo ratings yet

- Civil - Dairy Waste - Sheetal S Karale-With-Cover-Page-V2Document7 pagesCivil - Dairy Waste - Sheetal S Karale-With-Cover-Page-V2ShabanaNo ratings yet

- (BSC31T1S、S1S)MagaBio - FFPE Tissue Genomic DNA Extraction Kit IFUDocument2 pages(BSC31T1S、S1S)MagaBio - FFPE Tissue Genomic DNA Extraction Kit IFUAlejandro DottoreNo ratings yet

- Chapter 7 Natural Biological Treatment ProcessDocument20 pagesChapter 7 Natural Biological Treatment ProcessShafayet UllahNo ratings yet

- SESSION 5 - Presentation GBDocument26 pagesSESSION 5 - Presentation GBMarko KorenićNo ratings yet

- Analysis of The Combined Ammonia Production and Cyclohexane Dehydrogenation by A Novel Bifunctional ReactorDocument10 pagesAnalysis of The Combined Ammonia Production and Cyclohexane Dehydrogenation by A Novel Bifunctional ReactorSangHao NgNo ratings yet

- Upflow Anaerobic Sludge Blanket (Uasb) - En-04Document11 pagesUpflow Anaerobic Sludge Blanket (Uasb) - En-04Engr Shakeel AhmedNo ratings yet

- منظومة البحث الثاني PDFDocument1 pageمنظومة البحث الثاني PDFali abdulrahman al-ezziNo ratings yet

- Acs Spring 2020 Expo 3284738Document1 pageAcs Spring 2020 Expo 3284738Amm ÃrNo ratings yet

- P01181 2014P015 Structural Analysis of Photoresist at Boundary Area in Resist Pattern PDFDocument1 pageP01181 2014P015 Structural Analysis of Photoresist at Boundary Area in Resist Pattern PDFLauraNo ratings yet

- Beyond Batteries The Rise of Super Capacitors in Modern Energy StorageFrom EverandBeyond Batteries The Rise of Super Capacitors in Modern Energy StorageNo ratings yet

- Marine Reports: Yongkil Glen CHO, Ümüt YIGITDocument17 pagesMarine Reports: Yongkil Glen CHO, Ümüt YIGITNguyen AnNo ratings yet

- GTCNCHUYENKHOA0001Document2 pagesGTCNCHUYENKHOA0001Nguyen AnNo ratings yet

- H. Lee, G. H. Yun, T. U. Yoo, S. Kim, J. K. Hwang, W. Lee and Z. YunDocument1 pageH. Lee, G. H. Yun, T. U. Yoo, S. Kim, J. K. Hwang, W. Lee and Z. YunNguyen AnNo ratings yet

- EZLAND's Health & Safety Executive (HSE) Regulations For The Construction SiteDocument26 pagesEZLAND's Health & Safety Executive (HSE) Regulations For The Construction SiteNguyen AnNo ratings yet

- A Bio-Eco Combined Process For Decentralized Wastewater TreatmentDocument1 pageA Bio-Eco Combined Process For Decentralized Wastewater TreatmentNguyen AnNo ratings yet

- Iwa 9219Document1 pageIwa 9219Nguyen AnNo ratings yet

- Iwa 8932Document1 pageIwa 8932Nguyen AnNo ratings yet

- Development of A Novel 3-Stage BAF System For Enhancing Nitrification Performance at Short Hydraulic Retention TimeDocument1 pageDevelopment of A Novel 3-Stage BAF System For Enhancing Nitrification Performance at Short Hydraulic Retention TimeNguyen AnNo ratings yet

- J. Cumin, Y. Hong, M. Dagnew, R. Bayly, W. ParkerDocument1 pageJ. Cumin, Y. Hong, M. Dagnew, R. Bayly, W. ParkerNguyen AnNo ratings yet

- Iwa 8418Document1 pageIwa 8418Nguyen AnNo ratings yet

- Micropollutant 2016 ENGDocument12 pagesMicropollutant 2016 ENGNguyen AnNo ratings yet

- Iwa 8628Document1 pageIwa 8628Nguyen AnNo ratings yet

- Filtration2014 EN WebDocument6 pagesFiltration2014 EN WebNguyen AnNo ratings yet

- Ed 162869Document495 pagesEd 162869Nguyen AnNo ratings yet

- Wabag Bioden: Nitrate Removal Biological Denitrifi Cation of Ground WaterDocument6 pagesWabag Bioden: Nitrate Removal Biological Denitrifi Cation of Ground WaterNguyen AnNo ratings yet

- SludgeDigestion 2016 EN WEBDocument12 pagesSludgeDigestion 2016 EN WEBNguyen AnNo ratings yet

- ASABE Paper 141901300Document9 pagesASABE Paper 141901300Nguyen AnNo ratings yet

- WABAG Operations: Plant Management For The Private and Public SectorDocument14 pagesWABAG Operations: Plant Management For The Private and Public SectorNguyen AnNo ratings yet

- Marapur MBR Technology: Maximum PerformancesDocument12 pagesMarapur MBR Technology: Maximum PerformancesNguyen AnNo ratings yet

- World's Largest Science, Technology & Medicine Open Access Book PublisherDocument31 pagesWorld's Largest Science, Technology & Medicine Open Access Book PublisherNguyen AnNo ratings yet

- Material Spec Chart - 01Document1 pageMaterial Spec Chart - 01teaNo ratings yet

- API Recommended Practice 2001Document2 pagesAPI Recommended Practice 2001Ckaal74No ratings yet

- CWI Exam Sample Question Paper For Practice - UpWeldDocument16 pagesCWI Exam Sample Question Paper For Practice - UpWeldAhmed Shaban Kotb100% (2)

- Chemical Reaction Engineering and Reactor Technolo... - (Chapter 5. Catalytic Two-Phase Reactors) PDFDocument74 pagesChemical Reaction Engineering and Reactor Technolo... - (Chapter 5. Catalytic Two-Phase Reactors) PDFazNo ratings yet

- Catálogo Vontron - CompletoDocument57 pagesCatálogo Vontron - CompletomarianaNo ratings yet

- HilmaDocument4 pagesHilmaHaris ĐulićNo ratings yet

- Compre So RRRRRDocument6 pagesCompre So RRRRRAnonymous Ghf75CxaiN0% (1)

- 11 - SupaSep LGPDocument8 pages11 - SupaSep LGPDylan DooleyNo ratings yet

- Sprayglass SG20: Steel PreparationDocument1 pageSprayglass SG20: Steel PreparationfuffinoNo ratings yet

- Basic Punching Theory: ©2008 Mate Precision ToolingDocument79 pagesBasic Punching Theory: ©2008 Mate Precision ToolingBong ThoNo ratings yet

- Mixbond SBRDocument5 pagesMixbond SBRGelila TadesseNo ratings yet

- Union Simple Cobre So EpcDocument1 pageUnion Simple Cobre So EpcAngel Rojas FrancoNo ratings yet

- Drill Machine OperationsDocument3 pagesDrill Machine OperationsUmer RashidNo ratings yet

- Analysis of Rate For LinerDocument10 pagesAnalysis of Rate For LinerFahad ZulfiqarNo ratings yet

- 09D 22 00 A3 Sheet 01Document1 page09D 22 00 A3 Sheet 01RobsNo ratings yet

- Silverbraze 45T BAg-36 TDSDocument2 pagesSilverbraze 45T BAg-36 TDSMAURO MORESCONo ratings yet

- SiliconeSurfactants SILTECHDocument6 pagesSiliconeSurfactants SILTECHA MahmoodNo ratings yet

- Welding QC 10 - TIGDocument9 pagesWelding QC 10 - TIGExsan OthmanNo ratings yet

- Fire Sprinkler Systems ExplainedDocument3 pagesFire Sprinkler Systems ExplainedRomzy KutonNo ratings yet

- ASTM A480-A480M-04aDocument24 pagesASTM A480-A480M-04aNadhiraNo ratings yet

- Compact ESD Products DetailsDocument15 pagesCompact ESD Products DetailsSpark MeditechNo ratings yet

- 2 Stair Details: Approved: DateDocument1 page2 Stair Details: Approved: DateRycca DeeNo ratings yet

- Observaciones Instucciones de Montaje RingmotorDocument2 pagesObservaciones Instucciones de Montaje RingmotorNoname_user989No ratings yet

- Pune Business Directory-3000Document403 pagesPune Business Directory-3000maxisinc.inNo ratings yet

- S275 Low Carbon Manganese Steel - Murray Steel ProductsDocument1 pageS275 Low Carbon Manganese Steel - Murray Steel ProductsJosé CunhaNo ratings yet

- Landfill Leachate Treatment 2Document7 pagesLandfill Leachate Treatment 2Christian Mihai GNo ratings yet

- AL 6XN General PropertiesDocument1 pageAL 6XN General Propertiesah1525No ratings yet

- Weight of G.I.Strip Flat KG MT.: X X X X X X X X XDocument2 pagesWeight of G.I.Strip Flat KG MT.: X X X X X X X X XHiral SolankiNo ratings yet