Professional Documents

Culture Documents

Buckets For Loaders

Buckets For Loaders

Uploaded by

Maurynho ChavezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buckets For Loaders

Buckets For Loaders

Uploaded by

Maurynho ChavezCopyright:

Available Formats

Bucket Attachment

SELECTING THE RIGHT BUCKET FOR YOUR BOBCAT LOADER NEEDS

See Model Charts For Details

FEATURES AND BENEFITS OF GENUINE BOBCAT CONSTRUCTION/INDUSTRIAL AND LOW PROFILE BUCKETS

Channel Design Replaceable 3/4 in. x 6 in. Side Cutting Edges

Top and bottom bucket Cutting Edges Cutting Edge Give better performance,

sections are a formed Your Bobcat dealer has High carbon steel increased strength and

channel design to provide weld-on or bolt-on for longer wear. longer life to your bucket

extra strength and durability. edges available. when working in tough

On 74 in. and 80 in. widths, digging situations.

the channel is double-walled.

Steps

Make entering and

“Waffle” Type leaving the loader

Skid Plate easier for the operator.

Backs up the cutting

edge and adds strength Low Back

to the bottom of the Gives better cutting

bucket for longer life. edge visibility.

Cast Mounting Frame

Low Heel Improves service life of bucket

Makes cutting grade mount area by

and backdragging easier. approximately three times.

Flat Back

Round Back Design Assures a secure attaching

Enhances bucket area for the Bob-Tach

loading and cleanout. mounting system.

HEAVY-DUTY CONSTRUCTION/INDUSTRIAL BUCKETS OFFER EVEN

MORE FEATURES REQUIRED FOR HEAVY-DUTY USE:

• Side cutting edges: 3/8 in. thick versus 5/16 in. • Mounting frame: 3/8 in. for improved • Top channel crossmember: double-walled

thick on standard buckets life and durability • Bolt-on corner cutting edge standard

• Cutting edge: 3/4 in. X 8 in. versus 3/4 in. X 6 in. • Visibility: heavy-duty buckets have better cutting

on standard buckets edge visibility than standard C/I buckets

SEVERE-DUTY CONSTRUCTION/INDUSTRIAL BUCKETS OFFER MAXIMUM DURABILITY:

• 1” thick cutting edge provide improved rigidity and longer life

• Mounting frame and top channel cross member enhanced to provide more strength while pushing with the most powerful machines

FEATURES AND BENEFITS OF GENUINE BOBCAT® GENERAL PURPOSE AND DIRT BUCKETS

Withstands the power of smaller Bobcat loaders for daily use; also works well for light, occasional use on some of our larger machines.

Replaceable Skid Bar Design ½ in. x 4 in.

Cutting Edges Backs up the cutting edge and adds strength Cutting Edge

Your Bobcat dealer has to the bottom of the bucket for longer life. High carbon steel

weld-on or bolt-on for longer wear.

edges available.

Fabricated Steps

Mounting Frame Make entering and

Complies with SAE J2513 leaving the loader

and ISO 24410 standards. easier for the operator.

Round Back Design Low Back

Enhances bucket loading Gives better cutting

and cleanout. edge visibility.

Flat Back

Assures a secure attachment area

for the Bob-Tach™ Mounting System.

ISO

A B C Weight 463/ 753/

BUCKETS Heaped MT52 MT55 S100 S150 S160 S175 S185 S205

Inches Inches Degrees lb. S70 S130

Cap

Bucket Specifications

36 in. C/I> 19.0 25.0 65 4.0 167 130.0

36 in. Dirt> 19.9 24.8 70 4.7 168 110.4 148.9

36 in. GP> 19.9 30.0 70 6.0 185 83.7 113.8

44 in. Dirt> 19.9 24.8 70 5.8 188 86.0 99.5 117.2

44 in. GP> 19.9 30.0 70 7.4 207 73.5 75.4 89.3

50 in. Dirt> 19.9 24.8 70 6.6 202 100.9 151.5

50 in. GP (463)> 19.9 30.0 70 8.5 223 75.9

50 in. GP> 19.9 30.0 70 8.5 223 115.2

50 in. C/I> 21.5 31.8 70 9.6 353 88.4

50 in. Low Profile> 21.5 35.5 70 11.6 377 71.1

54 in. Fertilizer & Grain* 22.6 33.6 60 14.7 337 135.4

56 in. GP> 19.9 30.0 70 9.4 239 102.4 141.9

56 in. C/I> 21.5 31.8 70 10.8 428 106.0

56 in. Low Profile> 21.5 35.5 70 13.1 428 87.4

60 in. Fertilizer & Grain* 19.9 36.6 60 16.6 428 73.2 96.8 102.8 111.9 118.9 130.2

62 in. GP> 19.9 30.0 70 10.5 257 125.3 162.7 172.2 186.5 196.0

62 in. C/I> 21.5 31.8 70 12.7 465 87.2 118.1 126.0 137.8 145.7 161.8

62 in. Low Profile> 21.5 35.5 70 14.5 483 75.2 102.2 109.1 119.4 126.3 140.5

66 in. Snow & Light Material* 26.6 39.1 70 23.9 502 44.8 61.2 65.4 71.7 75.9 84.4

66 in. Fertilizer & Grain* 28.5 46.4 60 30.3 500 48.3 51.7 56.6 59.9 66.7

68 in. GP> 19.9 30.0 70 11.6 274 145.8 154.4 167.3 175.9

68 in. C/I> 21.5 31.8 70 14.0 470 106.8 113.9 124.6 131.8 146.4

68 in. Low Profile> 21.5 35.5 70 16.0 515 90.6 96.9 106.3 112.5 125.3

72 in. Fertilizer & Grain* 28.5 46.6 60 32.8 507

74 in. GP> 19.9 30.0 70 12.7 290 131.9 139.8 151.6 159.4

74 in. C/I> 21.5 31.8 70 15.4 533 93.0 99.5 109.2 115.7 129.0

74 in. C/I Heavy-Duty> 24.1 38.1 70 20.5 681

74 in. Low Profile> 21.5 35.5 70 17.6 533 81.4 87.0 95.6 101.3 112.9

74 in. Snow & Light Material* 26.9 42.0 70 26.8 620 35.6 50.2 53.9 59.5 63.2 70.9

78 in. Dirt 24.3 32.4 70 20.1 584

78 in. Dirt (w/ teeth) 24.3 32.4 70 20.1 639

80 in. C/I> 21.5 31.8 70 16.7 565

80 in. C/I Heavy-Duty> 24.1 38.1 70 22.4 731

80 in. Low Profile> 21.5 35.5 70 19.1 586

80 in. Snow & Light Material* 26.9 42.0 70 29.1 651 48.8 53.9 57.4 64.2

82 in. C/I Severe-Duty> 24.1 38.2 70 22.8 844

84 in. C/I Heavy-Duty> 24.1 38.1 70 23.6 758

88 in. C/I Heavy-Duty> 24.1 38.1 70 24.6 775

88 in. C/I Severe-Duty> 24.1 38.2 70 24.6 888

88 in. Snow & Light Material* 26.9 42.0 70 32.3 693 47.3 50.4 56.6

100 in. Snow & Light Material> 33.7 48.5 70 54.2 878

HD indicates Heavy-Duty Bucket (recommended for severe-duty use).

* Buckets have holes predrilled to accept bolt-on cutting edges.

> Buckets have holes predrilled to accept bolt-on cutting edges and bolt-on teeth.

5600/

S205 S220 S250 S300 S330 S630 S650 A300 T110 T140 T180 T190 T250 T300 T320 T630 T650

5610

Rated Material Density lb. / ft.

114.6

92.8

129.6

106.9

130.2 116.8 122.8

144.6

161.8

140.5 125.1 132.0

84.4 93.3 105.9 128.2 92.5 113.8 75.1 79.3 52.5

66.7 73.7 83.6 101.2 73.0 89.9 59.3 62.6

129.4

146.4 161.6 183.1 221.0 160.2 196.6 130.5 137.6

125.3 138.6 157.4 190.6 137.4 169.3 111.4 117.6

67.9 77.0 92.3 102.4 67.3 82.8 92.3 68.8 79.1

116.9

129.0 142.9 162.3 194.8 216.4 141.6 152.8 194.8 111.4 121.0 144.8 166.9

100.1 114.7 139.1 155.3 99.1 124.0 139.1 78.8 83.7 116.3 140.7 101.6 118.1

112.9 125.0 142.0 170.5 189.3 123.9 152.8 170.5 100.2 105.9 126.7 146.0

70.9 78.8 90.0 108.7 121.1 78.1 97.1 108.7 62.6 66.3 80.0 92.7 42.4

106.9 121.8 146.7 163.2 146.7 131.7 156.6 158.3

104.2 119.1 144.0 160.5 144.0 94.2 129.0 155.5

129.8 147.8 177.7 197.6 128.6 159.2 177.7 131.6 152.0

89.4 102.8 125.1 139.9 88.5 111.3 125.1 111.6 133.9 135.4 90.7 105.9

112.4 128.1 154.3 171.7 111.4 138.6 154.3 114.0 131.8

64.2 71.6 81.9 100.1 110.4 70.9 88.4 99.0 55.6 59.1 72.6 84.3 38.0

119.3 132.5 97.4 119.3 123.7

85.0 99.4

79.6 91.8 112.1 125.6 112.1 99.8 120.2 121.5

108.8 121.0 108.8 112.9

56.6 63.2 72.4 88.9 98.2 62.5 78.3 98.7 48.8 51.9 64.1 74.6

39.8 49.0 55.1 49.0 43.4 52.6 53.3

A. Back height of bucket

B. Bucket length

C. Bucket back angle

®

BUY GENUINE BOBCAT BUCKETS!

Built Specifically For Bobcat Loaders!

Bobcat Whisker Push Broom Bolt-On Side Guard Combination Bucket

The Bobcat Whisker Get more

push broom quickly capacity out of your

pins onto your bucket C/I or low profile

for a clean sweep on buckets by turning

those small sweeping them into hard-

jobs. Use the Bobcat working utility

Whisker push broom buckets—just add

and clean up inside buildings, on driveways, sidewalks or bolt-on side plates.

anywhere your Bobcat loader can go. Most Bobcat buckets have pre-drilled holes to accept bolt-on

side plates.

The versatile Bobcat combination bucket is ideal for dozing,

Bucket Bite® Tooth Bar Bolt-On Corner Cutting Edge grappling, leveling, digging, loading and dumping. It’s built

The Bucket Bite tooth Add life to the high- with heavy-duty cutting edges and protected cylinders for

bar is available to help wear corners of your long life on construction, demolition, landscaping

smooth-lip buckets bucket by bolting on and municipal jobs.

chew through tough corner cutting edges.

digging conditions. Most Bobcat buckets

Available for most have pre-drilled holes Construction/Industrial or Low

Bobcat bucket sizes. to accept bolt-on Profile Bucket (with Grapple)

corner cutting edges.

Bolt-On Teeth With Bolt-On Side Cutting Edge Kit

Replaceable Points • Beveled

• Standard on 74 in. to 88 in. heavy-duty and

Made of heavy-duty severe-duty C/I buckets

cast steel. Choose • Available on most other buckets

from several styles:

standard bolt-on tooth

with four replaceable Bolt-On Cutting Edge

point options, For certain construction/industrial, Bolt-on cutting edges Your Bobcat construction/industrial or low profile bucket

standard forged point, low-profile and fertilizer buckets. give longer wear to your becomes a hard-working grapple with the bolt-on grapple

Hensley forged tooth loader’s bucket. Most attachment. Turn those hard-to-manage jobs into easy-to-

point, Hensley Tiger Bobcat buckets have handle jobs on the farm or at construction sites. It’s quick,

tooth point, or Hensley pre-drilled holes for easy and inexpensive.

Twin Tiger tooth point. bolt-on cutting edges.

For general purpose and dirt buckets.

Exclusive Bob-Tach™ System For

Spill Guards Fast, Secure Attachment Changes

For cylinder Your versatile Bobcat loader quickly turns into a multi-job

protection. machine with a tight-fit attachment hook-up....from bucket

• Protects twin- to grapple to pallet fork to backhoe...and a variety of other

cylinder loaders. Bobcat attachments.

• Helps reduce and

prevent build-up of

materials in lift-arm

The 4 in. wide Hensley Bucket tooth provides additional

and Bob-Tach pivot

wear surface and reduces the rate of wear at the bucket

points.

edge and corner.

The Bobcat Bucket Advantage

• Engineered to match the power and capacity of your loader

See your Bobcat dealer for more • Largest selection of bucket designs

information on these and other • Extra reinforcement for secure machine mounting

Side View

Left to right: Bob-Tach frame (A) moves into attachment

buckets and bucket accessories. • Longer lasting flange (B) handle (C) pushes down easily, pressing wedge

(D) through frame and attachment hole for solid Bob-Tach

Bobcat Company complies with the requirements of ISO 9001 as

registered with BSI. connection. (Power Bob-Tach System also available.)

Bobcat buckets offer many choices:

Construction/Industrial (C/I) Bucket Fertilizer Bucket General Purpose Buckets

The strongest of all Bobcat buckets. Ideal for everything from Fertilizer buckets have large capacities and more roll-back These buckets have a longer bottom than the dirt

tough digging to material handling. C/I buckets offer good cutting range. The greater roll-back allows granular materials to be style. They offer excellent cutting edge visibility

edge visibility and excellent bucket breakout force for better easily held in the bucket by minimizing spillage over the front and good bucket breakout force. General

digging and easier bucket filling. edge. Applications include fertilizer and grain handling. purpose buckets are ideal for light-duty grading

and leveling applications as well as material

handling.

W/Teeth

Low Profile Bucket Light Material Bucket Dirt Buckets

These buckets have a longer bottom than the C/I style. They offer These are large capacity buckets for loading and handling Ideal for everything from digging to material

excellent cutting edge visibility and good bucket breakout force. various light materials such as snow and mulch. They have handling. Dirt buckets offer good cutting edge

Low Profile buckets are ideal for grading and leveling applications high backs to help with pushing snow, and straight sides to visibility and excellent bucket breakout force for

as well as material handling. penetrate snow and mulch piles. better digging and easier bucket filling.

W/Teeth

SELECTING THE RIGHT BUCKET FOR THE JOB:

Example:

1. Find the Material Density for the material you will be What bucket would be best for a S150 handling dry sand?

handling. (The chart below lists many materials and their corresponding

3

density in “pounds per cubic foot.”) 1. From the table below, sand has a Material Density of 105 lb./ft .

2. Look at the model charts inside and find the Rated Material Density

2. The model chart for the S150 shows the 68 in. Construction/Industrial

that is slightly greater than the density taken from the table.

Bucket is the best bucket for the job since the Rated Material Density

is slightly more than the density of the material being handled.

This is the best bucket for the job and will keep the

loader from being overloaded.

Agricultural Materials

Material lb./ft. 3

Material lb./ft.3 Material lb./ft.3

Barley 39 Fertilizers 35-70 Oats 26

Beans 48 Lime 36-53 Peanuts (shelled) 18

Coffee Beans 45 Urea 45 Potatoes 48

Corn 45 MAP, DAP 60 Rice 44

Cottonseed (dry) 25 Potash 68 Soybeans 48

Flax Seed 45 Sugar Beets 40

Hay (baled) 20 Sunflowers 24

Wheat 48

Construction Materials

Material lb./ft. 3

Material lb./ft.3 Material lb./ft.3

Cement, Portland 94 Earth (wet, packed) 115 Sand (wet) 126

Concrete 86-111 Earth (dry, loose) 76 Sandstone 143

Clay (damp) 110 Gravel 90-126 Shale 92

Clay (dry excavated) 63 Sand (dry) 90-105 Stone (broken) 90-120

Miscellaneous Materials

Material lb./ft. 3

Material lb./ft.3 Material lb./ft.3

Ashes 35-52 Limestone 155 Slag, Iron 172

Bone Meal 57 Lye 106 Snow (wet) 40-50

Charcoal (oak) 35 Malt (dry) 45 Ice 37-56

Coal 40-58 Paper 58 Sulphur 55-83

Coke 32 Quartz (ground) 165 Wood (sawdust) 15-20

Copper Ore 262 Rubber (scrap) 50 Wood (chips) 18-20

Gypsum 159 Salt 35-48

Visit bobcat.com/anyjob for more information Bobcat Company • P.O. Box 6000 • West Fargo, ND 58078

B-1566 (7/09) Printed in U.S.A. Kn-10M-709-#16300-F

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Bobcat 637Document581 pagesBobcat 637Sava IonuTz88% (17)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Operator'S Manual: WheelloaderDocument94 pagesOperator'S Manual: WheelloaderMichael Akhramovich100% (1)

- Caterpillar 6e1780 Valve Gp-Bank 2 - BullpartsDocument2 pagesCaterpillar 6e1780 Valve Gp-Bank 2 - BullpartsEslam MansourNo ratings yet

- Cat 330D FMDocument24 pagesCat 330D FMIvan100% (1)

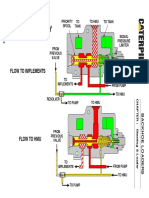

- Steering Priority Valve: Flow To ImplementsDocument19 pagesSteering Priority Valve: Flow To ImplementsAnonymous M28U3D100% (2)

- 348 JCB Telehandler 506CDocument8 pages348 JCB Telehandler 506Cvkannan07666100% (1)

- TA1 English - Backhoe LoaderDocument35 pagesTA1 English - Backhoe Loadercristian chuquicondor torresNo ratings yet

- Conectores ElectricosDocument129 pagesConectores Electricosjesusabreu38No ratings yet

- Dictionary of Pictograph Symbols: Excerpted From Operation & Maintenance Manual (SEBD0400-03-01)Document82 pagesDictionary of Pictograph Symbols: Excerpted From Operation & Maintenance Manual (SEBD0400-03-01)Franciscley CardosoNo ratings yet

- JCB Tracked Excavator JS130 L T.A.B.: Static DimensionsDocument6 pagesJCB Tracked Excavator JS130 L T.A.B.: Static DimensionsKovacs Zsolt-Istvan100% (1)

- Esquema Hidraulico Cat 420 eDocument4 pagesEsquema Hidraulico Cat 420 eVictor Enrique Silva Rodriguez100% (3)

- Wheel LoadersDocument32 pagesWheel LoadersBROCHIER100% (1)

- Dozer Blade Parts, Crawler Loader Parts, Suspension PartsDocument20 pagesDozer Blade Parts, Crawler Loader Parts, Suspension PartsJas SumNo ratings yet

- Auction 45Document6 pagesAuction 45fandi_mesin0787No ratings yet

- Backhoe Loaders: Engine DimensionsDocument1 pageBackhoe Loaders: Engine DimensionsToño MartinezNo ratings yet

- MTL No NameDocument63 pagesMTL No NameAlexander JohnsonNo ratings yet

- Pre-Test ExamDocument4 pagesPre-Test ExamVKG MANPOWERNo ratings yet

- Sip Report JCBDocument108 pagesSip Report JCBSmita Sharma100% (2)

- 01 - Brochure GB - SIIDocument12 pages01 - Brochure GB - SIIgreenmachinery.meNo ratings yet

- Backhoe Loaders: Product Comparison TRAININGDocument39 pagesBackhoe Loaders: Product Comparison TRAININGLuisalbertxNo ratings yet

- Mahindra Tractor WarrantyDocument3 pagesMahindra Tractor WarrantyNayaGaadi DavangereNo ratings yet

- Rocker Arm and Shaft InstallDocument3 pagesRocker Arm and Shaft Installaras aliNo ratings yet

- Catalogue Produits Rexroth Volvo DumperDocument108 pagesCatalogue Produits Rexroth Volvo DumperBoumediene CHIKHAOUINo ratings yet

- Gen00036-04 Wa600-6 Wheel LoaderDocument98 pagesGen00036-04 Wa600-6 Wheel LoaderJuan Araya BarrazaNo ratings yet

- SDLG BrowsingDocument2 pagesSDLG BrowsingLukman ExmesNo ratings yet

- Serv1820 01 SLD1Document83 pagesServ1820 01 SLD1mario saavedra tarazonaNo ratings yet

- JCB 214eDocument8 pagesJCB 214epankituna54870% (1)

- Manually Loaded Trucks For The Collection of Household Refuse Incorporating A Compression Mechanism - Interpretation of The TermDocument3 pagesManually Loaded Trucks For The Collection of Household Refuse Incorporating A Compression Mechanism - Interpretation of The TermŞahabettin IŞIKNo ratings yet

- Carbide Cutter: Owner's Manual and Parts Book (Originating W / Serial Number 42-1198)Document56 pagesCarbide Cutter: Owner's Manual and Parts Book (Originating W / Serial Number 42-1198)Joe ZhaoNo ratings yet