Professional Documents

Culture Documents

CIA 1B - Original Research Paper

CIA 1B - Original Research Paper

Uploaded by

Shreeyash agrawalCopyright:

Available Formats

You might also like

- Industry 4.0 in Logistics and Supply Chain Management: A Systematic Literature ReviewDocument17 pagesIndustry 4.0 in Logistics and Supply Chain Management: A Systematic Literature ReviewSivanantha MurtheeNo ratings yet

- 1 s2.0 S0360835222000705 MainDocument20 pages1 s2.0 S0360835222000705 MainsayaliNo ratings yet

- Industry 4.0 TechnologiesDocument34 pagesIndustry 4.0 Technologies08.reap-sendersNo ratings yet

- The Applications of Industry 4.0 Technologies in Manufacturing Context: A Systematic Literature ReviewDocument34 pagesThe Applications of Industry 4.0 Technologies in Manufacturing Context: A Systematic Literature ReviewMimnun NNo ratings yet

- "Supply Chain Innovation and Industry 4.0": Under The Guidance ofDocument28 pages"Supply Chain Innovation and Industry 4.0": Under The Guidance ofLPGtanker saigalseatradeNo ratings yet

- Proceeding 75 004 8667Document8 pagesProceeding 75 004 8667Jelena DjordjevicNo ratings yet

- How Data Will Transform Industrial Processes: Crowdsensing, Crowdsourcing and Big Data As Pillars of Industry 4.0Document14 pagesHow Data Will Transform Industrial Processes: Crowdsensing, Crowdsourcing and Big Data As Pillars of Industry 4.0Nur AthirahNo ratings yet

- Assignment 2 POMDocument4 pagesAssignment 2 POMarshad mehmoodNo ratings yet

- Supply Chain Innovation and Industry 4Document28 pagesSupply Chain Innovation and Industry 4LPGtanker saigalseatradeNo ratings yet

- Industry 4.0 and The Fourth Industrial Revolution (4IR)Document5 pagesIndustry 4.0 and The Fourth Industrial Revolution (4IR)pskmechpskNo ratings yet

- 1 s2.0 S221478532200462X MainDocument8 pages1 s2.0 S221478532200462X MainCristian Heidelberg Valencia PayanNo ratings yet

- Industry 4.0 1Document11 pagesIndustry 4.0 1Sakshi KshirsagarNo ratings yet

- Thoben Et Al - 2017 - Industrie40 and Smart ManufacturingDocument14 pagesThoben Et Al - 2017 - Industrie40 and Smart ManufacturingHoracioGutierrezNo ratings yet

- Manavalan 2018Document108 pagesManavalan 2018Hena ShabeebNo ratings yet

- "Industrie 4.0" and Smart Manufacturing - A Review of Research Issues and Application ExamplesDocument13 pages"Industrie 4.0" and Smart Manufacturing - A Review of Research Issues and Application ExamplesAlexandrina BugaNo ratings yet

- Applying Industry 4.0 and Education 4.0 To Engineering EducationDocument6 pagesApplying Industry 4.0 and Education 4.0 To Engineering EducationlazarNo ratings yet

- Paperpresentationoni4 0Document6 pagesPaperpresentationoni4 0Iwinx Digital TechnologiesNo ratings yet

- ML19 017Document8 pagesML19 017Zafar HafeezNo ratings yet

- Impact of Industry 4.0 On Production LogisticsDocument10 pagesImpact of Industry 4.0 On Production LogisticsGábor NagyNo ratings yet

- Nagy 2018 IOP Conf. Ser.: Mater. Sci. Eng. 448 012013Document10 pagesNagy 2018 IOP Conf. Ser.: Mater. Sci. Eng. 448 012013Gábor NagyNo ratings yet

- Task Eco Digital Business ResumeDocument3 pagesTask Eco Digital Business ResumeNovi IndrianiNo ratings yet

- Iot and Industry New RevoutionDocument9 pagesIot and Industry New Revoutionsidrasadoor27No ratings yet

- Industry 4.0 Technologies and Their Impact in Contemporary Logistics: A Systematic Literature ReviewDocument27 pagesIndustry 4.0 Technologies and Their Impact in Contemporary Logistics: A Systematic Literature ReviewSooraj Kumar RNo ratings yet

- Application of Data Stream Processing Technologies in Industry 4.0: What Is Missing?Document7 pagesApplication of Data Stream Processing Technologies in Industry 4.0: What Is Missing?Vignesh DeepNo ratings yet

- MBIS5013 Assessment 2 - Individual ReportDocument15 pagesMBIS5013 Assessment 2 - Individual ReportUmar AliNo ratings yet

- Logistics 4.0 Digital Transformation 11Document100 pagesLogistics 4.0 Digital Transformation 11mnunezNo ratings yet

- Turan Paksoy, Sadia Samar Ali, Cigdem Gonul Kochan - Logistics 4.0 - Digital Transformation of Supply Chain Management-CRC Press (2020)Document369 pagesTuran Paksoy, Sadia Samar Ali, Cigdem Gonul Kochan - Logistics 4.0 - Digital Transformation of Supply Chain Management-CRC Press (2020)Kovács Ferenc100% (1)

- New Paradigm of Industry 4.0 Internet of Things, Big Data Cyber Physical SystemsDocument187 pagesNew Paradigm of Industry 4.0 Internet of Things, Big Data Cyber Physical SystemsEgle Fitne100% (6)

- 1 s2.0 S294973612200001X MainDocument17 pages1 s2.0 S294973612200001X MainJerri Bernardes de SouzaNo ratings yet

- Thabit Atobishi Szalay Zsigmond Gábor Szilard Podruzsik: AbstractDocument7 pagesThabit Atobishi Szalay Zsigmond Gábor Szilard Podruzsik: AbstractNur Dini LeeNo ratings yet

- Big Data For Cyber Physical Systems in Industry 4.0: A SurveyDocument23 pagesBig Data For Cyber Physical Systems in Industry 4.0: A SurveyAnass CherrafiNo ratings yet

- INDUSTRY 4.0 Policy BriefDocument22 pagesINDUSTRY 4.0 Policy Briefser.lavieriNo ratings yet

- Industry 4.0 and Chemical Industry The Technology Enablers Behind Strategic Growth of Chemical CompaniesDocument16 pagesIndustry 4.0 and Chemical Industry The Technology Enablers Behind Strategic Growth of Chemical CompaniesIJRASETPublicationsNo ratings yet

- The Fit of Industry 4.0 Applications in Manufacturing Logistics - A Multiple Case StudyDocument16 pagesThe Fit of Industry 4.0 Applications in Manufacturing Logistics - A Multiple Case StudyIoan PascaNo ratings yet

- Koh 2019Document12 pagesKoh 2019Hoa Dao HuuNo ratings yet

- Technological Forecasting & Social Change: Tae Kyung SungDocument6 pagesTechnological Forecasting & Social Change: Tae Kyung SungEnd_06No ratings yet

- BATA Quick ScanDocument21 pagesBATA Quick ScanLars KampherbeekNo ratings yet

- Cloud AccountingDocument52 pagesCloud AccountingSanaullah SiddiqueNo ratings yet

- Industry 4.0Document9 pagesIndustry 4.0Kumar GoutamNo ratings yet

- Oztemel-Gursev2020 Article LiteratureReviewOfIndustry40AnDocument56 pagesOztemel-Gursev2020 Article LiteratureReviewOfIndustry40AnMarko BrkicNo ratings yet

- The Digitalisation of Supply Chain A ReviewDocument11 pagesThe Digitalisation of Supply Chain A ReviewatanasiijeNo ratings yet

- Industry 4.0 3Document6 pagesIndustry 4.0 3Mandhara KsNo ratings yet

- Keywords: Industry 4.0, Internet of Things, Big Data, Cloud, Intelligent ManufacturingDocument6 pagesKeywords: Industry 4.0, Internet of Things, Big Data, Cloud, Intelligent ManufacturingGilbert BettNo ratings yet

- Technology Management Final ReportDocument24 pagesTechnology Management Final ReportAbhishek KandeyNo ratings yet

- Implementation of Industry 4.0 Smart Manufacturing: MD Rafiqul Islam KhanDocument9 pagesImplementation of Industry 4.0 Smart Manufacturing: MD Rafiqul Islam KhanJatin SinghNo ratings yet

- A Perspective On Industry 4.0: From Challenges To Opportunities in Production SystemsDocument8 pagesA Perspective On Industry 4.0: From Challenges To Opportunities in Production SystemsNhư GiaNo ratings yet

- Industry Revolution 7Document7 pagesIndustry Revolution 7shahzaib tahirNo ratings yet

- Big Data As A Promoter of Industry 4.0: Lessons of The Semiconductor IndustryDocument6 pagesBig Data As A Promoter of Industry 4.0: Lessons of The Semiconductor IndustryHorst SmogerNo ratings yet

- Industry 4.0Document15 pagesIndustry 4.0Marie Faith MaramagNo ratings yet

- Conceptual Key Competency Model For Smart Factories in Production Processes2020OrganizacijaOpen AccessDocument12 pagesConceptual Key Competency Model For Smart Factories in Production Processes2020OrganizacijaOpen AccessChrist PradoNo ratings yet

- Industry 4.0: An Overview: July 2018Document7 pagesIndustry 4.0: An Overview: July 2018Romancing LoveNo ratings yet

- Operations Strategy For Industry 4.0Document6 pagesOperations Strategy For Industry 4.0Abhinav GuptaNo ratings yet

- Industry 4.0: An Overview: July 2018Document7 pagesIndustry 4.0: An Overview: July 2018Steve StevenNo ratings yet

- Industry 1.0 To 4.0: The Evolution of Smart Factories: October 2018Document8 pagesIndustry 1.0 To 4.0: The Evolution of Smart Factories: October 2018Mochamad Iqbal PratamaNo ratings yet

- From Concept To The Introduction of Industry 4.0: Marina CrnjacDocument10 pagesFrom Concept To The Introduction of Industry 4.0: Marina CrnjacAzrul ZafrieNo ratings yet

- Bibby & DeheDocument15 pagesBibby & DehePoonam ChawlaNo ratings yet

- Industry 4.0: Architecture and Equipment Revolution: Ech T Press ScienceDocument20 pagesIndustry 4.0: Architecture and Equipment Revolution: Ech T Press ScienceMFNo ratings yet

- Chapter 1Document35 pagesChapter 1Lợi Trần XuânNo ratings yet

- Digital Business Models in Industrial Ecosystems: Lessons Learned from Industry 4.0 Across EuropeFrom EverandDigital Business Models in Industrial Ecosystems: Lessons Learned from Industry 4.0 Across EuropeNo ratings yet

- Relative Strength Index (RSI)Document3 pagesRelative Strength Index (RSI)Shreeyash agrawalNo ratings yet

- Skill DDocument159 pagesSkill DShreeyash agrawalNo ratings yet

- IB Excel AssignmentDocument28 pagesIB Excel AssignmentShreeyash agrawalNo ratings yet

- Research PaperDocument14 pagesResearch PaperShreeyash agrawalNo ratings yet

- Crim 1 BDocument1 pageCrim 1 BJose Antonio Peralta Achaval Jr.No ratings yet

- Centrifugal CastingDocument12 pagesCentrifugal Castingsamurai7_77100% (1)

- Marketing Project Report On INDIAN ORGANIZED RETAIL INDUSTRY BIG BAZARDocument78 pagesMarketing Project Report On INDIAN ORGANIZED RETAIL INDUSTRY BIG BAZARSami Zama0% (1)

- B2-Hasebroock - PD Topics Completed 2015-2016Document2 pagesB2-Hasebroock - PD Topics Completed 2015-2016api-319600132No ratings yet

- Coke Drum Flow DistributionsDocument25 pagesCoke Drum Flow DistributionsFayaz MohammedNo ratings yet

- Duties and Tasks of Indonesian PoliceDocument1 pageDuties and Tasks of Indonesian PoliceName ToomNo ratings yet

- 8 - SS - Ch-6 Effects of The British Rule in IndiaDocument41 pages8 - SS - Ch-6 Effects of The British Rule in IndiaMaddy WinnerNo ratings yet

- GRE Verbal Reasoning Questions and AnswersDocument24 pagesGRE Verbal Reasoning Questions and AnswersTamunotonye Minaye-IlomboNo ratings yet

- The Haryana Value Added Tax ACT, 2003Document83 pagesThe Haryana Value Added Tax ACT, 2003adwiteya groverNo ratings yet

- ConTEXt - Installing Expert Fonts - Minion ProDocument17 pagesConTEXt - Installing Expert Fonts - Minion ProGuy StylesNo ratings yet

- A Small History of Subaltern Studies by Dibesh ChakravartyDocument12 pagesA Small History of Subaltern Studies by Dibesh ChakravartyHarini Kailasam GomathinayagamNo ratings yet

- 1000 Manual 0407Document60 pages1000 Manual 0407Dharmesh patelNo ratings yet

- Basic C ProgramDocument1 pageBasic C ProgramPallab DattaNo ratings yet

- An Evaluation System Interfacing The TSL230/TSL235/TSL245 Light-To - Frequency Converters To A MicrocontrollerDocument15 pagesAn Evaluation System Interfacing The TSL230/TSL235/TSL245 Light-To - Frequency Converters To A MicrocontrollerOscarNo ratings yet

- The Cumulative Frequency Graph Shows The Amount of Time in Minutes, 200 Students Spend Waiting For Their Train On A Particular MorningDocument8 pagesThe Cumulative Frequency Graph Shows The Amount of Time in Minutes, 200 Students Spend Waiting For Their Train On A Particular MorningJonathanNo ratings yet

- 05j - 21BB Model Region Berlin-Brandenburg PDFDocument9 pages05j - 21BB Model Region Berlin-Brandenburg PDFdean j almy IIINo ratings yet

- Front-End Web Development With React: Course Overview: Jogesh K. MuppalaDocument9 pagesFront-End Web Development With React: Course Overview: Jogesh K. MuppalaAshihsNo ratings yet

- Neonatal JaundiceDocument15 pagesNeonatal JaundiceSharan SekhonNo ratings yet

- Preparative Gas Chromatographyand Its ApplicationsDocument13 pagesPreparative Gas Chromatographyand Its ApplicationsFiji IndahNo ratings yet

- Muar Bio Term 2 TrialDocument12 pagesMuar Bio Term 2 TrialChee Beng YeapNo ratings yet

- Project Report "Solidworks" Six Months Software Training Project ReportDocument56 pagesProject Report "Solidworks" Six Months Software Training Project ReportakashNo ratings yet

- HarishDocument4 pagesHarishVivek PaulNo ratings yet

- Yea Siaz C844 0.2Document193 pagesYea Siaz C844 0.2Ivan SmolejNo ratings yet

- Huawei OSN1800 Pre-Sale Training Slide For Agent (2012) PDFDocument43 pagesHuawei OSN1800 Pre-Sale Training Slide For Agent (2012) PDFS. M. Arifinul KarimNo ratings yet

- Autonomous Systems: Inertial SystemsDocument50 pagesAutonomous Systems: Inertial SystemsSara Nieves Matheu GarciaNo ratings yet

- Safety Perforation Gun IncidentDocument5 pagesSafety Perforation Gun IncidentB Deyse FernandesNo ratings yet

- Биология. Общие Закономерности Жизни 9 КлассDocument129 pagesБиология. Общие Закономерности Жизни 9 КлассHell boyNo ratings yet

- Parametric Kerf Bending - ArticleDocument25 pagesParametric Kerf Bending - ArticleMIS-TRYNo ratings yet

- Sirius Timer Relay ManualDocument28 pagesSirius Timer Relay ManualVinoth MahendranNo ratings yet

- Unit 2 - Act 2 - Powers and Roots - 4º ESODocument3 pagesUnit 2 - Act 2 - Powers and Roots - 4º ESOlumaromartinNo ratings yet

CIA 1B - Original Research Paper

CIA 1B - Original Research Paper

Uploaded by

Shreeyash agrawalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CIA 1B - Original Research Paper

CIA 1B - Original Research Paper

Uploaded by

Shreeyash agrawalCopyright:

Available Formats

Engineering Management Journal

ISSN: (Print) (Online) Journal homepage: https://www.tandfonline.com/loi/uemj20

Industry 4.0 in Logistics and Supply Chain

Management: A Systematic Literature Review

Maryam Abdirad & Krishna Krishnan

To cite this article: Maryam Abdirad & Krishna Krishnan (2020): Industry 4.0 in Logistics and

Supply Chain Management: A Systematic Literature Review, Engineering Management Journal,

DOI: 10.1080/10429247.2020.1783935

To link to this article: https://doi.org/10.1080/10429247.2020.1783935

Published online: 13 Jul 2020.

Submit your article to this journal

Article views: 1405

View related articles

View Crossmark data

Citing articles: 9 View citing articles

Full Terms & Conditions of access and use can be found at

https://www.tandfonline.com/action/journalInformation?journalCode=uemj20

Industry 4.0 in Logistics and Supply Chain Management:

A Systematic Literature Review

Maryam Abdirad, Wichita State University

Krishna Krishnan, Wichita State University

Abstract: “Industry 4.0” is a concept that focuses on automa To have an MSC system to address dynamic conditions, it

tion of system and process, digitalization, and data exchange in is necessary to embrace a concept that facilitates transitioning

industries. Its goal is to achieve a smart factory to reduce lead from the traditional SC to an MSC. Industry 4.0 is a concept

time to respond to the customers’ demand or to unforeseen that focuses on automation, digitalization, and networking in

events and improve productivity in the system. Using this companies. It helps companies develop a flexible supply chain

concept can lead to improvements in manufacturing, supply system when they are faced with dynamic systems, especially in

chain (SC), and logistics. The adoption of Industry 4.0 in enabling integration among all elements of the SC, including

supply chain management (SCM) is a new and critical subject suppliers, manufacturers, and customers. Because Industry 4.0

with a need for more research. A few studies have started focuses on mobility and real-time integration, it can be a good

reviewing the existing works on Industry 4.0; however, they framework in MSCs (Barata et al., 2017).

do not focus on its role in SCM. This paper presents The first industrial revolution began with the development of

a systematic review and synthesis of the current literature on water power and steam power and the mechanization of the

Industry 4.0 in SCM that brings out some interesting findings, production system in 1784. The second industrial revolution

which will be helpful for the academic and industry, especially changed the production system to a mass production system

top managers. This work identifies three categories from the and advanced assembly lines using electricity in the 1870s. The

content of the papers as exploratory vs. confirmatory, qualita third industrial revolution was the automation of production

tive vs. quantitative, management level vs. process/technology processes by using computers in 1970. The fourth industrial

level. Additionally, based on the Topic Modeling (TM) techni revolution leads to the integration of systems through digitaliza

que, three different clusters of Supply Chain, Logistics and tion among devices by using IoT and cyber-physical systems

Manufacturing topics were extracted. Current shortcomings, (CPSs) (Lu, 2017), termed as Industry 4.0 (Da Xu, Xu, & Li,

challenges, and future research directions are discussed in the 2018; Tang & Veelenturf, 2019). Armengaud et al. defined Indus

conclusion. try 4.0 as “the comprehensive introduction of information and

communication technology (ICT) as well as their connection to an

Keywords: Industry 4.0, Smart factory, Supply chain, Logistic, internet of things, services and data, which enables a real-time

Internet of Things production. Industry 4.0 means a higher degree of digitalization

for products, value creation chain, and business models. Industry

EMJ Focus Areas: Supply Chain Management, Supply Chain 4.0 supports digitalization by IT solutions and connections to

& Logistics - Industry 4.0, Technology Management improve productivity and reduce costs” (Armengaud et al.,

2017). Exhibit 1 demonstrates the four industrial revolutions.

All companies can use Industry 4.0 for their project. In

H

aving a modern and agile supply chain (SC) is cur Industry 4.0, project managers are the key leaders of projects

rently the goal of every company, because a modern with significant strategic importance for the future of companies.

supply chain (MSC) is fast, automatic in the process Companies require to have well-informed managers about Indus

(accept orders, preparing orders and distribute to customers), try 4.0 to apply it in their company. Managers who are interested

more flexible, and transparent. Moreover, an MSC can work in in digitalization will play a significant role as companies move

dynamic systems and with a high volume of data (Barata et al., forward. They lead companies to digitalization and use innova

2017; Butner, 2010; Yin et al., 2018). tion, for example, connect sensors to vehicles, attach radio fre

As an example of MSC, Amazon has millions of orders quency identification (RFID) to delivery packages and/or utilize

every day. Amazon robots fetch and pick up those orders and cloud technology to restore data. These technologies can help

bring them to the employees to fill them at the right time. An managers to make timely decisions, reduce risk and increase

interesting example of the use of Big Data technologies in the productivity (Saucedo-Martínez et al., 2018). This research can

area of MSC is DHL. Big Data makes it possible to analyze the be a decent start for managers to understand Industry 4.0 and

data at a more advanced level than traditional tools allowed. identify the major classification of supply chain in Industry 4.0.

By collecting and evaluating big data from customers, DHL This research provides a review of the existing literature on

can provide customers with information on potential inter Industry 4.0 and MSC and highlights advances, gaps, and future

ference of their respective supply chains. It is possible to directions for further research. Although there has been an

protect and also to improve the efficiency of the supply increasing interest in applying Industry 4.0 in manufacturing

chain and no operation interruption in the system. It is pro and logistics systems in recent years, a large gap still exists in the

mising to permanently achieve customer satisfaction (Wit knowledge regarding the concepts of this topic, in industries and

kowski, 2017). academic venues (Qin et al., 2016). The goal of this research is to

Refereed Research Manuscript. Accepted by Associate Editor LaScola Needy.

Engineering Management Journal Vol. 00 No. 00 2020 1

Exhibit 1. The Four Industrial Revolutions

First Industrial Revolution

•Mechanization, Water and Steam Power Engine (1784)

Second Industrial Revolution

•Mass Production, Assembly Line using Electriacal Energy (1870)

Third Industrial Revolution

•Use of PLC and IT systems for Automation (1970)

Fourth Industrial Revolution

•Use of IoT and Cyber Physical System (Today)

systematically review the relevant studies: (1) to find and report on with no human involvement (Gilchrist, 2016; Vladimirovich

various articles about the existing knowledge on the topic, (2) to Sokolov et al., 2017). Moreover, the outcome of Industry 4.0

perform content analysis of the current papers by authors’ opinion is the development of factory smart systems that included smart

and Topic Modeling (TM) and find research key topics and areas, machines, smart devices, smart manufacturing processes, smart

and (3) to synthesize research outcomes to frame conclusions and engineering, smart logistics, smart suppliers and smart pro

possibilities for future research. ducts, etc. (Kamble et al., 2018; Li, 2018; Schmidt et al., 2015;

This paper is organized as follows: Section 2 presents the Shrouf et al., 2014).

fundamental concept of Industry 4.0 and its role in the supply Industry 4.0 promotes the use of cyber-physical systems, Inter

chain. Section 3 explains the research method applied in this net of Things, Internet of Services (IoS), robotics, big data, and

paper. Section 4 provides a review of the research trends. cloud manufacturing, thus including devices, machines, production

Section 5 reviews and analyzes the content of the selected modules, and products and applying them to various fields such as

papers with two different approaches, authors’ opinion and the supply chain, manufacturing, and management, especially to

TM of the papers. Section 6 discusses avenues for research in respond in real time (Pereira & Romero, 2017; Kang et al., 2016;

the supply chain with the advent of Industry 4.0. Section 7 Moeuf et al., 2018; (Haddud et al., 2017). Machine learning (ML)

presents conclusions and future work. algorithms, artificial intelligence (AI), business analysis (BA), and

optimization, especially dynamic optimization (DM), are applicable

Concept and Role of Industry 4.0 techniques for implementing Industry 4.0 in a system, to maximize

Concept of Industry 4.0 automation. Readers interested in these topics can refer to several

The concept of Industry 4.0 was presented in 2011 by Henning references: (Kolberg & Zühlke, 2015; Neugebauer et al., 2016;

Kagermann (former top manager of the SAP software corpora Saucedo-Martínez et al., 2018; Wank et al., 2016; Zheng et al., 2018).

tion in Germany) (Paprocki, 2016). Industry 4.0, referred to as

the “Fourth Industrial Revolution,” is also known as “smart

manufacturing,” “industrial internet” or “integrated industry” Role of Industry 4.0 in the Supply Chain

(Hofmann & Rüsch, 2017). This concept is increasingly becom Industry 4.0 is expected to have a significant impact on supply

ing more popular and has been receiving attention all over the chains, business models, and processes in order to achieve an

world (Liao et al., 2017; Rennung et al., 2016). According to MSC. Researchers use different names for Industry 4.0 in the

Google Trend, the number of google searches that contained supply chain management context: digital supply network

the term “Industry 4.0” and “Fourth Industrial Revolution” (DSN), Internet of Things, E-Supply Chain, Supply Chain 4.0,

began in 2012 and 2015 and there has been an upward trend E-logistics, or Logistics 4.0. As explained in the previous sub

as of December 2018, which shows the popularity of this topic section, Industry 4.0 increases digitalization and automation in

(Exhibit 2). This graph shows that industry 4.0 is an emerging manufacturing, and creates a digital process to facilitate inter

topic and needs more research. This is a wonderful opportunity action among all parts of a company. By implementing Indus

for researchers to develop their research expanse and managers try 4.0 in the supply chain systems, four main SC elements—

to discover more about this topic and figure out how they can integration, operations, purchasing, and distribution—are

implement Industry 4.0 in their companies. However, an exact affected and can increase the productivity of companies as

definition of Industry 4.0 has not been determined yet. As said well (Kayikci, 2018). The main benefits of Industry 4.0 in the

by Lopes de Sousa Jabbour et al. (Lopes de Sousa Jabbour et al., SC are to reduce the lead time for delivery of products to

2018), “the core feature of Industry 4.0 is connectivity between customers, reduce the time to respond to an unforeseen

machines, orders, employees, suppliers, and customers due to event, and to prompt a significant increase in decision-

the Internet of Things (IoT), and electronic devices; as making quality (Barreto et al., 2017). Industry 4.0 can help

a consequence, firms are able to produce products using decen companies afford complicated and dynamic processes in their

tralized decisions and autonomous systems.” SC and to handle large-scale production and integration of

The primary focus of Industry 4.0 is to have a smart customers (Rennung et al., 2016). Industry 4.0 can bring posi

manufacturing network based on digitalization and automati tive benefits in current sales and operations planning and also

zation where machines and products interact with each other in the logistics process (Santos et al., 2017). After implementing

2 Engineering Management Journal Vol. 00 No. 00 2020

Exhibit 2. Number of Google Searches Conducted between January 2012 to December 2018 by Contains the Keywords “Fourth Industrial

Revolution” and “Industry 4.0”

120

100

80

60

40

20

0

Jan Jan Jan Jan Jan Jan Jan

2012 2013 2014 2015 2016 2017 2018

Fourth Industrial Revolution: (Worldwide) Industry 4.0: (Worldwide)

Industry 4.0, real-time information can be shared across this previous studies. Then, two questions were formulated to guide

digitalized process to drive useful decisions. the data collection and analysis, as shown in Exhibit 4.

Step 2: Locating Studies

Research Method The relevant research related to the particular review questions

Based on the topic and existing research in this area, were located, selected, and appraised (Denyer & Tranfield,

a systematic review on Industry 4.0 in logistics and SCM was 2009). Five search keyword phrases: “Industry 4.0 and Supply

implemented. For this paper, a structured review methodology Chain,” “Industry 4.0 and Logistics,” “Smart Supply Chain,”

was adopted based on the five steps (Denyer & Tranfield, 2009) “E-Logistics,” and “E-Supply Chain,” were used to access Goo

suggested for conducting systematic reviews: (1) question for gle Scholar first, because this search engine shows most of the

mulation, (2) locating studies, (3) study selection and evalua results from all databases. To identify relevant papers, the title,

tion, (4) analysis and synthesis, and (5) reporting and using abstract, or keywords contained were analyzed. Furthermore, it

results (Exhibit 3) (Abdirad & Dossick, 2016). was decided to look at other major research databases, includ

ing Taylor & Francis, Emerald, Elsevier, IEEE, and Springer, to

determine whether relevant papers could be found.

Step 1: Question Formulation

Keyword selection and database lists caused some limita

First, the authors analyzed the general research trends in the

tions on finding papers in this research. Because this subject

literature from the standpoint of the number of studies on Indus

topic is still new, all review papers in this research were pub

try 4.0 in the supply chain, Industry 4.0 in logistics, and related

lished after 2014. Furthermore, only those papers written in

subjects, evaluating the context of studies and different methods.

English were selected.

Second, the authors analyzed findings from the existing research,

the state of research on this subject, and the pros and cons of

Step 3: Study Selection and Evaluation

To evaluate relevant studies on this topic, the authors reviewed

Exhibit 3. Steps of the Systematic Review in Current Research the content of each paper. They selected related papers, which

discuss supply chain in smart factories with Industry 4.0

Question Exhibit 4. Question Formula and Analysis Criteria

Formulation

Question 1: What are the Trends in Industry 4.0 Based on the SC?

Reporting and Locating

Using Results Studies Analysis Number of studiesPublication datesResearch

Criteria methodsDatabaseGeographical location

Question 2: What is the existing knowledge addressed in research?

Analysis Content analysis based on selected categoriesContent

Criteria analysis based on TMOutcome, advantages, and

Analysis and Study Selection disadvantages of adopted categoriesResearch gaps and

Synthesis and Evaluation

future research

Engineering Management Journal Vol. 00 No. 00 2020 3

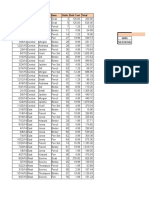

Exhibit 5. Number of Reviewed and Selected Studies in Each Exhibit 6. Number of Publications Distributed by Year

Database

Database (Number of Reviewed Papers) Number of Selected Papers

Number of Publications

30

Taylor & Francis (123) 9 25

Emerald (56) 6 20

Elsevier (37) 16 15

IEEE (27) 2 10

Springer (211) 7 5

Wiley (38) 1 0

Other (15) 16 2014 2015 2016 2017 2018

Total 507 56 Year

a significant growth in the number of studies on Industry 4.0

approach. Because there were not enough published papers in in the supply chain until 2017. Because the last selected papers

this area and more papers were needed for this research, the were published in July 2018, this year’s data does not follow the

authors looked to other databases like Wiley and Semantic trend, because it represents only about half of the year.

Scholar. They selected relevant published papers with potential In Exhibit 5, Elsevier had more contributions with the

content about this research, which did not appear during the highest number of publications of 16 papers, followed by Tay

search of the selected papers. lor and Francis with 9 papers. This indicates that Industry 4.0

Exhibit 5 presents the number of reviewed and selected in the supply chain is a priority topic and covered by the major

papers in each database. A total of 56 out of 507 papers were publishers and repositories.

selected and included in the analysis. In this study, 14 out of 56 papers on the topic of Industry

4.0 in the SC were published in Germany, as shown in Exhibit 7.

Step 4: Analysis and Synthesis As is known, Germany is a pioneer in this research area, which

In this step, each individual study was analyzed based on the this study confirmed. As shown previously in Exhibit 6, the

two questions mentioned above in Exhibit 4. The first question number of studies in this area is increasing, and more scholarly

involved a search for the trends of existing research in Industry research on Industry 4.0 in SC from other countries is expected

4.0 and the supply chain, for example, the number of studies, in the near future.

publication date, geographic location (country), and research In terms of research methods implemented in prior

method, which classified selected papers into six categories: research, most papers (31 out of 56) involve a content analysis

survey, interview, case study, content analysis, literature review, of Industry 4.0 in the SC (Exhibit 8), which indicates a paucity

and modeling. of other empirical research methods such as surveys, interviews,

To answer the second question about current research case studies, modeling, etc.

efforts, collected papers were analyzed and categorized as

exploratory vs. confirmatory, qualitative vs. quantitative, and

management level vs. process/technology level. For example, Content Analysis

a paper could be categorized as exploratory, quantitative, and To answer the second goal of current research, to find research

process level. Additionally, TM was used to cluster papers key topics and areas, the authors performed content analysis

based on their content, and terms that appropriately character based on two approaches, the first one is based on human

ize each cluster were derived using the non-negative matrix

factorization (NMF) method. The following results and analysis

are based on these two aforementioned approaches: human Exhibit 7. Geographical Locations of Studies

expert and machine based.

Number of Publications

Step 5: Reporting and Using Results 15

According to the methodology, in this step, the research results

10

are presented based on the evaluation of selected papers by

defined categories explained in the last subsection and also TM. 5

on the report of the results, research gaps are determined and 0

recommendations for future research are made. At the end of

this paper, a summary and conclusions are presented.

Review of Research Trends Country

Exhibit 6 shows the chronological distribution of publications

from 2014 to 2018. The first paper related to Industry 4.0 based

on the supply chain was published in 2014, and there is

4 Engineering Management Journal Vol. 00 No. 00 2020

Exhibit 8. Research Method Applied

35

30

Number of Publication

25

20

15

10

5

0

Survey Interview Case Content Literature Modeling

Study Analysis Review

Research Method Applied

expert analysis and the other one is TM. In the next two a digitized supply chain system. In contrast, process/technology-

subsections, the results are presented. Furthermore, the most level papers focus on improving the process and implementation of

important trends, issues and findings are discussed. concepts and frameworks of Industry 4.0 within company systems

(Pfohl et al., 2015). These classifications are being used in literature

Human Expert Content Analysis analysis.

In line with the literature, whether or not conceptual Industry Some of the 56 selected papers for this research are review

4.0 is more important than technical Industry 4.0 in the supply papers with the same nature as the current research but with

chain is an open question. The authors did not find any com a different focus, method, and content, so they cannot fit into

prehensive literature classification for the supply chain based on the management level vs. process/technology level categories.

Industry 4.0. Therefore, the authors reviewed selected papers to Therefore, it was decided not to consider them in this part of

analyze the content. They classified them into three dimensions: their analysis. For example, Barata et al. reviewed the mobile

exploratory vs. confirmatory, qualitative vs. quantitative, man supply chain management (mSCM) and integration (Barata

agement level vs. process/technology level. et al., 2017). Another paper reviewed the role of IoT and its

In the exploratory cluster, selected papers focus on answering impact on IoT on the supply chain (Ben-Daya et al., 2017).

a question about how Industry 4.0 can be implemented within the One paper offered a framework to identify Industry 4.0 in the

company’s supply chain. On the other hand, the confirmatory construction supply chain (CSC) (Dallasega et al., 2018).

cluster uses quantitative methods to analyze or provide an imple Strozzi et al. did a literature review on the “smart factory”

mentation model (Pfohl et al., 2015). Quantitative studies measure (Strozzi et al., 2017). Y. Zhong et al. prepared another review

variables with some precision using numeric scales and analysis. paper about Intelligent Manufacturing in the context of

Qualitative studies are based on direct observation of behavior, or Industry 4.0 (Zhong et al., 2017). A review of Industry 4.0

on transcripts of unstructured interviews with experts. Manage implications in logistics is dealt with in the work of Barreto

ment-level papers propose an approach to support companies in et al. (Barreto et al., 2017). A summary of the classified papers

understanding the needed organizational changes to reach is presented in Exhibit 9.

Exhibit 9. Analysis Level

30 30

Number of Publication

25 25

Number of Publication

20 20

15 15

10 10

5 5

0 0

Process/ Process/

Management Management

technology technology

level level

level level

Qualitative 22 11 Exploratory 22 16

Quantitative 1 15 Confirmatory 1 10

Quantitative Qualitative Confirmatory Exploratory

Engineering Management Journal Vol. 00 No. 00 2020 5

Management level. Some of the papers classified as Another paper proposed a framework that identified

management level papers discussed the concept of Industry a correlation between supply chain risks and suitable Industry

4.0 and the supply chain as well as proposing a framework of 4.0 technologies with an example in a steel SC (Schlüter &

implementing of Industry 4.0 and supply chain. In the Sprenger, 2016). Dossou and Nachidi chose the graphs with

conceptual realm, Industry 4.0 was selected as an innovation results and actions inter-related (GRAI) methodology to model

in logistics and the SC (Witkowski, 2017). Researchers believe supply chain performance (Dossou & Nachidi, 2017).

that this represents an end to the traditional supply chain and Premm and Kim used a model involving multi-agent systems

that they should use the main elements of Industry 4.0, such as to achieve logistics modeling approaches based on Industry 4.0

cyber-physical systems, IoT, IOS, smart factory, and big data, in (Premm & Kirn, 2015). In a similar paper, a framework was built

the development of logistics (Almada-Lobo, 2016; Altendorfer- for a digital supply chain (DSC) integration in multi-stakeholder

Kaiser, 2017; Douaioui et al., 2018; Ivanov, Das et al., 2018; environments based on the blockchain and Industry 4.0 principles

Kache & Seuring, 2017; Tuptuk & Hailes, 2018) Also, some (Korpela et al., 2017). Chhetri et al. discussed combinations of

research were done about the impact of the new digital different components of a manufacturing SC and Industry 4.0

technologies (Strange & Zucchella, 2017), process (Chhetri et al., 2018). Armengaud et al. investigated the impacts

improvement (Yin et al., 2018) and servitization (service- of Industry 4.0 along the entire automotive supply chain on the

based relationships between SC elements) in Industry 4.0 was production life cycle (Armengaud et al., 2017).

discussed (Ennis et al., 2018). The focus of some papers is on the process of SC and

Other papers in the Management Level concentrate more methods for improving it. For instance, Trstenjak and Cosic

on the theoretical framework or propose a conceptual frame (Trstenjak & Cosic, 2017) discussed process planning in an

work which classified them in the qualitative category. For Industry 4.0 environment. The benefits of Industry 4.0 and

instance, a categorical framework for manufacturing systems digitalization were evaluated and analyzed by several research

and Industry 4.0 was identified (Qin et al., 2016). In some ers (Bienhaus & Haddud, 2017; Melnyk et al., 2018; Tjahjono

research, a theoretical framework was proposed to evaluate et al., 2017), and the impacts of Industry 4.0 on the procure

the concepts and the implementation and use of logistics and ment function were explored by Glas and Kleemann (Glas &

supply chains by Industry 4.0 with respect to pros and cons in Kleemann, 2016). Branislav et al. mentioned the concept of

the supply chain systems (Bukova et al., 2018; Hofmann & intelligent logistics in the automotive industry (Branislav &

Rüsch, 2017; Pfohl et al., 2015). Brettel et al. illustrated Jozef, 2016), and the application of a production environment

a framework depending on related research streams and topics using manufacturing logistics toward Industry 4.0 was reviewed

in Industry 4.0 (Brettel et al., 2014). Another framework pro by Strandhagen et al. (J. W. Strandhagen et al., 2017). Valverde

vides the description of a complex management approach with and Saadé examined the impact of an e-supply chain (Valverde

the digitalization of the system in the supply chain and logistics & Saadé, 2015), and Szozda explained the challenges to reach

(Diedrich, 2017; Kayikci, 2018; Le Tan & Thi Dai Trang, 2017). an MSC (Szozda, 2017).

Jayaram proposed an enterprise model for a global supply chain The application of a supply chain model based on Industry

with support for IoT and Industry 4.0 (Jayaram, 2016). 4.0 was shown in a paper by Ignacio et al. that validated their

Moreover, Strandhagen et al. designed a framework related to model in a mobile application (Ignacio et al., 2017). Another

logistics and business operations and business models way to evaluate the role of Industry 4.0 is by using RFID

(J. O. Strandhagen et al., 2017). Additionally, Ivanov et al. looked (Bienhaus & Haddud, 2017). Interested readers for empirical

into the business, information, engineering, and analytics perspec research are requested to refer to several references (Fruth &

tives on digitalization and SC risk (Ivanov, Dolgui et al., 2018). Teuteberg, 2017; Majeed & Rupasinghe, 2017; Manoel Queiroz

Furthermore, a study by Man and Strandhagen proposed an & Telles, 2018). The results of the Content Analysis are sum

agenda for research into how Industry 4.0 can be used to create marized in Exhibit 10.

sustainable business models (De Man & Strandhagen, 2017).

Further discussion on content analysis. The distribution of

Process/technical level. Based on the literature, Industry 4.0 categories based on the stack charts shown previously in

works with real-time data in dynamic systems. Some papers Exhibit 9 indicates that the number of papers in management

worked on a dynamic system of SC. For example, Ivanov et al. level and process/technical level is not equal. Therefore, they

designed an algorithm for short-term supply chain scheduling were classified to determine more information about their

in smart factories (Ivanov et al., 2016). Similarly, Sokolov et al. content. By delving more deeply into them, it was found that

developed a model for dynamic scheduling of services for just 4% of the management-level papers are quantitative and

Industry 4.0 supply networks (Vladimirovich Sokolov et al., confirmatory, which means that most of them work on the

2017). In another research, Dunke et al. looked at the impact conceptual part of management.

of digitalization on Industry 4.0 and SC planning, and how From Exhibit 9, it can be seen that 57% of the technical

online optimization copes with real-time challenges (Dunke papers (process/technical level) are quantitative and try to

et al., 2018). explain their findings based on an analysis or to show a case-

In some papers, different technical frameworks for Indus study. The other papers in this category are quantitative. There

try 4.0 and the supply chain have been proposed and imple fore, it appears that there is a general lack of research in the

mented. For example, Dweekat et al. presented a framework for technical and analytical areas to show the possible ways of

an SC performance measurement approach by using IoT, and implementing Industry 4.0 and to present some case studies.

they evaluated their work using real examples (Dweekat et al., This study found that the number of exploratory papers is

2017). Avventuroso et al. offered a digital factory framework by more than the number of confirmatory level papers at the

focusing on data management (Avventuroso et al., 2017). technical level. This means that research is in the early stages,

6 Engineering Management Journal Vol. 00 No. 00 2020

Exhibit 10. Content Analysis Summery Based on Human Expert Approach

Process and/

Title Exploratory Confirmatory Qualitative Quantitative Management or Technology

A categorical framework of manufacturing for Industry 4.0 and * * *

beyond (Qin et al., 2016)

A conceptual framework for servitization in Industry 4.0: Distilling * * *

directions for future research (Ennis et al., 2018)

A dynamic model and an algorithm for short-term supply chain * * *

scheduling in the smart factory Industry 4.0 (Ivanov et al., 2016)

A Multi-agent Systems Perspective on Industry 4.0 Supply * * *

Networks (Premm & Kirn, 2015)

A networked production system to implement virtual enterprise * * *

and product lifecycle information loops (Avventuroso et al., 2017)

A supply chain performance measurement approach using the * * *

internet of things (Dweekat et al., 2017)

An Industry 4.0 research agenda for sustainable business models * * *

(Man & Strandhagen, 2017)

Big data analytics in supply chain and logistics: an empirical * * *

approach (Manoel Queiroz & Telles, 2018)

Challenges and opportunities of digital information at the * * *

intersection of Big Data Analytics and supply chain management

(Kache & Seuring, 2017)

Concept of intelligent logistic for automotive industry (Branislav * * *

& Jozef, 2016)

Digital supply chain transformation toward Blockchain * * *

integration (Korpela et al., 2017)

How virtualization, decentralization and network building * * *

change the manufacturing landscape: An Industry

4.0 perspective (Brettel et al., 2014)

How transport and logistics operators can implement the * * *

solutions of “Industry 4.0.” (Paprocki, 2016)

Industry 4.0 and its impact on the functioning of supply chains * * *

(Szozda, 2017)

Industry 4.0 and the current status as well as future prospects on * * *

logistics (Hofmann & Rüsch, 2017)

Industry 4.0 as digitalization over the entire product lifecycle: * * *

opportunities in the automotive domain (Armengaud et al.,

2017)

Industry 4.0, global value chains and international business * * *

(Strange & Zucchella, 2017)

Integrated scheduling of material flows and information services * * *

in Industry 4.0 supply networks (Vladimirovich Sokolov et al.,

2017)

Internet of Things (IoT) embedded future supply chains for * * *

Industry 4.0: An assessment from an ERP-based fashion apparel

and footwear industry (Majeed & Rupasinghe, 2017)

Internet of Things, Big Data, Industry 4.0 – Innovative solutions in * * *

logistics and supply chains management (Witkowski, 2017)

Issues of implementing electronic supply chain management * * *

(E-SCM) in enterprise (Le Tan & Thi Dai Trang, 2017)

Logistics 4.0 and emerging sustainable business models * * *

(J. O. Strandhagen et al., 2017)

Engineering Management Journal Vol. 00 No. 00 2020 7

Exhibit 10. Content Analysis Summery Based on Human Expert Approach (continued)

Process and/

Title Exploratory Confirmatory Qualitative Quantitative Management or Technology

Lean automation enabled by Industry 4.0 technologies (Kolberg * * *

& Zühlke, 2015)

Lean Six Sigma approach for global supply chain management * * *

using Industry 4.0 and IIoT (Jayaram, 2016)

Manufacturing supply chain and product lifecycle security in the * * *

era of Industry 4.0 (Chhetri et al., 2018)

Framework for digitalized proactive supply chain risk * * *

management (Diedrich, 2017)

Migration framework for decentralized and proactive risk * * *

identification in a steel supply chain via Industry 4.0 technologies

(Schlüter & Sprenger, 2016)

Modeling supply chain performance (Dossou & Nachidi, 2017) * * *

New flexibility drivers for manufacturing, supply chain and * * *

service operations (Ivanov, Das et al., 2018)

Process planning in Industry 4.0 environment (Trstenjak & Cosic, * * *

2017)

Procurement 4.0: factors influencing the digitization of * * *

procurement and supply chains (Bienhaus & Haddud, 2017)

Security of smart manufacturing systems (Tuptuk & Hailes, 2018) * * *

Simulation based validation of supply chain effects through ICT * * *

enabled real-time-capability in ETO production planning

(Dallasega et al., 2017)

Supply chain architecture model based in the Industry 4.0, * * *

validated through a mobile application (Ignacio et al., 2017)

Sustainability impact of digitization in logistics (Kayikci, 2018) * * *

The best of times and the worst of times: empirical operations * * *

and supply chain management research (Melnyk et al., 2018)

The effect of E-supply chain management systems in the north * * *

american electronic manufacturing services industry (Valverde &

Saadé, 2015)

The evolution of production systems from Industry 2.0 through * * *

Industry 4.0 (Yin et al., 2018)

The fit of Industry 4.0 applications in manufacturing logistics: * * *

a multiple case study (J. W. Strandhagen et al., 2017)

The impact of digital technology and Industry 4.0 on the ripple * * *

effect and supply chain risk analytics (Ivanov, Dolgui et al., 2018)

The Impact of Industry 4.0 on procurement and supply * * *

management: A conceptual and qualitative analysis (Glas &

Kleemann, 2016)

The impact of Industry 4.0 on the supply chain (Pfohl et al., 2015) * * *

The industrial management of SMEs in the era of Industry 4.0 * * *

(Moeuf et al., 2018)

The Industry 4.0 revolution and the future of Manufacturing * * *

Execution Systems (MES) (Almada-Lobo, 2016)

The influence of big data on production and logistics * * *

(Altendorfer-Kaiser, 2017)

The interaction between Industry 4.0 and smart logistics: * * *

concepts and perspectives (Douaioui et al., 2018)

8 Engineering Management Journal Vol. 00 No. 00 2020

Exhibit 10. Content Analysis Summery Based on Human Expert Approach (continued)

Process and/

Title Exploratory Confirmatory Qualitative Quantitative Management or Technology

The position of Industry 4.0 in the worldwide logistics chains * * *

(Bukova et al., 2018)

Time traps in supply chains: Is optimal still good enough? (Dunke * * *

et al., 2018)

What does Industry 4.0 mean to supply chain? (Tjahjono et al., * * *

2017)

Review Papers

Digitization in maritime logistics—What is there and what is *

missing?

Industry 4.0 as an enabler of proximity for construction supply *

chains: A systematic literature review

Industry 4.0 implications in logistics: an overview *

Intelligent Manufacturing in the Context of Industry 4.0: *

A Review

Internet of things and supply chain management: a literature *

review

Literature review on the ‘Smart Factory’ concept using *

bibliometric tools

Mobile supply chain management in the Industry 4.0 era *

and investigators are still exploring this subject more than The (TF-IDF) were calculated for selected papers. As

confirming that their hypotheses are correct. a result, a ranking of the top 20 terms was determined, which

To answer raised the question of this section, the authors shows a very rough sense of the content of the document

claim that most of the articles have more focus on conceptual collection (Exhibit 11).

Industry 4.0 in the supply chain than technical Industry 4.0 in

the supply chain. Therefor more papers are needed to explain Non-negative matrix factorization topic modeling. One

more about the technical part of Industry 4.0 in the supply approach for TM to discover the hidden thematic structure in

chain. a large dataset is to apply matrix factorization methods, such as

independent component analysis, singular value

Content Analysis Based on Topic Modeling decomposition, and non-negative matrix factorization (NMF).

TM is a type of unsupervised machine learning that uses One advantage of NMF is to generate a matrix with the positive

clustering to derive latent variables or hidden structures of component that causes a better result for TM than the other

words in documents (O’Callaghan et al., 2015). The goal of methods. Therefore, it was decided to apply the NMF method

applying TM is to find possible hidden topics in selected papers (Rakesh et al., 2009). The output of the NMF method contains

and offer them to researchers for future researches. Therefore, the term weight for each of the k topics and documents

TM was selected to cluster abstracts of 56 collected papers. membership weights.

To apply TM, the data were cleaned and preprocessed to

remove non-informative stop words, capitalization, suffixes, Parameter selection. It is applied to evaluate the different NMF

prefixes, digits, and punctuation to make it ready to use in topics and to select a useful value for the number of topics.

Python programming language. A common approach for parameter selection is the topic

coherence approach, to measure and compare the coherence

Term weighting. In this technique, important terms give of models generated for different values of k clusters

higher weights in the document term matrix. The common (Coherence is called TC-W2 V as a measure to evaluate topic

approach for term-weighting is term frequency-inverse models).

document frequency (TF-IDF). The following formula is used In this research, the minimum K = 2 and the maximum

to calculate term-weighting by TF-IDF, K = 10 were chosen as the number of topics for parameter

� � � � selection. Additionally, to build a word-embedding model for

n coherence measure, which is used for the calculation of coher

wðt; DÞ ¼ tf ðt; dÞ� log þ1

df ðt Þ ence, the Stanford Natural Language Processing (NLP) dataset

was selected. As shown in Exhibit 12, the highest mean coher

which tf(t,d) is the number of times that term t occurs in ence (0.5030) by the top five terms, three topics (Topic 1:

document d. n is the total number of documents. df(t) is the manufacturing, Topic 2: supply chain, and Topic 3: logistics)

number of terms that appear in documents. were selected for this database, which is explained below.

Engineering Management Journal Vol. 00 No. 00 2020 9

Exhibit 11. Term Frequency-Inverse Document Frequency

Number Top Word Weight

1 Industry 5.98

2 Supply 5.58

3 Chain 4.34

4 Production 3.70

5 Manufacturing 3.56

6 Logistics 3.50

7 Research 3.16

8 Systems 2.89

9 Data 2.76

10 Technologies 2.75

11 Business 2.62

12 Industrial 2.52

13 Supply Chain Management 2.50

14 Paper 2.49

15 Information 2.45

16 Product 2.36

17 Management 2.33

18 Chains 2.30

19 Companies 2.15

20 Literature 2.14

Topic 1: manufacturing, production, industry, product, This topic includes papers that explain Industry 4.0 and its

systems impact on SCM as well as the effect of integrated SCM on the

Papers assigned to this topic generally discuss the integra IoT and digitalization technology. There is also an attempt to

tion of smart manufacturing systems and production systems, determine if there is any risk to control it.

how to implement Industry 4.0 in these systems, and the effects Topic 3: logistics, industry, information, business, solutions

of Industry 4.0 on them. The selected papers on this topic show that Industry 4.0 is

Topic 2: supply, chain, SCM, risk, management changing in industries, logistics, and their business. Some

Exhibit 12. Number of Topics Based on Coherence

10 Engineering Management Journal Vol. 00 No. 00 2020

researchers introduced Industry 4.0 as solutions for process is proposed new research topics by incorporating TM and

improvement in their system. classification. Researchers can modify their research line by

Because all paper subjects are about Industry 4.0, the word incorporating the provided insight gained from this paper

“industry” is repeated in the selected papers. This word has (Daneshvar Kakhki & Gargeya, 2019).

appeared in topic 1 and topic 3. It means that this word is in

the top five terms of selected papers for topic 1 and topic 3. Challenges

Other words of supply chain or manufacturing and logistics There is a set of challenges for implementing Industry 4.0. For

make each topic very especial. instance, the lack of technology infrastructure makes its imple

The extracted research topics indicate that, to have MSC, mentation hard. Furthermore, there is a shortage of experts and

Industry 4.0 affects three major aspects of smart factories knowledgeable employees in this area to start a new system or

including; supply chain, logistics and manufacturing. To benefit remodel the current system to obtain the maximum outcome.

from these results, these three key topics proposed for future Additionally, for most of the managers, it is not yet clear if

research of researchers who are interested in Industry 4.0 in there is any benefit or return on the investment and the payoff

supply chain topic. period is also not known. Consequently, there is insufficient

support and commitment from managers for implementing

Discussion of Avenues for Research in Supply Chain with Industry 4.0. According to Industry 4.0, implementing this

Advent of Industry 4.0 standard would minimize human involvement and interactions

In the current research, the content analysis of the selected in the system. A question remains as to what would happen to

papers is explained in two ways: the first one based on the employees who lose their job. Industry 4.0 needs to address

authors’ systematic review, and the second one based on the system integration and ways to increase reliability in this envir

TM that leads this research to find research gaps and future onment. Further research in this subject would clarify these

research opportunities. vague points, potential benefits and the effects on companies’

productivity.

● Most of the papers in the technical part of this literature

review point out an aspect of a conceptual or technical Managerial Implications

framework. However, there remains a large gap, which Currently, most major companies are employing engineering

needs more technical papers to explain the possible process managers for various leadership roles. Engineering managers

and technical implementations. coordinate and direct projects, create detailed plans to accom

● The small number of studies show the impact of Industry plish goals and lead the integration of technical activities.

4.0 on the supply chain and to evaluate it by showing Besides analyzing pertinent technologies and assessing the fea

different case studies before and after implementation. sibility of projects, an engineering manager’s responsibilities

Furthermore, it is necessary to know what the achieve also include planning and directing the installation, testing,

ments would be after implementing Industry 4.0 in com operation, maintenance, and repair of better technologies for

pany systems or if there is any impact on company facilities and equipment. Therefore, implementing Industry 4.0

productivity. is a tremendous undertaking as a part of their responsibilities.

● Almost half of the technical papers identified a type of Hence, an exposure to the concept is important for them to

framework to integrate Industry 4.0 into a specific supply facilitate executing their responsibilities more effectively. If the

chain. However, these studies could not come up with engineering manager reads this research, they become more

a generalizable framework for an Industry 4.0-based supply familiar with Industry 4.0 and different perspectives and char

chain that could be used as an implementation guideline by acteristics about it. Additionally, they become familiar with

companies (firms). different infrastructures in smart factories for Industry 4.0 in

● Small number of studies worked in the quantitative area, supply chain. In its contribution to the engineering managers,

suggesting that there is not enough research based on this paper shows Industry 4.0 can provide a framework for

analytical results and proves the lack of technical know- addressing productivity, traceability, transparency, and effi

how in this area. ciency in the production system which are known as grand

● Each of the proposed topics can be searched and negotiated challenges in Engineering management. This review helps engi

in three different classification approaches (exploratory vs. neering managers understand the pros and cons of Industry 4.0

confirmatory, qualitative vs. quantitative, management and where the current state of Industry 4.0 in supply chain that

level vs. process/technology level) as well which are applic focuses more on theoretical Industry 4.0, thus providing better

able for engineering managers and researchers. decision criteria for the application of Industry 4.0 and digita

lization. They can be familiar with how companies approach

Industry 4.0 and implement digitalization. As observed, the

Contributions and Implication number of companies willing to experiment and implement

The present research provides research opportunities for Industry 4.0 is very low for various reasons, such as payback

researchers. First, this research reflects the current state of period and initial capital requirement. Thus, a better under

research on this topic. Second, developing a classification of standing of the technology helps managers make better-

reviewed papers is insightful and could be further used by informed decisions toward the implementation process.

researchers for similar studies in Industry 4.0 and supply

chain. Third, the clustering of selected papers based on topics Limitation

and methodologies represent the main aspects of this topic for The authors explored the major limitations of this study. First,

future research. Finally, the fourth contribution of this research for this research like other systematic papers specific keywords

Engineering Management Journal Vol. 00 No. 00 2020 11

such as “Industry 4.0,” “supply chain,” or “logistics” was used References

(Abdirad & Dossick, 2016). The second limitation of this Abdirad, H., & Dossick, C. S. (2016). BIM curriculum design in

research is the English language that removes non-English architecture, engineering, and construction education:

papers. Some other existing papers, especially in German, A systematic review. ITcon, 21(17), 250–271. https://www.

were ignored in this research. The third limitation of this itcon.org/2016/17

work is the scarcity of articles on this subject that limit TM Almada-Lobo, F. (2016). The Industry 4.0 revolution and the

results in three clusters, and it was impossible to create sub- future of manufacturing execution systems (MES). Journal

clusters to develop this research. The final limitation of this of Innovation Management, 3(4), 16–21. https://doi.org/

work is the potential flaws in the search process. Authors spent 10.24840/2183-0606_003.004_0003

a considerable amount of time in the search process finding Altendorfer-Kaiser, S. (2017). The influence of big data on

papers. Despite their effort, and due to the scope of work, some production and logistics. In H. Lödding, R. Riedel, K. D.

papers might be neglected accidentally or because of the errors Thoben, G. von Cieminski, & D. Kiritsis (Eds.), Advances

in the search process (Daneshvar Kakhki & Gargeya, 2019). in production management systems. The path to intelligent,

collaborative and sustainable manufacturing. APMS 2017.

IFIP advances in information and communication technol

Suggestions ogy, Cham (Vol. 513). Springer.

The small number of papers on this topic indicates that Armengaud, E., Sams, C., Von Falck, G., List, G., Kreiner, C.,

a comprehensive solid document is lacking. It is suggested & Riel, A. (2017). Industry 4.0 as digitalization over the

that a set of guidelines be written by experts in this area to entire product lifecycle: Opportunities in the automotive

serve as a dependable reference for factories when starting and domain. Systems, Software and Services Process Improve

developing this new concept. More than suggested research ment. EuroSPI 2017. Communications in Computer and

topics, there is an opportunity for further research with Information Science, 748. https://doi.org/10.1007/

a narrower concentration on identifying factory roles in Indus 978-3-319-64218-5_28

try 4.0 in the supply chain. As mentioned in the introduction, Avventuroso, G., Silvestri, M., & Pedrazzoli., P. (2017).

this subject is very applicable to real-time problems. For future A networked production system to implement virtual

work, topics such as “The Role of Industry 4.0 in the Supply enterprise and product lifecycle information loops. IFAC-

Chain Using a Dynamic Problem Approach” is suggested. PapersOnLine, 50(1), 7964–7969. https://doi.org/10.1016/J.

Implementing Industry 4.0 is complex and challenging. One IFACOL.2017.08.902

of the major topics of research in this field as future works is Barata, J., Rupino Da Cunha, P., & Stal, J. (2017). Mobile supply

defining where, when and how companies should implement chain management in the industry 4.0 era: An annotated

Industry 4.0 in their SC approach. Another topic would be to bibliography and guide for future research. Journal of

determine the advantages and disadvantages of Industry 4.0 Enterprise Information Management, 31(1), 173–192.

implementation and the total cost and benefits of implementa https://doi.org/10.1108/IMDS-09-2017-0403

tion to companies. Barreto, L., Amaral, A., & Pereira, T. (2017). Industry 4.0 implica

tions in logistics: An overview. Procedia Manufacturing, 13,

1245–1252. https://doi.org/10.1016/J.PROMFG.2017.09.045

Conclusion Ben-Daya, M., Hassini, E., & Bahroun, Z. (2017). Internet of

In this paper, the authors conducted and reported a systematic things and supply chain management: A literature review.

literature review to highlight the trends, advances, and gaps in International Journal of Production Research, 57, 15–16,

research on the application of Industry 4.0 in supply chain 4719–4742. https://doi.org/10.1080/00207543.2017.1402140

management. The findings from the literature review of this Bienhaus, F., & Haddud, A. (2017). Procurement 4.0: Factors

study show that Industry 4.0 is seen as a concept that has an influencing the digitisation of procurement and supply

important role in the MSC. By applying this concept, human chains. Business Process Management Journal, 24(4),

interaction would be minimized, and productivity would be 965–984. https://doi.org/10.1108/BPMJ-10-2016-0214

increased in companies (Kayikci, 2018). Branislav, M., & Jozef, H. (2016). Concept of intelligent logistic for

This work provides both researchers and managers with an automotive industry. Journal of Applied Engineering Science,

insightful description of the current state of research in Indus 14(2), 233–238. https://doi.org/10.5937/jaes14-10907

try 4.0 in supply chain and related future trends in research and Brettel, M., Friederichsen, N., Keller, M., & Rosenberg, M.

practice. Moreover, through the analysis performed, the results (2014). How virtualization, decentralization and network

showed that supply chain, logistics, and manufacturing are building change the manufacturing landscape: An Industry

affected areas through Industry 4.0 in supply chain. Adding 4.0 perspective. World Academy of Science, Engineering and

three dimensions; exploratory vs. confirmatory, qualitative vs. Technology, International Journal of Mechanical, Aerospace,

quantitative, management level vs. process/technology level to Industrial, Mechatronic and Manufacturing Engineering, 8,

three mentioned clustered, open new research topics for 37–44. https://doi.org/10.5281/zenodo.1336426

researchers, as well. These fields can be a baseline for engineer Bukova, B., Brumercikova, E., Cerna, L., & Drozdziel, P. (2018).

ing managers to start Industry 4.0 implementation and for The position of Industry 4.0 in the worldwide logistics

researchers to develop their research in these areas. These can chains. LOGI-Scientific Journal on Transport and Logistics,

be the important topics for future research and need further 9(1), 18–23. https://doi.org/10.2478/logi-2018-0003

investigation. However, the limited number of professionals Butner, K. (2010). The smarter supply chain of the future.

with expertise in Industry 4.0 is a factor that limits advance Strategy & Leadership, 38(1), 22–31. https://doi.org/

research and discussion about this subject. 10.1108/10878571011009859

12 Engineering Management Journal Vol. 00 No. 00 2020

Chhetri, S. R., Faezi, S., Rashid, N., & Abdullah, M. (2018). Manu through Servitization. Aston Business School. http://dx.doi.

facturing supply chain and product lifecycle security in the era org/10.2139/ssrn.3529276

of Industry 4.0. Journal of Hardware and Systems Security, 2(1), Fruth, M., & Teuteberg, F. (2017). Digitization in maritime

51–68. https://doi.org/10.1007/s41635-017-0031-0 logistics—What is there and what is missing? Cogent Busi

Da Xu, L., Xu, E. L., & Li, L. (2018). Industry 4.0: State of the ness & Management, 4(1), 1–40. https://doi.org/10.1080/

art and future trends. International Journal of Production 23311975.2017.1411066

Research, 56(8), 2941–2962. https://doi.org/10.1080/ Gilchrist, A. (2016). Introducing Industry 4.0. Springer. https://

00207543.2018.1444806 doi.org/10.1007/978-1-4842-2047-4_13

Dallasega, P., Rauch, E., & Linder, C. (2018). Industry 4.0 as an Glas, A. H., & Kleemann, F. C. (2016). The Impact of Industry

enabler of proximity for construction supply chains: 4.0 on procurement and supply management: A conceptual

A systematic literature review. Computers in Industry, 99, and qualitative analysis. International Journal of Business

205–225. https://doi.org/10.1016/J.COMPIND.2018.03.039 and Management Invention , 5(6), 55–66. https://www.

Dallasega, P., Rojas, R. A., Rauch, E., & Matt, D. T. (2017). ijbmi.org/papers/Vol(5)6/I0506055066.pdf

Simulation based validation of supply chain effects through Haddud, A., DeSouza, A., Khare, A., & Lee, H. (2017). Exam

ICT enabled Real-time-capability in ETO production ining potential benefits and challenges associated with the

planning. Procedia Manufacturing, 11, 846–853. https:// Internet of Things integration in supply chains. Journal of

doi.org/10.1016/J.PROMFG.2017.07.187 Manufacturing Technology Management, 28(8), 1055–1085.

Daneshvar Kakhki, M., & Gargeya, V. B. (2019). Information https://doi.org/10.1108/JMTM-05-2017-0094

systems for supply chain management: A systematic litera Hofmann, E., & Rüsch, M. (2017). Industry 4.0 and the current

ture analysis. International Journal of Production Research, status as well as future prospects on logistics. Computers in

57(15–16), 5318–5339. https://doi.org/10.1080/ Industry, 89, 23–34. https://doi.org/10.1016/j.

00207543.2019.1570376 compind.2017.04.002

de Man, J. C., & Strandhagen, J. O. (2017). An Industry 4.0 Ignacio, J., Molano, R., Emiro, L., Bravo, C., & Trujillo, E. R.

research agenda for sustainable business models. Procedia (2017). Supply chain architecture model based in the

CIRP, 63, 721–726. https://doi.org/10.1016/J. Industry 4.0, validated through a mobile application. Con

PROCIR.2017.03.315 temporary Engineering Sciences, 10(32), 1581–1594. https://

Denyer, D., & Tranfield, D. (2009). Producing a systematic doi.org/10.12988/ces.2017.711186

review. In D. A. Buchanan & A. Bryman (Eds.), The sage Ivanov, D., Das, A., & Choi, T.-M. (2018). New flexibility

handbook of organizational research methods (pp. 671– drivers for manufacturing, supply chain and service

689). Sage Publications Ltd. https://psycnet.apa.org/ operations. New Flexibility Drivers for Manufacturing, Sup

record/2010-00924-039 ply Chain and Service Operations, International Journal of

Diedrich, K. (2017). Framework for digitalized proactive supply Production Research, 56(10), 3359–3368. https://doi.org/

chain risk management. In W. B. Kersten & C. M. Thor 10.1080/00207543.2018.1457813

sten Ringle (Eds.), Digitalization in supply chain manage Ivanov, D., Dolgui, A., & Sokolov, B. (2018). The impact of

ment and logistics: Smart and digital solutions for an digital technology and Industry 4.0 on the ripple effect and

industry 4.0 environment. Proceedings of the Hamburg supply chain risk analytics. International Journal of Produc

International Conference of Logistics (HICL) (Vol. 23, pp. tion Research, 57(3), 829–846. https://doi.org/10.1080/

381–403). http://dx.doi.org/10.15480/882.1456 00207543.2018.1488086

Dossou, P. E., & Nachidi, M. (2017). Modeling supply chain Ivanov, D., Dolgui, A., Sokolov, B., Werner, F., & Ivanova, M.

performance. Procedia Manufacturing, 11, 838–845. (2016). A dynamic model and an algorithm for short-term

https://doi.org/10.1016/J.PROMFG.2017.07.186 supply chain scheduling in the smart factory Industry 4.0.

Douaioui, K., Fri, M., Mabroukki, C., & Semma, E. A. (2018). International Journal of Production Research, 54(2),

The interaction between Industry 4.0 and smart logistics: 386–402. https://doi.org/10.1080/00207543.2014.999958

Concepts and perspectives. In 2018 International Collo Jayaram, A. (2016). Lean six sigma approach for global supply

quium on Logistics and Supply Chain Management (LOGIS chain management using Industry 4.0 and IIoT. In 2016

TIQUA), Tangier (pp. 128–132). IEEE. https://doi.org/ 2nd International Conference on Contemporary Computing

10.1109/LOGISTIQUA.2018.8428300 and Informatics (IC3I), Noida, India (pp. 89–94). https://

Dunke, F., Heckmann, I., Nickel, S., & Saldanha-da-Gama, F. doi.org/10.1109/IC3I.2016.7917940

(2018). Time traps in supply chains: Is optimal still good Kache, F., & Seuring, S. (2017). Challenges and opportunities of

enough? European Journal of Operational Research, Else digital information at the intersection of Big Data Analytics

vier, 264(3), 813–829. https://doi.org/10.1016/j. and supply chain management. International Journal of

ejor.2016.07.016 Operations & Production Management, 37(1), 10–36.

Dweekat, A. J., Hwang, G., & Park, J. (2017). A supply chain https://doi.org/10.1108/IJOPM-02-2015-0078

performance measurement approach using the internet of Kamble, S. S., Gunasekaran, A., & Gawankar, S. A. (2018).

things: Toward more practical SCPMS. Industrial Manage Sustainable Industry 4.0 framework: A systematic literature

ment & Data Systems, 117(2), 267–286. https://doi.org/ review identifying the current trends and future

10.1108/IMDS-03-2016-0096 perspectives. Process Safety and Environmental Protection,

Ennis, C., Barnett, N., de Cesare, S., Lander, R., & Pilkington, A. 117, 408–425. https://doi.org/10.1016/j.psep.2018.05.009

(2018). A conceptual framework for servitization in industry Kang, H. S., Lee, J. Y., Choi, S., Kim, H., Park, J. H., Son, J. Y.,

4.0: Distilling directions for future research. Proceedings of the & Kim, B. H. (2016). Smart manufacturing: Past research,

Spring Servitization Conference: Driving Competitiveness present findings, and future directions. International

Engineering Management Journal Vol. 00 No. 00 2020 13

Journal of Precision Engineering and Manufacturing-Green O’Callaghan, D., Greene, D., Carthy, J., & Cunningham, P.

Technology, 3(1), 111–128. https://doi.org/10.1007/s40684- (2015). An analysis of the coherence of descriptors in

016-0015-5 topic modeling. Expert Systems with Applications, 42(13),

Kayikci, Y. (2018). Sustainability impact of digitization in 5645–5657. https://doi.org/10.1016/j.eswa.2015.02.055