Professional Documents

Culture Documents

Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number

Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number

Uploaded by

sudipta dasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number

Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number

Uploaded by

sudipta dasCopyright:

Available Formats

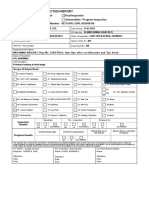

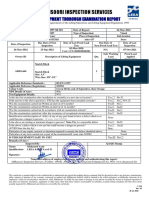

INSPECTION REPORT

Report of Final Inspection

Intermediate / Progress Inspection

QETO

QUALITY SERVICES Report Number QETO/EMPL/NSEI/SUD-PRG/00198

Client: M/s NIPPON STEEL ENGINEERING INDIA Date of Insp.: 01.08.2021

PVT. LTD.

Purchase Order No. NTBC2004FA1000000, dt.08.03.21 PO Line No:

Contractor M/s VISESH ENTERPRISE Place of Inspection Dasnagar, Howrah

Subcontractor NA Manuf. Order No.

QAP NoVE/QA/NSEI/20-21/02, Dtd. 29.03.21 Data Sheet No. NA

Equipment Description:

Rolled and Forged items for Bucket and Carriage

Basis of Inspection:

PO

Test Condition:

Status Review

Scope of Inspections:

01. Manuf. Progress 09. Fit-up / Alignment Check 17. Assembly 25. Completeness

02. QAP / QCP Verification 10. Dimensional Checks 18. Performance 26. Marking

03. Welder Qualification 11. Welds Edge Preparation 19. Functional Test 27. Environment-Health-Safety

OK

04.Material Identification 12. Visual Check of Welds 20. Test Run 28. Inst. calibration verified.

Not OK

05. Lab Witness of Samples 13. NDTUT 21. Strip Test 29. others

06. Inspection Documents 14. Hardness 22. PMI Test 30.others

07. Visual Condition 15. Load Test 23. Surface Preparation 31.others

08. Workmanship 16. Pressure / Tightness 24. Painting / Protection 32.others

Objections: Re – Inspection: Released for

Inspection

Results:

yes no see remarks yes no see remarks yes no see remarks

Earliest Date acc. to Delivery date acc. estimation

Contract Delivery Date Confirmed by Manufacturer

manufacturer of inspector

Progress Results

yes no see remarks

This inspection does not release the manufacturer / contractor from any contractual obligations to the purchaser also in case of discrepancies occurring after delivery or within the

period of guaranty. Any defects / deviations observed on receipt of materials at Client’s works / sites shall be intimated to the manufacturer. It is the responsibility of the manufacturer to

rectify / replace the defective material in time and free of cost. Anti-rust must be applied on all the machined surface before dispatch.

For QETO – Quality Services For Contractor / Subcontractor For Client Representative

Inspector:SUDIPTA DAS Name: VISESH JAISWAL Name:

Signature: Signature: Signature:

Date: Date: Date:

Seal: Seal: Seal:

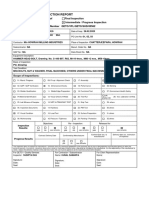

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.02 Page 1 of 6

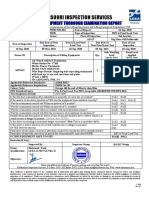

presented

required

Test Documents

discussed not discussed

Material Certificates acc. to specification -

Welding Filler Material Certificates

Dimensions Records / Drawings containing nominal and actual dimensions

Heat Treatment Certificates

Inspection Reports prepared by manufacturers Quality Control Department

Official Certificates of Inspection Authority

Pressure / Tightness Test Certificates

Records of NDT Testing UT Report

Welders Qualification Certificates

Works Certificates

Painting Certificate

Hardness Test Report

Field report of mechanical and chemical tests

Others

Others

Others

Others

Inspection documents handed over during inspection

Inspection documents will be handed over by

Observations / Details of Inspection carried out:

Materials are under different stages of manufacturing as per detail list attached herewith

Conclusion: Status of manufacturing of above mentioned PO verified physically. Detailed

report attached.

For QETO – Quality Services For Contractor / Subcontractor For Client Representative

Inspector: SUDIPTA DAS Name: VISHES JAISWAL Name:

Signature: Signature: Signature:

Date: Date: Date:

Seal: Seal: Seal:

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.02 Page 2 of 6

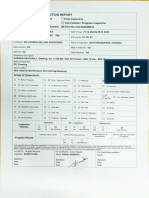

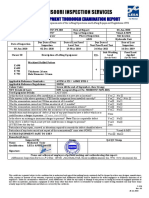

Small Forging - Status as on

16th Jul 21

5230-Bucket-Small Forging

List

Sl. Drawing Mark Item Material- Qty Heat Treatment Machining Status Final

No. No. No. Description HT for 3 Status (Mention Qty wise) Surface

Sets (Mention Qty Heat

wise) Treatment

(IH) Status

(Mention

Qty wise)

1 EAXX05C5 Pin 45C8-T3 12 Normalising Rough machining Not

230612 done complete Applicable

3

2 EAXX05C5 Pin 45C8-T3 12 Normalising Rough machining Not

230612 done complete Applicable

4

3 EAXX05C5 5 Roller 45C8-T14 12 NOT YET DONE Rough machining NOT YET

230612 not started yet. DONE

13pcs found in cut to

length size from

rolled bar.

4 EAXX05C5 6 Roller 45C8-T14 12 NOT YET DONE Not verified NOT YET

230612 physically due to DONE

workshop was

closed. As per

supplier 13pcs are in

cut to length size

from rolled bar.

5 EAXX05C5 Roller 45C8-T3 12 Normalising Rough machining Not

230614 done complete Applicable

1

6 EAXX05C5 3 Pin 45C8-T3 24 Normalising Rough machining Not

230614 done complete Applicable

7 EAXX05C5 3 Plate 45C8-T3 12 Under Rough machining Not

230619 normalising complete Applicable

(inside HT

furnace)

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.02 Page 3 of 6

5210-Carriage-Small Forging

List

Sl. Drawing No. Mark Item Material Qty Heat Treatment Machining Status Final

No. No. Descript for 3 Status (Mention Qty wise) Surface

ion Sets (Mention Qty Heat

wise) Treatment

Status

(Mention

Qty wise)

1 EAXX05C5210 2 Bush 35C8-T3 NOT YET DONE Machining not Not

606 started yet.7pcs Applicable

6

found in as forged

condition

2 EAXX05C5210 Sleeve 35C8-T3 NOT YET DONE Rough machining NOT YET

72

606 9 complete for 73pcs DONE

3 EAXX05C5210 Plate 35C8-T3 Under Rough machining Not

608 normalising complete Applicable

6

(inside HT

3 furnace)

4 EAXX05C5210 3 Spacer 35C8-T3 NOT YET DONE Rough machining NOT YET

614 complete for 17pcs. DONE

Rest 3pcs under

24

machining and 4pcs

found in as forged

condition

5 EAXX05C5210 2 Brake 35C8-T3 NOT YET DONE 8pcs found in as NOT YET

618 Housing forged condition. DONE

Condition of rest pcs

12 could not be verified

due to closed

workshop at

Belgachia

6 EAXX05C5210 Reamer 45C8-T14 NOT YET DONE Under forging as Not

618 Bolt conveyed by the Applicable

144

supplier. Not

4 verified physically.

7 EAXX05C5210 Spacer 35C8-T3 NOT YET DONE Rough machining Not

618 complete except Applicable

144

centre bore for total

7 quantity.

8 EAXX05C5210 4 Bush 42CrMo4 Hardening Rough machining NOT YET

620 +QT done. complete DONE

Tempering

6

awaited as

hardness level

not specified

9 EAXX05C5210 6 Bush 42CrMo4 Hardening Rough machining Not

620 +QT done. complete Applicable

Tempering

12

awaited as

hardness level

not specified

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.02 Page 4 of 6

Photographs

5230

5210

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.02 Page 5 of 6

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.02 Page 6 of 6

You might also like

- IQ, OQ, PQ Protocol PREMIX MACHINE BlenderDocument29 pagesIQ, OQ, PQ Protocol PREMIX MACHINE BlenderF87 Operators100% (2)

- Sample Template Itp For Piping Fabrication and InstallationDocument10 pagesSample Template Itp For Piping Fabrication and Installationmohd as shahiddin jafri100% (1)

- How Amazon Is Changing Supply Chain ManagementDocument13 pagesHow Amazon Is Changing Supply Chain ManagementBATRA INFOTEC100% (1)

- Prelim ExaminationDocument46 pagesPrelim ExaminationJenny Rose M. YocteNo ratings yet

- Deckblatt - : First Sample Test Report VDADocument9 pagesDeckblatt - : First Sample Test Report VDAJuliaNo ratings yet

- Sample ChecklistDocument3 pagesSample ChecklistrkssNo ratings yet

- Getting Started With Data Governance Using COBIT 5 - Res - Eng - 1017 PDFDocument20 pagesGetting Started With Data Governance Using COBIT 5 - Res - Eng - 1017 PDFSot racNo ratings yet

- IR204 - Siddheswari Evaluation - SUD 06.08.21Document2 pagesIR204 - Siddheswari Evaluation - SUD 06.08.21sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00196Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00196sudipta dasNo ratings yet

- Ir562 Hmi 28.02.23Document2 pagesIr562 Hmi 28.02.23Pinki Mitra DasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194Document2 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00197Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00197sudipta dasNo ratings yet

- Qeto Report - 00531Document2 pagesQeto Report - 00531Pinki Mitra DasNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- SAIC-RT-2001 Revw of RT ProcedureDocument1 pageSAIC-RT-2001 Revw of RT ProcedureKirubhakarPooranamNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Cherry Picker MTCDocument2 pagesCherry Picker MTCeldhoNo ratings yet

- Hydro Test ProcedureDocument5 pagesHydro Test ProcedureBharat BhoirNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument5 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Inspection and Test PlanDocument2 pagesInspection and Test PlantayyabNo ratings yet

- Pressure Test ReportDocument9 pagesPressure Test Reportjaysonquitelgonzales06No ratings yet

- Project Eagle: Quality Management Inspection ReportDocument2 pagesProject Eagle: Quality Management Inspection ReportrcpretoriusNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- IQWQ-CE1091-VPNDT-00-2566 - A PT ProcedureDocument23 pagesIQWQ-CE1091-VPNDT-00-2566 - A PT Procedurejacksonbello34No ratings yet

- BOP Plate Load Test Cert. DILJITH 1 NOV-20Document2 pagesBOP Plate Load Test Cert. DILJITH 1 NOV-20RanjithNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument4 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- NDT Request Form: Project Quality Assurance & ControlDocument1 pageNDT Request Form: Project Quality Assurance & ControlIzar Irhamni, ST100% (1)

- Ca NC-02Document51 pagesCa NC-02Nikshit RafaliyaNo ratings yet

- Saudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 18-May-05 HvacDocument1 pageSaudi Aramco Test Report: On-Site Built-Up Shower Receptor Watertightness Test SATR-S-4006 18-May-05 HvacNoor Mohamed AzeezNo ratings yet

- Appendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementDocument37 pagesAppendix 2 - Inspection & Test Plan, Forms and Check Lsit, and Method of StatementMohammed AlbayatiNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Ray Itp For PaitingDocument18 pagesRay Itp For PaitingVinayaga MoorthiNo ratings yet

- 2 Pre & Post-Concreting Check List - FootingsDocument2 pages2 Pre & Post-Concreting Check List - Footingsgopi.bcimNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- ELECT-TIC-2.8 (Torque Testing and Final Inspection)Document4 pagesELECT-TIC-2.8 (Torque Testing and Final Inspection)Muhammad IrfanNo ratings yet

- Precommissioning Checklist of Pa SystemDocument1 pagePrecommissioning Checklist of Pa SystemTamer EidNo ratings yet

- Snatch Block VisualDocument10 pagesSnatch Block VisualRanjithNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/114Document2 pagesInspection Report: IR No.: QETO/IR/SUD/114sudipta dasNo ratings yet

- Abj 89 103778 Ba 6070 00024 0000 01Document16 pagesAbj 89 103778 Ba 6070 00024 0000 01Nithin GNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/115Document2 pagesInspection Report: IR No.: QETO/IR/SUD/115sudipta dasNo ratings yet

- SATR-A-2001 Pressure Test ReportDocument8 pagesSATR-A-2001 Pressure Test Reportjohn ajitNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument9 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/119Document2 pagesInspection Report: IR No.: QETO/IR/SUD/119sudipta dasNo ratings yet

- Visual Test Procedure: P & S Technical Consultant and Serviced Co.,Ltd Visual Examination ReportDocument2 pagesVisual Test Procedure: P & S Technical Consultant and Serviced Co.,Ltd Visual Examination Reportpstechnical_43312697100% (1)

- Manufacturin Quality Plan: Sheet No.: Page 1 of 23Document23 pagesManufacturin Quality Plan: Sheet No.: Page 1 of 23ashiihsaNo ratings yet

- Satr W 2012Document1 pageSatr W 2012Mohammed Hamed BaganNo ratings yet

- SAIC-W-2009 Revw-Control of Weld Consum - On PlotDocument1 pageSAIC-W-2009 Revw-Control of Weld Consum - On PlotAnonymous S9qBDVkyNo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- IRN For QC 64210-1 Ansao Venturi Pin (1-800)Document1 pageIRN For QC 64210-1 Ansao Venturi Pin (1-800)Senthil KumarNo ratings yet

- 021-Checklist For Trial Mix and Testing For Concrete Repair MaterialDocument1 page021-Checklist For Trial Mix and Testing For Concrete Repair MaterialAlvin BastianNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/116Document1 pageInspection Report: IR No.: QETO/IR/SUD/116sudipta dasNo ratings yet

- Satip A 000 01Document10 pagesSatip A 000 01Akansha SharmaNo ratings yet

- Barrel Lifter VisualDocument1 pageBarrel Lifter VisualRanjithNo ratings yet

- Liquid Penetrant Inspection Report: Industrial Proforma FormDocument1 pageLiquid Penetrant Inspection Report: Industrial Proforma FormJohn DolanNo ratings yet

- SAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalDocument1 pageSAIC-A-1017 Rev 8 HDPE Liner Final Inspection FinalGOSP3 QC MechanicalNo ratings yet

- Itp FinalDocument5 pagesItp Finalchristopher Adajo100% (1)

- Qality Assurance Inspection and Test Plan: Piping Fabrication & InstallationDocument16 pagesQality Assurance Inspection and Test Plan: Piping Fabrication & Installationmanoj thakkarNo ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test ReportziaNo ratings yet

- Form 02 Crane Inspection FormDocument2 pagesForm 02 Crane Inspection FormDenny SyafwalufiNo ratings yet

- Revised Rate List Under The West Bengal Health Scheme, 2008 (Notification No. 796-F (MED) Dated 31-01-2011)Document110 pagesRevised Rate List Under The West Bengal Health Scheme, 2008 (Notification No. 796-F (MED) Dated 31-01-2011)sudipta dasNo ratings yet

- West Bengal Health Scheme, 2008 Form E: Checklist For Reimbursement of Medical Claims/ Sanction of AdvanceDocument2 pagesWest Bengal Health Scheme, 2008 Form E: Checklist For Reimbursement of Medical Claims/ Sanction of Advancesudipta dasNo ratings yet

- West Bengal Health Scheme, 2008: Engineering Institute For Junior ExecutivesDocument3 pagesWest Bengal Health Scheme, 2008: Engineering Institute For Junior Executivessudipta dasNo ratings yet

- Form C: NONGPF/WB/20171123114956897/1/5 Sudipta DasDocument3 pagesForm C: NONGPF/WB/20171123114956897/1/5 Sudipta Dassudipta dasNo ratings yet

- Qeto - Quality Services: Ultrasonic Test ReportDocument1 pageQeto - Quality Services: Ultrasonic Test Reportsudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194Document2 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00194sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00195sudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00197Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/AD/JSPL/SUD/00197sudipta dasNo ratings yet

- Qeto - Quality Services: Ultrasonic Test ReportDocument1 pageQeto - Quality Services: Ultrasonic Test Reportsudipta dasNo ratings yet

- Qeto - Quality Services: Penetrant Test ReportDocument1 pageQeto - Quality Services: Penetrant Test Reportsudipta dasNo ratings yet

- Inspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00196Document3 pagesInspection Report: Report of Final Inspection Intermediate / Progress Inspection Report Number QETO/VFL/JSPL/SUD/00196sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/114Document2 pagesInspection Report: IR No.: QETO/IR/SUD/114sudipta dasNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Total Qty - 4 Nos Material - UNS F33100 / ASTM A536 65-45-12Document1 pageTotal Qty - 4 Nos Material - UNS F33100 / ASTM A536 65-45-12sudipta dasNo ratings yet

- Ingot Crack: Presentation By: Sudipta DasDocument19 pagesIngot Crack: Presentation By: Sudipta Dassudipta dasNo ratings yet

- IR204 - Siddheswari Evaluation - SUD 06.08.21Document2 pagesIR204 - Siddheswari Evaluation - SUD 06.08.21sudipta dasNo ratings yet

- Qty - 366 Nos Material - UNS F33100 / ASTM A536 65-45-12: Z002BX0D A Ecn NoDocument1 pageQty - 366 Nos Material - UNS F33100 / ASTM A536 65-45-12: Z002BX0D A Ecn Nosudipta dasNo ratings yet

- Inspection Report: Page 1 of 3 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 3 Vendor P.O. NOsudipta dasNo ratings yet

- Bestscope 6010TR-Specs-280619-DF&BFDocument1 pageBestscope 6010TR-Specs-280619-DF&BFsudipta dasNo ratings yet

- 23-Dalalpukur-Axioscope Specs MAT With C-DIC & 305Document2 pages23-Dalalpukur-Axioscope Specs MAT With C-DIC & 305sudipta dasNo ratings yet

- Inspection Report: QETO/IR/SUD/104) and Following Are The ObservationDocument2 pagesInspection Report: QETO/IR/SUD/104) and Following Are The Observationsudipta dasNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/115Document2 pagesInspection Report: IR No.: QETO/IR/SUD/115sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/118Document2 pagesInspection Report: IR No.: QETO/IR/SUD/118sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/119Document2 pagesInspection Report: IR No.: QETO/IR/SUD/119sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/116Document1 pageInspection Report: IR No.: QETO/IR/SUD/116sudipta dasNo ratings yet

- Business Model Canvas-Car DealershipDocument5 pagesBusiness Model Canvas-Car DealershipDavid Matthew Kurniawan BEngNo ratings yet

- SAP MM OverviewDocument113 pagesSAP MM OverviewPatil MGNo ratings yet

- Ayuwulandari Suyoto: Awards & AchievementsDocument1 pageAyuwulandari Suyoto: Awards & AchievementsAyuNo ratings yet

- Review of LitretureDocument6 pagesReview of LitretureKeerrthana NairNo ratings yet

- AssignmentDocument6 pagesAssignmentkingNo ratings yet

- Factors Affecting Customer Satisfaction in The Fast Food Restaurants of KathmanduDocument11 pagesFactors Affecting Customer Satisfaction in The Fast Food Restaurants of KathmanduRoshanNo ratings yet

- Astm A668Document2 pagesAstm A668ErickNo ratings yet

- CRM of WiproDocument15 pagesCRM of WiproSaurabh Seth0% (1)

- Changing Profile of Indian ConsumerDocument29 pagesChanging Profile of Indian ConsumerSridhar_Sunchu_8095100% (1)

- Production Management of Vinamilk Company: Project ReportDocument20 pagesProduction Management of Vinamilk Company: Project ReportThiên NhãNo ratings yet

- Chap 11Document12 pagesChap 11Mohamed El-Mutasim El-FeelNo ratings yet

- Lecture 12 Contemporary Management Concepts and Techniques PDFDocument18 pagesLecture 12 Contemporary Management Concepts and Techniques PDF石偉洛No ratings yet

- Custionario 11inglesDocument12 pagesCustionario 11inglesJairo RamosNo ratings yet

- Daftar Hadir Internal AuditDocument2 pagesDaftar Hadir Internal AuditMIE Internal AuditNo ratings yet

- Retail Data Analysis in Istanbul - Demo - Guide FileDocument25 pagesRetail Data Analysis in Istanbul - Demo - Guide FileShayekh M ArifNo ratings yet

- QHSE Audit Schedule: SL No Date Time Auditor Auditee DepartmentDocument2 pagesQHSE Audit Schedule: SL No Date Time Auditor Auditee DepartmentMuthusamy AyyanapillaiNo ratings yet

- Porter's Five Five Force Analysis (Part-1)Document4 pagesPorter's Five Five Force Analysis (Part-1)Pooja Rani-48No ratings yet

- Methods of Enhancing Wood and Bamboo ProductsDocument4 pagesMethods of Enhancing Wood and Bamboo ProductsKring-kring GumanaNo ratings yet

- 007 Out of SpecificationDocument12 pages007 Out of Specificationmarkandey gupta100% (2)

- Introduction and Instructions: ForewordDocument19 pagesIntroduction and Instructions: Forewordjose floresNo ratings yet

- Sociotechnical Management Model For Governance of An ECO System..Document11 pagesSociotechnical Management Model For Governance of An ECO System..Antonio José BalloniNo ratings yet

- Struktur OrganisasiDocument2 pagesStruktur OrganisasiKamal GlobalNo ratings yet

- Training Presentation: at India Yamaha Motors PVT LTD Surajpur, Gautambudh Nagar, UTTAR PRADESH-201306Document22 pagesTraining Presentation: at India Yamaha Motors PVT LTD Surajpur, Gautambudh Nagar, UTTAR PRADESH-201306Vibhor JainNo ratings yet

- Evaluating Each Market Segment's Attractiveness Market SegmentsDocument11 pagesEvaluating Each Market Segment's Attractiveness Market SegmentsHíu Trừn Thu HaiNo ratings yet

- Workshop-7-Qs Warwick AccountsDocument4 pagesWorkshop-7-Qs Warwick AccountsNaresh SehdevNo ratings yet

- System Development Life Cycle (SDLC)Document28 pagesSystem Development Life Cycle (SDLC)wasiuddin100% (1)