Professional Documents

Culture Documents

Concrete Reinforcment

Concrete Reinforcment

Uploaded by

Noor Mohamed Azeez0 ratings0% found this document useful (0 votes)

43 views5 pagesThis document provides specifications for reinforcement works for concrete on a construction project for special emergency forces camps. It outlines requirements for reinforcement steel materials, manufacturing, installation, and execution. The key points are:

1) Reinforcement steel must meet standards like ASTM A615 and be free of defects.

2) Shop drawings must be submitted showing bar sizes, layout, and special reinforcement.

3) Bars must be installed according to codes and specifications, securely held in place with ties and spacers, and have the proper concrete cover.

4) Installation includes cleaning bars and protecting reinforcement prior to concrete pouring.

Original Description:

Original Title

03200 Concrete Reinforcment

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for reinforcement works for concrete on a construction project for special emergency forces camps. It outlines requirements for reinforcement steel materials, manufacturing, installation, and execution. The key points are:

1) Reinforcement steel must meet standards like ASTM A615 and be free of defects.

2) Shop drawings must be submitted showing bar sizes, layout, and special reinforcement.

3) Bars must be installed according to codes and specifications, securely held in place with ties and spacers, and have the proper concrete cover.

4) Installation includes cleaning bars and protecting reinforcement prior to concrete pouring.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

43 views5 pagesConcrete Reinforcment

Concrete Reinforcment

Uploaded by

Noor Mohamed AzeezThis document provides specifications for reinforcement works for concrete on a construction project for special emergency forces camps. It outlines requirements for reinforcement steel materials, manufacturing, installation, and execution. The key points are:

1) Reinforcement steel must meet standards like ASTM A615 and be free of defects.

2) Shop drawings must be submitted showing bar sizes, layout, and special reinforcement.

3) Bars must be installed according to codes and specifications, securely held in place with ties and spacers, and have the proper concrete cover.

4) Installation includes cleaning bars and protecting reinforcement prior to concrete pouring.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 5

The Camps Construction Project for the Special Emergency Forces

Section – 03200

The Concrete's reinforcement works

Part 1: General

1/1. This part includes:

A. The reinforcement steel of molded concrete on site according to

the determined in drawings and specified in this section.

1/2. The References

A. ACI The American Institute of concrete

ACI 315 The reinforcing steel details

ACI 318 The requirements of armed concrete regulations

ASTM The American Association for testing and materials

B. ASTM A 82 The steel wires and smooth steel for concrete

reinforcement

ASTM A 184 The reinforcement steel kink, which are

manufactured with Protrusions for concrete

reinforcement.

ASTM A 185 The normal welded for concrete reinforcement

ASTM A615 The steel bars with protrusions and smooth for

concrete reinforcement

C. CRSI The institute of concrete reinforcement

CRSI MSP-1 The booklet of the standard practice to install the

reinforcement bars – chapter 3

D. AWS The American Association of welding

AWS D 12.1 The regulation of structural welding

AWS D 12.4 The regulation of structural welding- reinforcement

steel

E. SASO The Saudi Arabian organization of specifications and

standards

SSA 223 The testing methods of the manufactured steel for

concrete reinforcement

SSA 244 The manufactured steel for concrete reinforcement.

1/3. Submissions:

A. Factory certificates: the steel manufacturer's Certificates should

be submitted with attached factory tests for arming steel.

The Concrete's reinforcement works

The Camps Construction Project for the Special Emergency Forces

Certificates should specify the chemical and physical properties of

the steel bars including the records of tensile and flexion tests of

an independent testing laboratory.

B. Executive workshop drawings: Provides graphics workshop

drawings should be submitted for manufacturing, flexion and

installation of the concrete reinforcement steel that should

confirmed with detailed reinforcement of concrete origins booklet

ACI 135, which clarifies bars, distribution and assembly as required

for the manufacturing and installation including the required

special reinforcement at slots of concrete origins.

1/4. Transportation, storage and handling

A. The reinforcement will be supplied in marked packing with

identification card. The identification metal cards will be used to

determine the bars size, lengths and other information

representing the described signs on installation schemes.

B. is stored in concrete reinforcement materials should be stored on

site high off the ground in covered and shaded stores to prevent

damage and accumulation of dirt and rust or other harmful

substances.

Part (2): Products

2/1. Materials:

A. General: the reinforcement bars should be free of peel loose rust

and manufacturing shrapnel, the layers of paint or any other

material which can either reduce or prevent the cohesion with

Concrete.

B. The reinforcement bars should be confirmed with standards

ASTM A615 or SSA 223 including requirements of appendix S1 or

ASTM A 706. It uses 60 degree (undergo stress 420MPa.). The bars

with protrusion will be used, unless otherwise specified in

drawings.

C. Steel wires should be confirmed with the standards ASTM A 82,

cold-pulling smooth steel. (Undergo Stress 465 MPa.).

D. The assembled and welded wires should be confirmed with the

standards ASTM A 185 or SSA 224 (Undergo Stress 500 MPa.).

The Concrete's reinforcement works

The Camps Construction Project for the Special Emergency Forces

E. The reinforcement installation materials: The stirrups, seats,

spacers and other materials will be used to save benny distance,

pivot and reinforcement for iron installation in placements.

1. The used wire bars should be confirmed with requirements CRSI

or precast concrete pillars and according to Eng.'s approval, unless

otherwise specified. The non-acceptable materials of wood and

bricks should not be used.

2. The plastic pillars will be used for the apparent concrete surfaces,

when pillars are touching the formwork.

2/2. Manufacturing

A. General

1. The reinforcement bars will be manufactured to comply with the

required shapes and dimensions with manufacturing tolerances

according to standards ACI 315.

2. The reinforcement bars will be cold-flexed, unless otherwise

permitted by Eng.

3. In the case of there is an error in manufacturing, the bars should

not re-flexing or re-straightening by manner, which will occur

damage or weakening of the material.

B. Unacceptable materials: defective reinforcing defective in any of

the following defects will not be allowed to use it in work:

1. Lengths, diameters and flexed bars that exceed the specified

manufacturing tolerances.

2. The non-specified flexion and twists in drawings or final executive

workshop drawings.

3. Bars, which have reduced sectors as a result of rust or any other

reason.

4. Bars with surfaces that have rust or rust peel or factory shrapnel

or contaminated by dust or soil or paints or oils or any other

harmful materials.

Part (3): execution

3/1 Previewing

A. The lower surfaces should be inspected as well as the conditions

that will be existence and influence of concrete formwork

implementation. Any unsatisfactory conditions should be

The Concrete's reinforcement works

The Camps Construction Project for the Special Emergency Forces

corrected and work will be continuing after correcting the

unsatisfactory situation by acceptable manner to the engineer.

3/2 Installation:

A. The specified regulations, standards and recommended practices

of concrete reinforcement Institute for the installation of

reinforcement bars with details and methods of installation

according to the specifications in this section.

B. The bars should be cleaned to remove rust or rust peel or factory

unassembled shrapnel, dirt and soil, paints, oils or other harmful

substances.

C. Reinforcement bars will be installed, placed and secured against

displacement as a result of the establishment of formwork or

concrete molding process. Reinforcement will be placed by seats,

stirrups, spacers and relationships as required.

D. The reinforcement should be installed to achieve the basic cover

for the protection of concrete. The installation and linking bars will

distribute, spaced and secured together by flexible wires with

diameter 1.6 mm to connect the reinforcement accurately in its

placements during concrete molding. The linking wires will be

placed whereas their ends will be routed away from the apparent

concrete surface.

E. The assembled welded wire should be installed with usable

lengths. The overlap between the contiguous parts will be as

defined but at least the whole unit of the network and the links

are connected by flexible wire 1.6 mm. The end of the overlap will

be separated of contiguous width to prevent the continuation of

overlay.

F. The sufficient number of pillars with enough strong to carry the

reinforcement. The reinforcement bars should not be putted in

distance greater than 50 mm from the tip end of the continually

installation bar. Pillars should not be used as bases of concrete

equipment transportation corridors and the similar of

construction loads.

G. Links: reinforced links will be made at ends of overlap by

installation the contacted bars and they will be linked tightly by

connectivity wired. The requirements of drawings of placement

The Concrete's reinforcement works

The Camps Construction Project for the Special Emergency Forces

and overlay links will be applied. In case of there is no

identification or clarification of the requirements or standards, the

standards ACI 318 will be applied for the minimum limit of overlap

the bars links.

H. Reinforcement should be protected after installation even the

concrete molding by covers of Polyethylene or other similar slices,

which should not be impermeable.

I. Reinforcement should not be welded.

The end of this section

03200-6

The Concrete's reinforcement works

You might also like

- Steel Joists - MST PDFDocument7 pagesSteel Joists - MST PDFwafikmh4No ratings yet

- Morth 1600 ReinforcementDocument7 pagesMorth 1600 ReinforcementRameshNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- MWPS 1 Complete Book PDFDocument655 pagesMWPS 1 Complete Book PDFsharkNo ratings yet

- Concrete Reinforcing SpecsDocument3 pagesConcrete Reinforcing Specsطه حلمىNo ratings yet

- Concrete ReinforcementDocument5 pagesConcrete Reinforcementsethu1091No ratings yet

- Section 03200-Concrete ReinforcementDocument4 pagesSection 03200-Concrete ReinforcementMØhãmmed ØwięsNo ratings yet

- Reinforcing SteelDocument5 pagesReinforcing SteelStraus WaseemNo ratings yet

- Concrete Reinforcing IFC PDFDocument5 pagesConcrete Reinforcing IFC PDFTEC PlantNo ratings yet

- SECTION 03200 Concrete ReinforcementDocument8 pagesSECTION 03200 Concrete ReinforcementSuranga ManuNo ratings yet

- Early Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementDocument3 pagesEarly Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementZain AbidiNo ratings yet

- FL - Ta1056Document8 pagesFL - Ta1056ery achjariNo ratings yet

- Concrete ReinforcingDocument7 pagesConcrete ReinforcingZul StudiozNo ratings yet

- Structural SteelDocument4 pagesStructural Steelrize1159No ratings yet

- Mixville Pond Dam Cheshire, Connecticut September 4, 2014: Concrete Reinforcing 03 20 00 - 1Document4 pagesMixville Pond Dam Cheshire, Connecticut September 4, 2014: Concrete Reinforcing 03 20 00 - 1Juan José Ricaldi MirandaNo ratings yet

- Sec 05520 - Handrails and RailingsDocument5 pagesSec 05520 - Handrails and Railingstiju2005hereNo ratings yet

- Metal Gratings TA1056 - MBI Sampang Agung Factory Extension 1Document6 pagesMetal Gratings TA1056 - MBI Sampang Agung Factory Extension 1ery achjariNo ratings yet

- 16.sec.1600 (Steel Reinforcement)Document4 pages16.sec.1600 (Steel Reinforcement)aalignup arc & const. pvt ltdNo ratings yet

- Section 03210 Epoxy Coated Concrete ReinforcementDocument7 pagesSection 03210 Epoxy Coated Concrete ReinforcementgulzamanNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09250-1 Gypsum BoardDocument5 pagesITCC in Riyadh Residential Complex J10-13300 09250-1 Gypsum BoarduddinnadeemNo ratings yet

- GratingsDocument6 pagesGratingsHusen ZahranNo ratings yet

- Section 09100 Metal Framing SystemDocument5 pagesSection 09100 Metal Framing Systemestimasi100% (1)

- FL - Ta1056Document10 pagesFL - Ta1056ery achjariNo ratings yet

- Division 5Document15 pagesDivision 5hari banggaNo ratings yet

- NU - Division 05 - MetalsDocument18 pagesNU - Division 05 - Metalsyamanta_rajNo ratings yet

- Sec 05810 - Expansion Joint Cover AssembliesDocument4 pagesSec 05810 - Expansion Joint Cover Assembliestiju2005hereNo ratings yet

- Note Cho Ban VeDocument17 pagesNote Cho Ban VeHoang Duc LocNo ratings yet

- FL - Ta1056Document4 pagesFL - Ta1056ery achjariNo ratings yet

- PCI Hollowcore Specifications 4-8-11Document8 pagesPCI Hollowcore Specifications 4-8-11Roberto Pérez LeónNo ratings yet

- Concrete ReinforcementDocument15 pagesConcrete ReinforcementIm ChinithNo ratings yet

- 04200Document17 pages04200Arif MohammedNo ratings yet

- SEC 1600 (MOST Version)Document7 pagesSEC 1600 (MOST Version)shubhapal883No ratings yet

- ACS Specs GFRC1Document10 pagesACS Specs GFRC1Chrill DsilvaNo ratings yet

- SECTION 03 41 13 Precast Concrete Hollow Core Planks Spec Writer NoteDocument4 pagesSECTION 03 41 13 Precast Concrete Hollow Core Planks Spec Writer NoteJuanPaoloYbañezNo ratings yet

- GFRCDocument11 pagesGFRCMhmd AbdoNo ratings yet

- Section 05500 Metal FabricationsDocument7 pagesSection 05500 Metal FabricationsMØhãmmed ØwięsNo ratings yet

- 04200Document9 pages04200uddinnadeemNo ratings yet

- Metal StairsDocument5 pagesMetal Stairsshivayogi asundiNo ratings yet

- Jhlasalle 055213 Pipes&TubingDocument6 pagesJhlasalle 055213 Pipes&TubingPonz MadianoNo ratings yet

- Concrete ReinforcementDocument5 pagesConcrete ReinforcementBenjo FaustoNo ratings yet

- T - Proc Notices-Notices 035 K-Notice Doc 31830 923021450Document8 pagesT - Proc Notices-Notices 035 K-Notice Doc 31830 923021450Jaime GuamanNo ratings yet

- FL - Ta1056Document7 pagesFL - Ta1056ery achjariNo ratings yet

- Steel Stairs, Ladders and Platforms - MSTDocument13 pagesSteel Stairs, Ladders and Platforms - MSTwafikmh4No ratings yet

- FL - Ta1056Document7 pagesFL - Ta1056ery achjariNo ratings yet

- 05 40 00ssbDocument12 pages05 40 00ssbJerico NamucoNo ratings yet

- SF - Unbonded Post-Tensioned ConcreteDocument8 pagesSF - Unbonded Post-Tensioned ConcreteMuwafaq_mibNo ratings yet

- Section 05120 Structural Steel Part 1Document43 pagesSection 05120 Structural Steel Part 1jacksondcplNo ratings yet

- Part 1 General: SECTION 03210 Reinforcing SteelDocument4 pagesPart 1 General: SECTION 03210 Reinforcing SteelJojolasNo ratings yet

- Section 031000 - Concrete FormworkDocument31 pagesSection 031000 - Concrete FormworkBotirNo ratings yet

- Tie Back Anchors For Soldier Pile N Lagging Wall - Iowa-DOT - SP-150358aDocument19 pagesTie Back Anchors For Soldier Pile N Lagging Wall - Iowa-DOT - SP-150358aRakesh KapoorNo ratings yet

- Handrail & PlatformDocument58 pagesHandrail & Platformvhung TranNo ratings yet

- Conc. Reinf.Document5 pagesConc. Reinf.mohamed fathiNo ratings yet

- Section 03300 Cast-In-Place Concrete: Part 1 - General 1.1 ScopeDocument18 pagesSection 03300 Cast-In-Place Concrete: Part 1 - General 1.1 Scopeاحمد علي احمدNo ratings yet

- SECTION 03100 Concrete Forms and Accessories: Part 1 GeneralDocument20 pagesSECTION 03100 Concrete Forms and Accessories: Part 1 GeneralJoseph AsfourNo ratings yet

- Report 1 Waffle SlabDocument25 pagesReport 1 Waffle SlabEmil John BaticulaNo ratings yet

- Bt4 Midterm OmañaDocument14 pagesBt4 Midterm OmañaDerick John RoselNo ratings yet

- Concrete Form WorkDocument7 pagesConcrete Form WorkabdouNo ratings yet

- SharonStairsSpecs PDFDocument7 pagesSharonStairsSpecs PDFJohn TreffNo ratings yet

- GRATINGS Rev.1Document7 pagesGRATINGS Rev.1mohdNo ratings yet

- Specifications For Epoxy-Coated Reinforcing BarsDocument4 pagesSpecifications For Epoxy-Coated Reinforcing BarsRavi KanchepoguNo ratings yet

- Concrete PouredDocument50 pagesConcrete PouredNoor Mohamed AzeezNo ratings yet

- Method Statement Guidelines and Checklist: A Safe System of WorkDocument2 pagesMethod Statement Guidelines and Checklist: A Safe System of WorkNoor Mohamed AzeezNo ratings yet

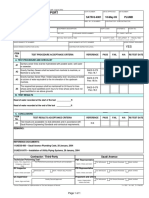

- Saudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 18-May-05 PlumbDocument2 pagesSaudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 18-May-05 PlumbNoor Mohamed AzeezNo ratings yet

- Satr S 4001Document1 pageSatr S 4001Noor Mohamed AzeezNo ratings yet

- Satr S 4002Document1 pageSatr S 4002Noor Mohamed AzeezNo ratings yet

- Saudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 18-May-05 HvacDocument1 pageSaudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 18-May-05 HvacNoor Mohamed AzeezNo ratings yet

- Saudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 18-May-05 PlumbDocument3 pagesSaudi Aramco Inspection Checklist: Emergency Eyewash/Shower System Installation SAIC-B-4002 18-May-05 PlumbNoor Mohamed AzeezNo ratings yet

- Saic G 2023Document2 pagesSaic G 2023Noor Mohamed AzeezNo ratings yet

- Non Structural CrackDocument62 pagesNon Structural CrackAnonymous oruqRPeqn100% (4)

- Analysis and Design of G+21 Building Using ETABS A ReviewDocument5 pagesAnalysis and Design of G+21 Building Using ETABS A ReviewIJRASETPublicationsNo ratings yet

- Reinforced Concrete Frank ColumbusDocument194 pagesReinforced Concrete Frank ColumbusKamilly100% (3)

- Construction and Building Materials: Chaomei Meng, Wenzhe Li, Liangcai Cai, Xingang Shi, Chunlin JiangDocument15 pagesConstruction and Building Materials: Chaomei Meng, Wenzhe Li, Liangcai Cai, Xingang Shi, Chunlin JiangpranavNo ratings yet

- Assignment-8 CE39 NOC20 - PDFDocument10 pagesAssignment-8 CE39 NOC20 - PDFjayadeep ksNo ratings yet

- Design of Buried Rigid Pipes: StandardsDocument26 pagesDesign of Buried Rigid Pipes: StandardsVarun VermaNo ratings yet

- Charles2004 - Settlement and Tilt of Low-Rise BuildingsDocument11 pagesCharles2004 - Settlement and Tilt of Low-Rise BuildingsAbd100% (1)

- Krishak Bazar at Tehatta-I Block Seed Farm2 (Unhide)Document18 pagesKrishak Bazar at Tehatta-I Block Seed Farm2 (Unhide)Hironmoy DashNo ratings yet

- Fibre Reinforced ConcreteDocument50 pagesFibre Reinforced ConcreteAishwarya Madhivanan100% (3)

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe: Standard Specification ForDocument11 pagesReinforced Concrete Culvert, Storm Drain, and Sewer Pipe: Standard Specification ForMahmoud HakimNo ratings yet

- A Sant Elia Manifesto of Futurist ArchitectureDocument4 pagesA Sant Elia Manifesto of Futurist Architectureanita08No ratings yet

- NDT Report of WIP ColumnsDocument23 pagesNDT Report of WIP ColumnsOM Pandey100% (1)

- Control Room Building DesignDocument45 pagesControl Room Building DesignArit Srivastava100% (1)

- NESCC 12-097 - NRC Perspectives On AISC N 690 and Appendix On Modular ConstructionDocument10 pagesNESCC 12-097 - NRC Perspectives On AISC N 690 and Appendix On Modular ConstructioncohenfuNo ratings yet

- Lateral Stability Analysis of High Rise RCC Building Structure Using Outrigger Structural SystemDocument12 pagesLateral Stability Analysis of High Rise RCC Building Structure Using Outrigger Structural SystemAkshay ShindeNo ratings yet

- Lexsha's BoqDocument81 pagesLexsha's BoqJan Lawrence AlbertoNo ratings yet

- Thesis - g1-1Document53 pagesThesis - g1-1Pritesh ChouhanNo ratings yet

- DocDocument27 pagesDocNana BarimaNo ratings yet

- Concrete PoleDocument63 pagesConcrete PoleWilheim Janssen GoNo ratings yet

- Revised Contruction of Office Block TenderDocument710 pagesRevised Contruction of Office Block TenderKISUJA MADUHUNo ratings yet

- Integrated Design Project (ECC 584) : Ir. Khairul Anuar Bin KamaruddinDocument103 pagesIntegrated Design Project (ECC 584) : Ir. Khairul Anuar Bin KamaruddinFarhana HussinNo ratings yet

- Reinforced Concrete Shear WallsDocument15 pagesReinforced Concrete Shear WallsJaime VegaNo ratings yet

- Admixtures by Portland CementDocument36 pagesAdmixtures by Portland CementVijayakrishna SingamsettiNo ratings yet

- Word Design of ProjectDocument381 pagesWord Design of ProjectSantosh Basnet100% (1)

- 255-2901 - Civil Pcakage of Vivo Energy Tanzania Depot - R0Document216 pages255-2901 - Civil Pcakage of Vivo Energy Tanzania Depot - R0Bruno Richard PhocusNo ratings yet

- Ghali Et All - Headed Studs in Concrete State of The ArtDocument11 pagesGhali Et All - Headed Studs in Concrete State of The ArtbllldNo ratings yet

- JE OPRC DT 4th AugDocument425 pagesJE OPRC DT 4th Augrupaavath rajaanaikNo ratings yet

- Chapter-1: Department of Civil Engg, CBITDocument26 pagesChapter-1: Department of Civil Engg, CBITShashidhara TVNo ratings yet

- 5th SEM RECORD Pappers On Working Progress PDFDocument81 pages5th SEM RECORD Pappers On Working Progress PDFTechnical Media BossNo ratings yet