Professional Documents

Culture Documents

Eeaa090532 02 00

Eeaa090532 02 00

Uploaded by

Amogh AbhyankarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eeaa090532 02 00

Eeaa090532 02 00

Uploaded by

Amogh AbhyankarCopyright:

Available Formats

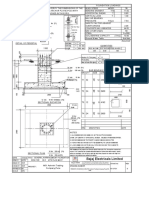

A - DESIGN DATA.

SCOPE OF SUPPLY (MECHANICAL) FOR ELECTRICAL T = THERMAX ENVIRO SR.NO. DESIGN PARAMETER Hot gases from Sponge

SUPPLY REFER C = CUSTOMER iron Kiln

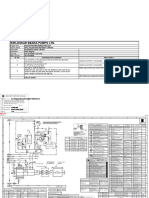

P & I DIAGRAM N = NA 1 DESIGN GAS FLOW RATE IN AM3/HR 50800

SR. DESCRIPTION SCOPE REMARKS 2 TEMPERATURE DEG.C ( OPERATING ) 200

NO. 3 CASING MECHANICAL DESIGN TEMPERATURE DEG.C 250

1 FOUNDATION BOLTS T 4 DUST TYPE SPONGE IRON

2 SUPPORT STRUCTURE IN STEEL C 5 MAXIMUM INLET DUST LOADING ( GM / NM3 ) 30

3 STRUCTURAL BEARINGS T 6 OUTLET EMISSION FOR ESP ( MGM / NM3) ALL FIELD WORKING. 30

4 STAIRCASE ASSEMBLY C 7

5 PLATFORM AT CASING ACCESS DOOR C 8 MOISTURE IN GAS ( % V / V ) 22.8

6 PLATFORM AT DUST DISCHARGE LEVEL C 9 UNBURNT CARBON IN FLY ASH ( % ) 7

7 HOPPER ASSEMBLY C 10 COLLECTION AREA M2 1485.00

8 CASING ASSEMBLY C 11 SPECIFIC COLLECTION AREA M2 / M3 / SEC. 105.24

9 INLET NOZZLE FABRICATED COMPONENTS C 12 NO OF GAS PASSAGES 11

10 INLET NOZZLE PERFORATED SHEETS T 13 EFFECTIVE C E WIDTH (METER) 3

11 INLET NOZZLE RAPPER COMPONENTS T 14 EFFECTIVE C E HEIGHT (METER) 7.5

12 OUTLET NOZZLE FABRICATED COMPONENTS C 15 VELOCITY THROUGH ESP M/SEC. 0.42

13 OUTLET NOZZLE PERFORATED SHEET T 16 TREATMENT TIME (SEC.) 21

14 PENTHOUSE ASSEMBLY C 17 NO OF FIELDS IN SERIES 3

15 MONORAIL STRUCTURE C 18 MIGRATION VELOCITY (CM/SEC.) 6.56

16 CHAIN PULLEY BLOCK FOR MONORAIL C 19 DESIGN PRESSURE (mmWG) ±300

17 HV ASSEMBLY AND T.R. SET BASE FRAME T 20 DUST DENSITY FOR POWER (KG/M3) 1200

18 PURGE AIR ASSEMBLY T 21 DUST DENSITY FOR DISCHARGE (KG/M3) 800

19 COLLECTING ASSEMBLY T TTR (T1) 22 FLG TO FLG PRESSURE DROP (mmWC) 20-25

20 E-TUBE ASSEMBLY T 23 EFFICIENCY (%) 99.9

21 ACCESS DOORS T -

22 INSULATION AND CLADDING ASSEMBLY C -

23 METALLIC EXPANSION JOINTS AT INLET AND OUTLET T -

24 SIGNS AND BRACKETS T -

25 -

26 SLIDE GATE VALVE FOR HOPPER T -

27 ERECTION TOOLS FOR ESP C -

28 OPERATION AND MAINTENANCE MANUAL FOR ESP T

29 ERECTION AND COMMISSIONING C

30 SUPERVISION ERECTION & COMMISSIONING T C - PROCUCT DATA B - LOAD DATA

31 EXCLUSIONS AS PER CONTRACT DOCUMENT C

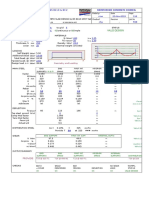

32 COMMISSIONING SPARES T C-1 CASING THK. mm. 5 DESIGN WIND PRESSURE (KG/M2) 120 SEISMIC ZONE III AS PER IS: 1893

33 C-2 HOPPER WALL THK. mm. 5 ESP LOAD DATA ON RCC PEDESTAL TOP ALL LOADS ARE IN TON / COLUMN

34 C-3 INLET & OUTLET NOZZLE THK. mm. 5 SR NO. COLUMN STATIC DUST LOADS DUE TO WIND IN LOADS DUE TO SEISMIC IN LIVE

35 C-4 PENTHOUSE SIDE WALL THK. mm. 3 NUMBER LOAD LOAD HORIZONTAL VERTICAL HORIZONTAL VERTICAL LOAD

36 C-5 PENTHOUSE TOP SHEET CHQ. PLT. THK. mm. 4 +/- X +/- Z +/- X +/- Z +/- X +/- Z +/- X +/- Z

37 C-6 PERFORATED SHEET FOR NOZZLE THK. Mm 2.5 1 A1, A2 15 6 3 4 4 17 3 3 3 6 1.5

38 C-7 INSULATION THK. mm 50 2 B1, B2 26 12 5 5 15 23 6 4 18 8 1.5

39 C-8 INSULATION DENSITY Kg/M3 100 3 C1, C2 26 12 5 5 15 23 6 4 18 8 1.5

40 C-9 CLADDING TYPE / THK. (SWG) 24 4 D1, D2 15 6 1.5

3 4 4 17 3 3 3 6

41 C - 10 HOPPER VOLUME M3 (100% FULL) 18.58 5 E3, E4 0.5

42 6

43 7

44 D - TR SET DETAILS 8

45 9

46 D-1 T.R. CONTROLL TYPE MICRO PROCESSOR BASED CONTROL. 10

47 D-2 T.R. SET RATING DETAILS - 11

48 a] OUTPUT VOLTAGE 95 KV DC PEAK (3 PH) 12

49 b] OUTPUT CURRENT (mA) 13

50 1) TR SET NO.1 100 5) TR SET NO.5 0 14

2) TR SET NO.2 200 6) TR SET NO.6 0 15

F - GENERAL NOTES 3) TR SET NO.3 200 7) TR SET NO.7 0 ASH DENSITY CONSIDERED (KG/M3) = 1200

4) TR SET NO.4 0 CIVIL FOUNDATION DETAILS SHOWN IN THIS DRG. ARE PICTORIAL ONLY.

1 TOTAL UNIT IS INSULATED WITH LRB MATTRESSES OF MINERAL WOOL AND PLAIN ALUMINUM CLADDING. CIVIL FOUNDATION DESIGN & DETAILING IS IN CUSTOMER SCOPE BASED ON LOAD DATA MENTIONED ABOVE.

2 NOZZLE FLANGES ARE NOT DESIGNED TO TAKE ANY EXTERNAL LOAD AND DUCT EXPANSIONS. E - PAINTING DETAILS

3 THE EQUIPMENT SHALL BE DISPATCHED IN KNOCK DOWN CONDITION. G - ASH COLLECTION RATE IN EACH FIELD (KG/HR)

4 WEIGHT OF HEAVIEST COMPONENT IN TONNES (DESPATCHABLE) 3.0 T / T.R. SET. TYPE INSULATED (INSIDE & OUTSIDE) NON INSULATED

5 SUPPLY VOLTAGE : 415±10%, 50Hz ±5%, 3 PHASE, 3 WIRE AC. Casing, Hopper, Nozzle, Pent Support Structure, Monorails, Staircase & Platforms, SR NO. FUAL Hot gases from Sponge

Components

6 DUST MUST BE CONTINUOUSLY EVACUATED FROM HOPPERS THE FIELD WISE ASH COLLECTION House/Insulator Box & misc. Ladder, Canopy if applicable iron Kiln

RATES AS INDICATED IN TABLE - G Surface Preparation Mechanical Cleaning to ST-2 Grade Mechanical Cleaning to ST-2 Grade 1 FIELD-1 792

7 THE EQUIPMENT SHALL BE DISPATCHED IN CKD CONDITION. CASING, NOZZLES, HOPPERS AND 2 FIELD-2 79

Red oxide Red oxide

PENTHOUSE SHALL BE SUPPLIED IN PANEL FORM. Primer 3 FIELD-3 8

8 CUSTOMER TO PROVIDE 100 NB X 150 LG. SAMPLING PORT ON ESP INLET AND OUTLET DUCT. DFT/Coat : 20-30 micrins, 2 coats DFT/Coat : 20-30 micrins, 2 coats 4 FIELD-4

9 CUSTOMER SHOULD PROVIDE GUIDE VANES AT THE INLET DUCTING OF ESP TO ENSURE UNIFORM GAS DISTRIBUTION AT THE INLET Intermediate Paint Not Applicable Not Applicable 5 FIELD-5

OF ESP TO GET DESIRED PERFORMANCE 6 FIELD-6

Finish Paint Not Applicable Not Applicable

10 IN CASE OF HOPPER FILLED CONDITION ARISE DUE TO ABNORMAL WORKING CONDITIONS, HOPPER TO BE EVACUATED 7 FIELD-7

ONE BY ONE BEFORE NORMAL START-UP. THIS IS TO AVOID ANY OVERLOADING OF DOWNSTREAM CONVEYING SYSTEMS. Finish Paint Shade Not Applicable Not Applicable 8 TOTAL DUST COLLECTED

879

11 CUSTOMER TO PROVIDED APPROPRIATE SEALING ARRANGEMENT BELOW HOPPER IN ABSENCE OF RAV. Grating for Staircase & Platform As per Non-insulated scheme. IN ESP (KG/HR)

12 FOR CIVIL WORK ONLY STR CTC DIMENSIONS TO BE REFEREED. Railing for Staircase & Platform As per Non-insulated scheme.

13 MATERIAL OF CONSTRUCTION :- CARBON STEEL AS PER IS 2062. Internals Rust preventive Oil Coating VALUES IN PARENTHESIS ARE FOR FIRST FIELD OUT OF SERVICE. NA

14 CUSTOMER TO PROVIDE ALL GROUTING & PACKING MATERIAL REQUIRED FOR FOUNDATION WORK. Bought outs As per manufacturer STD ROTARY AIR LOCK VALVE CAPACITY IN M3/HR. AT 50 % FILLING EFFICIENCY. 5.8

Hardware STD MINIMUM WIDTH OF ASH HANDLING SYSTEM SHALL BE GREATER THAN 350 mm.

Amol.Pulate

2021.06.23

12:14:35

+05'30'

You might also like

- Ycua Ydf (Tech. Guide) 2Document20 pagesYcua Ydf (Tech. Guide) 2Elmer80% (5)

- Technical Data Sheet Avikote Av 650 R PDFDocument2 pagesTechnical Data Sheet Avikote Av 650 R PDFCIAKNo ratings yet

- Umpco: CAGE CODE No. 18076 Part NumberDocument4 pagesUmpco: CAGE CODE No. 18076 Part NumberFredNo ratings yet

- SA - 980 - P - 11440 Fuel - Water Coalescer Separator Rev T02Document2 pagesSA - 980 - P - 11440 Fuel - Water Coalescer Separator Rev T02altipatlarNo ratings yet

- Datasheet Package Unit (Split Unit With Outdoor)Document28 pagesDatasheet Package Unit (Split Unit With Outdoor)Alif FirdausNo ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Engineering Change Order: IntentDocument3 pagesEngineering Change Order: IntentYanethNo ratings yet

- MDS Diesel TankDocument2 pagesMDS Diesel TankrifkynetNo ratings yet

- Heat ExchangersDocument34 pagesHeat Exchangerssantosh awateNo ratings yet

- PTX - Iom ManualDocument53 pagesPTX - Iom Manualghassan MirghnyNo ratings yet

- SA 980 P 11401 Flow Switch Rev T02Document1 pageSA 980 P 11401 Flow Switch Rev T02altipatlarNo ratings yet

- 0244 DD 10 02 Fe DWG 30006 D7Document1 page0244 DD 10 02 Fe DWG 30006 D7julia bordenNo ratings yet

- FM000570-1012203042-30.5M - FM - Ashwini Trading Company, Pune-R0-HVR-Cal.Document1 pageFM000570-1012203042-30.5M - FM - Ashwini Trading Company, Pune-R0-HVR-Cal.sujanNo ratings yet

- Form Final Check TIP. 01Document1 pageForm Final Check TIP. 01gazali.jodiNo ratings yet

- Joined DrawingsDocument5 pagesJoined Drawingsapi-439340483No ratings yet

- se(ty(ty(reDocument3 pagesse(ty(ty(reRé Marc TathyNo ratings yet

- Environmental MonitoringDocument1 pageEnvironmental MonitoringResearcherNo ratings yet

- Heat ExchangersDocument66 pagesHeat ExchangerssafwanNo ratings yet

- Dibujos Válvulas-Bola Top Entry y CompuertaDocument4 pagesDibujos Válvulas-Bola Top Entry y CompuertaJUAN ANTONIO HERNANDEZ SOSANo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116Document1 pageSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116mathewsujith31No ratings yet

- Mml4-Ca09-Chctpl-Civ-Dwg-D-Stn-Cmn-60231. (Rev-A) 08.02.2023 (Typical DWG For Twin Column) (1) - Sh. 2 of 4Document1 pageMml4-Ca09-Chctpl-Civ-Dwg-D-Stn-Cmn-60231. (Rev-A) 08.02.2023 (Typical DWG For Twin Column) (1) - Sh. 2 of 4AJAY SHINDENo ratings yet

- Normal 6043734659e08Document1 pageNormal 6043734659e08Hemanth KumarNo ratings yet

- General: CRUDE OIL / Liquid 313.9 / 313.9Document1 pageGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirNo ratings yet

- Strength Calculation Sheet For Item No. C-053-12Document297 pagesStrength Calculation Sheet For Item No. C-053-12Urdian Syah100% (1)

- Akt-Bpm-Stl-Spek-Mec-Bkw-002 Data Sheet BlowerDocument4 pagesAkt-Bpm-Stl-Spek-Mec-Bkw-002 Data Sheet Blowernuridin sakwadNo ratings yet

- Data Sheet-Emf)Document2 pagesData Sheet-Emf)Karthikeyan100% (1)

- D PRXDocument1 pageD PRXDiana ArredondoNo ratings yet

- dytur urtytDocument3 pagesdytur urtytRé Marc TathyNo ratings yet

- Bhushan Ics+bcsDocument24 pagesBhushan Ics+bcsmukesh_kht1No ratings yet

- 30 May 2022Document1 page30 May 2022sankhadeep goswamiNo ratings yet

- 2.1 Mechanical Datasheet For Air Compressor SkidDocument8 pages2.1 Mechanical Datasheet For Air Compressor SkidTrung Trinh BaoNo ratings yet

- 97B0138N01Document40 pages97B0138N01Muhammad BasriNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Introduction/Abstract: TeknikgruppenDocument14 pagesIntroduction/Abstract: TeknikgruppenKlaas Krona100% (1)

- Index: SR. NO. Descriptions Sheets Part A - General Design Requirement and ConsiderationDocument9 pagesIndex: SR. NO. Descriptions Sheets Part A - General Design Requirement and ConsiderationDarshan PanchalNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- Flange Design As Per PedDocument10 pagesFlange Design As Per Pedvaibhavd123No ratings yet

- Engineering Change Order: IntentDocument2 pagesEngineering Change Order: IntentYanethNo ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- 1kzte (1) Sbloccato Protetto Parte97Document2 pages1kzte (1) Sbloccato Protetto Parte97lscionti08No ratings yet

- Vent Silencer Data SheetDocument1 pageVent Silencer Data SheetRamazan YaşarNo ratings yet

- CTsyfytytzDocument3 pagesCTsyfytytzRé Marc TathyNo ratings yet

- Technical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKDocument7 pagesTechnical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKAshok reddyNo ratings yet

- Fire Departement Connection (Siames Connection)Document1 pageFire Departement Connection (Siames Connection)Mohamed HassanNo ratings yet

- Axial Piston Pumps: Variable Displacement Worldcup Series P6, 7 & 8W Design BDocument52 pagesAxial Piston Pumps: Variable Displacement Worldcup Series P6, 7 & 8W Design BSwaminathan KbNo ratings yet

- Job Method Sheet: Furnace CRU Shutdown 2013Document30 pagesJob Method Sheet: Furnace CRU Shutdown 2013Khan ArshiNo ratings yet

- KE3-DST-ELC-0908-6040 - DST-Electric - Motor-LV (19-11-09)Document3 pagesKE3-DST-ELC-0908-6040 - DST-Electric - Motor-LV (19-11-09)SUBAS CHANDRA BEHERANo ratings yet

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Document4 pages15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanNo ratings yet

- Amphenol - 05022017 - TP 101 CP 1156596Document2 pagesAmphenol - 05022017 - TP 101 CP 1156596Fredson SidileneNo ratings yet

- Mechanical Data Sheet For Nitrogen ReceiverDocument8 pagesMechanical Data Sheet For Nitrogen ReceiversudjonoNo ratings yet

- Attachment-2, Form Sheet of Test Run RecordDocument12 pagesAttachment-2, Form Sheet of Test Run Recordvirat_daveNo ratings yet

- Document No C.C.G Reply Aconex Reference Number Discip Line of Submi Ttal Type of Subm Ittal Description BuildingDocument11 pagesDocument No C.C.G Reply Aconex Reference Number Discip Line of Submi Ttal Type of Subm Ittal Description BuildingBassam Al shammariNo ratings yet

- SealDocument3 pagesSealshashwatchaurasia83No ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CDocument7 pagesSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CKhan EngrNo ratings yet

- Scientific Design Company, Inc.: Drum Data SheetDocument1 pageScientific Design Company, Inc.: Drum Data SheetAtomic JNo ratings yet

- Datasheet For Hopper (D-3103)Document1 pageDatasheet For Hopper (D-3103)Joe GrosirNo ratings yet

- Foundation ScheduleDocument2 pagesFoundation ScheduleAlways CivilNo ratings yet

- STL 2 2NDDocument15 pagesSTL 2 2NDngoctuan50hkNo ratings yet

- Bridge Note Book SampleDocument2 pagesBridge Note Book SampleGerik Almarez100% (1)

- Intensity ModulationDocument3 pagesIntensity Modulationanon-323096100% (1)

- CH 5 Heat Exchanger Design MethodsDocument30 pagesCH 5 Heat Exchanger Design Methodsapi-3765936100% (1)

- Pipe Bend RadiusDocument8 pagesPipe Bend RadiusAdagharaNo ratings yet

- Chapter 2 AisDocument27 pagesChapter 2 AisPhrexilyn PajarilloNo ratings yet

- WIFI Training Syllybus & OutlineDocument3 pagesWIFI Training Syllybus & Outlinezulkipliyaacob100% (1)

- ISD1700 Design Guide - pdf1Document83 pagesISD1700 Design Guide - pdf1leomancaNo ratings yet

- Practice Final SolutionsDocument41 pagesPractice Final SolutionsHareesha N GNo ratings yet

- Suprema PC SDK 3.1 (3.1.0.0) Reference ManualDocument300 pagesSuprema PC SDK 3.1 (3.1.0.0) Reference ManualRafael SperandioNo ratings yet

- Exercise 02 - BKF1313 Chapter 2 Part 2Document2 pagesExercise 02 - BKF1313 Chapter 2 Part 2Cornelius PhilipNo ratings yet

- Control Tutorials For MATLAB and Simulink - Suspension - Simulink ControlDocument1 pageControl Tutorials For MATLAB and Simulink - Suspension - Simulink ControlMohamed Amine ZouhriNo ratings yet

- Python Modules: What Is A Module?Document9 pagesPython Modules: What Is A Module?Krishnaprasad kNo ratings yet

- Portable Gas Detector Protege ZM Datasheet ANZDocument5 pagesPortable Gas Detector Protege ZM Datasheet ANZCarlos PereaNo ratings yet

- Java Quiz PDFDocument106 pagesJava Quiz PDFNadaBelaRadaNo ratings yet

- Driver Drowsiness and Sleep Detection Alert For Accident Prevention SystemDocument6 pagesDriver Drowsiness and Sleep Detection Alert For Accident Prevention SystemGulshan VermaNo ratings yet

- CameraDocument10 pagesCameraminh thành nguyễnNo ratings yet

- Experiment 2 PDFDocument3 pagesExperiment 2 PDFVmosaNo ratings yet

- AppcDocument19 pagesAppcسعيد سبع العيشNo ratings yet

- Spectroscopic Analysis of Archaeological Pottery Excavated From Alagapuri, Tamilnadu, IndiaDocument9 pagesSpectroscopic Analysis of Archaeological Pottery Excavated From Alagapuri, Tamilnadu, IndiaCJBAS ManagerNo ratings yet

- Mooring of Ships - Forces (Document168 pagesMooring of Ships - Forces (shakirhamid6687100% (5)

- Message Authentication CodesDocument18 pagesMessage Authentication CodesNguyễn Hồng LêNo ratings yet

- Die Casting: From Wikipedia, The Free EncyclopediaDocument6 pagesDie Casting: From Wikipedia, The Free EncyclopediagodseNo ratings yet

- Vultex Cable Brochure Lowres 2Document24 pagesVultex Cable Brochure Lowres 2Tadala MaluwaNo ratings yet

- Fernando, Logit Tobit Probit March 2011Document19 pagesFernando, Logit Tobit Probit March 2011Trieu Giang BuiNo ratings yet

- Cambridge IGCSE: Computer Science 0478/23Document16 pagesCambridge IGCSE: Computer Science 0478/23Sean KeithNo ratings yet

- Axiom Art Is U Data SheetDocument12 pagesAxiom Art Is U Data SheetDaniel DinisNo ratings yet

- Aspnet CompilerDocument5 pagesAspnet Compilerapi-19750719No ratings yet

- TCS Question Bank Without AnswerDocument9 pagesTCS Question Bank Without AnswerGanesh MagarNo ratings yet

- Service Ariston Cibubur 082122541663Document56 pagesService Ariston Cibubur 082122541663Service Pemanas AirNo ratings yet

- Principles of Marketing-HpDocument23 pagesPrinciples of Marketing-HpVarun KumarNo ratings yet