Professional Documents

Culture Documents

Bubble Into A Horizontal Double Pipe HE

Bubble Into A Horizontal Double Pipe HE

Uploaded by

SonNguyenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bubble Into A Horizontal Double Pipe HE

Bubble Into A Horizontal Double Pipe HE

Uploaded by

SonNguyenCopyright:

Available Formats

Heat transfer enhancement due to air bubble injection into a horizontal

double pipe heat exchanger

H. Sadighi Dizaji a, S.Jafarmadar a*

a Department of mechanical Engineering, Urmia University, Urmia, Iran

* S.jafarmadar@urmia.ac.ir

Abstract

If an air flow is injected into a liquid fluid, many ambulant air bubbles are formed inside the fluid. Air

bubbles move inside the liquid fluid because of the buoyancy force, and the mobility of these air bubbles

makes sizable commixture and turbulence inside the fluid. This mechanism was employed to enhance the

heat transfer rate of a horizontal double pipe heat exchanger in this paper. However it can be used in any

other type of heat exchanger. Especially, this method can be expanded as a promising heat transfer

improvement technique in automotive cooling system, for instance in radiator which contains of water or

other liquid fluid. Bubbles were injected via a special method. Present type of air bubbles injection and also

the use of this mechanism for double tube heat exchanger have not been investigated before. Results are

reported for varying bubble inlet parameters. The main scope of the present work is to experimentally

clarify the effect of air bubble injection on the heat transfer rate and effectiveness through a horizontal

double pipe heat exchanger.

Keywords: Air bubble injection, Heat exchanger, Heat transfer, Effectiveness

1. Introduction inevitably mixing can cause more hydraulic power

requirement. But, this is not the main scope of this

Numerous methods have been presented to study. Here, we want to use of two air bubbles

increase the heat transfer rate and performance of heat important properties for heat transfer enhancement.

exchangers in the past decades. Generally, these First, the vertical mobility of air bubbles which is due

techniques can be categorized into two principal to buoyancy force and it occurs when an air bubble is

types: (1) passive techniques which require no direct begotten under a liquid. Indeed, this mechanism can

application of external power, such as using of act as a turbulator along the heat exchanger. Second,

nanofluids, coarsening heat exchanger surfaces and the use of air stream pressure (which has been

inserting fluid turbulators (2) active techniques which produced by the air bump) as an extra motive power.

require external power, for instance surface vibration Indeed, it is released when the air flow is exited

and electrostatic fields. Sub millimeter bubble from the tiny holes which were contrived inside the

injection has been studied as one of the promising test section. Hence, in this study, air flow and water

techniques for heat transfer intensification for the flow don`t have any contact outside of the test section

laminar natural convection of static liquids by some and the air mass flow rate is negligible compared to

researchers (for instance Kitagawa et al. [1] (2008)). the water mass flow rate. Bubbles were injected via a

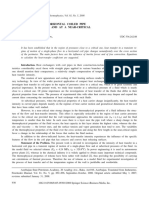

Some other researchers (such as Vlasogiannis et al. special method (see Fig. 1) which is explained in next

[2] (2002)) focused on the use of air-water two phase sections. So the main scope of the present work is to

flow to enhance the heat transfer rate of heat experimentally clarify the effect of air bubble

exchangers (forced convection). It should be noted injection on heat transfer rate, number of heat transfer

that, in their study air flow was combined with water units (NTU) and effectiveness through a horizontal

flow before they could arrive inside the heat double pipe heat exchanger. Investigations on air

exchanger. So there was a complete-mixed two phase injection into a liquid fluid and double pipe heat

flow along the heat exchanger. In those cases, heat exchangers are summarized chronologically as

transfer enhancement is related to considerable follows. Oh et al. [3] (2000) Studied on bubble

interaction between liquid, gas and solid bounding behavior and boiling heat transfer enhancement under

surfaces, and obviously it produces extra shear, and electric field. Gabillet et al. [4] (2002) experimentally

studied on the bubble injection in a turbulent

International Journal of Automotive Engineering Vol. 4, Number 4, Dec 2014

903 Heat transfer enhancement due to…

boundary layer. Experiments were performed in a 2.1. Air bubble injection method

horizontal channel in order to simulate the dynamical

effects of the nucleation of bubbles. Their findings If an air flow is injected into the inner or outer

showed that the mean velocity is nearly the same as in tube (annular space between the two tubes) of a

single phase flow, except near the wall where the horizontal double pipe heat exchanger, many

shear stress is greater than in single phase flow. ambulant air bubbles are formed inside the test

Funfschilling and Li [5] (2006) studied the influence section. The mobility of said air bubbles (because of

of the injection period on the bubble rise velocity. buoyancy force) makes considerable commixture

They found that the rise velocity decreases inside the heat exchanger. Hence, the movement of

significantly with the injection period. Ide et al. [6] air bubbles through the heat exchanger increases the

(2007) measured the void fraction and bubble size heat transfer rate by increasing the turbulence level of

distributions in a microchannel. Kitagawa et al. [1] the water flow and mixing the thermal boundary

(2008) studied on heat transfer enhancement for layer. This mechanism was employed to enhance the

laminar natural convection along a vertical plate due heat transfer rate through a horizontal double pipe

to sub millimeter bubble injection. Their heat exchanger in this paper as described below.

measurements showed that the ratio of the heat Air bubbles were injected inside the double pipe

transfer coefficient with sub millimeter bubble heat exchanger as shown in Fig.1. As seen in Fig. 1,

injection to that without injection increases with an some tiny holes have been begotten on a plastic tube.

increase in the bubble flow rate or a decrease in the This tube was inserted inside the inner tube or outer

wall heat flux and that the ratio ranges from 1.35 to tube of heat exchanger, and air flow was injected

1.85. Nouri et al. [7] (2009) carried out an from the two side of the plastic tube inside the heat

experimental study on the effect of air bubble exchanger (See Fig. 1). Many small bubbles were

injection on the flow induced rotational hub. formed inside the heat exchanger duo to the air flow

Kitagawa and Kitada [8] (2010) studied exit from the tiny holes on the plastic tube. The

experimentally on turbulent natural convection heat diameter of plastic tube was 3 mm, and the number of

transfer in water with sub millimeter bubble injection. holes and their diameter are two variant parameters in

Their results showed that in the transition region, the this study. The mass flow rate and temperate of the air

maximum heat transfer coefficient ratio is flow through the plastic tube were 0.098 × 10-3 Kg/s

approximately 1.9. Sub millimeter bubble injection is and 26°C respectively. It is noted, air mass flow rate

also effective in the laminar region as well as the was negligible in comparison with water mass flow

transition region. In the turbulent region, the heat rate (at least 0.083 Kg/s). Indeed, air flow was

transfer coefficient ratio for Q = 56 mm3/s is 1.2–1.3, injected by means of a small air pump (aquarium air

which means that the heat transfer enhancement pump).

occurs as a result of the bubble injection. Saffari et al.

[9] (2013) investigated the effect of bubble injection 2.2. Experimental apparatus

on pressure drop reduction in helical coil. The

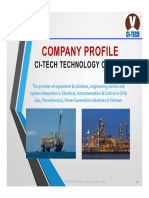

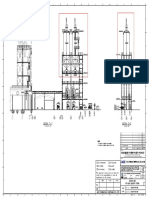

experimental results indicated that the maximum Fig. 2 represents a general view of test set-up. As

reduction of friction drag is 25%, which occurs at low seen in Fig. 2 the system basically comprises a test

Reynolds numbers. Samaroo et al. [10] (2014) section, a cooling unit and a heating unit. The test

performed an experiment on the turbulent flow section consists of an inner tube, an outer tube, a

characteristics in an annulus under air bubble plastic tube, two insulated grooved end plates and

injection and subcooled flow boiling conditions with four screwed steel rods. The tubes of test section were

water as the working fluid. Their findings indicated placed between the end-plates, and screwed steel rods

that, in the laminar flow case, the coalescence of two were used to hold and adjust the position of the end-

bubbles successively injected is seen, and in turbulent plates. The inner tube is made from copper material

flow, the bubble departure frequency increases and no and the outer tube is made from PVC. Geometric

coalescence are observed. specifications of the tubes are tabulated in table 1

It is noted, the novelty of this study in comparison where t, L, D and 2r, are the air inlet diameter, tube

with above studies was totally described in second length, tube diameter and diameter of cold water

paragraph of introduction. (outer tube) inlets or outlets respectively.

2. Experiments

International Journal of Automotive Engineering Vol. 4, Number 4, Dec 2014

H. Sadighi Dizaji , S.Jafarmadar 904

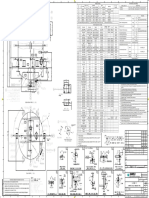

Fig1. A general view of air bubble injection methods

Fig2. (a) A schematic illustration of the test set-up: 1-test section, 2-Rotameter, 3-warm water tank, 4-dimmer and thermostat, 5-heater, 6-

water pump, 7-codenser, 8-compressor, 9-cold water tank, 10-evaporator, 11-tube, 12-endplates of test section, 13-air pump and (b)

Experimental setup

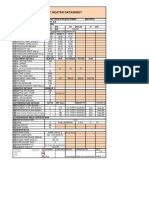

Table1. Experiment conditions and air bubble injection

International Journal of Automotive Engineering Vol. 4, Number 4, Dec 2014

905 Heat transfer enhancement due to…

Qh = h Cph (Th,in – Th,out) , Qc= c Cpc (Tc,out –

2.3. Experiments procedure

Tc,in)

Where Cp, and T represent the mass flow rate,

Inside of the inner tube and outer tube were

specific heat of the fluid at constant pressure, bulk

occupied with hot and cold water respectively.

temperature of the fluid. The subscripts h, c, in and

Counter flow was used through the heat exchanger for

out designate the hot fluid, cold fluid, inlet and outlet

all conditions. Table 2 provides seven various

respectively.

experiment conditions of this study, where n, d are

It is noted that, the air mass flow rate (0.098 × 10-

number of holes on plastic tube (with equal distances)

3 kg/s) assumed to be negligible compared to the

and holes diameter respectively. Each condition was

water mass flow rate (at least 0.083 kg/s) through the

performed with five different amount of hot water

test heat exchanger in this study. Indeed, the effect of

mass flow rate. It should be noted that, the effects of

air mass flow rate on water properties is very small

other parameters of double tube heat exchanger such

and negligible.

as, fluids inlet temperature, flows directions and etc.

The experimental average overall heat transfer

have been investigated abundantly in previous

coefficient (U exp) in a double pipe heat exchanger

studies.

can be obtained by the following correlations.

For this reason, the variants of this study are

related to bubbles inlet parameters. Outer tube and

water tanks were covered with a 2-cm layer of the

glass wool insulation to prevent heat loss to

surrounding. Cold water (outer tube) water flow rate

and inlet temperature were kept at around 0.083 kg/s

(Reynolds number of 4000 based on water flow rate)

and 25°C respectively. Hot water inlet temperature Where A is the inner tube surface area, ΔTLMTD

was maintained at around 40°C and it was pumped is the logarithmic mean temperature difference across

inside the inner tube with different mass flow rate heat exchanger, and the subscripts h, c, in, out,

from 0.0831 Kg/s to 0.2495 kg/s (Reynolds number designate the hot fluid, cold fluid, inlet and outlet

of 5000 to 16000). During the experiments, inlets and respectively.

outlets bulk temperature were measured at steady Heat transfer coefficients (hi), are evaluated by

state condition. “Wilson plots” method as describe below; (Wilson

plots method has been exactly described in Rose

3. Results and discussions study [12] and also it was employed to “h” calculation

by many other researchers, for instances Wongcharee

3.1 Validation et al. [13], Petkhool et al. [14], Jamshidi et al. [15]

and Shokouhmand et al. [16]).

Nusselt number (without air injection) was

validated with equation of Naphon et al [11] study.

This experimental correlation is given as follow:

Nu = 1.84 (Re – 1500)0.32 Pr0.7 5000 ≤ Re ≤

Where, the subscripts i and o pertain to the inside

25000 (1)

and outside of the inner tube. L is the length of heat

Where, Re is Reynolds number and Pr is Prandtl

exchanger. Shell side Reynolds number (water mass

number. Fig. 3 presents the results of this validation.

flow rate) is a constant value. So, it can be assumed

As seen in Fig. 3 the results of this present study

that ho and thereupon the last two terms on the right-

agree admissibly with mentioned equation within 8%

hand side of Eq. (4) are constants. Hence, the Eq. (4)

maximum difference for Nusselt number. Entrance

can be re-written as

effects, deference between roughness of two tubes,

unavoidable errors in the present study and aforesaid

equation can be discussed as reasons of discrepancies.

The shell side (outer tube) heat transfer coefficient

3.2. Heat transfer studies is assumed to behave in the following manner with

the hot water Reynolds number [13]

The average heat transfer rate (Qave) in a double

pipe heat exchanger can be calculated with: Substituting Eq. (6) into Eq. (5) yields

Qave = (Qh + Qc) (1)

International Journal of Automotive Engineering Vol. 4, Number 4, Dec 2014

H. Sadighi Dizaji , S.Jafarmadar 906

Fig3. Nusselt number validation (Without air injection)

Table 2. Tubes geometry

amounts of Nusselt number than those for the heat

exchanger without air bubble injection. Dependent on

air injection condition and Reynolds number, air

Constants B and M, and also the exponent m can bubbles increased the amount of Nusselt number

be obtained through curve fitting. The amount of hi about 6% - 35%. Maximum Nusselt number

can then be calculated. enhancement was obtained for air bubble injection

Finally, the experimental Nusselt number can be into the outer tube with n = 80 at low amount of

evaluated by: Reynolds number (about 5000). Minimum Nusselt

number enhancement was occurred for air bubble

injection into the inner tube with n = 40 and d=0.7 at

high amount of Reynolds number (about 15000). The

Here, k is the thermal conductivity of the working ratio of enhanced Nusselt number to the non –

fluid. The Nusselt number results are demonstrated in enhanced Nusselt number decreases with the increase

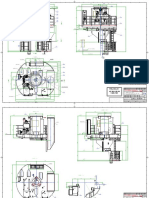

Fig. 4 for all cases. Fig. 4a represents the changes of of Reynolds number for all conditions.

Nusselt number with Reynolds number for air bubble The key findings from the heat transfer study are

injection into the inner tube with n = 40. Fig. 4b described as follows:

shows the changes of Nusselt number with Reynolds a)Air bubble injection into the inner tube of heat

number for air bubble injection into the inner tube exchanger:

with n = 80. And Fig.4c shows the changes of Nusselt The influence of air bubble injection into the inner

number with Reynolds number for air bubble tube is less than the influence of the air bubble

injection into the outer tube. Comparisons of injection into the outer tube on heat transfer rate. This

increased Nusselt number (air injection) with the non result can be due to two factors. Firstly, despite the air

– increased Nusselt number (Nun, without air bubbles increase the turbulence level of the fluid

injection) are presented in Fig. 4d-f. flow, but also these air bubbles may be congregated

As seen in Fig. 4, in all arrangements, the heat near the inner side of the inner tube (when the

exchanger with air bubble injection were gave higher bubbles are injected into the inner tube) and act as an

insulator. Secondly, outer tube Reynolds number was

International Journal of Automotive Engineering Vol. 4, Number 4, Dec 2014

907 Heat transfer enhancement due to…

Fig4. (a – c): Relationship between Nusselt number and Reynolds number. (d – f ): Comparison between enh Nusselt number with non-

enhanced Nusselt number

International Journal of Automotive Engineering Vol. 4, Number 4, Dec 2014

H. Sadighi Dizaji , S.Jafarmadar 908

Kept constant at 4000 in all conditions whereas indicative of the size of the heat exchanger and it is

the Reynolds number of the inner tube was changed evaluated by,

from 5000 to 16000. Indeed, it can be said that the

velocity of water flow (Reynolds number) may

impress the effect of air bubble injection on heat

transfer rate.

In the air bubble injection into the inner tube,

Where Cmin is the minimum thermal capacity and

Nusselt number increases with increase of n and

it is defined as bellow,

decrease of d. Indeed, the use of plastic tube with

more number of holes increases the number of air

bubbles inside the inner tube. Also, in the same air

flow rate through the plastic tube, smaller holes cause Double pipe heat exchanger effectiveness can be

higher air bubble velocity at the air outlets (the holes calculated with:

on plastic tube). It seems that the influence of d (holes

diameter) is more significant than the influence of n

on the amount of heat transfer rate. To this reason, the

plastic tube with n=40 and d = 0.3 has more positive

efficacy on heat transfer rate compared to the plastic

Maximum possible heat transfer is expressed as

tube with n = 80 and d = 0.7. Indeed, as mentioned

before, big air bubbles may be congregated on the

inner side of the inner tube and act as an insulator. On

the other hand, despite the use of plastic tube with

more number of holes, increases the number of air Heat exchanger effectiveness was calculated for

bubbles inside the inner tube, but also it decreases the all cases. The heat exchanger effectiveness for heat

air bubbles velocity at the outlet of holes on plastic exchanger without air bubble injection was defined as

tube (because the air flow rate through the plastic tube Es.

is constant). n: Heat exchanger effectiveness without air bubble

Generally, it can be concluded that the ratio of n injection. (Non-enhanced)

to d (n/d) is a determinant parameter in these cases. Changes of the E / En with NTU are shown in

Hence, high amount of n to d ratio (n /d) gives more Fig.5a-c. Also, changes of the NTU with Reynolds

heat transfer rate through the horizontal double pipe number are shown in Fig.5d-f. It is observed that with

heat exchanger. It means that, more number of the increase of NTU, the amount of E/ En decreases.

bubbles with the smallest size can be better condition Air bubble injection has increased the effectiveness of

for heat transfer enhancement. heat exchanger. It is observed that with the increase

b) Air bubble injection into the outer tube of heat of Re, the amount of NTU increases. Dependent on

exchanger: air bubbles injection conditions and Reynolds

The influence of the air bubble injection into the number, air bubble injection increased the amount of

outer tube is more than the influence of the air bubble effectiveness about 10% - 40%. Maximum

injection into the inner tube on heat transfer rate. If effectiveness (E/En) was obtained about 40% when

the air bubbles are injected into the outer tube, the air bubbles were injected into the annular space

probable accumulation of the air bubbles can occur on between the two tubes (outer tube). In high amounts

the inner side of the outer tube. And obviously it has of Reynolds numbers or NTU, bubbles size is

no negative affect on heat transfer rate between the important than the number of bubbles. For example,

two tubes. in each of the Fig.5a to Fig.5c, at high amounts of

NTU, “d=0.7” (big air bubbles) have equal or better

effectiveness compared to the “d=0.3”. In other

3.3. Effectiveness words, despite “d=0.3” has more effectiveness at

lower amounts of Reynolds number, but the slope of

The effectiveness-NTU charts can be of great the E/En curve reduction, in “d=0.3” is faster than the

practical utility in design problems. More elaborate other (d=0.7). So the amount of E/En slakes rapidly in

design procedures, requiring analytical expression for “d=0.3”. However, the proficient design of air outlets

these curves. NTU (number of heat transfer units) is (holes on plastic tube) and logical choice of other

International Journal of Automotive Engineering Vol. 4, Number 4, Dec 2014

909 Heat transfer enhancement due to…

parameters can improve the effectiveness of heat exchanger.

Fig5. (a – c) :Relationship between enhanced effectiveness to non – enhanced effectiveness ratio and NTU. (d – f) : Relationship between

NTU and Reynolds number

International Journal of Automotive Engineering Vol. 4, Number 4, Dec 2014

H. Sadighi Dizaji , S.Jafarmadar 910

4. Conclusion [7]. N.M. Nouri, A. Sarreshtehdari, An experimental

study on the effect of air bubble injection on the

The main scope of the present study is to flow induced rotational hub , Exp. Thermal

experimentally clarify the effect of air bubble Fluid Sci 33 (2009) 386–392.

injection on heat transfer rate, number of heat transfer [8]. A. Kitagawa. K. Kitada.Y. Hagiwara,

units and effectiveness in a horizontal double pipe Experimental study on turbulent natural

heat exchanger. Air bubbles were injected at various convection heat transfer in water with sub-

conditions into the heat exchanger. Air bubble millimeter-bubble injection. Exp Fluids 49

injection was found as a promising technique to (2010) 613–622.

increase the heat transfer rate through the horizontal [9]. H. Saffari. R. Moosavi. E. Gholami. N. Nouri,

double pipe heat exchanger in this study, and the key The effect of bubble on pressure drop reduction

findings are summarized as follows: in helical coil, Exp Thermal. Fluid Sci 51

Dependent on air injection condition and (2013) 251–256.

Reynolds number, air bubbles increased the amount [10]. R. Samaroo, N. Kaur, K. Itoh, T. Lee, S.

of Nusselt number about 6% - 35%. Banerjee, M. Kawaji, Turbulent flow

Air bubble injection increased the effectiveness characteristics in an annulus under air bubble

of heat exchanger about 10%- 40%. injection and subcooled flow boiling conditions,

Maximum effectiveness was obtained when air Nuclear Engineering and Design. 268 (2014)

bubbles were injected into the annular space between 203– 214.

the two tubes (outer tube). [11]. P. Naphon, M. Nuchjapo, J. Kurujareon, Tube

Generally, it can be concluded that the ratio of n side heat transfer coefficient and friction factor

to d (n / d) is a considerable parameter in these cases. characteristics of horizontal tubes with helical

However, proficient design of holes on plastic tube rib, Energy Conversion and Management 47

and logical choice of their number and diameter can (2006) 3031–3044.

improve the performance of heat exchangers. [12]. J. Rose, Heat-transfer coefficients, Wilson plots

and accuracy of thermal measurements,

References Experimental Thermal and Fluid Science, 28,

77–86, 2004.

[1]. A. Kitagawa, K. Kosuge, K. Uchida, Y. [13]. K. Wongcharee, .S. Eiamsa-ard, Heat transfer

Hagiwara, Heat transfer enhancement for enhancement by using CuO/water nanofluid in

laminar natural convection along a vertical plate corrugated tube equipped with twisted tape, Int.

due to sub-millimeter-bubble injection, Exp Comm. Heat Mass Transfer 39(2012) 251–257.

Fluids. 45 (2008) 473–484. [14]. S. Pethkool, S. Eiamsa-ard, S. Kwankaomeng,

[2]. P. Vlasogiannis, G. Karagiannis, P. P. Promvonge, Turbulent heat transfer

Argyropoulos, V. Bontozoglou, Air–water two- enhancement in a heat exchanger using helically

phase flow and heat transfer in a plate heat corrugated tube, Int. Comm. Heat Mass Transfer

exchanger, International Journal of Multiphase 38 (2011) 340–347.

Flow 28, 577-772, 2002. [15]. N. Jamshidi, M. Farhadi, D.D. Ganji, K.

[3]. S. Oh, H. Kwak, A Study of Bubble Behavior Sedighi, Experimental analysis of heat transfer

and Boiling Heat Transfer Enhancement under enhancement in shell and helical tube heat

Electric Field, Heat Transfer Engineering 21, exchangers, Applied Thermal Eng. 51, 644–652,

33–45, 2000. 2013.

[4]. C. Gabillet, C. Colin, J. Fabre, Experimental [16]. H. Shokouhmand, M.R. Salimpour, M.A.

study of bubble injection in a turbulent Akhavan-Behabadi, Experimental investigation

boundary layer, Int. J. Multiphase Flow28 of shell and coiled tube heat exchangers using

(2002) 553–578. Wilson plots, International Communications in

[5]. D. FunfschillIng ,H. Z. LI, Effects of the Heat and Mass Transfer 35 (2008) 84–92.

injection period on the rise velocity and shape

of a bubble in a non-newtonina fluid, Int.

Chemical Engineers 84 (2006) 875–883.

[6]. H. Ide ,R. Kimura, M. Kawaji, Optical

Measurement of Void Fraction and Bubble Size

Distributions in a Microchannel, Int. Heat

Transfer Engineering 28, 713–719, 2007.

International Journal of Automotive Engineering Vol. 4, Number 4, Dec 2014

You might also like

- Charging A Grounded Conducting RodDocument3 pagesCharging A Grounded Conducting RodrtcaluyaNo ratings yet

- Heat Transfer Analysis of Integral-Fin TubesDocument12 pagesHeat Transfer Analysis of Integral-Fin Tubeshermez19No ratings yet

- A Review of Heat Transfer and Pressure Drop Correlations For Laminar Flow in Curved Circular DuctsDocument26 pagesA Review of Heat Transfer and Pressure Drop Correlations For Laminar Flow in Curved Circular DuctsRiddhesh PatelNo ratings yet

- Physics of SkatingDocument12 pagesPhysics of SkatingCeline YâùNo ratings yet

- Chapter 09 HomeworkDocument27 pagesChapter 09 HomeworkFatboy9194% (17)

- Natural Convection Heat Transfer in Vertical Internally Finned TubeDocument10 pagesNatural Convection Heat Transfer in Vertical Internally Finned TubeAdarsh Kumar AngNo ratings yet

- International Communications in Heat and Mass Transfer: SciencedirectDocument11 pagesInternational Communications in Heat and Mass Transfer: SciencedirecthjggNo ratings yet

- Optimization of Heat Transfer and Pressure Drop Characteristics Via Air Bubble Injection Inside A Shell and Coiled Tube Heat ExchangerDocument9 pagesOptimization of Heat Transfer and Pressure Drop Characteristics Via Air Bubble Injection Inside A Shell and Coiled Tube Heat Exchangerहरिओम हरीNo ratings yet

- Chapter Two: Literature ReviewDocument7 pagesChapter Two: Literature ReviewDiyar NezarNo ratings yet

- Method For Evaluating The Effect of Inclination On The Performance of Large Flattened-Tube Steam Condensers With Visualization of Flow RegimesDocument11 pagesMethod For Evaluating The Effect of Inclination On The Performance of Large Flattened-Tube Steam Condensers With Visualization of Flow Regimesnikhil gulhaneNo ratings yet

- An Experimental Investigation of Turbulent Forced-Convection Into A Horizontal Finned Eccentric AnnulusDocument13 pagesAn Experimental Investigation of Turbulent Forced-Convection Into A Horizontal Finned Eccentric Annulusمحمد جواد فاضل / ميكانيك عامNo ratings yet

- Research On Heat Transfer Coefficient of Horizontal Tube Falling Film Evaporator PDFDocument7 pagesResearch On Heat Transfer Coefficient of Horizontal Tube Falling Film Evaporator PDFdonyaNo ratings yet

- Geometric Modifications and Their Impact On The Performance of The Vortex TubeDocument12 pagesGeometric Modifications and Their Impact On The Performance of The Vortex Tubeabcpqr123456No ratings yet

- Study and Analysis On Boiler Tubes For Performance Enhancement With Varying Corrugated Tube ShapesDocument6 pagesStudy and Analysis On Boiler Tubes For Performance Enhancement With Varying Corrugated Tube ShapesukachukwuNo ratings yet

- Accepted Manuscript: Experimental Thermal and Fluid ScienceDocument25 pagesAccepted Manuscript: Experimental Thermal and Fluid Scienceali engnNo ratings yet

- SSRN Id3368815Document7 pagesSSRN Id3368815Syed AmirNo ratings yet

- Applied Thermal Engineering: Ya-Ling He, Pan Chu, Wen-Quan Tao, Yu-Wen Zhang, Tao XieDocument14 pagesApplied Thermal Engineering: Ya-Ling He, Pan Chu, Wen-Quan Tao, Yu-Wen Zhang, Tao XieGagan DeepNo ratings yet

- Heat Transfer Enhancement in A Circular Tube Twisted With Swirl Generator: A ReviewDocument5 pagesHeat Transfer Enhancement in A Circular Tube Twisted With Swirl Generator: A ReviewAvinash RoshanNo ratings yet

- Heat and Mass Transfer of Ammonia-Water in Falling Film EvaporatorDocument9 pagesHeat and Mass Transfer of Ammonia-Water in Falling Film Evaporatorcemal gümrükçüoğluNo ratings yet

- Allison DallyDocument15 pagesAllison Dallykalyan1492No ratings yet

- ThesisDocument46 pagesThesisManideep AnanthulaNo ratings yet

- Zheng 2016Document12 pagesZheng 2016PriamdanduNo ratings yet

- Heat Transfer Processes and Equipment in The Detergent IndustryDocument17 pagesHeat Transfer Processes and Equipment in The Detergent Industryعبدالمحسن علي ENo ratings yet

- IETEPune2094ijarseDocument13 pagesIETEPune2094ijarseVictor BettNo ratings yet

- Flow and Convective Heat Transfer Characteristics of Spiral Pipe For NanofluidsDocument13 pagesFlow and Convective Heat Transfer Characteristics of Spiral Pipe For NanofluidsjegjegtNo ratings yet

- Applied Energy: Junye WangDocument8 pagesApplied Energy: Junye WangResearcherzNo ratings yet

- Review of Experiment On Spiral Heat ExchangerDocument4 pagesReview of Experiment On Spiral Heat ExchangerEditor IJIRMFNo ratings yet

- 3 Design and Thermal Analysis of Segmental Baffle and Helical Baffle in Shell and Tube Heat Exchangers Using Kern Method PDFDocument7 pages3 Design and Thermal Analysis of Segmental Baffle and Helical Baffle in Shell and Tube Heat Exchangers Using Kern Method PDFserious96No ratings yet

- PHD - Condensation Heat Transfer and Pressure Drop of Hfc-134a in A Helically Coiled Concentric Tube-In-tube Heat ExchangerDocument13 pagesPHD - Condensation Heat Transfer and Pressure Drop of Hfc-134a in A Helically Coiled Concentric Tube-In-tube Heat ExchangerHassan AgNo ratings yet

- Design and Thermal Analysis of Segmental Baffle and Helical Baffle in Shell and Tube Heat Exchangers Using Kern MethodDocument7 pagesDesign and Thermal Analysis of Segmental Baffle and Helical Baffle in Shell and Tube Heat Exchangers Using Kern MethodIJAERS JOURNALNo ratings yet

- Ijaiem 2014 08 09 12Document3 pagesIjaiem 2014 08 09 12International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- CFD Investigation of Heat Transfer and Flow Patterns in Tube Side Laminar Flow and The Potential For EnhancementDocument6 pagesCFD Investigation of Heat Transfer and Flow Patterns in Tube Side Laminar Flow and The Potential For EnhancementRipmi KamandanuNo ratings yet

- Researchpaper Review On Twisted Tapes Heat Transfer EnhancementDocument9 pagesResearchpaper Review On Twisted Tapes Heat Transfer EnhancementShreyas RathoreNo ratings yet

- Rdme 7Document5 pagesRdme 7emir123456No ratings yet

- Enhancement of Heat Transfer Through Air Jet Impingement by Using Axisymmetric Detached RibsDocument24 pagesEnhancement of Heat Transfer Through Air Jet Impingement by Using Axisymmetric Detached RibsRohan GulavaniNo ratings yet

- 6 PDFDocument5 pages6 PDFmukesh poundekarNo ratings yet

- Thermal Performance of A Premixed Impinging Circular Ame Jet Array With Induced-SwirlDocument8 pagesThermal Performance of A Premixed Impinging Circular Ame Jet Array With Induced-Swirl邱志斌No ratings yet

- Forced ConvectionDocument9 pagesForced ConvectionAmeer ShNo ratings yet

- Heat Transfer in The Transitional Flow Regime: September 2011Document17 pagesHeat Transfer in The Transitional Flow Regime: September 2011JAIR DIEGO VIDAURRE QUISPENo ratings yet

- Arsana 2020 J. Phys. Conf. Ser. 1569 042091 PDFDocument8 pagesArsana 2020 J. Phys. Conf. Ser. 1569 042091 PDFMita syantikNo ratings yet

- Fabrication and Experimental Analysis of A Vortex Tube Refrigeration SystemDocument6 pagesFabrication and Experimental Analysis of A Vortex Tube Refrigeration SystemMaheshNo ratings yet

- Natural Convection Over A Flat Plate From Side To Side EnclosuresDocument6 pagesNatural Convection Over A Flat Plate From Side To Side EnclosuresInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- VVVVVVBNNJJJDocument9 pagesVVVVVVBNNJJJShubham JaiswalNo ratings yet

- Hydrodynamics and Heat Transfer Characteristics of A Novel Heat Exchanger With Delta-Winglet Vortex Generators - 2010Document12 pagesHydrodynamics and Heat Transfer Characteristics of A Novel Heat Exchanger With Delta-Winglet Vortex Generators - 2010Imam SyarifudinNo ratings yet

- Air Pressure Dependence of Natural-Convection HeatDocument5 pagesAir Pressure Dependence of Natural-Convection HeatNatalia SouzaNo ratings yet

- Vapor Mistlift OtecDocument6 pagesVapor Mistlift OtecemergingengineerNo ratings yet

- Processes 09 00939 v2Document19 pagesProcesses 09 00939 v2selisenNo ratings yet

- Heat Transfer Analysis of Triple Tube Heat Exchanger Using Water and Titanium-Dioxide Nano UidDocument4 pagesHeat Transfer Analysis of Triple Tube Heat Exchanger Using Water and Titanium-Dioxide Nano UidrssardarNo ratings yet

- Heat Transfer in A Horizontal Coiled Pipe in A Transient Regime and at A Near-Critical Pressure of A FluidDocument5 pagesHeat Transfer in A Horizontal Coiled Pipe in A Transient Regime and at A Near-Critical Pressure of A FluidM. SukarmanNo ratings yet

- Numerical Investigation of Heat Transfer Coefficient in Ribbed Rectangular Duct With Various Shaped Ribs and Different CoolantsDocument4 pagesNumerical Investigation of Heat Transfer Coefficient in Ribbed Rectangular Duct With Various Shaped Ribs and Different CoolantsedNo ratings yet

- Haryoko 2020 IOP Conf. Ser. Earth Environ. Sci. 463 012030Document7 pagesHaryoko 2020 IOP Conf. Ser. Earth Environ. Sci. 463 012030Luthfi AdyNo ratings yet

- Experimental and Numerical Study of Gas-Solid Flow Behavior in The Standpipe of A Circulating Fluidized BedDocument12 pagesExperimental and Numerical Study of Gas-Solid Flow Behavior in The Standpipe of A Circulating Fluidized BedLaith jaafer HabeebNo ratings yet

- Plagarism PDFDocument45 pagesPlagarism PDFrahulpeddakotlaNo ratings yet

- Experimental Investigation On Forced Convection Over A Rough Flat Plate and Related ImplicationsDocument5 pagesExperimental Investigation On Forced Convection Over A Rough Flat Plate and Related ImplicationsInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Electronic Cooling Using Synthetic Jet ImpingementDocument11 pagesElectronic Cooling Using Synthetic Jet ImpingementEKKACHAI PRABNAKORNNo ratings yet

- A Comprehensive Numerical Study On Nanofluid FlowDocument13 pagesA Comprehensive Numerical Study On Nanofluid FlowIrIFM IUSTNo ratings yet

- Flow Instabilities in A Horizontal Thermosyphon Reboiler LoopDocument22 pagesFlow Instabilities in A Horizontal Thermosyphon Reboiler Loopwylie01No ratings yet

- J Enconman 2006 03 034Document16 pagesJ Enconman 2006 03 034sergioteroNo ratings yet

- Thermodynamic Effects During Growth and Collapse of A Single Cavitation BubbleDocument23 pagesThermodynamic Effects During Growth and Collapse of A Single Cavitation BubbleHéctor ParrAlNo ratings yet

- Numerical Study and Visualization On Flow Characteristics of Reflux CondensationDocument32 pagesNumerical Study and Visualization On Flow Characteristics of Reflux CondensationAnthony LobatoNo ratings yet

- Heat and Moisture Transfer between Human Body and EnvironmentFrom EverandHeat and Moisture Transfer between Human Body and EnvironmentNo ratings yet

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManFrom EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManNo ratings yet

- Preliminary: Not Released For Fabrication!Document2 pagesPreliminary: Not Released For Fabrication!SonNguyenNo ratings yet

- Preliminary: Not Released For Fabrication!Document2 pagesPreliminary: Not Released For Fabrication!SonNguyenNo ratings yet

- Quotation - Iwisu - Samec-3-1-2020Document1 pageQuotation - Iwisu - Samec-3-1-2020SonNguyenNo ratings yet

- CITECH Company Profile - 2020Document18 pagesCITECH Company Profile - 2020SonNguyenNo ratings yet

- Test-02-Static With Fillet WeldDocument16 pagesTest-02-Static With Fillet WeldSonNguyenNo ratings yet

- Preliminary: Not Released For Fabrication!Document1 pagePreliminary: Not Released For Fabrication!SonNguyenNo ratings yet

- Preliminary: Not Released For Fabrication!Document1 pagePreliminary: Not Released For Fabrication!SonNguyenNo ratings yet

- Preliminary: Not Released For Fabrication!Document3 pagesPreliminary: Not Released For Fabrication!SonNguyenNo ratings yet

- Preliminary: GermanyDocument3 pagesPreliminary: GermanySonNguyenNo ratings yet

- 000-OkDocument2 pages000-OkSonNguyenNo ratings yet

- 100% Volume 5 M: PreliminaryDocument3 pages100% Volume 5 M: PreliminarySonNguyenNo ratings yet

- Niewiadomsky, AngelikaDocument1 pageNiewiadomsky, AngelikaSonNguyenNo ratings yet

- B-RO-M-TS-3034 - R13 (DUAL MEDIA FILTER) 1 OF 2-LayoutDocument1 pageB-RO-M-TS-3034 - R13 (DUAL MEDIA FILTER) 1 OF 2-LayoutSonNguyenNo ratings yet

- 7854-Hds-2e2301 Rev 8Document3 pages7854-Hds-2e2301 Rev 8SonNguyenNo ratings yet

- Cliente / Customer Commessa N. / Job No. Impianto / Plant Water Treatment Plant - Sand Filters - Disegno N. / DWG NoDocument8 pagesCliente / Customer Commessa N. / Job No. Impianto / Plant Water Treatment Plant - Sand Filters - Disegno N. / DWG NoSonNguyenNo ratings yet

- XPXXXX XBXX M2100 AD001 - 001 - 00 Layout1 PDFDocument1 pageXPXXXX XBXX M2100 AD001 - 001 - 00 Layout1 PDFSonNguyenNo ratings yet

- 8303344R 001-TrspDocument1 page8303344R 001-TrspSonNguyenNo ratings yet

- Circumferential Seam L.S. Longitudinal Seam L.S.H. Longitudinal Seam HeadDocument1 pageCircumferential Seam L.S. Longitudinal Seam L.S.H. Longitudinal Seam HeadSonNguyenNo ratings yet

- 8670 HAP3135 - HDS - REV 1 (250NB #2500 U Stamp)Document3 pages8670 HAP3135 - HDS - REV 1 (250NB #2500 U Stamp)SonNguyenNo ratings yet

- 8670 HAP3125 - HDS - REV 1 (150NB #600 U Stamp)Document3 pages8670 HAP3125 - HDS - REV 1 (150NB #600 U Stamp)SonNguyenNo ratings yet

- Electric Heater Datasheet: Domgas PreheaterDocument3 pagesElectric Heater Datasheet: Domgas PreheaterSonNguyenNo ratings yet

- Electric Heater Datasheet: Duty Bundle (@nom Voltage) Duty Heater (@nom Voltage)Document3 pagesElectric Heater Datasheet: Duty Bundle (@nom Voltage) Duty Heater (@nom Voltage)SonNguyenNo ratings yet

- VD164-PP-PLT-004 Section View ModelDocument1 pageVD164-PP-PLT-004 Section View ModelSonNguyenNo ratings yet

- Enquiry List of EquipmentsDocument4 pagesEnquiry List of EquipmentsSonNguyenNo ratings yet

- Appendix 3.2 - Technical Confirmation TableDocument6 pagesAppendix 3.2 - Technical Confirmation TableSonNguyenNo ratings yet

- Equipment Drawing List: No. Drawing No. Tag No. Description Q'tyDocument7 pagesEquipment Drawing List: No. Drawing No. Tag No. Description Q'tySonNguyenNo ratings yet

- Part A - Instruction For QuotationDocument10 pagesPart A - Instruction For QuotationSonNguyenNo ratings yet

- General Arrangement For Platform & Ladder Acf Condensate Carbon Filter PackageDocument5 pagesGeneral Arrangement For Platform & Ladder Acf Condensate Carbon Filter PackageSonNguyenNo ratings yet

- Catalogue Gentec-EO V2.01Document112 pagesCatalogue Gentec-EO V2.01nonoy_sgNo ratings yet

- Grade 8 Chemistry Unit Planner 1 2015 16Document14 pagesGrade 8 Chemistry Unit Planner 1 2015 16Anupa Medhekar100% (9)

- Motion in Two or Three DimesionsDocument7 pagesMotion in Two or Three Dimesionsminh hoàng nguyễnNo ratings yet

- Heat Conduction in A Long Solid Rod: Experiment 2, Part 1Document6 pagesHeat Conduction in A Long Solid Rod: Experiment 2, Part 1Hassan TalhaNo ratings yet

- Chpt07-FEM For Plates & ShellsnewDocument32 pagesChpt07-FEM For Plates & Shellsnewernestnsabimana74No ratings yet

- Micronote #101Document2 pagesMicronote #101eng,amNo ratings yet

- Experiment 1 Moment of Inertia and Angular MomentumDocument3 pagesExperiment 1 Moment of Inertia and Angular MomentumRikachuNo ratings yet

- Pumping Energy and Variable Frequency DrivesDocument4 pagesPumping Energy and Variable Frequency DrivesHerman Dwi NoviantoNo ratings yet

- heat transfer one ملزمة PDFDocument40 pagesheat transfer one ملزمة PDFمحمد باسلNo ratings yet

- A Process Design EngineerDocument10 pagesA Process Design EngineerjokishNo ratings yet

- Psychology As A Biological ScienceDocument1,113 pagesPsychology As A Biological ScienceAlex Rodriguez100% (1)

- Isbn-13: 978-0078028182 Isbn-10: 0078028183Document24 pagesIsbn-13: 978-0078028182 Isbn-10: 0078028183pham minhNo ratings yet

- Variation of Velocity and Acceleration in Suction and Delivery Pipes Due To Acceleration of PistonDocument9 pagesVariation of Velocity and Acceleration in Suction and Delivery Pipes Due To Acceleration of PistonSAATVIK JAINNo ratings yet

- TH Solution Vector AnalysisDocument2 pagesTH Solution Vector AnalysisShinjiYumikuraNo ratings yet

- Nptel: Chemical Process InstrumentationDocument76 pagesNptel: Chemical Process InstrumentationSaurav SatyarthiNo ratings yet

- 0 - Model HMT Question PaperDocument2 pages0 - Model HMT Question PaperAshish RanjanNo ratings yet

- PhysicsDocument68 pagesPhysicsMišel VuittonNo ratings yet

- STRAINDocument30 pagesSTRAINMelanie SamsonaNo ratings yet

- Modeling of Harmonic Sources Magnetic Core SaturationDocument7 pagesModeling of Harmonic Sources Magnetic Core SaturationratheeshkumardNo ratings yet

- Pi Phase 2Document2 pagesPi Phase 2ranaateeqNo ratings yet

- Double Angle CapacityDocument2 pagesDouble Angle CapacityAmey GudigarNo ratings yet

- Telegram Channel Telegram GroupDocument221 pagesTelegram Channel Telegram GroupSapna RaiNo ratings yet

- Mit ExamDocument11 pagesMit ExamAli RostamiNo ratings yet

- GPR Sample Report & MethodologyDocument211 pagesGPR Sample Report & MethodologyMari Muthu100% (1)

- Cable 4 PDFDocument46 pagesCable 4 PDFmuhammadshafiq69No ratings yet

- Student Exploration: IsotopesDocument3 pagesStudent Exploration: Isotopestmorales1726No ratings yet

- MIT8 02SC Notes16to18Document30 pagesMIT8 02SC Notes16to18GeorgeChangNo ratings yet