Professional Documents

Culture Documents

ESLe Y-Axis

ESLe Y-Axis

Uploaded by

baajpurCopyright:

Available Formats

You might also like

- Mesa Quirurgica Opt 70 Ec 02 PDFDocument36 pagesMesa Quirurgica Opt 70 Ec 02 PDFTEYLER BARBOZANo ratings yet

- Printbar RemovalDocument21 pagesPrintbar RemovalTaur1968100% (1)

- Kearney and Trecker Installation ManualDocument12 pagesKearney and Trecker Installation Manualaa987100% (1)

- Report On Four Bar Mechanism of Sewing MachineDocument8 pagesReport On Four Bar Mechanism of Sewing MachineshazedislamNo ratings yet

- RepymotDocument4 pagesRepymotEngin UzunNo ratings yet

- Qauntum FRU Y Trayrobot Scalar I40 I80 RevADocument26 pagesQauntum FRU Y Trayrobot Scalar I40 I80 RevAScramble 69No ratings yet

- Ex 4650Document16 pagesEx 4650Ulzii AltansukhNo ratings yet

- Inverter Mid Power Assembly ReplacementDocument13 pagesInverter Mid Power Assembly ReplacementRubén Cadima BarrientosNo ratings yet

- HP p3015 50.3 ErrorDocument4 pagesHP p3015 50.3 Errorwinner mediaNo ratings yet

- Surgical C-Arm Tables: Service ManualDocument80 pagesSurgical C-Arm Tables: Service ManualArt Messick100% (1)

- Aste-6z8l9t r0 enDocument3 pagesAste-6z8l9t r0 enfilip_kecNo ratings yet

- Exp 9 Introduction To MachinesDocument11 pagesExp 9 Introduction To MachinesMuhammad AwaisNo ratings yet

- Eaton CM-52 Remote Racking IL02400003EDocument16 pagesEaton CM-52 Remote Racking IL02400003EadvancedmotorNo ratings yet

- WheelHorse Electric Lift Accessory For Long Frame Tractors 8-4221Document4 pagesWheelHorse Electric Lift Accessory For Long Frame Tractors 8-4221Kevins Small Engine and Tractor ServiceNo ratings yet

- Planmed Sophie Part2 - ServicemanualDocument99 pagesPlanmed Sophie Part2 - ServicemanualOscar Orea100% (1)

- Manual de Servicio Inogen One - g3Document134 pagesManual de Servicio Inogen One - g3carlos andres hoyos perdomoNo ratings yet

- 7 Frame and WheelDocument12 pages7 Frame and Wheelalsief1951No ratings yet

- Chapter H - Parts Replacement & Repair Replacing Sensors & SwitchesDocument99 pagesChapter H - Parts Replacement & Repair Replacing Sensors & SwitchesolegNo ratings yet

- Maintenance Manual For BBS-V800 202109Document15 pagesMaintenance Manual For BBS-V800 202109thaungmtNo ratings yet

- Electrical Wireline Spooler User ManualDocument14 pagesElectrical Wireline Spooler User ManualJohn SimancaNo ratings yet

- B-3801 IOM - Rev - 2011-09-02 (1) MidlandDocument23 pagesB-3801 IOM - Rev - 2011-09-02 (1) MidlandLucas MonteNo ratings yet

- Xserve Raid Left or Right Light PipeDocument11 pagesXserve Raid Left or Right Light PipeRoberto BruniNo ratings yet

- Rack Installation Instructions: GuidelinesDocument16 pagesRack Installation Instructions: Guidelinesovidiu981No ratings yet

- Mini X Motor Replacement With Fan UpgradeDocument7 pagesMini X Motor Replacement With Fan UpgradeLucian ComanNo ratings yet

- UH-60A EH60A: RemovalDocument2 pagesUH-60A EH60A: RemovalaugustinhodjNo ratings yet

- RepheadDocument4 pagesRepheadEngin UzunNo ratings yet

- Quick Start Ex4600Document10 pagesQuick Start Ex4600Елена ШевчукNo ratings yet

- Balança 4182-A (Mecanica) - Revisão 02.08.2007 PDFDocument12 pagesBalança 4182-A (Mecanica) - Revisão 02.08.2007 PDFKadson AmaralNo ratings yet

- AA06058 Modificacion de La Caja de Resistencia Camion 129 y 130Document7 pagesAA06058 Modificacion de La Caja de Resistencia Camion 129 y 130Jose A. Basanta H.No ratings yet

- Dokumen - Tips - Planmed Sophie Part2 ServicemanualDocument37 pagesDokumen - Tips - Planmed Sophie Part2 ServicemanualMohammed BenzaidiNo ratings yet

- Rack Installation Guide-DA240Document8 pagesRack Installation Guide-DA240Fabricio RiverNo ratings yet

- Instrument Panel Systems: Removal and Installation Headlamp Leveling SwitchDocument2 pagesInstrument Panel Systems: Removal and Installation Headlamp Leveling SwitchCarlos Gabriel EstergaardNo ratings yet

- Roboitic Transfer All Actions of IntegraDocument19 pagesRoboitic Transfer All Actions of Integrapranshu126545No ratings yet

- Challenger 24012 IOMDocument19 pagesChallenger 24012 IOMgmsapiensNo ratings yet

- Minivator 1000 Series Installation Manual PDFDocument36 pagesMinivator 1000 Series Installation Manual PDFSergio PNo ratings yet

- Service Manual FOR Medical Diagnostic X-Ray Radiograph TableDocument6 pagesService Manual FOR Medical Diagnostic X-Ray Radiograph TableWael Fuad AL-MaktariNo ratings yet

- Rail Kit II Installation InstructionsDocument4 pagesRail Kit II Installation InstructionsSaurabhNo ratings yet

- 93ZJ Secc 8J Turn Signals and Hazard Warning FlashesDocument4 pages93ZJ Secc 8J Turn Signals and Hazard Warning Flasheshelgith74No ratings yet

- DrivetrainDocument43 pagesDrivetrainfuckoffalreadyNo ratings yet

- Sinowon Vertical Profile Projector Operation Manual enDocument16 pagesSinowon Vertical Profile Projector Operation Manual enJohnny DaiNo ratings yet

- F2O Feed Take UpAdjustmentDocument6 pagesF2O Feed Take UpAdjustmentdeniNo ratings yet

- Rotating Beam Fatigue Test MachineDocument13 pagesRotating Beam Fatigue Test MachineReNo ratings yet

- Rotary TablesDocument30 pagesRotary TablesCarlos MendozaNo ratings yet

- Cetac Z Drive AssemblyDocument13 pagesCetac Z Drive AssemblyYanine Aranda MosqueraNo ratings yet

- Wingspan ManualDocument9 pagesWingspan ManualalirioNo ratings yet

- E S S O S M: Lectric Lideout Ystem Peration AND Ervice AnualDocument21 pagesE S S O S M: Lectric Lideout Ystem Peration AND Ervice AnualJuan ContrerasNo ratings yet

- Alternator 130a.xmlDocument16 pagesAlternator 130a.xmlAnjaliNo ratings yet

- Training With HazloDocument17 pagesTraining With HazloChris ChromikNo ratings yet

- 06 E85 Chassis DynamicsDocument24 pages06 E85 Chassis DynamicsCristianNo ratings yet

- Isri Repair ManualDocument8 pagesIsri Repair ManualPaweł B100% (1)

- Djj10033 Chapter 3Document50 pagesDjj10033 Chapter 3YogenNo ratings yet

- BS 160 Selected PagesDocument52 pagesBS 160 Selected Pagesramesh suvvadaNo ratings yet

- Section 5 - Repair/Replacement Procedures: Part Number/ Nomenclature DescriptionDocument4 pagesSection 5 - Repair/Replacement Procedures: Part Number/ Nomenclature DescriptionGregorio1927No ratings yet

- 7chapter 9.1 Rotary TablesDocument26 pages7chapter 9.1 Rotary TablesRogerNo ratings yet

- How To Fine Tune Your 3D Printer ENDER 3Document87 pagesHow To Fine Tune Your 3D Printer ENDER 3Michaël Memeteau100% (5)

- User Instructions For R1100S Gear Switch IndicatorDocument17 pagesUser Instructions For R1100S Gear Switch Indicatorbuzzz57No ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsFrom EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Legazpi Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceDocument6 pagesLegazpi Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceCharina Balunso-BasiloniaNo ratings yet

- Cardboard Geodesic DomeDocument5 pagesCardboard Geodesic DomeJuan BurgayaNo ratings yet

- PBM350Document110 pagesPBM350okz119No ratings yet

- Stanley BSL Catalogue 2013Document40 pagesStanley BSL Catalogue 2013Jonathan Alejandro Gutierrez CoronadoNo ratings yet

- The Institute of Chartered Accountants of IndiaDocument10 pagesThe Institute of Chartered Accountants of IndiaArun SNo ratings yet

- Pricing Office CatalogueDocument130 pagesPricing Office CatalogueSheikh GeeNo ratings yet

- Annual Implementation Plan: Masicampo - Es@deped - Gov.phDocument10 pagesAnnual Implementation Plan: Masicampo - Es@deped - Gov.phDonnalyn Tagpuno VilladoresNo ratings yet

- App PPMPDocument187 pagesApp PPMPNived Lrac Pdll SgnNo ratings yet

- Travel JournalDocument6 pagesTravel JournalLalaine JuanNo ratings yet

- Tyvek Installation Guide - Residential-WRB-Install PDFDocument24 pagesTyvek Installation Guide - Residential-WRB-Install PDFDavid TorskeNo ratings yet

- BaseLok GeoCell Installation GuideDocument4 pagesBaseLok GeoCell Installation GuideThameem SharaafNo ratings yet

- Gastrointestinal SurgDocument217 pagesGastrointestinal Surgagung permanaNo ratings yet

- User GuideDocument190 pagesUser GuideSaiful GhoziNo ratings yet

- Model 26-26D Manual-1008Document46 pagesModel 26-26D Manual-1008Anonymous 2MRGC0w1No ratings yet

- RS Alligator Staple Ab FastenersDocument4 pagesRS Alligator Staple Ab FastenersAdelia RachmanNo ratings yet

- RICOH Pro C5300s-C5310s Final Brochure v2 - HR - tcm100-39832Document12 pagesRICOH Pro C5300s-C5310s Final Brochure v2 - HR - tcm100-39832Pascu DanNo ratings yet

- A641 PDFDocument5 pagesA641 PDFandresNo ratings yet

- Ricoh Pro8100 Detailed DescriptionDocument514 pagesRicoh Pro8100 Detailed DescriptionMaria FedaltoNo ratings yet

- HARGADocument15 pagesHARGAgalihrahman51No ratings yet

- EB Electric Furnace Install InstructionsDocument20 pagesEB Electric Furnace Install InstructionsABHISHEK THAKURNo ratings yet

- Stores Items For Mv. Ceylon Princess DelivDocument98 pagesStores Items For Mv. Ceylon Princess DelivTharinSiriwardanaNo ratings yet

- Duplo System 2000Document2 pagesDuplo System 2000Георгий ПрокофьевNo ratings yet

- Module 2 Assignment: Hint - Double-Click So That Format Painter Remains Active. Member DiscountDocument10 pagesModule 2 Assignment: Hint - Double-Click So That Format Painter Remains Active. Member DiscountsnehaNo ratings yet

- Bostitch D62ADCDocument28 pagesBostitch D62ADCGus PeixotoNo ratings yet

- EPSON WF-C20590 Service Manual Page501-550Document50 pagesEPSON WF-C20590 Service Manual Page501-550ion ionNo ratings yet

- Catalogo Sistema Grapas Alligator para Aplicaciones Ligeras A PesadasDocument20 pagesCatalogo Sistema Grapas Alligator para Aplicaciones Ligeras A Pesadasluis carlos martin contrerasNo ratings yet

- POPR2 Oct 20222Document34 pagesPOPR2 Oct 20222MARJORIE LANORIONo ratings yet

- Ticket: CruiseDocument4 pagesTicket: CruisejuniorrachelNo ratings yet

- Paper Cone Wreath (12") : This Tutorial Provides Instructions For A 12" WreathDocument12 pagesPaper Cone Wreath (12") : This Tutorial Provides Instructions For A 12" WreathmariaNo ratings yet

- Scope of WorkDocument69 pagesScope of WorkRashad MallakNo ratings yet

ESLe Y-Axis

ESLe Y-Axis

Uploaded by

baajpurOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESLe Y-Axis

ESLe Y-Axis

Uploaded by

baajpurCopyright:

Available Formats

10. Flip the two breaker switches on at the AC power fail-over unit.

11. Close the front and back doors.

12. Power on the library (see Powering the library off and on).

The OCP cable replacement procedure is complete.

Y-axis motor assembly

Table 33 Y-axis motor assembly

Part number 351130-0011 or 410648–011

Location Under robotics shelf

Characteristics Contains motor which drives robot up and down

Function Provides power to the vertical (Y-axis) belt assembly

Y-axis motor assembly

1

Use this non-RoHS-compliant part in libraries whose part numbers end with the letters A or B. For more information, see “IM-

PORTANT” on page 41.

Required tools

These tools are required for removing and replacing the Y-axis motor assembly and adjusting the

laser scanner:

• # 1 and 2 Phillips screwdriver

• 1/4 in. nut driver

• Tension gauge

Removing the Y-axis motor assembly

1. Power off the library (see Powering the library off and on).

2. Open the back door and flip the two breaker switches off at the power fail-over unit.

3. Open the front doors.

HP StorageWorks ESL E-Series Tape Library 135

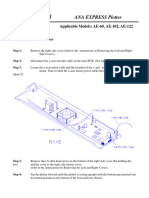

4. Disconnect the motor power and the two encoder cables from the Y-axis motor (see Figure 55).

CAUTION:

Note which edge of the encoder cable is red. It will need to be reinstalled in the same

orientation. Inverted installation could cause damage to the robotics.

1. Motor power cable 2. Encoder cable

3. Y-axis motor, shown outside of library for clarity

Figure 55 Disconnecting the Y-axis motor cables

.

136 FRU removal and replacement

5. Move the robot towards the base of the library until the vertical restraint holes line up (see Figure

56).

1. Robot platform 2. Base of library

3. Vertical restraint holes 4. Y-axis rail

Figure 56 Lining up the vertical restraint holes

.

NOTE:

When the vertical restraint holes are aligned, the counterweight restraint holes also line up

in the back of the library.

HP StorageWorks ESL E-Series Tape Library 137

6. Using a 7/16-inch socket wrench with a minimum 1-foot extender, remove the counterweight

restraint, flip it over pin side in so that it holds the counter weight, and secure it with the 2 nuts

(see Figure 57).

1. Nuts 2. Shipping restraint

Figure 57 Installing the counterweight restraint

.

7. Slide the lower right bin panel out of the library to gain access to the counterweight connection.

138 FRU removal and replacement

8. Lift up slightly on the robotic platform, near its front end, and unhook the counterweight line

located at the back of the robotics platform (see Figure 58). Carefully lower the robot to the

library floor.

WARNING!

Ensure you properly support the robotics platform when you unhook the cable and lower

it to the base of the cabinet, as it is heavy and will drop suddenly otherwise.

1. Counterweight cable 2. Counterweight hook (detach here)

3. Belt 4. Back belt clamp

Figure 58 Unhooking the counterweight line

.

HP StorageWorks ESL E-Series Tape Library 139

9. Remove 4 Phillips screws (2 at the top and 2 at the bottom) securing the Y-axis front rail to the

library frame and remove the Y-axis front rail (see Figure 59).

1. Y-axis front rail

Figure 59 Removing the Y-axis front rail

.

10. Remove 2 3/8 in. nuts as shown in Figure 60 and remove 4 Phillips screws securing the belt

clamp assembly to the robotics platform.

1. Phillips screws 2. 3/8 inch nuts

Figure 60 Removing the front belt clamp

.

140 FRU removal and replacement

11. Let the belt clamp assembly hang down as shown in Figure 61.

1. Belt clamp assembly

Figure 61 Belt clamp assembly

.

HP StorageWorks ESL E-Series Tape Library 141

12. Remove the top portion of the belt from the Y-axis motor assembly rollers (see Figure 62).

1. Top belt

Figure 62 Removing the belt from the Y-axis motor assembly

.

142 FRU removal and replacement

13. Remove 4 Phillips screws (2 in front and 2 on side) securing the Y-axis motor assembly and

remove it from the library (see Figure 63).

1. Y-axis motor 2. Phillips screws

3. Phillips screws

Figure 63 Removing the Y-axis motor

.

14. Install the replacement Y-axis motor assembly and secure with 4 Phillips screws previously removed.

Tighten the front screws first then the side screws.

15. Reattach the motor power and the two encoder cables from the Y-axis motor (see Figure 55).

CAUTION:

Install the encoder cable in the exact orientation as it was when removed to avoid damaging

the robotics.

16. Secure the belt clamp assembly with two nuts previously removed previously. Do NOT tighten

the nuts at this time.

17. Thread the top portion of the belt through the Y-axis assembly rollers.

HP StorageWorks ESL E-Series Tape Library 143

18. Pull the belt down and secure it loosely with the top front clamp and the four Phillips screws (see

Figure 64).

1. Top clamp 2. Phillips screws

3. Tension screw

Figure 64 Securing the top clamp

.

19. Attach the top and bottom clamps to each other with the tension screw previously removed.

20. Check the belt tension using a force touch gauge in the vertical center of the belt. Measure the

force as the front belt touches the rear belt loop. Tighten or loosen the tension screw to adjust

the belt tension to 24 oz. +/- 1 oz.

144 FRU removal and replacement

21. Once the belt tension is adjusted correctly, secure the top clamp by tightening the four Phillips

screws (see Figure 65).

1. Phillips screws

Figure 65 Securing the top Phillips screws

.

22. Install the Y-axis front rail previously removed.

23. Align the vertical rail so that the left side of it fits between the rollers.

24. Loosely attach the top 2 Phillips screws and tighten the bottom 2 Phillips screws first. You may

need to lift up on the rail to do so.

25. Insert a #1 Phillips screwdriver under the robotics platform to slightly raise the platform in the

front and tighten the two 3/8-inch nuts as shown in Figure 66.

1. Hex nuts

Figure 66 Securing the robotics platform

.

26. Remove the #1 Phillips screwdriver from the library.

27. Lift up the platform from near its front end and reattach the counterweight cable to the

counterweight hook (see Figure 67). Ensure that the cable does not interfere with the bin racks

or side panels.

HP StorageWorks ESL E-Series Tape Library 145

28. Remove counterweight restraint from the back of the library and return it to its stored position.

1. Counterweight cable 2. Counterweight hook (detach here)

3. Belt 4. Back belt clamp

Figure 67 Attaching the counterweight hook

.

29. Flip the two breaker switches on at the AC power fail-over unit.

30. Close the library doors.

31. Power on the library (see Powering the library off and on).

The Y-axis motor replacement procedure is complete.

Y-axis belt

Table 34 Y-axis belt

Part number 351131-001

Location Right side of robotics platform

• XL pitch belt

Characteristics • 3/4 in. wide

• Self lubricating

Function Driven by the Y-axis motor to position the Y-axis

146 FRU removal and replacement

Y-axis belt

Required tools

These tools are required for this operation:

• # 1 and 2 Phillips screwdriver

• 7/16 in. nut driver

• 1/4 in. nut driver

• Scissors or knife

• Tension gauge

• Office stapler

Removing the Y-axis belt

1. Power off the library (see Powering the library off and on).

2. Open the front doors.

HP StorageWorks ESL E-Series Tape Library 147

3. Move the robot towards the base of the library until the vertical restraint holes line up (see Figure

68).

NOTE:

When the vertical restraint holes are aligned, the counterweight restraint holes also line up

in the back of the library.

1. Robot platform 2. Base of library

3. Vertical restraint holes 4. Y-axis rail

Figure 68 Lining Up the Vertical Restraint Holes

.

148 FRU removal and replacement

4. Using a 7/16-inch socket wrench with a minimum 1-foot extender, remove the counterweight

restraint, flip it over, and reinstall it pin side in to hold the counterweight in place (see Figure

69).

1. Nuts 2. Shipping restraint

Figure 69 Installing the counterweight restraint

.

5. Slide the lower right bin panel out of the library to gain access to the counterweight connection.

HP StorageWorks ESL E-Series Tape Library 149

6. Lift up slightly on the robotic platform, near its front end, and unhook the counterweight line

located at the back of the robotics platform (see Figure 70). Carefully lower the robot to the

library floor.

WARNING!

Ensure you properly support the robotics platform when you unhook the cable and lower

it to the base of the cabinet, as it is heavy and will drop suddenly otherwise.

1. Counterweight cable 2. Counterweight hook (detach here)

3. Belt 4. Back belt clamp

Figure 70 Unhooking the counterweight line

.

150 FRU removal and replacement

7. Remove 4 Phillips screws (2 at the top and 2 at the bottom) securing the Y-axis front rail to the

library frame and remove the Y-axis front rail (see Figure 71).

1. Y-axis front rail

Figure 71 Removing the Y-axis front rail

.

HP StorageWorks ESL E-Series Tape Library 151

8. With the robotics platform resting on the base of the library, remove the 2 3/8-inch nuts securing

the back belt clamp and remove the clamp from the library (see Figure 72).

1. 3/8 inch nuts 2. Back belt clamp

Figure 72 Removing the back belt clamp

.

152 FRU removal and replacement

9. Loosen the 2 nuts as shown in Figure 73 and remove the 6 Phillips screws securing the front belt

clamp to the robotics platform.

1. Phillips screws 2. 3/8 inch nuts

Figure 73 Removing the front belt clamp

.

10. Remove the Phillips screw connecting the two pieces of the front belt clamp.

HP StorageWorks ESL E-Series Tape Library 153

11. Attach the new belt to the lower portion of the old belt with a stapler.

• Ensure that the new belt overlays the top of, and is in the same orientation (the teeth face the

same way) as, the old belt.

• Use at least 3 standard office staples.

• Staple the belts so that the flat side of the staple is on the flat side, not on the tooth side, of

the belt.

• If necessary, fold the ends of the staple over to make sure the belts are held together securely

(see Figure 74).

1. Old belt 2. New belt

Figure 74 Attaching the new belt

.

154 FRU removal and replacement

12. Gently guide the new belt in as you pull the top portion of the belt through the rollers until the

old belt is completely out of the library (see Figure 75). Make sure that the new belt does not get

twisted as it is fed through.

1. Top portion of belt 2. Lower portion of belt

Figure 75 Pulling the new belt through the rollers

.

13. When the old belt is completely out of the library, remove the staples to free it from the new belt

and discard it.

14. Align the belt teeth on the lower portion of the belt with the slots in the bottom front clamp (the

smaller of the two clamps).

HP StorageWorks ESL E-Series Tape Library 155

15. Secure the lower portion of the belt with the bottom front clamp using 2 Phillips screws previously

removed (see Figure 76).

1. Lower clamp 2. Phillips screws

3. Belt

Figure 76 Securing the lower belt clamp

.

156 FRU removal and replacement

16. Pull the top portion of the belt down into the track as shown in Figure 77. The middle holes on

the belt track show where to cut and remove the excess belt. Use scissors or a knife to cut the

belt.

1. New belt 2. Cut off excess belt

Figure 77 Cutting the belt to fit

.

HP StorageWorks ESL E-Series Tape Library 157

17. Pull the belt down and secure it loosely with the top front clamp (the larger of the two clamps)

and the four Phillips screws (see Figure 78). The belt must be secured loosely enough to be able

to slide up and down.

NOTE:

Ensure that the top of the clamp is slightly higher than the top of the plate to which it is

attached so that once the tension screw is tightened, the clamp will be better aligned with

the top of the plate.

1. Top clamp 2. Phillips screws

3. Tension screw

Figure 78 Securing the top clamp

.

18. Attach the top and bottom clamps to each other with the tension screw removed.

19. Check the belt tension using a force touch gauge in the vertical center of the belt. Measure the

force as the front belt touches the rear belt loop. Tighten or loosen the tension screw to adjust

the belt tension to 24 oz. +/- 1 oz.

158 FRU removal and replacement

20. Once the belt tension is adjusted correctly, secure the top clamp by tightening the four Phillips

screws (see Figure 79).

1. Phillips screws

Figure 79 Securing the top Phillips screws

.

21. Vertically center the two hex nuts in the slots of the front clamp assembly (loosened in step 10).

Do NOT tighten the nuts at this time.

22. Reattach the back belt clamp previously removed. Ensure that the belt teeth align with the clamp

slots.

23. Install the Y-axis front rail previously removed.

24. Align the vertical rail so that the left side of it fits between the rollers.

25. Loosely attach the top 2 Phillips screws and tighten the bottom 2 Phillips screws first. You may

need to lift up on the rail to do so.

26. Insert a #1 Phillips screwdriver under the robotics platform to slightly raise the platform in the

front and tighten the two 3/8-inch nuts as shown in Figure 80.

1. Hex nuts

Figure 80 Securing the robotics platform

.

27. Remove the #1 Phillips screwdriver from the library.

HP StorageWorks ESL E-Series Tape Library 159

28. Lift up the platform from near its front end and reattach the counterweight cable to the

counterweight hook (see Figure 81). Ensure that the cable does not interfere with the bin racks

or side panels.

1. Counterweight cable 2. Counterweight hook (detach here)

3. Belt 4. Back belt clamp

Figure 81 Attaching the counterweight hook

.

29. Remove counterweight restraint from the back of the library and return it to its stored position.

30. Flip the two breaker switches on at the AC power fail-over unit.

31. Close the library doors.

32. Power on the library (see Powering the library off and on).

The belt replacement procedure is complete.

Drive cluster assembly

Table 35 Drive cluster assembly

Part number 351136-0011 or 410654–001

Location Mounts in the rear of the library

Characteristics Contains positions for four tape drive modules and two power supplies

Function Provides the interface for the tape drive modules

160 FRU removal and replacement

You might also like

- Mesa Quirurgica Opt 70 Ec 02 PDFDocument36 pagesMesa Quirurgica Opt 70 Ec 02 PDFTEYLER BARBOZANo ratings yet

- Printbar RemovalDocument21 pagesPrintbar RemovalTaur1968100% (1)

- Kearney and Trecker Installation ManualDocument12 pagesKearney and Trecker Installation Manualaa987100% (1)

- Report On Four Bar Mechanism of Sewing MachineDocument8 pagesReport On Four Bar Mechanism of Sewing MachineshazedislamNo ratings yet

- RepymotDocument4 pagesRepymotEngin UzunNo ratings yet

- Qauntum FRU Y Trayrobot Scalar I40 I80 RevADocument26 pagesQauntum FRU Y Trayrobot Scalar I40 I80 RevAScramble 69No ratings yet

- Ex 4650Document16 pagesEx 4650Ulzii AltansukhNo ratings yet

- Inverter Mid Power Assembly ReplacementDocument13 pagesInverter Mid Power Assembly ReplacementRubén Cadima BarrientosNo ratings yet

- HP p3015 50.3 ErrorDocument4 pagesHP p3015 50.3 Errorwinner mediaNo ratings yet

- Surgical C-Arm Tables: Service ManualDocument80 pagesSurgical C-Arm Tables: Service ManualArt Messick100% (1)

- Aste-6z8l9t r0 enDocument3 pagesAste-6z8l9t r0 enfilip_kecNo ratings yet

- Exp 9 Introduction To MachinesDocument11 pagesExp 9 Introduction To MachinesMuhammad AwaisNo ratings yet

- Eaton CM-52 Remote Racking IL02400003EDocument16 pagesEaton CM-52 Remote Racking IL02400003EadvancedmotorNo ratings yet

- WheelHorse Electric Lift Accessory For Long Frame Tractors 8-4221Document4 pagesWheelHorse Electric Lift Accessory For Long Frame Tractors 8-4221Kevins Small Engine and Tractor ServiceNo ratings yet

- Planmed Sophie Part2 - ServicemanualDocument99 pagesPlanmed Sophie Part2 - ServicemanualOscar Orea100% (1)

- Manual de Servicio Inogen One - g3Document134 pagesManual de Servicio Inogen One - g3carlos andres hoyos perdomoNo ratings yet

- 7 Frame and WheelDocument12 pages7 Frame and Wheelalsief1951No ratings yet

- Chapter H - Parts Replacement & Repair Replacing Sensors & SwitchesDocument99 pagesChapter H - Parts Replacement & Repair Replacing Sensors & SwitchesolegNo ratings yet

- Maintenance Manual For BBS-V800 202109Document15 pagesMaintenance Manual For BBS-V800 202109thaungmtNo ratings yet

- Electrical Wireline Spooler User ManualDocument14 pagesElectrical Wireline Spooler User ManualJohn SimancaNo ratings yet

- B-3801 IOM - Rev - 2011-09-02 (1) MidlandDocument23 pagesB-3801 IOM - Rev - 2011-09-02 (1) MidlandLucas MonteNo ratings yet

- Xserve Raid Left or Right Light PipeDocument11 pagesXserve Raid Left or Right Light PipeRoberto BruniNo ratings yet

- Rack Installation Instructions: GuidelinesDocument16 pagesRack Installation Instructions: Guidelinesovidiu981No ratings yet

- Mini X Motor Replacement With Fan UpgradeDocument7 pagesMini X Motor Replacement With Fan UpgradeLucian ComanNo ratings yet

- UH-60A EH60A: RemovalDocument2 pagesUH-60A EH60A: RemovalaugustinhodjNo ratings yet

- RepheadDocument4 pagesRepheadEngin UzunNo ratings yet

- Quick Start Ex4600Document10 pagesQuick Start Ex4600Елена ШевчукNo ratings yet

- Balança 4182-A (Mecanica) - Revisão 02.08.2007 PDFDocument12 pagesBalança 4182-A (Mecanica) - Revisão 02.08.2007 PDFKadson AmaralNo ratings yet

- AA06058 Modificacion de La Caja de Resistencia Camion 129 y 130Document7 pagesAA06058 Modificacion de La Caja de Resistencia Camion 129 y 130Jose A. Basanta H.No ratings yet

- Dokumen - Tips - Planmed Sophie Part2 ServicemanualDocument37 pagesDokumen - Tips - Planmed Sophie Part2 ServicemanualMohammed BenzaidiNo ratings yet

- Rack Installation Guide-DA240Document8 pagesRack Installation Guide-DA240Fabricio RiverNo ratings yet

- Instrument Panel Systems: Removal and Installation Headlamp Leveling SwitchDocument2 pagesInstrument Panel Systems: Removal and Installation Headlamp Leveling SwitchCarlos Gabriel EstergaardNo ratings yet

- Roboitic Transfer All Actions of IntegraDocument19 pagesRoboitic Transfer All Actions of Integrapranshu126545No ratings yet

- Challenger 24012 IOMDocument19 pagesChallenger 24012 IOMgmsapiensNo ratings yet

- Minivator 1000 Series Installation Manual PDFDocument36 pagesMinivator 1000 Series Installation Manual PDFSergio PNo ratings yet

- Service Manual FOR Medical Diagnostic X-Ray Radiograph TableDocument6 pagesService Manual FOR Medical Diagnostic X-Ray Radiograph TableWael Fuad AL-MaktariNo ratings yet

- Rail Kit II Installation InstructionsDocument4 pagesRail Kit II Installation InstructionsSaurabhNo ratings yet

- 93ZJ Secc 8J Turn Signals and Hazard Warning FlashesDocument4 pages93ZJ Secc 8J Turn Signals and Hazard Warning Flasheshelgith74No ratings yet

- DrivetrainDocument43 pagesDrivetrainfuckoffalreadyNo ratings yet

- Sinowon Vertical Profile Projector Operation Manual enDocument16 pagesSinowon Vertical Profile Projector Operation Manual enJohnny DaiNo ratings yet

- F2O Feed Take UpAdjustmentDocument6 pagesF2O Feed Take UpAdjustmentdeniNo ratings yet

- Rotating Beam Fatigue Test MachineDocument13 pagesRotating Beam Fatigue Test MachineReNo ratings yet

- Rotary TablesDocument30 pagesRotary TablesCarlos MendozaNo ratings yet

- Cetac Z Drive AssemblyDocument13 pagesCetac Z Drive AssemblyYanine Aranda MosqueraNo ratings yet

- Wingspan ManualDocument9 pagesWingspan ManualalirioNo ratings yet

- E S S O S M: Lectric Lideout Ystem Peration AND Ervice AnualDocument21 pagesE S S O S M: Lectric Lideout Ystem Peration AND Ervice AnualJuan ContrerasNo ratings yet

- Alternator 130a.xmlDocument16 pagesAlternator 130a.xmlAnjaliNo ratings yet

- Training With HazloDocument17 pagesTraining With HazloChris ChromikNo ratings yet

- 06 E85 Chassis DynamicsDocument24 pages06 E85 Chassis DynamicsCristianNo ratings yet

- Isri Repair ManualDocument8 pagesIsri Repair ManualPaweł B100% (1)

- Djj10033 Chapter 3Document50 pagesDjj10033 Chapter 3YogenNo ratings yet

- BS 160 Selected PagesDocument52 pagesBS 160 Selected Pagesramesh suvvadaNo ratings yet

- Section 5 - Repair/Replacement Procedures: Part Number/ Nomenclature DescriptionDocument4 pagesSection 5 - Repair/Replacement Procedures: Part Number/ Nomenclature DescriptionGregorio1927No ratings yet

- 7chapter 9.1 Rotary TablesDocument26 pages7chapter 9.1 Rotary TablesRogerNo ratings yet

- How To Fine Tune Your 3D Printer ENDER 3Document87 pagesHow To Fine Tune Your 3D Printer ENDER 3Michaël Memeteau100% (5)

- User Instructions For R1100S Gear Switch IndicatorDocument17 pagesUser Instructions For R1100S Gear Switch Indicatorbuzzz57No ratings yet

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsFrom EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Legazpi Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceDocument6 pagesLegazpi Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceCharina Balunso-BasiloniaNo ratings yet

- Cardboard Geodesic DomeDocument5 pagesCardboard Geodesic DomeJuan BurgayaNo ratings yet

- PBM350Document110 pagesPBM350okz119No ratings yet

- Stanley BSL Catalogue 2013Document40 pagesStanley BSL Catalogue 2013Jonathan Alejandro Gutierrez CoronadoNo ratings yet

- The Institute of Chartered Accountants of IndiaDocument10 pagesThe Institute of Chartered Accountants of IndiaArun SNo ratings yet

- Pricing Office CatalogueDocument130 pagesPricing Office CatalogueSheikh GeeNo ratings yet

- Annual Implementation Plan: Masicampo - Es@deped - Gov.phDocument10 pagesAnnual Implementation Plan: Masicampo - Es@deped - Gov.phDonnalyn Tagpuno VilladoresNo ratings yet

- App PPMPDocument187 pagesApp PPMPNived Lrac Pdll SgnNo ratings yet

- Travel JournalDocument6 pagesTravel JournalLalaine JuanNo ratings yet

- Tyvek Installation Guide - Residential-WRB-Install PDFDocument24 pagesTyvek Installation Guide - Residential-WRB-Install PDFDavid TorskeNo ratings yet

- BaseLok GeoCell Installation GuideDocument4 pagesBaseLok GeoCell Installation GuideThameem SharaafNo ratings yet

- Gastrointestinal SurgDocument217 pagesGastrointestinal Surgagung permanaNo ratings yet

- User GuideDocument190 pagesUser GuideSaiful GhoziNo ratings yet

- Model 26-26D Manual-1008Document46 pagesModel 26-26D Manual-1008Anonymous 2MRGC0w1No ratings yet

- RS Alligator Staple Ab FastenersDocument4 pagesRS Alligator Staple Ab FastenersAdelia RachmanNo ratings yet

- RICOH Pro C5300s-C5310s Final Brochure v2 - HR - tcm100-39832Document12 pagesRICOH Pro C5300s-C5310s Final Brochure v2 - HR - tcm100-39832Pascu DanNo ratings yet

- A641 PDFDocument5 pagesA641 PDFandresNo ratings yet

- Ricoh Pro8100 Detailed DescriptionDocument514 pagesRicoh Pro8100 Detailed DescriptionMaria FedaltoNo ratings yet

- HARGADocument15 pagesHARGAgalihrahman51No ratings yet

- EB Electric Furnace Install InstructionsDocument20 pagesEB Electric Furnace Install InstructionsABHISHEK THAKURNo ratings yet

- Stores Items For Mv. Ceylon Princess DelivDocument98 pagesStores Items For Mv. Ceylon Princess DelivTharinSiriwardanaNo ratings yet

- Duplo System 2000Document2 pagesDuplo System 2000Георгий ПрокофьевNo ratings yet

- Module 2 Assignment: Hint - Double-Click So That Format Painter Remains Active. Member DiscountDocument10 pagesModule 2 Assignment: Hint - Double-Click So That Format Painter Remains Active. Member DiscountsnehaNo ratings yet

- Bostitch D62ADCDocument28 pagesBostitch D62ADCGus PeixotoNo ratings yet

- EPSON WF-C20590 Service Manual Page501-550Document50 pagesEPSON WF-C20590 Service Manual Page501-550ion ionNo ratings yet

- Catalogo Sistema Grapas Alligator para Aplicaciones Ligeras A PesadasDocument20 pagesCatalogo Sistema Grapas Alligator para Aplicaciones Ligeras A Pesadasluis carlos martin contrerasNo ratings yet

- POPR2 Oct 20222Document34 pagesPOPR2 Oct 20222MARJORIE LANORIONo ratings yet

- Ticket: CruiseDocument4 pagesTicket: CruisejuniorrachelNo ratings yet

- Paper Cone Wreath (12") : This Tutorial Provides Instructions For A 12" WreathDocument12 pagesPaper Cone Wreath (12") : This Tutorial Provides Instructions For A 12" WreathmariaNo ratings yet

- Scope of WorkDocument69 pagesScope of WorkRashad MallakNo ratings yet