Professional Documents

Culture Documents

Job No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)

Job No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)

Uploaded by

A N MadhavanCopyright:

Available Formats

You might also like

- Pacemaker I and Ii Triplex Pump: Standard Parts CatalogDocument131 pagesPacemaker I and Ii Triplex Pump: Standard Parts CatalogHerlis Savitri93% (15)

- Pumps Problems 20 ItemsDocument10 pagesPumps Problems 20 ItemsDexter Contawe87% (23)

- BB831 Xa02xen E1 PDFDocument65 pagesBB831 Xa02xen E1 PDFDaniel Ramirez100% (1)

- (Takács, Gábor) Gas Lift Manual PDFDocument495 pages(Takács, Gábor) Gas Lift Manual PDFLuu Cong Son100% (2)

- Note 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Light Blue and GreenDocument6 pagesNote 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Light Blue and Greensunii19847908No ratings yet

- AL Hashemiah International Contracting Co.Document3 pagesAL Hashemiah International Contracting Co.Ahmed SakrNo ratings yet

- Nipping of Reformer Tubes.: Precaution and Mitigation of IncidentsDocument12 pagesNipping of Reformer Tubes.: Precaution and Mitigation of IncidentsJak AshishNo ratings yet

- Technical Handbook EN 2019-07 E2029 Web No PDFDocument96 pagesTechnical Handbook EN 2019-07 E2029 Web No PDFFelipe SantosNo ratings yet

- Check Valve MS and Type R CameronDocument2 pagesCheck Valve MS and Type R CameronRuben Dario Conde LeonNo ratings yet

- Turbo Generator & Its AuxiliariesDocument89 pagesTurbo Generator & Its AuxiliariesPapun ScribdNo ratings yet

- Boiler Materials: P.Sundaramoorthy BHEL, TiruchirappalliDocument47 pagesBoiler Materials: P.Sundaramoorthy BHEL, Tiruchirappalliteddy tavaresNo ratings yet

- Thermal Power PlantDocument15 pagesThermal Power PlantJane PondulanNo ratings yet

- Tech Paper - Reheat Steam Temperature Control Concept in Once-Through Boilers - A ReviewDocument5 pagesTech Paper - Reheat Steam Temperature Control Concept in Once-Through Boilers - A ReviewQen Zyg EizernNo ratings yet

- Parts of Sprial Casing: Satish 12S/ME145 Mechanical Engineering DepartmentDocument15 pagesParts of Sprial Casing: Satish 12S/ME145 Mechanical Engineering DepartmentsatishNo ratings yet

- LT Compressor Condensate Loading To The Road Tankers Through Buffer TankDocument2 pagesLT Compressor Condensate Loading To The Road Tankers Through Buffer TankMugesh KannaNo ratings yet

- ALL Specification Sheet ExcelDocument20 pagesALL Specification Sheet Exceladitya.ablazeexportNo ratings yet

- Specification of GCF-G-455DG Oilfield PDFDocument17 pagesSpecification of GCF-G-455DG Oilfield PDFShahaji ChavanNo ratings yet

- Final Revision: Nghi Son 2 Bot Thermal Power Plant ProjectDocument10 pagesFinal Revision: Nghi Son 2 Bot Thermal Power Plant ProjectĐể Mai100% (1)

- Pratt AirPro Max Air Valve Sizing CalculatorDocument1 pagePratt AirPro Max Air Valve Sizing CalculatorAndrei IngelbergNo ratings yet

- Tankfarm DesignDocument15 pagesTankfarm DesignVaibhavladNo ratings yet

- A4 Desuperheater PDFDocument6 pagesA4 Desuperheater PDF련서긔No ratings yet

- BY K.Prabhu 12BEEE1039Document30 pagesBY K.Prabhu 12BEEE1039raspberry piNo ratings yet

- Approved: Pöyry EnergyDocument2 pagesApproved: Pöyry Energytvpham123No ratings yet

- C.B.G. (Compressed BioGas) Biogas Purification and Bottling, Environmental Engineering - Biogas C.BDocument4 pagesC.B.G. (Compressed BioGas) Biogas Purification and Bottling, Environmental Engineering - Biogas C.BMuhammad IrfanNo ratings yet

- Sikafloor 92EGDocument2 pagesSikafloor 92EGthe pilotNo ratings yet

- MD1 0 V 111 01 00003 BDocument5 pagesMD1 0 V 111 01 00003 Btvpham1230% (1)

- Curves and Correction Curves For Steam TurbineDocument18 pagesCurves and Correction Curves For Steam Turbinearunrajmech09No ratings yet

- Balancing of LP Rotor at Site PDFDocument5 pagesBalancing of LP Rotor at Site PDFsanjeevchhabra0% (1)

- Agathiyar2000Part 1 TextDocument164 pagesAgathiyar2000Part 1 TextsriramktNo ratings yet

- The Feasibility Study Report On Lagos Thermal Power Plant Expansion Project in Federal Republic of NigeriaDocument21 pagesThe Feasibility Study Report On Lagos Thermal Power Plant Expansion Project in Federal Republic of NigeriaasdasdNo ratings yet

- 2-1 Tech Spec Ashuganj R0Document181 pages2-1 Tech Spec Ashuganj R0Anup Mitra100% (1)

- PWP03 Fire System Pre-Comm PDFDocument3 pagesPWP03 Fire System Pre-Comm PDFJaldoNo ratings yet

- 1aha054179 ADocument56 pages1aha054179 Adebu1985No ratings yet

- Asme B133.10-1981Document42 pagesAsme B133.10-1981vijay pawarNo ratings yet

- Decanter Centrifuge Data Sheet: High-Performance Decanter Centrifuge Model (LYNX 40) Single Hydraulic StandDocument2 pagesDecanter Centrifuge Data Sheet: High-Performance Decanter Centrifuge Model (LYNX 40) Single Hydraulic StandSudjono BroNo ratings yet

- 28-JAN-2019 Sadhna Singh (8424) : Interlock SummaryDocument24 pages28-JAN-2019 Sadhna Singh (8424) : Interlock SummarySandip SurNo ratings yet

- VT4-YT01-P1LAC-120004 - RE - Technical Data Sheet For Main BFP& BFBPDocument7 pagesVT4-YT01-P1LAC-120004 - RE - Technical Data Sheet For Main BFP& BFBPNguyễn Hữu LượngNo ratings yet

- Kta Tb-Pac03-C01-002 Rev G VDRLDocument28 pagesKta Tb-Pac03-C01-002 Rev G VDRLLê Đức ThiệnNo ratings yet

- Annx. 1 RLA of TurbineDocument2 pagesAnnx. 1 RLA of Turbinerashm006ranjan100% (1)

- Energy Recovery Devices in Seawater Reverse Osmosis DesalinationDocument123 pagesEnergy Recovery Devices in Seawater Reverse Osmosis DesalinationVuthpalachaitanya KrishnaNo ratings yet

- Pipes. Pressure and Temperature Ratings For Carbon Steel Flanges of Material Groups 1.1 and 1.2Document51 pagesPipes. Pressure and Temperature Ratings For Carbon Steel Flanges of Material Groups 1.1 and 1.2JMVNo ratings yet

- Main Control: Process Diagram - General Arrangement Selcoperm SES (Selcoperm Electrolysis System)Document1 pageMain Control: Process Diagram - General Arrangement Selcoperm SES (Selcoperm Electrolysis System)YJNo ratings yet

- Spray Cooling Enhancement of Air - Cooled CondensersDocument142 pagesSpray Cooling Enhancement of Air - Cooled CondensersRicardo OrtizNo ratings yet

- Spec Water Storage TanksDocument5 pagesSpec Water Storage TanksparthivNo ratings yet

- Checklist For Roof Skin CasingDocument7 pagesChecklist For Roof Skin CasingRamalingam PrabhakaranNo ratings yet

- Veo HRSG Brochure 2012Document6 pagesVeo HRSG Brochure 2012Jayanath Nuwan SameeraNo ratings yet

- 135 TPH Boiler-2. Erection ReportDocument12 pages135 TPH Boiler-2. Erection ReportVijay RajNo ratings yet

- Design and Analysis of Boiler Pressure Vessels Based On IBR CodesDocument9 pagesDesign and Analysis of Boiler Pressure Vessels Based On IBR Codesgermantoledo244596No ratings yet

- HRSG - Recommended Lay Up-VerfahrenDocument9 pagesHRSG - Recommended Lay Up-VerfahrenaminNo ratings yet

- Water Handbook - Chemical Cleaning of Steam Generator Systems - VeoliaDocument6 pagesWater Handbook - Chemical Cleaning of Steam Generator Systems - VeoliaRafael SimbaNo ratings yet

- Cooling Tower Parts Reference GuideDocument64 pagesCooling Tower Parts Reference GuideLy Ca TieuNo ratings yet

- Disturbance FactorDocument46 pagesDisturbance FactorBossNo ratings yet

- Summary Sheet of Unit Process: Luoyang Petrochemical Engineering Design, Co.,LtdDocument5 pagesSummary Sheet of Unit Process: Luoyang Petrochemical Engineering Design, Co.,LtdidilfitriNo ratings yet

- AED Design Requirements - Hydro-Pneumatic Tanks - Sep09Document5 pagesAED Design Requirements - Hydro-Pneumatic Tanks - Sep09mojeebmashalNo ratings yet

- Az - Zour R&M Furnace Dimensions - ADocument1 pageAz - Zour R&M Furnace Dimensions - AShameer MajeedNo ratings yet

- P NagamanickamDocument109 pagesP Nagamanickamrashm006ranjanNo ratings yet

- Consulting Service Report: Comments ActionDocument4 pagesConsulting Service Report: Comments ActionVijayakumar KarunanidhiNo ratings yet

- Retention Time For N2 System - Room Integrity-2Document2 pagesRetention Time For N2 System - Room Integrity-2anwerquadriNo ratings yet

- Steam & Water Analysis System PDFDocument144 pagesSteam & Water Analysis System PDFtrung2i100% (1)

- Stud Bolt Length For Upload PDFDocument1 pageStud Bolt Length For Upload PDFDiego Martínez FernándezNo ratings yet

- Energy Management System For Combined Cycle Power Plant TrainingDocument4 pagesEnergy Management System For Combined Cycle Power Plant Trainingglenlcy100% (2)

- T219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationDocument6 pagesT219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationvankayalasuryaNo ratings yet

- Pe TS 409 167 A001 PDFDocument95 pagesPe TS 409 167 A001 PDFRaghbir KaushikNo ratings yet

- Eco Solutions - Saving Resources, Creating ValueDocument17 pagesEco Solutions - Saving Resources, Creating ValueChayon MondalNo ratings yet

- Item 1 Bilge Pump - 803-101.10 BDocument91 pagesItem 1 Bilge Pump - 803-101.10 BИгорь КлимовNo ratings yet

- Calculation Cover Sheet: ClientDocument9 pagesCalculation Cover Sheet: Clientanamaria ursuNo ratings yet

- Application Data Sheet: Product: StoplogsDocument4 pagesApplication Data Sheet: Product: StoplogsA N MadhavanNo ratings yet

- Hydraulic Structures Design ManualDocument171 pagesHydraulic Structures Design ManualA N Madhavan100% (1)

- 876 - Section V CompiledDocument4,176 pages876 - Section V CompiledA N MadhavanNo ratings yet

- Lecture On TWS, TR&CS, SLG - 04.09.2019Document93 pagesLecture On TWS, TR&CS, SLG - 04.09.2019A N MadhavanNo ratings yet

- FD 36628 Gonfreville 2009 AngDocument5 pagesFD 36628 Gonfreville 2009 AngA N MadhavanNo ratings yet

- Presiones Generales 340D2LDocument4 pagesPresiones Generales 340D2Ljorge luis rodriguezNo ratings yet

- Aml XRVS 476Document3 pagesAml XRVS 476jvicher61No ratings yet

- SMMS-7 ProductOverview Ver2Document113 pagesSMMS-7 ProductOverview Ver2Tín Nguyễn ThànhNo ratings yet

- Accumulation and Over-Pressure: Difference Between Accumulation and OverpressureDocument6 pagesAccumulation and Over-Pressure: Difference Between Accumulation and Overpressurevarun1567No ratings yet

- 150 BulletinDocument8 pages150 BulletinFranco YnquillaNo ratings yet

- MAN Turbo - Damaged Stator PartsDocument16 pagesMAN Turbo - Damaged Stator PartsEliyanto E BudiartoNo ratings yet

- Record of Hydrostatic TestDocument16 pagesRecord of Hydrostatic TestKrishna SaiNo ratings yet

- ASEAN Maintanance Repair and Overhaul - MRO - Catalogue - 92 PDFDocument1 pageASEAN Maintanance Repair and Overhaul - MRO - Catalogue - 92 PDFANDRESNo ratings yet

- Fluid B SheetDocument7 pagesFluid B SheetmustafaNo ratings yet

- Content (SG) PDFDocument88 pagesContent (SG) PDFshare irgaNo ratings yet

- Advanced Water Distribution Modeling and ManagementDocument54 pagesAdvanced Water Distribution Modeling and Managementscorpio1878No ratings yet

- Smokelesss Flare - Air AssistsedDocument19 pagesSmokelesss Flare - Air Assistsedvasu100% (1)

- Axial Flow Pump Design PDFDocument10 pagesAxial Flow Pump Design PDFHalit Baris SertbakanNo ratings yet

- Wellhead Control Panel: 1 General IntroductionDocument7 pagesWellhead Control Panel: 1 General IntroductionLord KrsnikNo ratings yet

- RotodynamicDocument69 pagesRotodynamicSyed Ahmed RazaNo ratings yet

- Solberg: Multistage Liquid/Particulate SeparatorDocument4 pagesSolberg: Multistage Liquid/Particulate SeparatorRUN GONo ratings yet

- Api 576 Q 1Document10 pagesApi 576 Q 1abdoNo ratings yet

- Welcome To The Test and Production Separation Production Separation PresentationDocument73 pagesWelcome To The Test and Production Separation Production Separation PresentationhamdiiiiiiiiiiiiiiiiNo ratings yet

- Anderson Greenwood Series 90/9000 Pilot Operated Pressure Relief ValvesDocument56 pagesAnderson Greenwood Series 90/9000 Pilot Operated Pressure Relief ValvesMohamed MekkyNo ratings yet

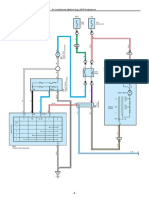

- Air Conditioner (Before Aug. 2015 Production)Document3 pagesAir Conditioner (Before Aug. 2015 Production)iwan darmawanNo ratings yet

- T2pg94 102 PDFDocument9 pagesT2pg94 102 PDFakamalapuri388No ratings yet

- 03-04-45-03 6081H Nao ParteDocument2 pages03-04-45-03 6081H Nao Partefranc.silveiNo ratings yet

- Compressor Turbine MatchingDocument2 pagesCompressor Turbine MatchingSumesh SpankoNo ratings yet

- Ocp6 and Ssr6 Plus Spare PartsDocument2 pagesOcp6 and Ssr6 Plus Spare PartsahnafNo ratings yet

- Directional Control Valve: V20 SeriesDocument8 pagesDirectional Control Valve: V20 SeriesRAY100% (1)

Job No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)

Job No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)

Uploaded by

A N MadhavanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)

Job No: 6812A: NTPC - Lara Super Thermal Power Project Stage 1 (2X800 MW)

Uploaded by

A N MadhavanCopyright:

Available Formats

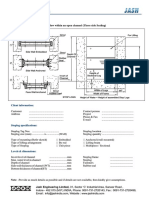

SHEET 1+1 OF 7

Job No: 6812A NTPC - LARA SUPER THERMAL POWER PROJECT STAGE 1 (2X800 MW)

HEATER DRAINS - LINE SIZING CALCULATION

PREPARED BY : PVK Doc No. TCE.6812A-ME-CALC-590-030

CHECKED BY : BSU NTPC No 9548-110-PVM-F-178A

APPROVED BY: RP Date 9/1/2015

Rev R3

Pressure Design Operating Reqd. Pipe Act. Velocity based on Act. Velocity based

S.No Pipe KKS code Line description Pipe Material kg/cm2(a) Temp oC Flow Flow

Sp. Vol Assumed Vel

size

Selected pipe size (mm)

Operating Flow on Design Flow

Revision Remarks

Oper Oper T/Hr. T/Hr. m3 / kg m / sec ID (m) NB OD Thk. m /sec m /sec

1 HP HEATER CASCADING AND EMERGENCY DRAINS

HPH#9A normal cascading drain line to HPH

1.1 10LCH30BR001 ASTM A106 GR. B 69.68 267.7 81.049 71.280 0.00129 2 0.136 150 168.3 10.97 1.52 1.73 R2

#8A upto control valve

HPH#9A normal cascading drain line to HPH

1.2 10LCH30BR002 ASTM A106 GR. B 49.60 262.11 81.049 71.280 0.00128 2 0.135 200 219.1 12.70 - - R2

#8A after control valve

HPH#9A emergency drain line upto control

1.3 10LCH31BR001 ASTM A106 GR. B 69.68 284.23 81.049 71.280 0.00135 2 0.139 150 168.3 10.97 1.58 1.80 R2

valve

HPH#9A emergency drain line from the control

1.4 10LCH31BR002 ASTM A106 GR. B 0.105 46.3 81.049 71.280 6.3590 2 9.549 200 219.1 8.18 - - R2

valve to condenser

HPH#8A normal cascading drain line to HPH

1.5 10LCH20BR001 ASTM A106 GR. B 49.48 215.5 219.314 198.551 0.00118 2 0.214 250 273 12.70 1.35 1.49 R2

#7A upto control valve

HPH#8A normal cascading drain line to HPH

1.6 10LCH20BR002 ASTM A106 GR. B 18.84 208.2 219.314 198.551 0.00302 2 0.342 300 323.8 9.53 - - R2

#7A after control valve

HPH #8A emergency drain line upto control

1.7 10LCH21BR001 ASTM A106 GR. B 49.48 262.1 219.314 198.551 0.00128 2 0.223 250 273 12.70 1.47 1.62 R2

valve

HPH#8A emergency drain line from control

1.8 10LCH21BR002 ASTM A106 GR. B 0.105 46.3 219.314 198.551 5.6776 2 14.843 300 323.8 9.53 - - R2

valve to condenser

HPH#7A normal cascading drain line to

1.9 10LCH10BR001 ASTM A106 GR. B 18.76 176.4 298.228 271.105 0.00112 2 0.243 250 273 9.27 1.66 1.83 R3

deaerator upto control valve

HPH#7A normal cascading drain line to

1.10 10LCH10BR002 ASTM A106 GR. B 7.87 165.7 298.228 271.105 0.00629 2 0.576 300 323.8 9.53 - - R3

deaerator after control valve

HPH #7A emergency drain line upto control

1.11 10LCH11BR001 ASTM A106 GR. B 18.76 176.4 298.228 271.105 0.00117 2 0.248 250 273 9.27 1.73 1.91 R3

valve

HPH #7A emergency drain line from control

1.12 10LCH11BR002 ASTM A106 GR. B 0.105 46.3 298.228 271.105 4.1535 2 14.804 300 323.8 9.53 - - R2

valve to condenser

HPH#9B normal cascading drain line to HPH

1.13 10LCH35BR001 ASTM A106 GR. B 69.68 267.7 81.049 71.280 0.00129 2 0.136 150 168.3 10.97 1.52 1.73 R2

#8B upto control valve

HPH#9B normal cascading drain line to HPH

1.14 10LCH35BR002 ASTM A106 GR. B 49.60 262.11 81.049 71.280 0.00128 2 0.135 200 219.1 12.7 - - R2

#8B after control valve

HPH#9B emergency drain line upto control

1.15 10LCH36BR001 ASTM A106 GR. B 69.68 284.23 81.049 71.280 0.00135 2 0.139 150 168.3 10.97 1.59 1.81 R2

valve

LINE SIZING CALCULATION TATA CONSULTING ENGINEERS LIMITED

SHEET 2+1 OF 7

Job No: 6812A NTPC - LARA SUPER THERMAL POWER PROJECT STAGE 1 (2X800 MW)

HEATER DRAINS - LINE SIZING CALCULATION

PREPARED BY : PVK Doc No. TCE.6812A-ME-CALC-590-030

CHECKED BY : BSU NTPC No 9548-110-PVM-F-178A

APPROVED BY: RP Date 9/1/2015

Rev R3

Pressure Design Operating Reqd. Pipe Act. Velocity based on Act. Velocity based

S.No Pipe KKS code Line description Pipe Material kg/cm2(a) Temp oC Flow Flow

Sp. Vol Assumed Vel

size

Selected pipe size (mm)

Operating Flow on Design Flow

Revision Remarks

Oper Oper T/Hr. T/Hr. m3 / kg m / sec ID (m) NB OD Thk. m /sec m /sec

HPH#9B emergency drain line from the control

1.16 10LCH36BR002 ASTM A106 GR. B 0.105 46.3 81.049 71.280 6.3590 2 9.549 200 219.1 8.18 - - R2

valve to condenser

HPH#8B normal cascading drain line to HPH

1.17 10LCH25BR001 ASTM A106 GR. B 49.48 262.1 219.314 198.551 0.00118 2 0.214 250 273 12.7 1.35 1.49 R2

#7A upto control valve

HPH#8B normal cascading drain line to HPH

1.18 10LCH25BR002 ASTM A106 GR. B 18.84 208.2 219.314 198.551 0.00302 2 0.342 300 323.8 9.53 - - R2

#7B after control valve

HPH #8B emergency drain line upto control

1.19 10LCH26BR001 ASTM A106 GR. B 49.48 215.5 219.314 198.551 0.00128 2 0.223 250 273 12.7 1.47 1.62 R2

valve

HPH#8B emergency drain line from control

1.20 10LCH26BR002 ASTM A106 GR. B 0.105 46.3 219.314 198.551 5.6776 2 14.843 300 323.8 9.53 - - R2

valve to condenser

HPH#7B normal cascading drain line to

1.21 10LCH15BR001 ASTM A106 GR. B 18.76 176.4 298.228 271.105 0.00112 2 0.243 250 273 9.27 1.66 1.83 R3

deaerator upto control valve

HPH#7B normal cascading drain line to

1.22 10LCH15BR002 ASTM A106 GR. B 7.87 165.7 298.228 271.105 0.00629 2 0.576 300 323.8 9.53 - - R3

deaerator after control valve

HPH #7B emergency drain line upto control

1.23 10LCH16BR001 ASTM A106 GR. B 18.76 176.4 298.228 271.105 0.00117 2 0.248 250 273 9.27 1.73 1.91 R3

valve

HPH #7B emergency drain line from control

1.24 10LCH16BR002 ASTM A106 GR. B 0.105 46.3 298.228 271.105 4.1535 2 14.804 300 323.8 9.53 - - R2

valve to condenser

2 LP HEATER CASCADING AND EMERGENCY DRAINS

LPH#5 normal cascading drain line to LPH#4

2.1 10LCJ50BR001 ASTM A106 GR. B 4.78 127.3 83.256 76.843 0.00107 2 0.125 150 168.3 7.11 1.22 1.32 R2

upto control valve

LPH#5 normal cascading drain line to LPH#4

2.2 10LCJ50BR002 ASTM A106 GR.B 2.32 124.36 83.256 76.843 0.00560 2 0.287 200 219.1 8.18 - - R2

after control valve

2.3 10LCJ51BR001 LPH#5 emergency drain line upto control valve ASTM A106 GR. B 4.78 149.45 83.256 76.843 0.00109 2 0.127 150 168.3 7.11 1.25 1.35 R2

LPH#5 emergency drain line from control valve

2.4 10LCJ51BR002 ASTM A106 GR. B 0.105 46.3 83.256 76.843 2.6029 2 6.192 200 219.1 8.18 - - R2

to condenser

LPH 4 normal cascading drain line upto drain

2.5 10LCJ40BR001 ASTM A106 GR. B 2.31 124.3 172.909 118.832 0.00106 2 0.180 200 219.1 8.18 1.08 1.58 R3

receiver tank

10LCM10BR001 /

2.6 10LCM11BR001 / Drip pump suction line from drain receiver tank ASTM A106 GR. B 2.41 125 154.387 118.832 0.00106 2 0.170 200 219.1 8.18 1.08 1.41 R3 The Design flow for the drip pump

10LCM12BR001 is taken from the Drip pump

10LCM11BR002 / sizing document (9548-110-PVM-

2.7 10LCM12BR002 / Drip pump discharge line to condensate line ASTM A106 GR. B 18.0 125 154.387 118.832 0.00106 3 0.139 150 168.3 7.11 1.88 2.44 R1 P-1496, R4), Annexure 1, case 1.

10LCM13BR001

10LCM11BR003 / Drip pump minimum recirculation line to drain

2.8 ASTM A106 GR. B 18.0 125 155 35.65 0.00106 3 0.139 100 114.3 6.02 1.28 5.56 R1

10LCM12BR003 receiver tank

2.9 10LCM14BR001 Drain from drain receiver tank upto control valve ASTM A106 GR. B 2.31 124.3 128.78 118.832 0.00106 2 0.155 200 219.1 8.18 1.08 1.18 R3

Drain from drain receiver tank from control

2.10 10LCM14BR002 ASTM A106 GR. B 0.105 46.3 128.78 118.832 1.95680 2 6.677 200 219.1 8.18 - - R3

valve to condenser

LPH#3 normal cascading drain line to LPH#2

2.11 10LCJ30BR001 ASTM A106 GR. B 1.47 91.7 67.746 62.798 0.00104 2 0.112 100 114.3 6.02 2.21 2.38 R2

upto control valve

LPH#3 normal cascading drain line to LPH#2

2.12 10LCJ30BR002 ASTM A106 GR. B 0.703 88.875 67.746 62.798 0.01386 2 0.408 150 168.3 7.11 - - R3

from control valve

LPH#3 emergency drain line to the flash tank

2.13 10LCJ31BR001 ASTM A106 GR. B 1.47 110.3 67.746 62.798 0.00105 2 0.112 100 114.3 6.02 2.23 2.41 R2

upto control valve

LINE SIZING CALCULATION TATA CONSULTING ENGINEERS LIMITED

SHEET 3+1 OF 7

Job No: 6812A NTPC - LARA SUPER THERMAL POWER PROJECT STAGE 1 (2X800 MW)

HEATER DRAINS - LINE SIZING CALCULATION

PREPARED BY : PVK Doc No. TCE.6812A-ME-CALC-590-030

CHECKED BY : BSU NTPC No 9548-110-PVM-F-178A

APPROVED BY: RP Date 9/1/2015

Rev R3

Pressure Design Operating Reqd. Pipe Act. Velocity based on Act. Velocity based

S.No Pipe KKS code Line description Pipe Material kg/cm2(a) Temp oC Flow Flow

Sp. Vol Assumed Vel

size

Selected pipe size (mm)

Operating Flow on Design Flow

Revision Remarks

Oper Oper T/Hr. T/Hr. m3 / kg m / sec ID (m) NB OD Thk. m /sec m /sec

LPH#3 emergency drain line to the flash tank

2.14 10LCJ31BR002 ASTM A106 GR. B 0.105 46.3 67.746 62.798 1.6008 2 4.380 150 168.3 7.11 - - R2

from control valve

LPH#2 normal cascading drain line to LPH#1

2.15 10LCJ21BR001 ASTM A106 GR. B 0.685 69.8 135.393 125.327 0.00102 2 0.156 150 168.3 7.11 1.91 2.06 R2

upto control valve

LPH#2 normal cascading drain line to LPH#1

2.16 10LCJ21BR002 ASTM A106 GR. B 0.285 67.01 135.393 125.327 5.47200 2 11.449 200 219.1 8.18 - - R2

after control valve

LPH#2 emergency drain line to LP condenser

2.17 10LCJ20BR001 ASTM A106 GR. B 0.685 88.87 135.393 125.327 0.00102 2 0.156 150 168.3 7.11 1.91 2.06 R2

hotwell upto control valve

LPH#2 emergency drain line to LP condenser

2.18 10LCJ20BR002 ASTM A106 GR. B 0.105 46.3 135.393 125.327 1.0638 2 5.048 200 219.1 8.18 - - R2

hotwell after control valve

LPH#1 normal cascading drain line upto HP

2.19 10LCJ10BR001 ASTM A106 GR. B 0.279 52.9 189.781 172.489 0.00101 2 0.184 200 219.1 8.18 1.50 1.65 R3

condenser Hotwell

Q=A*V Where, NOTES:

A = (pi / 4) * d2 Q = Volumetric flow, m3/sec

1. Operating flow is considered from the HBD No - 310SD01-469 Rev 3 (EMCR condition)

Q = m * nu A = area of flow, m2

V = Velocity m/sec

2. Design Flow is taken from HBD No - 310SD05-034 Rev 2 (VWO + 3% MU)

d = sqrt( (m * nu *4*1000) / ( pi * V*3600)) nu = Specific Volume, m3/kg

m = mas flow rate, tph 3. Operating pressure and temperature are taken from HBD No - 310SD01-469 Rev 3 (EMCR

condition).

d = diameter of the pipe, m

4. For Design pressure, temperature and flow plese refer the "Design memo for design parameter

selection of power cycle piping" (9548-110-PVM-X-185, R3)

LINE SIZING CALCULATION TATA CONSULTING ENGINEERS LIMITED

SHEET 4+4 OF 7

HEATER DRAINS - THICKNESS CALCULATION

Allowable

Pressure (P) Temp (T) Dia (D) Coefficients Corrosion Allowance Tmin (OD Based) MNT Tnom Bending

Stress T Cal T Sel

Sl. No. Pipe KKS code Line Description Pipe Material in Kg/cm2 (g) in C

0

in mm in mm in mm Allowance Schedule Revision

in mm in Kg/cm2 y E (ASME) E (IBR) W Max. of

Oper Des Test Oper Des IBR ASME IBR ASME % IBR ASME % in mm in mm

IBR/ASME

1 HP HEATER CASCADING AND EMERGENCY DRAINS

HPH#9A normal cascading drain line to

1.1 10LCH30BR001 ASTM A106 GR.B 68.647 87 130.50 267.7 305 168.3 1202.249 0.4 1 1 1 0.75 1.6 6.63 7.52 12.5 7.57 8.59 8.59 0 8.59 10.97 80 R2

HPH #8A upto control valve

HPH#9A normal cascading drain line to

1.2 10LCH30BR002 ASTM A106 GR.B 48.567 64 96.00 262.11 285 219.1 1202.249 0.4 1 1 1 0.75 1.6 6.43 7.31 12.5 7.35 8.35 8.35 0 8.35 12.70 80 R2

HPH #8A after control valve

HPH#9A emergency drain line upto

1.3 10LCH31BR001 ASTM A106 GR.B 68.647 87 130.50 284.23 305 168.3 1202.249 0.4 1 1 1 0.75 1.6 6.63 7.52 12.5 7.57 8.59 8.59 0 8.59 10.97 80 R2

control valve

HPH#9A emergency drain line from the

1.4 10LCH31BR002 ASTM A106 GR.B -0.928 0.047 0.071 46.3 120 219.1 1202.249 0.4 1 1 1 0.75 1.6 0.75 1.60 12.5 0.86 1.83 1.83 0 1.83 8.18 40 R2

control valve to condenser

HPH#8A normal cascading drain line to

1.5 10LCH20BR001 ASTM A106 GR.B 48.447 64 96.00 215.5 285 273 1202.249 0.4 1 1 1 0.75 1.6 7.83 8.71 12.5 8.95 9.96 9.96 0 9.96 12.70 60 R2

HPH #7A upto control valve

HPH#8A normal cascading drain line to

1.6 10LCH20BR002 ASTM A106 GR.B 17.807 23 34.5 208.2 225 323.8 1202.249 0.4 1 1 1 0.75 1.6 3.82 4.67 12.5 4.36 5.34 5.34 0 5.34 9.53 STD R2

HPH #7A after control valve

HPH #8A emergency drain line upto

1.7 10LCH21BR001 ASTM A106 GR.B 48.447 64 96 262.1 285 273 1202.249 0.4 1 1 1 0.75 1.6 7.83 8.71 12.5 8.95 9.96 9.96 0 9.96 12.70 60 R2

control valve

HPH#8A emergency drain line from

1.8 10LCH21BR002 ASTM A106 GR.B -0.928 0.047 0.071 46.3 120 323.8 1202.249 0.4 1 1 1 0.75 1.6 0.76 1.61 12.5 0.86 1.84 1.84 0 1.84 9.53 STD R2

control valve to condenser

HPH#7A normal cascading drain line to

1.9 10LCH10BR001 ASTM A106 GR.B 17.727 23 34.5 176.4 225 273 1202.249 0.4 1 1 1 0.75 1.6 3.34 4.19 12.5 3.81 4.79 4.79 0 4.79 9.27 STD R3

deaerator upto control valve

HPH#7A normal cascading drain line to

1.10 10LCH10BR002 ASTM A106 GR.B 6.837 8 12 165.7 180 323.8 1202.249 0.4 1 1 1 0.75 1.6 1.82 2.67 12.5 2.08 3.06 3.06 0 3.06 9.53 STD R3

deaerator after control valve

HPH #7A emergency drain line upto

1.11 10LCH11BR001 ASTM A106 GR.B 17.727 23 34.5 176.4 225 273 1202.249 0.4 1 1 1 0.75 1.6 3.34 4.19 12.5 3.81 4.79 4.79 0 4.79 9.27 STD R3

control valve

HPH #7A emergency drain line from

1.12 10LCH11BR002 ASTM A106 GR.B -0.928 0.047 0.071 46.3 120 323.8 1202.249 0.4 1 1 1 0.75 1.6 0.76 1.61 12.5 0.86 1.84 1.84 0 1.84 9.53 STD R2

control valve to condenser

HPH#9B normal cascading drain line to

1.13 10LCH35BR001 ASTM A106 GR.B 68.647 87 130.50 267.7 305 168.3 1202.249 0.4 1 1 1 0.75 1.6 6.63 7.52 12.5 7.57 8.59 8.59 0 8.59 10.97 80 R2

HPH #8B upto control valve

HPH#9B normal cascading drain line to

1.14 10LCH35BR002 ASTM A106 GR.B 48.567 64 96.00 262.11 285 219.1 1202.249 0.4 1 1 1 0.75 1.6 6.43 7.31 12.5 7.35 8.35 8.35 0 8.35 12.70 80 R2

HPH #8B after control valve

HPH#9B emergency drain line upto

1.15 10LCH36BR001 ASTM A106 GR.B 68.647 87 130.50 284.23 305 168.3 1202.249 0.4 1 1 1 0.75 1.6 6.63 7.52 12.5 7.57 8.59 8.59 0 8.59 10.97 80 R2

control valve

HPH#9B emergency drain line from the

1.16 10LCH36BR002 ASTM A106 GR.B -0.928 0.047 0.071 46.3 120 219.1 1202.249 0.4 1 1 1 0.75 1.6 0.75 1.60 12.5 0.86 1.83 1.83 0 1.83 8.18 40 R2

control valve to condenser

HPH#8B normal cascading drain line to

1.17 10LCH25BR001 ASTM A106 GR.B 48.447 64 96.00 262.1 285 273 1202.249 0.4 1 1 1 0.75 1.6 7.83 8.71 12.5 8.95 9.96 9.96 0 9.96 12.70 60 R2

HPH #7A upto control valve

HPH#8B normal cascading drain line to

1.18 10LCH25BR002 ASTM A106 GR.B 17.807 23 34.5 208.2 225 323.8 1202.249 0.4 1 1 1 0.75 1.6 3.82 4.67 12.5 4.36 5.34 5.34 0 5.34 9.53 STD R2

HPH #7B after control valve

HPH #8B emergency drain line upto

1.19 10LCH26BR001 ASTM A106 GR.B 48.447 64 96 215.5 285 273 1202.249 0.4 1 1 1 0.75 1.6 7.83 8.71 12.5 8.95 9.96 9.96 0 9.96 12.70 60 R2

control valve

HPH#8B emergency drain line from

1.20 10LCH26BR002 ASTM A106 GR.B -0.928 0.047 0.071 46.3 120 323.8 1202.249 0.4 1 1 1 0.75 1.6 0.76 1.61 12.5 0.86 1.84 1.84 0 1.84 9.53 STD R2

control valve to condenser

SHEET 5+4 OF 7

HEATER DRAINS - THICKNESS CALCULATION

Allowable

Pressure (P) Temp (T) Dia (D) Coefficients Corrosion Allowance Tmin (OD Based) MNT Tnom Bending

Stress T Cal T Sel

Sl. No. Pipe KKS code Line Description Pipe Material in Kg/cm2 (g) in C

0

in mm in mm in mm Allowance Schedule Revision

in mm in Kg/cm2 y E (ASME) E (IBR) W Max. of

Oper Des Test Oper Des IBR ASME IBR ASME % IBR ASME % in mm in mm

IBR/ASME

HPH#7B normal cascading drain line to

1.21 10LCH15BR001 ASTM A106 GR.B 17.727 23 34.5 176.4 225 273 1202.249 0.4 1 1 1 0.75 1.6 3.34 4.19 12.5 3.81 4.79 4.79 0 4.79 9.27 STD R3

deaerator upto control valve

HPH#7B normal cascading drain line to

1.22 10LCH15BR002 ASTM A106 GR.B 6.837 8 12 165.7 180 323.8 1202.249 0.4 1 1 1 0.75 1.6 1.82 2.67 12.5 2.08 3.06 3.06 0 3.06 9.53 STD R3

deaerator after control valve

HPH #7B emergency drain line upto

1.23 10LCH16BR001 ASTM A106 GR.B 17.727 23 34.5 176.4 225 273 1202.249 0.4 1 1 1 0.75 1.6 3.34 4.19 12.5 3.81 4.79 4.79 0 4.79 9.27 STD R3

control valve

HPH #7B emergency drain line from

1.24 10LCH16BR002 ASTM A106 GR.B -0.928 0.047 0.071 46.3 120 323.8 1202.249 0.4 1 1 1 0.75 1.6 0.76 1.61 12.5 0.86 1.84 1.84 0 1.84 9.53 STD R2

control valve to condenser

2 LP HEATER CASCADING AND EMERGENCY DRAINS

LPH#5 normal cascading drain line to

2.1 10LCJ50BR001 ASTM A106 GR.B 3.750 6 9.00 127.3 170 168.3 1202.249 0.4 1 1 1 0.75 1.6 1.17 2.02 12.5 1.34 2.31 2.31 0 2.31 7.11 STD R2

LPH#4 upto control valve

LPH#5 normal cascading drain line to

2.2 10LCJ50BR002 ASTM A106 GR.B 1.282 3.6 5.4 124.36 153 219.1 1202.249 0.4 1 1 1 0.75 1.6 1.08 1.93 12.5 1.23 2.20 2.20 0 2.20 8.18 STD R2

LPH#4 after control valve

LPH#5 emergency drain line upto

2.3 10LCJ51BR001 ASTM A106 GR.B 3.747 6 9 149.45 170 168.3 1202.249 0.4 1 1 1 0.75 1.6 1.17 2.02 12.5 1.34 2.31 2.31 0 2.31 7.11 STD R2

control valve

LPH#5 emergency drain line from

2.4 10LCJ51BR002 ASTM A106 GR.B -0.928 0.047 0.071 46.3 120 219.1 1202.249 0.4 1 1 1 0.75 1.6 0.75 1.60 12.5 0.86 1.83 1.83 0 1.83 8.18 STD R2

control valve to condenser

LPH 4 normal cascading drain line upto

2.5 10LCJ40BR001 ASTM A106 GR. B 1.277 3.6 5.400 124.3 155 219.1 1202.249 0.4 1 1 1 0.75 1.6 1.08 1.93 12.5 1.23 2.20 2.20 0 2.20 8.18 STD R3

drain receiver tank

10LCM10BR001 /

Drip pump suction line from drain

2.6 10LCM11BR001 / ASTM A106 GR. B 1.377 3.6 5.400 125 155 219.1 1202.249 0.4 1 1 1 0.75 1.6 1.08 1.93 12.5 1.23 2.20 2.20 0 2.20 8.18 STD R3

receiver tank

10LCM12BR001

10LCM11BR002 /

Drip pump discharge line to condensate

2.7 10LCM12BR002 / ASTM A106 GR. B 16.967 19.96 29.940 125 155 168.3 1202.249 0.4 1 1 1 0.75 1.6 2.14 2.99 12.5 2.44 3.41 3.41 0 3.41 7.11 STD R1

line

10LCM13BR001

10LCM11BR003 / Drip pump minimum recirculation line to

2.8 ASTM A106 GR. B 16.967 19.96 29.940 125 155 114.3 1202.249 0.4 1 1 1 0.75 1.6 1.69 2.54 12.5 1.93 2.91 2.91 0 2.91 6.02 STD R1

10LCM12BR003 drain receiver tank

Drain from drain receiver tank upto

2.9 10LCM14BR001 ASTM A106 GR. B 1.277 3.6 5.400 124.3 155 219.1 1202.249 0.4 1 1 1 0.75 1.6 1.08 1.93 12.5 1.23 2.20 2.20 0 2.20 8.18 STD R3

control valve

Drain from drain receiver tank from

2.10 10LCM14BR002 ASTM A106 GR. B -0.928 3.5 5.250 46.3 155 219.1 1202.249 0.4 1 1 1 0.75 1.6 1.07 1.92 12.5 1.22 2.19 2.19 0 2.19 8.18 STD R3

control valve to condenser

LPH#3 normal cascading drain line to

2.11 10LCJ30BR001 ASTM A106 GR. B 0.441 3.6 5.400 91.7 155 114.3 1202.249 0.4 1 1 1 0.75 1.6 0.92 1.77 12.5 1.05 2.02 2.02 0 2.02 6.02 STD R2

LPH#2 upto control valve

LPH#3 normal cascading drain line to

2.12 10LCJ30BR002 ASTM A106 GR. B -0.330 3.6 5.400 88.875 155 168.3 1202.249 0.4 1 1 1 0.75 1.6 1.00 1.85 12.5 1.14 2.12 2.12 0 2.12 7.11 STD R3

LPH#2 from control valve

LPH#3 emergency drain line to the flash

2.13 10LCJ31BR001 ASTM A106 GR. B 0.437 3.6 5.400 110.3 153 114.3 1202.249 0.4 1 1 1 0.75 1.6 0.92 1.77 12.5 1.05 2.02 2.02 0 2.02 6.02 STD R2

tank upto control valve

LPH#3 emergency drain line to the flash

2.14 10LCJ31BR002 ASTM A106 GR. B -0.928 0.047 0.071 46.3 120 168.3 1202.249 0.4 1 1 1 0.75 1.6 0.75 1.60 12.5 0.86 1.83 1.83 0 1.83 7.11 STD R2

tank from control valve

LPH#2 normal cascading drain line to

2.15 10LCJ21BR001 ASTM A106 GR. B -0.348 3.6 5.400 69.8 153 168.3 1202.249 0.4 1 1 1 0.75 1.6 1.00 1.85 12.5 1.14 2.12 2.12 0 2.12 7.11 STD R2

LPH#1 upto control valve

LPH#2 normal cascading drain line to

2.16 10LCJ21BR002 ASTM A106 GR. B -0.748 3.6 5.400 67.01 153 219.1 1202.249 0.4 1 1 1 0.75 1.6 1.08 1.93 12.5 1.23 2.20 2.20 0 2.20 8.18 STD R2

LPH#1 from control valve

LPH#2 emergency drain line to LP

2.17 10LCJ20BR001 ASTM A106 GR. B -0.348 3.6 5.400 88.87 153 168.3 1202.249 0.4 1 1 1 0.75 1.6 1.00 1.85 12.5 1.14 2.12 2.12 0 2.12 7.11 STD R2

condenser hotwell upto control valve

LPH#2 emergency drain line to LP

2.18 10LCJ20BR002 ASTM A106 GR. B -0.928 0.047 0.071 46.3 120 219.1 1202.249 0.4 1 1 1 0.75 1.6 0.75 1.60 12.5 0.86 1.83 1.83 0 1.83 8.18 STD R2

condenser hotwell after control valve

LPH#1 normal cascading drain line upto

2.19 10LCJ10BR001 ASTM A106 GR. B -0.754 0.047 0.071 52.9 120 219.1 1202.249 0.4 1 1 1 0.75 1.6 0.75 1.60 12.5 0.86 1.83 1.83 0 1.83 8.18 STD R3

HP condenser Hotwell

SHEET 6+4 OF 7

HEATER DRAINS - THICKNESS CALCULATION

Allowable

Pressure (P) Temp (T) Dia (D) Coefficients Corrosion Allowance Tmin (OD Based) MNT Tnom Bending

Stress T Cal T Sel

Sl. No. Pipe KKS code Line Description Pipe Material in Kg/cm2 (g) in C0

in mm in mm in mm Allowance Schedule Revision

in mm in Kg/cm2 y E (ASME) E (IBR) W Max. of

Oper Des Test Oper Des IBR ASME IBR ASME % IBR ASME % in mm in mm

IBR/ASME

3 SMALL BORE LINES

3.1 - DN 15 ASTM A106 GR. B 68.647 87 130.50 267.7 305 21.3 1202.249 0.4 1 1 1 0.75 1.6 1.49 2.35 12.5 1.71 2.68 2.68 25 3.36 3.73 80

3.2 - DN 25 ASTM A106 GR. B 68.647 87 130.50 267.7 305 33.4 1202.249 0.4 1 1 1 0.75 1.6 1.92 2.77 12.5 2.19 3.17 3.17 25 3.96 4.55 80

3.3 - DN 40 ASTM A106 GR. B 68.647 87 130.50 267.7 305 48.3 1202.249 0.4 1 1 1 0.75 1.6 2.44 3.30 12.5 2.78 3.77 3.77 25 4.71 5.08 80

3.4 - DN 50 ASTM A106 GR. B 68.647 87 130.50 267.7 305 60.3 1202.249 0.4 1 1 1 0.75 1.6 2.86 3.72 12.5 3.26 4.25 4.25 25 5.31 5.54 80

Note:

Allowable Stress for material is referred from ASME B31.1 Edition.2012

As per IBR Regulation 350, the corrosion allowance (A) is 0.75mm. For ASME as per NTPC's requirement (A) is 1.6mm

The OD & Thickness is referred from ASME B36.10 Edition.2004

Temperature Coefficient(y) is referred from the Table 104.1.2(A) of ASME B31.1 Edition.2012

MINIMUM PIPE WALL THICKNESS FORMULA DUE TO INTERNAL PRESSURE

As per ASME B31.1 Rev.2010 Para 104.1.4 Equ.(11) As per IBR Reg 350 Rev.2006 Equ.(91) After Rearranging the IBR formula:

tmin = P*D P = 2 * S * E * (tmin - A) tmin = P*D

____________________ + A _________________ _________________ +A

2 * ((S * E* W) + (P * y)) D - tmin + A ( 2 * S * E) + P

Where,

tmin = Minimum required Wall thickness of pipe.(mm)

P = Internal Design Pressure kg/cm^2(g)

D = Outside Diameter of Pipe (mm)

S = Maximum allowable stress of material corresponding to design temperature (deg C)

y = Temperature Coefficient

E = Weld Joint Efficiency factor

A = Corrosion Allowance (mm)

MNT = Mill Negative Tolerance

Tnom = Nominal Wall Thickness (mm)

Tsel = Selected Wall Thickness (mm)

W = Weld Strength reduction factor

You might also like

- Pacemaker I and Ii Triplex Pump: Standard Parts CatalogDocument131 pagesPacemaker I and Ii Triplex Pump: Standard Parts CatalogHerlis Savitri93% (15)

- Pumps Problems 20 ItemsDocument10 pagesPumps Problems 20 ItemsDexter Contawe87% (23)

- BB831 Xa02xen E1 PDFDocument65 pagesBB831 Xa02xen E1 PDFDaniel Ramirez100% (1)

- (Takács, Gábor) Gas Lift Manual PDFDocument495 pages(Takács, Gábor) Gas Lift Manual PDFLuu Cong Son100% (2)

- Note 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Light Blue and GreenDocument6 pagesNote 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Light Blue and Greensunii19847908No ratings yet

- AL Hashemiah International Contracting Co.Document3 pagesAL Hashemiah International Contracting Co.Ahmed SakrNo ratings yet

- Nipping of Reformer Tubes.: Precaution and Mitigation of IncidentsDocument12 pagesNipping of Reformer Tubes.: Precaution and Mitigation of IncidentsJak AshishNo ratings yet

- Technical Handbook EN 2019-07 E2029 Web No PDFDocument96 pagesTechnical Handbook EN 2019-07 E2029 Web No PDFFelipe SantosNo ratings yet

- Check Valve MS and Type R CameronDocument2 pagesCheck Valve MS and Type R CameronRuben Dario Conde LeonNo ratings yet

- Turbo Generator & Its AuxiliariesDocument89 pagesTurbo Generator & Its AuxiliariesPapun ScribdNo ratings yet

- Boiler Materials: P.Sundaramoorthy BHEL, TiruchirappalliDocument47 pagesBoiler Materials: P.Sundaramoorthy BHEL, Tiruchirappalliteddy tavaresNo ratings yet

- Thermal Power PlantDocument15 pagesThermal Power PlantJane PondulanNo ratings yet

- Tech Paper - Reheat Steam Temperature Control Concept in Once-Through Boilers - A ReviewDocument5 pagesTech Paper - Reheat Steam Temperature Control Concept in Once-Through Boilers - A ReviewQen Zyg EizernNo ratings yet

- Parts of Sprial Casing: Satish 12S/ME145 Mechanical Engineering DepartmentDocument15 pagesParts of Sprial Casing: Satish 12S/ME145 Mechanical Engineering DepartmentsatishNo ratings yet

- LT Compressor Condensate Loading To The Road Tankers Through Buffer TankDocument2 pagesLT Compressor Condensate Loading To The Road Tankers Through Buffer TankMugesh KannaNo ratings yet

- ALL Specification Sheet ExcelDocument20 pagesALL Specification Sheet Exceladitya.ablazeexportNo ratings yet

- Specification of GCF-G-455DG Oilfield PDFDocument17 pagesSpecification of GCF-G-455DG Oilfield PDFShahaji ChavanNo ratings yet

- Final Revision: Nghi Son 2 Bot Thermal Power Plant ProjectDocument10 pagesFinal Revision: Nghi Son 2 Bot Thermal Power Plant ProjectĐể Mai100% (1)

- Pratt AirPro Max Air Valve Sizing CalculatorDocument1 pagePratt AirPro Max Air Valve Sizing CalculatorAndrei IngelbergNo ratings yet

- Tankfarm DesignDocument15 pagesTankfarm DesignVaibhavladNo ratings yet

- A4 Desuperheater PDFDocument6 pagesA4 Desuperheater PDF련서긔No ratings yet

- BY K.Prabhu 12BEEE1039Document30 pagesBY K.Prabhu 12BEEE1039raspberry piNo ratings yet

- Approved: Pöyry EnergyDocument2 pagesApproved: Pöyry Energytvpham123No ratings yet

- C.B.G. (Compressed BioGas) Biogas Purification and Bottling, Environmental Engineering - Biogas C.BDocument4 pagesC.B.G. (Compressed BioGas) Biogas Purification and Bottling, Environmental Engineering - Biogas C.BMuhammad IrfanNo ratings yet

- Sikafloor 92EGDocument2 pagesSikafloor 92EGthe pilotNo ratings yet

- MD1 0 V 111 01 00003 BDocument5 pagesMD1 0 V 111 01 00003 Btvpham1230% (1)

- Curves and Correction Curves For Steam TurbineDocument18 pagesCurves and Correction Curves For Steam Turbinearunrajmech09No ratings yet

- Balancing of LP Rotor at Site PDFDocument5 pagesBalancing of LP Rotor at Site PDFsanjeevchhabra0% (1)

- Agathiyar2000Part 1 TextDocument164 pagesAgathiyar2000Part 1 TextsriramktNo ratings yet

- The Feasibility Study Report On Lagos Thermal Power Plant Expansion Project in Federal Republic of NigeriaDocument21 pagesThe Feasibility Study Report On Lagos Thermal Power Plant Expansion Project in Federal Republic of NigeriaasdasdNo ratings yet

- 2-1 Tech Spec Ashuganj R0Document181 pages2-1 Tech Spec Ashuganj R0Anup Mitra100% (1)

- PWP03 Fire System Pre-Comm PDFDocument3 pagesPWP03 Fire System Pre-Comm PDFJaldoNo ratings yet

- 1aha054179 ADocument56 pages1aha054179 Adebu1985No ratings yet

- Asme B133.10-1981Document42 pagesAsme B133.10-1981vijay pawarNo ratings yet

- Decanter Centrifuge Data Sheet: High-Performance Decanter Centrifuge Model (LYNX 40) Single Hydraulic StandDocument2 pagesDecanter Centrifuge Data Sheet: High-Performance Decanter Centrifuge Model (LYNX 40) Single Hydraulic StandSudjono BroNo ratings yet

- 28-JAN-2019 Sadhna Singh (8424) : Interlock SummaryDocument24 pages28-JAN-2019 Sadhna Singh (8424) : Interlock SummarySandip SurNo ratings yet

- VT4-YT01-P1LAC-120004 - RE - Technical Data Sheet For Main BFP& BFBPDocument7 pagesVT4-YT01-P1LAC-120004 - RE - Technical Data Sheet For Main BFP& BFBPNguyễn Hữu LượngNo ratings yet

- Kta Tb-Pac03-C01-002 Rev G VDRLDocument28 pagesKta Tb-Pac03-C01-002 Rev G VDRLLê Đức ThiệnNo ratings yet

- Annx. 1 RLA of TurbineDocument2 pagesAnnx. 1 RLA of Turbinerashm006ranjan100% (1)

- Energy Recovery Devices in Seawater Reverse Osmosis DesalinationDocument123 pagesEnergy Recovery Devices in Seawater Reverse Osmosis DesalinationVuthpalachaitanya KrishnaNo ratings yet

- Pipes. Pressure and Temperature Ratings For Carbon Steel Flanges of Material Groups 1.1 and 1.2Document51 pagesPipes. Pressure and Temperature Ratings For Carbon Steel Flanges of Material Groups 1.1 and 1.2JMVNo ratings yet

- Main Control: Process Diagram - General Arrangement Selcoperm SES (Selcoperm Electrolysis System)Document1 pageMain Control: Process Diagram - General Arrangement Selcoperm SES (Selcoperm Electrolysis System)YJNo ratings yet

- Spray Cooling Enhancement of Air - Cooled CondensersDocument142 pagesSpray Cooling Enhancement of Air - Cooled CondensersRicardo OrtizNo ratings yet

- Spec Water Storage TanksDocument5 pagesSpec Water Storage TanksparthivNo ratings yet

- Checklist For Roof Skin CasingDocument7 pagesChecklist For Roof Skin CasingRamalingam PrabhakaranNo ratings yet

- Veo HRSG Brochure 2012Document6 pagesVeo HRSG Brochure 2012Jayanath Nuwan SameeraNo ratings yet

- 135 TPH Boiler-2. Erection ReportDocument12 pages135 TPH Boiler-2. Erection ReportVijay RajNo ratings yet

- Design and Analysis of Boiler Pressure Vessels Based On IBR CodesDocument9 pagesDesign and Analysis of Boiler Pressure Vessels Based On IBR Codesgermantoledo244596No ratings yet

- HRSG - Recommended Lay Up-VerfahrenDocument9 pagesHRSG - Recommended Lay Up-VerfahrenaminNo ratings yet

- Water Handbook - Chemical Cleaning of Steam Generator Systems - VeoliaDocument6 pagesWater Handbook - Chemical Cleaning of Steam Generator Systems - VeoliaRafael SimbaNo ratings yet

- Cooling Tower Parts Reference GuideDocument64 pagesCooling Tower Parts Reference GuideLy Ca TieuNo ratings yet

- Disturbance FactorDocument46 pagesDisturbance FactorBossNo ratings yet

- Summary Sheet of Unit Process: Luoyang Petrochemical Engineering Design, Co.,LtdDocument5 pagesSummary Sheet of Unit Process: Luoyang Petrochemical Engineering Design, Co.,LtdidilfitriNo ratings yet

- AED Design Requirements - Hydro-Pneumatic Tanks - Sep09Document5 pagesAED Design Requirements - Hydro-Pneumatic Tanks - Sep09mojeebmashalNo ratings yet

- Az - Zour R&M Furnace Dimensions - ADocument1 pageAz - Zour R&M Furnace Dimensions - AShameer MajeedNo ratings yet

- P NagamanickamDocument109 pagesP Nagamanickamrashm006ranjanNo ratings yet

- Consulting Service Report: Comments ActionDocument4 pagesConsulting Service Report: Comments ActionVijayakumar KarunanidhiNo ratings yet

- Retention Time For N2 System - Room Integrity-2Document2 pagesRetention Time For N2 System - Room Integrity-2anwerquadriNo ratings yet

- Steam & Water Analysis System PDFDocument144 pagesSteam & Water Analysis System PDFtrung2i100% (1)

- Stud Bolt Length For Upload PDFDocument1 pageStud Bolt Length For Upload PDFDiego Martínez FernándezNo ratings yet

- Energy Management System For Combined Cycle Power Plant TrainingDocument4 pagesEnergy Management System For Combined Cycle Power Plant Trainingglenlcy100% (2)

- T219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationDocument6 pagesT219AB-384A9554 Rev E Deaerating Condenser Functional SpecificationvankayalasuryaNo ratings yet

- Pe TS 409 167 A001 PDFDocument95 pagesPe TS 409 167 A001 PDFRaghbir KaushikNo ratings yet

- Eco Solutions - Saving Resources, Creating ValueDocument17 pagesEco Solutions - Saving Resources, Creating ValueChayon MondalNo ratings yet

- Item 1 Bilge Pump - 803-101.10 BDocument91 pagesItem 1 Bilge Pump - 803-101.10 BИгорь КлимовNo ratings yet

- Calculation Cover Sheet: ClientDocument9 pagesCalculation Cover Sheet: Clientanamaria ursuNo ratings yet

- Application Data Sheet: Product: StoplogsDocument4 pagesApplication Data Sheet: Product: StoplogsA N MadhavanNo ratings yet

- Hydraulic Structures Design ManualDocument171 pagesHydraulic Structures Design ManualA N Madhavan100% (1)

- 876 - Section V CompiledDocument4,176 pages876 - Section V CompiledA N MadhavanNo ratings yet

- Lecture On TWS, TR&CS, SLG - 04.09.2019Document93 pagesLecture On TWS, TR&CS, SLG - 04.09.2019A N MadhavanNo ratings yet

- FD 36628 Gonfreville 2009 AngDocument5 pagesFD 36628 Gonfreville 2009 AngA N MadhavanNo ratings yet

- Presiones Generales 340D2LDocument4 pagesPresiones Generales 340D2Ljorge luis rodriguezNo ratings yet

- Aml XRVS 476Document3 pagesAml XRVS 476jvicher61No ratings yet

- SMMS-7 ProductOverview Ver2Document113 pagesSMMS-7 ProductOverview Ver2Tín Nguyễn ThànhNo ratings yet

- Accumulation and Over-Pressure: Difference Between Accumulation and OverpressureDocument6 pagesAccumulation and Over-Pressure: Difference Between Accumulation and Overpressurevarun1567No ratings yet

- 150 BulletinDocument8 pages150 BulletinFranco YnquillaNo ratings yet

- MAN Turbo - Damaged Stator PartsDocument16 pagesMAN Turbo - Damaged Stator PartsEliyanto E BudiartoNo ratings yet

- Record of Hydrostatic TestDocument16 pagesRecord of Hydrostatic TestKrishna SaiNo ratings yet

- ASEAN Maintanance Repair and Overhaul - MRO - Catalogue - 92 PDFDocument1 pageASEAN Maintanance Repair and Overhaul - MRO - Catalogue - 92 PDFANDRESNo ratings yet

- Fluid B SheetDocument7 pagesFluid B SheetmustafaNo ratings yet

- Content (SG) PDFDocument88 pagesContent (SG) PDFshare irgaNo ratings yet

- Advanced Water Distribution Modeling and ManagementDocument54 pagesAdvanced Water Distribution Modeling and Managementscorpio1878No ratings yet

- Smokelesss Flare - Air AssistsedDocument19 pagesSmokelesss Flare - Air Assistsedvasu100% (1)

- Axial Flow Pump Design PDFDocument10 pagesAxial Flow Pump Design PDFHalit Baris SertbakanNo ratings yet

- Wellhead Control Panel: 1 General IntroductionDocument7 pagesWellhead Control Panel: 1 General IntroductionLord KrsnikNo ratings yet

- RotodynamicDocument69 pagesRotodynamicSyed Ahmed RazaNo ratings yet

- Solberg: Multistage Liquid/Particulate SeparatorDocument4 pagesSolberg: Multistage Liquid/Particulate SeparatorRUN GONo ratings yet

- Api 576 Q 1Document10 pagesApi 576 Q 1abdoNo ratings yet

- Welcome To The Test and Production Separation Production Separation PresentationDocument73 pagesWelcome To The Test and Production Separation Production Separation PresentationhamdiiiiiiiiiiiiiiiiNo ratings yet

- Anderson Greenwood Series 90/9000 Pilot Operated Pressure Relief ValvesDocument56 pagesAnderson Greenwood Series 90/9000 Pilot Operated Pressure Relief ValvesMohamed MekkyNo ratings yet

- Air Conditioner (Before Aug. 2015 Production)Document3 pagesAir Conditioner (Before Aug. 2015 Production)iwan darmawanNo ratings yet

- T2pg94 102 PDFDocument9 pagesT2pg94 102 PDFakamalapuri388No ratings yet

- 03-04-45-03 6081H Nao ParteDocument2 pages03-04-45-03 6081H Nao Partefranc.silveiNo ratings yet

- Compressor Turbine MatchingDocument2 pagesCompressor Turbine MatchingSumesh SpankoNo ratings yet

- Ocp6 and Ssr6 Plus Spare PartsDocument2 pagesOcp6 and Ssr6 Plus Spare PartsahnafNo ratings yet

- Directional Control Valve: V20 SeriesDocument8 pagesDirectional Control Valve: V20 SeriesRAY100% (1)