Professional Documents

Culture Documents

42ace (Us: 1,110,487. E-Patented Sept, 15, 1914

42ace (Us: 1,110,487. E-Patented Sept, 15, 1914

Uploaded by

MURALIPRAKASH.S 18BIT131Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

42ace (Us: 1,110,487. E-Patented Sept, 15, 1914

42ace (Us: 1,110,487. E-Patented Sept, 15, 1914

Uploaded by

MURALIPRAKASH.S 18BIT131Copyright:

Available Formats

J. A.

, HITLERICH,

BAT,

APPLICATION FILED AUG, 21, 1913,

1,110,487. e- Patented Sept, 15, 1914.

3-vuovo

John A.Hillerieh.

68)ivico-oes

42ace (us

42%232. 33 61.32% 8ttow

Te vorris Ferers co, proto-lirthd., Washiwotton. D. C.

UNITED STATES PATENT OFFICE.

JOHN A. HILLERICH, OF LOUISVILLE, KENTUCKY, ASSIGNOR TO J. F. HILLERICH &

SON COMPANY, INCORPORATED, OF LOUISVILLE, KENTUCKY.

B.A.

1,110,487. specification of Letters Patent, Patented Sept. 15, 1914.

Application filed August 21, 1913. Serial No.786,010.

To all whom it may concern: to the contour of the handle, so that when

Be it known that I, JoHN A. HILLERICH, it is applied around the handle in proper

a citizen of the United States, residing at position its said longitudinal edges will not

Louisville, in the county of Jefferson and

5 State of Kentucky, have invented certain. quite meet. This sheet of cork is preferably

new and useful Improvements in Bats, of abouta one-sixteenth

and convenient

of an inch

length for

in

the

thickness,

same is 60

which the following is a specification. about fifteen inches. . . ...

The present improvement relates to han In applying the cork sheet to the bat han

dles for bats, and consists in a bat the handle dle I first give to both the cork and the

of which is covered with a layer of cork handle a coating of waterproof fish glue

applied and maintained under tension. The cement and then curl the sheet around the

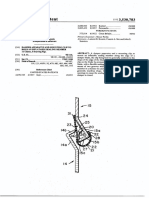

cork is applied to the extreme exterior pe handle. Then a thread or cord 4 is wound

riphery or surface of the handle without the around the cork sheet in such manner as to

cutting into or removal of any portion of

5 the handle. compress the same and increase its width,

Where cork has been applied to serve as and this compression is continued until the 70

a handle covering for various implements, edges of the cork sheet are brought firmly

portions of the material of the handle have together. The cement is then allowed to

been removed, so as to materially weaken become thoroughly dry and the cord 4 is

20 the bat or other implement; also the cork removed. The inner surface or skin of the

cork, sheet is then coincident with and prac

has not been applied under tension with the tically

result that it becomes loose and more or less integral with the extreme exterior

detached from the substance of the handle Surfaceportions

of the bat handle, and the outer

of the cork are in a state of tension,

So as to be inefficient for the purpose of af

25 fording a strong and firm grip of the bat. which gives great firmness to the handle and

These difficulties are overcome by my said at prevents the sheet from becoming detached 80

improvements, and for the purposes of mak of any the

point from the handle. The tension

cork sheet is evenly distributed from

ing the invention more clearly understood

have shown in the accompanying drawings

I end to end of the same, by reason of the

30 means for carrying the same into practical preliminary shaping of the sheet and the

effect. manner in which it was applied to the bat 85

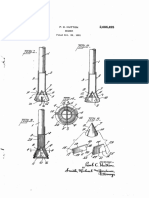

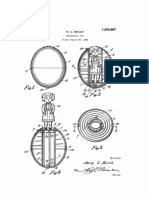

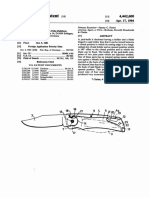

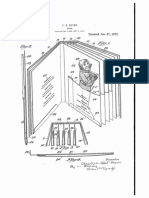

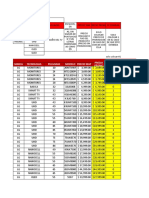

In the said drawings:-Figure 1 is a side cork sheetThe

handle. longitudinal edges 5 of the

view of a base ball bat embodying the in joint, as indicatedbe atshaped

may

6 in

to form a butt

Fig. 5; or they

vention. Fig. 2 is a longitudinal section of

35 the same on line II-II, Fig. 1, on a larger may be shaped to form a lap joint as indi

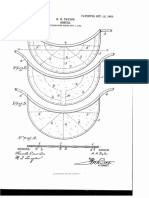

scale. Fig. 3 is a plan view of the sheet or cated The

at 7 in Figs. 6 and 7.

thread or cord 4 is applied by a wind

90

layer of cork before it is applied to the bat

handle. Fig. 4 is a cross section, of full ing cork

machine, while the operator holds the

sheet in proper position curled around

size, of the bat handle, illustrating

40 ner of applying the cork thereto under ten

the man the bat handle, proper tension being main

sion. Fig. 5 is a similar view after the or stretch thethecork

tained upon cord to flatten out or spread 95

thread or cord which has been used for giv make a perfect jointasand may be necessary to

ing tension to the cork has been removed. its final stretched condition leave the cork in

after it has dried

Fig. 6 is a cross section on an exaggerated

45 scale showing the layer of cork as shaped to and the cord has been removed.

form a lap-joint, and before such joint has in Base ball bat handles vary considerably 100

diameter and contour, according to the

had its parts brought together by the ten models preferred

sion-applying thread or cord. Fig. 7 is a yet an exact joint by different players, and

along the edges 5 of the

similar view showing the joint completed. cork must be formed in order

50 Referring to the drawings, 1 indicates the may be durable. The difficultiesthat the bat

incident to 05

body of a base ball bat, and 2 the handle securing this result are overcome by my im

thereof. provements, and any tearing or splitting of

3 is a sheet or layer of cork of sufficient the cork is avoided. The cork sheet is origi

length to form the necessary grip, and nally of sufficient thickness to allow of its

shaped at its longitudinal edges, according being spread and thinned until the required O

2 1,110,487

joint has been made, and after drying every the said edges are caused to be tapered down

part of the cork is so fixedly and perma- entirely to the surface of the handle, so that

nently united with the bat handle surface they cannot be struck or engaged by any

that the tension set up in the cork can not object or loosened from the handle.

cause any tearing or splitting after the cord I am aware of the British patent granted 30

4 has been removed. After the cork has to Dark, for cricket bats, May 6, 1891, No.

been applied as described, and the bat dried, 7,842, and I do not wish to be understood as

the bat is put in a lathe and the end edges claiming anything disclosed therein.

of the cork sheet are finished to a feather What is claimed is:

0 edge, as indicated at 8 in Fig. 2, so as to 1. A bat having its handle covered with 35

prevent any pushing up and roughening or cork under tension and applied on the ex

loosening of the cork at these points. As a terior of the full circumference of the han

result of the described improvements all of dle, substantially as set forth.

the advantages of cork in giving a good 2. A bat having applied to the exterior

5 grip, absorbing shock, etc., are made avail of the full circumference of the handle cork 40

able in practical and durable form; also the under tension, the end edges of which are

bat is strengthened in its weakest part by the tapered to the surface of the handle, sub

application of the cork to the extreme pe stantially as set forth.

riphery of the handle, instead of cutting In testimony whereof I affix my signature

20 away any part of the latter. If the cork in presence of two witnesses.

should become Wet from rain or perspiration JOHN A. HILLERICH.

its swelling may for the time being relieve

the said tension, but cannot cause the cork Witnesses:

to Wrinkle up or become detached. By the F. W. BRADSBY,

said finishing of the end edges of the cork J. J. HAYES.

Copies of this patent may be obtained for five cents each, by addressing the “Commissioner of Patents,

Washington, D.C.'

You might also like

- Click Here For Download: (PDF) Single-Case Designs For Educational ResearchDocument4 pagesClick Here For Download: (PDF) Single-Case Designs For Educational ResearchMURALIPRAKASH.S 18BIT1310% (2)

- Wheeler & Wilson No 9 Form 41 - TextDocument8 pagesWheeler & Wilson No 9 Form 41 - TextGramma JoNo ratings yet

- SPM Add Maths Past Year QuestionDocument61 pagesSPM Add Maths Past Year QuestionLoh Chee Wei100% (2)

- Spiral Dynamics Integral 1Document3 pagesSpiral Dynamics Integral 1Wangshosan100% (2)

- 1,067,012. Patented July 8, 1913,: E, FaberDocument4 pages1,067,012. Patented July 8, 1913,: E, FaberGalo YambayNo ratings yet

- Filed Oct. 22, 1951: P. C. HuttonDocument5 pagesFiled Oct. 22, 1951: P. C. HuttonGalo YambayNo ratings yet

- US741184Document3 pagesUS741184Katrin MoragNo ratings yet

- US1029846 - Metal Insert-01Document3 pagesUS1029846 - Metal Insert-01gauravNo ratings yet

- Electricidad Diseño ElectricoDocument6 pagesElectricidad Diseño ElectricoemernelsonmanNo ratings yet

- Wire Rope Splice and Method of Making The SameDocument3 pagesWire Rope Splice and Method of Making The SameFiqri AnraNo ratings yet

- G. E. V.On Hoff Mann.: Patented Nov, 8, 1921Document2 pagesG. E. V.On Hoff Mann.: Patented Nov, 8, 1921VyacheslavNo ratings yet

- Zeze 7&aal. 37e/arz.: No. 405,068, Patented June 11, 1889Document3 pagesZeze 7&aal. 37e/arz.: No. 405,068, Patented June 11, 1889Daniel GoffNo ratings yet

- Nov. 27, 1934. - H. E. Peterson 1,982,142: ' ?Enrgepel'Ens'OhDocument4 pagesNov. 27, 1934. - H. E. Peterson 1,982,142: ' ?Enrgepel'Ens'OhJorge MartinezNo ratings yet

- Circuito Electronico de ControlDocument3 pagesCircuito Electronico de ControlemernelsonmanNo ratings yet

- 06.damper Apparatus and Mounting Clip ToDocument4 pages06.damper Apparatus and Mounting Clip ToRohit BirajdarNo ratings yet

- United States Patent (19) : (54) Roll-Reefing JibsailDocument8 pagesUnited States Patent (19) : (54) Roll-Reefing Jibsail63No ratings yet

- US3841371-metal InsertDocument5 pagesUS3841371-metal InsertgauravNo ratings yet

- QZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Document3 pagesQZZZZZZZZZZZZ: PATENTED AUG, 21, 1906. No. 829,327Galo YambayNo ratings yet

- US527955Document5 pagesUS527955moonstarNo ratings yet

- Cementing Patent 2Document3 pagesCementing Patent 2Lara CitlalliNo ratings yet

- Us2018240 PDFDocument4 pagesUs2018240 PDFPolygrapack SA DE CVNo ratings yet

- N Patented Dec. 25, 1900.: G. C. Ains WorthDocument5 pagesN Patented Dec. 25, 1900.: G. C. Ains Worthsorin robertNo ratings yet

- Sept. 20, 1971 H. J. Girard 3,605,159: Pipe Line Pig or SwipeDocument5 pagesSept. 20, 1971 H. J. Girard 3,605,159: Pipe Line Pig or SwipeOngollo RegisNo ratings yet

- Us 2345069Document4 pagesUs 234506916f628aNo ratings yet

- Detective CameraDocument3 pagesDetective CameraAndrei PoseaNo ratings yet

- MVMK Mm. .: File?d Jan. 29, 1944Document4 pagesMVMK Mm. .: File?d Jan. 29, 1944Syed Umair RizviNo ratings yet

- Us4171605 PDFDocument13 pagesUs4171605 PDFkartikkeyyanNo ratings yet

- United States Patent (19) : Putnam, Jr. Et Al. (11) 4,171,605Document13 pagesUnited States Patent (19) : Putnam, Jr. Et Al. (11) 4,171,605kartikkeyyanNo ratings yet

- 24% Zevery A. Aeger.: H. F. Wheeler Patented June 17, 1890Document4 pages24% Zevery A. Aeger.: H. F. Wheeler Patented June 17, 1890Слэйтер Строительная компанияNo ratings yet

- Patented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Document3 pagesPatented Sept. 15, 1891,: S. Wheeler, Wrapping or Toilet Paper, Roll, No. 459,516Oscar DorantesNo ratings yet

- Lathe Modelling1Document4 pagesLathe Modelling1Frenchwolf420No ratings yet

- Us465588 PDFDocument2 pagesUs465588 PDFEmmanuel Avalos HuarteNo ratings yet

- ?é4%.276 /4.7 Easter: RT - A2 (Alw'celeteDocument8 pages?é4%.276 /4.7 Easter: RT - A2 (Alw'celeteСлэйтер Строительная компанияNo ratings yet

- USRX52Document3 pagesUSRX52nmfzkwy2rNo ratings yet

- Supply Grille For Circular Duct: UDC SeriesDocument1 pageSupply Grille For Circular Duct: UDC SeriesBFCF TunisieNo ratings yet

- 970,603. ' Patented Sept. 20, 1910.:, Winding Key Fob CamerasDocument4 pages970,603. ' Patented Sept. 20, 1910.:, Winding Key Fob CamerasAndrei PoseaNo ratings yet

- Adhesive UnitDocument3 pagesAdhesive UnitVansala GanesanNo ratings yet

- Crane Drums and CablesDocument4 pagesCrane Drums and Cablesjoe_frangieh100% (1)

- Us 2412693Document5 pagesUs 2412693Trades India InternationalNo ratings yet

- Covering A Light Airplane FuselageDocument6 pagesCovering A Light Airplane FuselageFlorian SterchiNo ratings yet

- Us1259684 PDFDocument3 pagesUs1259684 PDFDiogo CorreaNo ratings yet

- 1955 - Patente - Velvet Type Fabric and Method of Producing SameDocument3 pages1955 - Patente - Velvet Type Fabric and Method of Producing SamePaulo De Melo MacedoNo ratings yet

- March 25, 1969: Original Filed Sept. 21, 1964Document6 pagesMarch 25, 1969: Original Filed Sept. 21, 1964Wilberth FrancoNo ratings yet

- L'atented June 20, 1916. WS: B, M, W, HansonDocument8 pagesL'atented June 20, 1916. WS: B, M, W, Hansonfrank saruhanNo ratings yet

- United States PatentDocument10 pagesUnited States Patent63No ratings yet

- Popular Mechanics Encyclopedia 06 PDFDocument260 pagesPopular Mechanics Encyclopedia 06 PDFeuqehtb100% (1)

- United States PatentDocument13 pagesUnited States Patent63No ratings yet

- E. K. R00T, No. 13,999.: Patented Dec 25, 1855Document2 pagesE. K. R00T, No. 13,999.: Patented Dec 25, 1855vadimNo ratings yet

- BY WWW/a : April 12, 1960v A. Witte - 2,932,081Document3 pagesBY WWW/a : April 12, 1960v A. Witte - 2,932,081PrasadNo ratings yet

- US1585887Document3 pagesUS1585887Oliver EngelmohrNo ratings yet

- Aug-24, 1954 E. S. Titus Ei'Al: NiorsDocument5 pagesAug-24, 1954 E. S. Titus Ei'Al: NiorsPedro MorenoNo ratings yet

- Rib Stitching FabricDocument1 pageRib Stitching FabricFlorian SterchiNo ratings yet

- United States Patent (19) : Felix-DalichowDocument5 pagesUnited States Patent (19) : Felix-DalichowBarmak CheraghiNo ratings yet

- B. M. W. Hanson,: AzzzzessesDocument6 pagesB. M. W. Hanson,: Azzzzessesfrank saruhanNo ratings yet

- IFU JonesJig Inst ENGDocument1 pageIFU JonesJig Inst ENGnomanNo ratings yet

- No. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70Document3 pagesNo. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70AlecsandrNo ratings yet

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- SeaHawk 11 15Document8 pagesSeaHawk 11 15pastronauta23No ratings yet

- HatschekfilmsummaryDocument16 pagesHatschekfilmsummaryTushar GargNo ratings yet

- Rope and Harness Work on the Farm - With Information on Rope Construction and Various Knots Used on the FarmFrom EverandRope and Harness Work on the Farm - With Information on Rope Construction and Various Knots Used on the FarmNo ratings yet

- United States Patent: Huang (45) Date of Patent: Jun - 25, 2019Document55 pagesUnited States Patent: Huang (45) Date of Patent: Jun - 25, 2019MURALIPRAKASH.S 18BIT131No ratings yet

- United States Patent: (73) Assignee: Corning IncorporatedDocument71 pagesUnited States Patent: (73) Assignee: Corning IncorporatedMURALIPRAKASH.S 18BIT131No ratings yet

- United States: Patent OfficeDocument2 pagesUnited States: Patent OfficeMURALIPRAKASH.S 18BIT131No ratings yet

- United States Patent: Henry (45) Date of Patent: Oct. 31, 2006Document6 pagesUnited States Patent: Henry (45) Date of Patent: Oct. 31, 2006MURALIPRAKASH.S 18BIT131No ratings yet

- United States Patent: (45) Date of Patent: Nov - 28, 2017Document19 pagesUnited States Patent: (45) Date of Patent: Nov - 28, 2017MURALIPRAKASH.S 18BIT131No ratings yet

- United States Patent: Kinney Et AlDocument37 pagesUnited States Patent: Kinney Et AlMURALIPRAKASH.S 18BIT131No ratings yet

- United: States PatentDocument45 pagesUnited: States PatentMURALIPRAKASH.S 18BIT131No ratings yet

- Patent Application Publication (10) Pub - No .: US 2020/0134977 A1Document8 pagesPatent Application Publication (10) Pub - No .: US 2020/0134977 A1MURALIPRAKASH.S 18BIT131No ratings yet

- 1,405,134, Patented Jan, 31, 1922.: C, R, HoymeDocument3 pages1,405,134, Patented Jan, 31, 1922.: C, R, HoymeMURALIPRAKASH.S 18BIT131No ratings yet

- US9631016Document92 pagesUS9631016MURALIPRAKASH.S 18BIT131No ratings yet

- July 5, 1966: Filed Oct. 24, 1961Document9 pagesJuly 5, 1966: Filed Oct. 24, 1961MURALIPRAKASH.S 18BIT131100% (1)

- United States Patent: (10) Patent No .: US 10, 177, 911 B2Document64 pagesUnited States Patent: (10) Patent No .: US 10, 177, 911 B2MURALIPRAKASH.S 18BIT131No ratings yet

- With Mati Tru: NlandDocument51 pagesWith Mati Tru: NlandMURALIPRAKASH.S 18BIT131No ratings yet

- Zyzews/35.5% Az6.: Dec. 23, 1941. W.E. Corduan Etal 2,267,444Document4 pagesZyzews/35.5% Az6.: Dec. 23, 1941. W.E. Corduan Etal 2,267,444MURALIPRAKASH.S 18BIT131No ratings yet

- April 23, 1968 R. F. Mes 3,379,341: Kobert FmilesDocument6 pagesApril 23, 1968 R. F. Mes 3,379,341: Kobert FmilesMURALIPRAKASH.S 18BIT131No ratings yet

- Catalogue of Industrial Laundry EquipmentDocument8 pagesCatalogue of Industrial Laundry EquipmentTrung TrịnhNo ratings yet

- P.5 English Revision Set 2 Namagunga Primary Boarding SchoolDocument14 pagesP.5 English Revision Set 2 Namagunga Primary Boarding SchoolnkugwafavourNo ratings yet

- Blue Land Concept NoteDocument2 pagesBlue Land Concept Notenayan83No ratings yet

- Consolidation (2) - 4th SEMDocument3 pagesConsolidation (2) - 4th SEMDipankar NathNo ratings yet

- THESIS Evaluation of CO2 Supermarket Refrigeration Systems. Field Measurements in Three SupermarketsDocument83 pagesTHESIS Evaluation of CO2 Supermarket Refrigeration Systems. Field Measurements in Three SupermarketsP. ReobNo ratings yet

- Interior Design & Renovation Guide For Singapore Home OwnersDocument11 pagesInterior Design & Renovation Guide For Singapore Home OwnersPeter TanNo ratings yet

- 1986 GT CatalogDocument16 pages1986 GT CatalogtspinnerNo ratings yet

- Medibuddy-EnrolPolicyConditions 22Document23 pagesMedibuddy-EnrolPolicyConditions 22Vadivelan BaskarNo ratings yet

- 5 XerophtalmiaDocument36 pages5 XerophtalmiaMarshet GeteNo ratings yet

- XJ40 1991-92 3,2L 4L Boite Vitesse AutoDocument59 pagesXJ40 1991-92 3,2L 4L Boite Vitesse AutoTACHONNo ratings yet

- Ord2021082419220163Document1 pageOrd2021082419220163bujjishaikNo ratings yet

- Smudge Cells:: What Technologists Need To KnowDocument5 pagesSmudge Cells:: What Technologists Need To KnowdewaNo ratings yet

- Parad ShivlingDocument2 pagesParad ShivlingsharathVEMNo ratings yet

- MacNeal & Harder - Standard Problems FE AccuracyDocument18 pagesMacNeal & Harder - Standard Problems FE AccuracyRm1262No ratings yet

- Visit To Shivapuri Nagarjun National Park by 8001 GenialDocument4 pagesVisit To Shivapuri Nagarjun National Park by 8001 GenialGenial poudelNo ratings yet

- J.saintifika Uji Bioavailabilitas Dan BioekivalensiDocument8 pagesJ.saintifika Uji Bioavailabilitas Dan BioekivalensiAhmad MujahidinNo ratings yet

- 011CMEDDocument13 pages011CMEDphilip xeroNo ratings yet

- 2019 Asset Management PlanDocument162 pages2019 Asset Management PlanticoNo ratings yet

- GDM 24064 02Document31 pagesGDM 24064 02Fábio Vitor MartinsNo ratings yet

- AKVA Group Cage Farming Aquaculture 2014 2015Document78 pagesAKVA Group Cage Farming Aquaculture 2014 2015norisnorisNo ratings yet

- American Lincoln MPV 60 Ecp Parts List FordDocument153 pagesAmerican Lincoln MPV 60 Ecp Parts List FordYew LimNo ratings yet

- Exp#05 M.inshal Fa18 Bme 022Document5 pagesExp#05 M.inshal Fa18 Bme 022Muhammad inshalNo ratings yet

- San Andres Cop Pel 981Document21 pagesSan Andres Cop Pel 981RubenNo ratings yet

- Clarke No Clarke Yes (Clexa)Document7 pagesClarke No Clarke Yes (Clexa)mercedesmgNo ratings yet

- Department of Education: Learning Activity WorksheetsDocument4 pagesDepartment of Education: Learning Activity WorksheetsARLENE GRACE AVENUENo ratings yet

- Bentonite PropertiesDocument8 pagesBentonite PropertiesJulie SpencerNo ratings yet

- Review On Animal Tissues PDFDocument7 pagesReview On Animal Tissues PDFTitiNo ratings yet

- Cold-Rolled Magnetic Lamination Quality Steel, Semiprocessed TypesDocument5 pagesCold-Rolled Magnetic Lamination Quality Steel, Semiprocessed TypessamehNo ratings yet