Professional Documents

Culture Documents

Design of Air Pre Heater and Economizer

Design of Air Pre Heater and Economizer

Uploaded by

Ryan Perez0 ratings0% found this document useful (0 votes)

83 views4 pagesThis document discusses the design of an air preheater and economizer used in thermal power plants. It first describes how an air preheater works to increase combustion efficiency by preheating air using waste heat from flue gases. It then explains that an economizer recovers low-level waste heat from flue gases to preheat boiler feedwater. The document provides calculations to design an economizer with a surface area of 6.01 square meters and an air preheater with a surface area of 43.015 square meters based on given system parameters and heat transfer equations.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses the design of an air preheater and economizer used in thermal power plants. It first describes how an air preheater works to increase combustion efficiency by preheating air using waste heat from flue gases. It then explains that an economizer recovers low-level waste heat from flue gases to preheat boiler feedwater. The document provides calculations to design an economizer with a surface area of 6.01 square meters and an air preheater with a surface area of 43.015 square meters based on given system parameters and heat transfer equations.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

83 views4 pagesDesign of Air Pre Heater and Economizer

Design of Air Pre Heater and Economizer

Uploaded by

Ryan PerezThis document discusses the design of an air preheater and economizer used in thermal power plants. It first describes how an air preheater works to increase combustion efficiency by preheating air using waste heat from flue gases. It then explains that an economizer recovers low-level waste heat from flue gases to preheat boiler feedwater. The document provides calculations to design an economizer with a surface area of 6.01 square meters and an air preheater with a surface area of 43.015 square meters based on given system parameters and heat transfer equations.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

DESIGN OF AIR PRE HEATER AND ECONOMIZER

1. 1. DESIGN OF AIR PRE HEATER AND ECONOMIZER Under the guidance of(Internal)

N.B.PRAKASH TIRUVEEDULA ASSISTANT PROFESSOR VIGNAN UNIVERSITY Under

the guidance of(External) Mr. SREEKANTH JABADE GMAND PROJECT ENGG HARTEX

RUBBER PVT LTD Submitted by J.SHANMUKA VENKATA GOPICHAND (101FA08133)

L.SURYA TEJA (101FA08141)

2. 2. CONTENTS 1. Process of Air pre-heater 2. Economizer 3. Boiler basics 4. Heat

Exchangers 5. Cross Flow & Compact Heat Exchangers 6. Design Calculation of

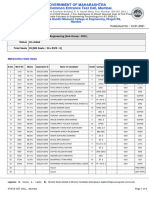

Economizer 7. Design Calculation of Air pre-heater 8. Boiler Efficiency 9. Heat Balance sheet

10. Conclusion

3. 3. Process of Air pre-heater • An air pre-heater (APH) is a general term to describe any

device designed to heat air before another process (for example, combustion in a boiler) with

the primary objective of increasing the thermal efficiency of the process. • There are two

types of air pre-heaters for use in steam generators in thermal power stations: One is a

tubular type built into the boiler flue gas ducting, and the other is a regenerative air pre-

heater. • Ambient air is forced by a fan through ducting at one end of the pre-heater tubes

and at other end the heated air from inside of the tubes emerges into another set of ducting,

which carries it to the boiler furnace for combustion

4. 4. • There are two types of regenerative air pre-heaters: the rotating-plate regenerative air

pre-heaters (RAPH) and the stationary-plate regenerative air pre-heaters. • Rotating-plate

regenerative air pre-heater

5. 5. • The rotating-plate design (RAPH) consists of a central rotating-plate element installed

within a casing that is divided into two (bi-sector type), three (tri-sector type) or four (quad-

sector type) sectors containing seals around the element. • In stationary-plate regenerative

air pre-heaters the heating plate elements are also installed in a casing, but the heating plate

elements are stationary rather than rotating.

6. 6. Economizer • Economizers are mechanical devices intended to reduce energy

consumption, or to perform another useful function such as preheating a fluid. • Economizer

performs a key function in providing high overall boiler thermal efficiency by recovering low

level energy from the flue gas before it is exhausted to the atmosphere. • Economizer

recovers the energy by heating the boiler feed water.

7. 7. • It scavenge the waste heat from thermal exhaust flue gases by passing the exhaust

effluent through heat transfer surfaces to transfer some of the waste heat to a process

media. • It Efficiency is in direct relationship to equipment design and stack gas velocities. •

Velocity increases through the stack as firing rate increases, which results in a decrease in

contact time with the economizer heating surfaces

8. 8. BOILER BASICS • The hot water or steam under pressure is then usable for transferring

the heat for the steam requirements of process industries or for power generation. • During

the combustion process, oxygen reacts with carbon, hydrogen and other elements in the fuel

to produce a flame and hot combustion gases. • As these gases are drawn through the

boiler, they cool as heat is transferred to water • The main components in a boiler system are

boiler feed water heaters, deaerator, feed pump, economizer, super heater, Attemperators,

condenser and condensate pump.

9. 9. Heat Exchangers Heat Exchangers are classified according to their function and

geometry: Function: Recuperative: two fluids separated by a solid wall Evaporative: enthalpy

of evaporation of one fluid is used to heat or cool the other fluid. Regenerative: use a third

material which stores/releases heat Geometry: 1. Double Tube 2. Shell and Tube 3. Cross-

flow Heat Exchangers 4. Compact Heat Exchangers

10. 10. Heat Exchangers • The heat transfer rate for most heat exchangers can be calculated

using the LMTD-method (Log Mean Temperature Difference), if the inlet (T1) and outlet (T2)

temperatures are known: U = Overall heat transfer coefficient [ W/m2-oC ] A = Effective heat

transfer surface area [ m2 ] F = Geometry correction factor = Log mean temperature

difference T T 2 1 F T T T ln / 2 1 Q U A T T

11. 11. Cross flow and compact heat exchangers • Cross-flow and compact heat exchangers are

used where space is limited. These aim to maximize the heat transfer surface area. •

Commonly used in gas (air) heating applications. • The heat transfer is influenced by

whether the fluids are unmixed (i.e. confined in a channel) or mixed (i.e. not confined, hence

free to contact several different heat transfer surfaces). • In a cross-flow heat exchanger the

direction of fluids are perpendicular to each other.

12. 12. Compact heat exchangers • In Compact heat exchangers, the heat transfer rate is

directly related to pressure loss Advantages: • very small • Ideal for transferring heat to / from

fluids with very low conductivity or where the heat transfer must be done in very small

spaces Disadvantages: • high manufacturing costs • very heavy • Extremely high pressure

losses.

13. 13. DESIGN OF ECONOMIZER ASSUMPTION: • The properties are remains constant

under steady state conditions and neglect surrounding losses. Kinetic and potential energies

are neglected. DESIGN ANALYSIS: Heat Transfer, Q = m x c x Δt • Where m = mass of fluid

in kg C = specific heat of water in kj/kg oc Δt = temperature difference

14. 14. • Here m = 1800 kg/h = 5 kg/sec • Specific heat of water is 4.18 kj/kg oc • Temperature

difference, Δt = (70oc - 40oc) = 30oc Q = 5 x 4.18 x 30oc Q = 627 kW • Heat loosing fluid Qc

= m x c x Δt = 16 x 1.005 x (200 – 160) = 643.2 kw.

15. 15. • In Counter flow LMTD = ((Th1 – Tc2) - (Th2– Tc1)) / ln ((Th1 – Tc2 ) - ( Th2 – Tc1 )) =

((200-70) – (160-40)) / ln ((200-70)/ (160-40)) = (130-120) / ln (130/120) = 10 / ln (1.083) =

10 / 0.0797 • LMTD = 125.47oc

16. 16. • Actually this economizer is a cross flow economizer so, the LMTD equation becomes,

(LMTD)cross = F X (LMTD)counter Here F = correction factor • It is calculated by using

graphical method by using dimension parameters P, Z from graph, P= (Tc2-Tc1)/(Th1-Tc2)

P= (70-40)/ (200-70) P= 0.2307

17. 17. • Z= (Th1-Th2)/(Tc2-Tc1) Z= (200-160)/ (70-40) Z= 1.33 • From this values we get F =

0.98 (from graphically, pgno:31) • So we have multiplied the counter flow LMTD with

correction factor F, then we get LMTD of cross flow (LMTD) cross = F X (LMTD) counter =

0.98 x 125.47 = 122.96oc

18. 18. • From heat transfer equation we calculate the area of economizer as follows Q = UA

ΔTm x F Here F = Correction factor F = 0.98 A = Area of Economizer A = (627 x 1000) / (850

x 125.4 x 0.98) A = 6.01 m2 U = 850 w / m2 oc (from tables)

19. 19. • From Average velocity in the tube and discharge we Calculate total flow area m = ρ A u

Here m = mass of water A = Tube flow area U = velocity of flow = 0.2 m/sec A = 5 / (1000 x

0.2) A = 0.025 m2

20. 20. • The above area is equal to actual cross – sectional area of tube 0.025 =n x π/4 x d2

0.025 = n x 3.14 x (0.025)2 / 4 n= 50 • From Equation 1 the area is 17.47 m2 • Then the total

surface area in 2 tube pass is given below 2nπdL = 6.01 L = 6.01/(2 x 0.025 x 3.14 x 50) L =

76 mtrs

21. 21. • Each tube = 2.2 mtrs No. of passes = 2 No. of tubes = 50

22. 22. DESIGN OF AIR PRE HEATER • ASSUMPTIONS: The properties are remains constant

under steady state conditions and neglect surrounding losses. Kinetic and potential energies

are neglected. • DESIGN ANALYSIS: Heat Transfer, Q = m x c x Δt Where m = mass flow

rate C = specific heat of air in kJ/kg oc C = 1.005 Δt = temperature difference in oc

23. 23. • Here m = 5 kg/sec Specific heat of water is 4.18 kJ/kg oc Temperature difference, Δt =

(110 oc - 50 oc) = 60 oc Q = 5 x 1.005 x 60 oc Q = 301.5 kw Heat loosing of fluid Q = m x c x

Δt = 5 x 1.005 x (270-200) = 351.75 kw

24. 24. • LMTD = ((Th1 – Tc2 ) - ( Th2 – Tc1 )) / ln((Th1 – Tc2 )- ( Th2 – Tc1 )) = ((270-110) –

(200-50))/ln ((270-110)/(200-50)) = (160-150)/ln (160/150) LMTD = 156.46 oc • Actually this

Air pre-heater is a cross flow Air pre-heater so the LMTD equation Becomes, (LMTD)cross =

F X (LMTD)counter Here F = correction factor

25. 25. • It is calculated by using graphical method by using dimension parameters P, Z from

graph, P= (Tc2-Tc1)/(Th1-Tc2) P= (110-50)/(270-110) P= 60/160 P=0.375 Z =

(Th1-Th2)/(Tc2-Tc1) Z = (270-200)/(110-50) Z = 70/60 Z = 1.16 • From this values we get F

= 0.94 (from graphically)

26. 26. • So we have multiplied the counter flow LMTD with correction factor F, then we get

LMTD of cross flow (LMTD)cross = F X (LMTD)counter = 0.94 x 156.46 = 147.07 oc • Q =

UA ΔTm x F Where U = overall heat transfer coefficient A = Area of Air Pre heater F =

correction factor U = 50 w / m2 oc (As per standard tables)

27. 27. • From Average velocity in the tube and discharge we Calculate total flow area Here

correction factor F = 0.94 A = q / U ΔTm x F = (301.5X 1000) / (50 x 0.94 x 156.4) =

43.015m2 m = ρA u Here m = mass flow rate kg/sec A = Tube flow area m2 U = velocity of

flow = 0.2 m/sec ρ = 1.5 kg / m3

28. 28. • From continuity equation Q = A1 X V1 5 / 1000 = 3.14 X (0.04)2 X V1 V1 = 3.98 m/sec

m = ρA u A= m/(ρ x V1) A=5/(1.5 x 3.98 ) = 0.83 m2 A = 0.83 m2

29. 29. • The above area is equal to actual cross – sectional area of tube 0.83 m2 = n X π/4 X d2

n = 658 tubes Length of tube for two passes nπdL = 43.015m2 L = 43.015 / (658 x 3.14 x

0.04) L = 0.52m No. of tubes = 658 No. of passes = 2, Length = 0.52m

30. 30. BOILER EFFICIENCY • Now we calculate the boiler efficiency of thermax boiler. •

Capacity of boiler = 6 tons/hour • Exisisting values • Water temperature (tw) = 35 oc • Mass

of steam (ms) = 6000kg/hr • Mass of fuel (mf) = 1250 kg/hr • Calorific value of husk = 3500

k.cal/kg = 14644.35kj/kg ( 1 joule = 0.239 k.cal ) • Temperature of steam (ts ) = 190 oc •

Boiler efficiency = ms (hs-hw)/mf x c.v

31. 31. • Enthalpy of water at 35 oc hw =hf +x hfg (x = 0, i.e., dryness factor, by using steam

tables) hw = 151.5 + 0 x hfg hw = 151.5 kj/kg • Enthalpy of steam at 190 oc hs =hf +x hfg hs

= 8067 + (0.8 X 1977.5) hs = 2388.7 kj/kg • Therefore, boiler efficiency = ms (hs-hw) /(mf x

c.v) x 100 = 6000(2388.7-151.5)/1250 x 14644.35) x 100 = 0.733 x 100 = 73.3%

32. 32. 8.1 BOILER EFFICIENCY WITH ECONOMIZER • Now introducing economizer the

temperature of water increases from 35 oc TO 50 oc now water temperature (tw) = 50 oc

And quality of steam increases up to 90 percent • Economizer with boiler efficiency = ms(hs-

hw)/mf x c.vx100 • enthalpy of water at 50 oc (hw) = hf + x hfg = 213.7 + 0 x hfg hw = 213.7

kj/kg

33. 33. • enthalpy of steam at 190 oc (hs) = hf+ x hfg = 806.7 + (0.9 x 1977.5) (here quality of the

steam 90%) = 806.7 + 1779.5 = 2586.45 kj/kg • Economizer with boiler effieciency = ms(hs-

hw)/mf x c.v x 100 = 6000 (2586.45 - 213.7)/(1250 x 14644.35) x 100 =0.77 x 100 =77%

34. 34. 8.2 BOILER EFFICIENCY WITH AIR PRE-HEATER • Now we are introducing air

preheater the husk consumption reduced to 1250 kg to 1083 kg/hr • Boiler efficiency with air

preheater = MS (HS –HW)/MF X CV X 100 = 6000 (2586.45-213.7)/1083 X 14644.35) X 100

= 14236500/15859831.05 X 100 = 0.89 X 100 • Boiler efficiency with air preheater = 89%

35. 35. • Water consumption per hour = 4250 • Specific heat of water = 1 ΔT = T2-T1 = 95 OC

-85 OC = 10OC • MCPΔT = 4250 X 1 X 10 X 24 = 1020000 K.CAL = 291.42857 KJ/KG •

Therefore 291.42857 KJ/KG Rice husk is saving

36. 36. Heat Balance Sheet • Pressure of Steam = 14.2 bar • Steam produced = 6000 kg/hour •

Coal used = 1250 kg/hour • Moisture in Fuel = 2% of mass • Mass of Dry Fuel gas = 9 kg of

fuel • Calorific Value of Fuel = 3500 k.cal • Temperature of gas = 2000c • Temperature of

Boiler room = 280c • Feed water Temperature = 500c • Specific heat of gas = 1.005 kj/kg •

Quality of steam = 0.9%

37. 37. • Heat supplied for the fuel = mf x c.v H.S = 1 x 3500 = 3500 k.cal • Heat supplied = 3500

k.cal • If moisture is present then heat supplied by 1 kg of fuel = (1- mm) c.v • Where mm is

percentage of moisture = (1-0.02) x 3500 = 3430 k.cal = 4913.043 kj • Heat utilized in

producing Steam = ms/mf (hs-hw) →1 Where hs = hf + x hfg = 806.7 + (0.9 x 977.5) =

2586.45 kg

38. • hw = hf hw = 806.7 = 6000/1250 (2586.45 – 206.7) = 4.8 x 2379.75 = 11422.8 kj

39. 39. • Heat carried away by the exert gases = mg cp g (Tg-Ts) = 9 x 1.005 (2000c – 500c) =

1356.75 kj • Heat carried away by the moisture in the fuel = mm (2676 + 2.1 (Tg – 100) – hf)

= 0.02 (2676 + 2.1 (200 – 100) - hf) = 0.02 (2676 + 2.1 (200 – 100) – 121.4) = 55.292 kj

40. 40. 1250 1250 1083 1300 1250 1200 1150 1100 1050 1000 950 100 90 80 70 60 50 40 30

20 10 0 1 2 3 fuel consumption ( kg/hr ) boiler efficiency (%) Name fuel consumption ( kg/hr )

Boiler efficiency (%) without airpreheater and economizer 1250 73.3 with economizer 1250

77 with airpreheater 1083 89

41. 41. CONCLUSION • In this course of project it came to learn about the Design of Air pre-

heater and Economizer in boiler. • By using the Air pre-heater and Economizer boiler

Efficiency can be increased. • Gas flow distribution or heat transfer into the economizer

section is improved through use of guide vanes at inlet of economizer duct. • Analysis of

economizer module was carried out to predict the economizer feed water outlet temperature.

• The economizer size optimized by reducing the number of tubes of module by enhancing

the heat transfer across the module. • By installing the Air pre-heater and Economizer the

total husk consumption rate is reduced and the efficiency of the boiler is also increased to

73% to 89%

You might also like

- Ntu MethodDocument11 pagesNtu MethodPradyumna DhamangaonkarNo ratings yet

- Shell & Tube Condenser Design: O O O O O ODocument6 pagesShell & Tube Condenser Design: O O O O O Otpcho100% (1)

- Dump CondenserDocument6 pagesDump CondensersakalidhasavasanNo ratings yet

- Design HeatexchangerDocument15 pagesDesign HeatexchangerMayurMahajan100% (1)

- Distillation Column ReboilerDocument13 pagesDistillation Column ReboilerLouie GresulaNo ratings yet

- (Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingDocument32 pages(Kern Metode) Design Data: Shell and Tube Heat Exchanger SizingLisa SeptidianaNo ratings yet

- Expansion Tanks Sizing ASMEDocument18 pagesExpansion Tanks Sizing ASMErodijammoulNo ratings yet

- Mollie ChartDocument15 pagesMollie ChartKriz EarnestNo ratings yet

- Cogenerations of Energy From Sugar Factory BagasseDocument8 pagesCogenerations of Energy From Sugar Factory BagasseTade GaromaNo ratings yet

- Condenser & EvaporatorDocument21 pagesCondenser & EvaporatorfitratulqadriNo ratings yet

- Transfer of Liquefied Natural Gas On Long Insulated Lines PDFDocument6 pagesTransfer of Liquefied Natural Gas On Long Insulated Lines PDFIgnacio ChaparroNo ratings yet

- Expt. 7 Finned TubeDocument6 pagesExpt. 7 Finned TubePradeep DiwakarNo ratings yet

- Heat Exchanger AnalysisDocument1 pageHeat Exchanger AnalysishuangjlNo ratings yet

- Heat Exhanger Individual ReportDocument16 pagesHeat Exhanger Individual ReportMusa OtoNo ratings yet

- What Is A Fired Heater in A RefineryDocument53 pagesWhat Is A Fired Heater in A RefineryCelestine OzokechiNo ratings yet

- Control Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4Document4 pagesControl Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4ghandri1986No ratings yet

- Agitated VesselDocument8 pagesAgitated VesselBharatShethNo ratings yet

- Flue Gas 360 PDFDocument2 pagesFlue Gas 360 PDFwatson123No ratings yet

- Heat Exchanger Effectiveness PDFDocument5 pagesHeat Exchanger Effectiveness PDFfrilofhNo ratings yet

- Solar Water Heating (SWH) Is The Conversion ofDocument5 pagesSolar Water Heating (SWH) Is The Conversion ofPratik Kisan SatavNo ratings yet

- Condenser CalculatorDocument17 pagesCondenser CalculatorSaurav KumarNo ratings yet

- Clean Coal Technologies For SustainabilityDocument37 pagesClean Coal Technologies For SustainabilityAnoop PatelNo ratings yet

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water RequirementmayurjannuNo ratings yet

- CH-14 Design Fundamentals of BoilerDocument15 pagesCH-14 Design Fundamentals of BoilerRavi ShankarNo ratings yet

- OrvDocument8 pagesOrviqtorresNo ratings yet

- Technologies For High Performance and Reliability of Geothermal Power PlantDocument4 pagesTechnologies For High Performance and Reliability of Geothermal Power Plantsum1else4No ratings yet

- InputCOIL PDFDocument9 pagesInputCOIL PDFneelNo ratings yet

- Pharma Engg. Heat Transfer AreaDocument4 pagesPharma Engg. Heat Transfer AreamanojNo ratings yet

- Steam EnthalpyDocument14 pagesSteam EnthalpyAshutosh YadavNo ratings yet

- Understanding Heat Flux Limitations CCTI 2010Document8 pagesUnderstanding Heat Flux Limitations CCTI 2010B rgNo ratings yet

- Guidelines For Sizing of Restriction Orifice For Single-Phase Fluids With PDFDocument8 pagesGuidelines For Sizing of Restriction Orifice For Single-Phase Fluids With PDFEPTCO LHDNo ratings yet

- Heat Loss From An Insulated Pipe: Chemical Engineer's GuideDocument10 pagesHeat Loss From An Insulated Pipe: Chemical Engineer's Guidesaurabh singhNo ratings yet

- HP Dosing - AgecDocument12 pagesHP Dosing - AgecShameer MajeedNo ratings yet

- Observations Water in DF Out DF Oil DF Flow Ml/s Flow ft3/hrDocument2 pagesObservations Water in DF Out DF Oil DF Flow Ml/s Flow ft3/hrUmair FareedNo ratings yet

- Formulas BoilerDocument0 pagesFormulas BoilerJopha S Deva100% (1)

- 9.global Environmental ConcernsDocument20 pages9.global Environmental ConcernsPrudhvi RajNo ratings yet

- Energy BalanceDocument11 pagesEnergy BalanceBharat VaajNo ratings yet

- Fuel Characteristic BiomassDocument365 pagesFuel Characteristic BiomassCalvin JunNo ratings yet

- Flash Tank PDFDocument19 pagesFlash Tank PDFMufita RamadhinaNo ratings yet

- Final Energy Balance-Vizag DT 9-6-18Document6 pagesFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYNo ratings yet

- HRSG ReportDocument46 pagesHRSG Reportoverlord5555No ratings yet

- Steam Trap & InsulationDocument16 pagesSteam Trap & InsulationArindomNo ratings yet

- Design of DryerDocument11 pagesDesign of DryerHARKULVINDER SINGHNo ratings yet

- File - 20220523 - 210015 - Pid FGDDocument11 pagesFile - 20220523 - 210015 - Pid FGDThắng NguyễnNo ratings yet

- CDQ Layout 567Document1 pageCDQ Layout 567Amit BalotNo ratings yet

- 12-Design Fundamentals of BoilerDocument12 pages12-Design Fundamentals of BoilerVishalVaishNo ratings yet

- Air PropertiesDocument19 pagesAir PropertiesVanbiervlietNo ratings yet

- A Guide To Assist in Evaluating Liquid Fuel FlamesDocument16 pagesA Guide To Assist in Evaluating Liquid Fuel FlamestinuvalsapaulNo ratings yet

- Rice Brochure V1Document36 pagesRice Brochure V1Naveenraj KrishnamoorthyNo ratings yet

- Cooling Tower. Application - TreybalDocument89 pagesCooling Tower. Application - TreybalProcess TiglobalNo ratings yet

- Typical Process / Facility Water Balance CalculationDocument5 pagesTypical Process / Facility Water Balance CalculationYesi CeballosNo ratings yet

- On Biogas Enrichment and Bottling Technology - IITD - IndiaDocument38 pagesOn Biogas Enrichment and Bottling Technology - IITD - Indiaअश्विनी सोनी100% (3)

- Cooling Tower 434Document15 pagesCooling Tower 434arslan MaqboolNo ratings yet

- Installing Vapor Recovery Units To Reduce Methane LossesDocument29 pagesInstalling Vapor Recovery Units To Reduce Methane Lossesandres100% (1)

- PG Test 1.11.12Document16 pagesPG Test 1.11.12abdulyunus_amirNo ratings yet

- CW Pipe Sizing CalcDocument1 pageCW Pipe Sizing Calcharoub_nasNo ratings yet

- Aph PRESENTATIONDocument42 pagesAph PRESENTATIONRajneesh VachaspatiNo ratings yet

- Design of Air Pre Heater and Economizer: Submitted by J.Shanmuka Venkata Gopichand (101fa08133) L.SURYA TEJA (101FA08141)Document42 pagesDesign of Air Pre Heater and Economizer: Submitted by J.Shanmuka Venkata Gopichand (101fa08133) L.SURYA TEJA (101FA08141)Chien NguyenNo ratings yet

- Department of Chemical Engineering Heat Transfer Lab (CHD-228)Document8 pagesDepartment of Chemical Engineering Heat Transfer Lab (CHD-228)prasoonNo ratings yet

- Design of LPG Refigeration System: 1. Copper TubesDocument20 pagesDesign of LPG Refigeration System: 1. Copper TubesJeevan Landge PatilNo ratings yet

- Paper 1 Each Questions Is Followed by Options A, B, and C. Circle The Correct AnswerDocument9 pagesPaper 1 Each Questions Is Followed by Options A, B, and C. Circle The Correct AnswerWan SafinaNo ratings yet

- SCIETECHNODocument19 pagesSCIETECHNOChini ChanNo ratings yet

- Resume of Noah C.D. HillDocument3 pagesResume of Noah C.D. HillNoah (AmericanGuy)No ratings yet

- 2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedDocument8 pages2127 - Mahatma Gandhi Missions College of Engineering, Hingoli RD, NandedAjit DeshmukhNo ratings yet

- ThevoidsummaryDocument6 pagesThevoidsummaryVaibhav Mishra80% (5)

- Anullment CATHOLIC TRIBUNALDocument20 pagesAnullment CATHOLIC TRIBUNALMons Jr BaturianoNo ratings yet

- 電容器絕緣油BDV 黏度 - SAS 40EDocument10 pages電容器絕緣油BDV 黏度 - SAS 40EShihlinElectricNo ratings yet

- Moral Stories - Situated Reasoning About Norms, Intents, Actions, and Their Consequences 2012.15738Document21 pagesMoral Stories - Situated Reasoning About Norms, Intents, Actions, and Their Consequences 2012.15738Zhu XUNo ratings yet

- Listen To The Following Words Carefully and Write Them. (Any Three)Document9 pagesListen To The Following Words Carefully and Write Them. (Any Three)Anonymous wfZ9qDMNNo ratings yet

- Vacant Seats: 5-Year Integrated M.Sc. (Hons.) ProgrammesDocument2 pagesVacant Seats: 5-Year Integrated M.Sc. (Hons.) Programmesmana khantNo ratings yet

- Test Bank For Clinical Nursing Skills 8th Edition SmithDocument7 pagesTest Bank For Clinical Nursing Skills 8th Edition Smithnoumenalskall0wewNo ratings yet

- Renewable Energy Sources and MethodsDocument225 pagesRenewable Energy Sources and MethodsSemir Đedović100% (1)

- SK 135 SR 3Document327 pagesSK 135 SR 3Trung Cuong100% (1)

- Nimble Number Logic Puzzle II QuizDocument1 pageNimble Number Logic Puzzle II QuizpikNo ratings yet

- Bibby CouplingsDocument25 pagesBibby CouplingsKemoy JohnsonNo ratings yet

- Brac Bank LimitedDocument1 pageBrac Bank LimitedMd Mojibar RahmanNo ratings yet

- English Project CompileDocument33 pagesEnglish Project CompileAbdul QayyumNo ratings yet

- Tacha's ReusmeDocument2 pagesTacha's ReusmeJames HamptonNo ratings yet

- Lesson 3 DiscussionDocument3 pagesLesson 3 DiscussionElaineVidalRodriguezNo ratings yet

- Excavation TrainingDocument60 pagesExcavation TrainingFahad Abdul HaqNo ratings yet

- Artificial Intelligence On Digital Marketing - An OverviewDocument14 pagesArtificial Intelligence On Digital Marketing - An Overviewammar zNo ratings yet

- Process Flow ChartDocument22 pagesProcess Flow ChartKumar Ashutosh100% (1)

- Detailed Lesson Plan in ICT ExcelDocument5 pagesDetailed Lesson Plan in ICT ExcelColleen Vender100% (3)

- Aras Innovator Programmers GuideDocument105 pagesAras Innovator Programmers Guidem0de570No ratings yet

- Pistons To JetsDocument41 pagesPistons To JetsRon Downey100% (2)

- Interactive Physics ManualDocument13 pagesInteractive Physics ManualMarciano SantamaríaNo ratings yet

- Allen Bradley 160 C SeriesDocument28 pagesAllen Bradley 160 C SeriesTihomir Matulić100% (1)

- Lab ReportpdfDocument7 pagesLab ReportpdfStefano FochesattoNo ratings yet

- Lean StartupDocument10 pagesLean StartupAlfredo Romero GNo ratings yet

- Lesson 4 - PF and Parallel AC CircuitsDocument12 pagesLesson 4 - PF and Parallel AC CircuitsMichael SalvahanNo ratings yet