Professional Documents

Culture Documents

Evaluation of Methods Applied For Extraction and Processing of Oil Palm Products in Selected States of Southern Nigeria

Evaluation of Methods Applied For Extraction and Processing of Oil Palm Products in Selected States of Southern Nigeria

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evaluation of Methods Applied For Extraction and Processing of Oil Palm Products in Selected States of Southern Nigeria

Evaluation of Methods Applied For Extraction and Processing of Oil Palm Products in Selected States of Southern Nigeria

Copyright:

Available Formats

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Evaluation of Methods Applied for Extraction and

Processing of Oil Palm Products in Selected States of

Southern Nigeria

Etuk E.U., Obafemi A.A., and Abagwa O.

Institute of Natural Resource, Environment and Sustainable Development, Faculty of Science, University of Port Harcourt, Port

Harcourt, Nigeria

Abstract:- The study evaluated the methods applied for (Bassey, 2016). Oil palm is also an essential food item.

extraction and processing of oil palm products in the About 90 percent of the palm oil produced ends in food

selected States of Southern Nigeria. The study adopted products, while the remaining 10 percent is used for

the use of cross sectional research design and made use industrial production. As a result of its many uses demand is

of 560 structured copies of questionnaire to elicit growing fast as the world’s population increases and

information from the oil palm farmers and producers standards of living rise (FAO, 2014). Production of palm oil

using purposive and random sampling techniques. is more sustainable than other vegetable oils. It consumes

Descriptive statistics were used for analyzing the data. considerably less energy in production, uses less land and

Results showed that majority (74.2%) of respondents generates more oil per hectare than other leading vegetable

were females and majority (78.3%) were within the age oils-rapeseed, Europe’s leading oil, or soybeans (Onoja and

of 36 and 55 years. More than 70% of respondents made Achike, 2015). Palm oil is used for preventing vitamin A

use of maximum of one hectare of land for oil palm deficiency and is rumored to be good for cancer sufferers,

production. Findings also revealed that native method of brain disease, aging; and treating malaria, high blood

oil palm extraction and processing dominated the entire pressure, high cholesterol, and cyanide poisoning. Palm oil

study area; and followed by squeeze press; with small is used for weight loss and increasing the body’s

scale utilization dominating in terms of oil palm metabolism. As a food, palm oil is used for cooking and

producers and methods applied for extraction in the frying. Industrially, palm oil is used for manufacturing

study area. The study therefore recommended that cosmetics, soaps, toothpaste, waxes, lubricants, and ink

government should support the oil palm (Bassey, 2016). Palm oil can be used to produce biodiesel,

farmers/producers with loans and adequate credit which is also known as Palm Oil Methyl Ester (Federal

facilities that will aid crude oil palm extractions and Ministry of Agriculture and Rural Development, 2016). Oil

productions because of its socio-economic benefits to palm is a typical crop of the rainy tropical lowlands. The

rural livelihoods and food production processes in the plant belongs to the kingdom Plantae, family Arecaceae, sub

study area and the increasing demands of crude oil palm. family Arecoideae, tribe Cocoeae, genius Elaeis, and it is

scientific name is Elaeis guineensis (Gledhill, 2008; FAO,

Keywords:- Methods, Extraction, Processing, Oil Palm, 2014). It is in the family along with coconut and date palms.

Southern Nigeria.

Palm produce accounted for about 82.1 % of the

I. INTRODUCTION Nigeria’s total domestic export between 1966 and 1973

(Adeniyi et al., 2014) and about 22 % of the foreign

The Oil palm is as old as creation. Every part of the exchange earnings up to the beginning of the civil war

tree is useful economically and for domestic purposes. It is (Modebe, 1978). As at 1986, the Nigeria’s domestic palm oil

generally agreed that the Oil Palm originated in the tropical production was estimated to be 760,000 metric tonnes while

rain forest region of West Africa (Food and Agriculture her imports then stood at 179,000 metric tonnes. Palm

Organization (FAO), 2014). The main belt runs through the kernel, a by-product of palm oil is also consequently

southern latitudes of Cameroon, Côte d’Ivoire, Ghana, produced in large quantities in Nigeria during the same

Liberia, Nigeria, Sierra Leone, Togo and into the equatorial period. Palm kernel output however declined from 419,000

region of Angola and the Congo (Agriculture Organization metric tonnes during the period 1960 –1965 to 385,000

of Nigeria (AON), 2019). Processing oil palm fruits for metric tonnes from 1985 –1987 probably due to poor market

edible oil has been practiced in Africa for thousands of outlet for the product. The oil palm is one of the important

years, and the oil produced, highly coloured and flavoured, economic crops in the tropics (Adeniyi et al., 2014). It is the

is an essential ingredient in much of the traditional West most important source of oil and produces more oil per

African cuisine. The traditional process is simple, but hectare than any of the oil producing crops. The primary

tedious and inefficient (FAO, 2014). Mature palms are products of the oil palm are palm oil (from the mesocarp)

single-stemmed and grow to 20 m tall. The leaves are and palm kernel oil obtained from the kernels (seeds). Palm

pinnate and reach between 3-5 m long. In Nigeria, it is oil contains carotene, a precursor of vitamin A, a high prized

cultivated in the South East Zone and the Niger Delta areas energy vitamin rich food used for cooking in oil producing

IJISRT21JUL093 www.ijisrt.com 1304

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

countries of Africa. Palm oil and palm kernel oil provide by process control laboratories ensure smooth, efficient

raw materials in the manufacture of soaps and detergents, operation. Although such large installations are capital

margarine, candle, confectionery, epoxy resins, bakery intensive, extraction rates of 23 - 24 percent palm oil per

trade, lubricants, pomades and cosmetics. Other uses include bunch can be achieved from good quality Tenera (PIND,

palm kernel cake obtained from the crushing of palm kernel 2011).

to extract oil. It serves as additives in livestock feed

manufacture. Conversion of crude palm oil to refined oil involves

removal of the products of hydrolysis and oxidation, colour

Processing oil palm fruits for edible oil has been and flavour. After refining, the oil may be separated

practiced in Africa for thousands of years, and the oil (fractionated) into liquid and solid phases by thermo-

produced, highly coloured and flavoured, is an essential mechanical means (controlled cooling, crystallization, and

ingredient in much of the traditional West African cuisine. filtering), and the liquid fraction (olein) is used extensively

The method used to extract vegetable oil depends on the as a liquid cooking oil in tropical climates, competing

type of raw material available. Raw materials may be successfully with the more expensive groundnut, corn, and

grouped according to the part of the plant that contains the sunflower oils.

fat or oil (seed, bean, nut or fruit). The main difference in

raw materials is the moisture content. Raw materials with Extraction of oil from the palm kernels is generally

low moisture content include seeds and beans and some separate from palm oil extraction, and will often be carried

nuts, which are dried on harvest. Palm fruit, olive fruits and out in mills that process other oilseeds (such as groundnuts,

some coconuts are processed wet (Adebiyi et al., 2017). rapeseed, cottonseed, shea nuts or copra). The stages in this

Only seeds, nuts and fruits that contain considerable process comprise grinding the kernels into small particles,

amounts of edible oil are used for small-scale oil extraction. heating (cooking), and extracting the oil using an oilseed

Other types (for example maize) may contain edible oil, but expeller or petroleum-derived solvent. The oil then requires

the quantities are too small for economic processing on a clarification in a filter press or by sedimentation. Extraction

small-scale. However, not all oil-rich seeds and fruits have is a well-established industry, with large numbers of

edible oil; some contain toxins (poisons, usually of bacterial international manufacturers able to offer equipment that can

origin) or have unpleasant flavours; these are used only for process from 10 kg to several tonnes per hour (Poku, 2002).

varnishes, paints, etc. Others, (for example castor oil) need Alongside the development of these large-scale fully

very careful processing to make them safe for use as mechanised oil palm mills and their installation in

medicines. These are not suitable for small-scale processing plantations supplying the international edible oil refining

(FAO, 2014). industry, small-scale village and artisanal processing has

continued in Africa. Ventures range in throughput from a

Palm fruit contains about 56 percent oil (25 percent on few hundred kilograms up to 8 tonnes FFB per day and

a fresh fruit bunch basis) which is edible with no known supply oil to the domestic market (Poku, 2002).

toxins. It is thus suitable for small-scale processing.

Research and development work in many disciplines - Efforts to mechanise and improve traditional manual

biochemistry, chemical and mechanical engineering - and procedures have been undertaken by research bodies,

the establishment of plantations, which provided the development agencies, and private sector engineering

opportunity for large-scale fully mechanized processing, companies, but these activities have been piecemeal and

resulted in the evolution of a sequence of processing steps uncoordinated. They have generally concentrated on

designed to extract, from a harvested oil palm bunch, a high removing the tedium and drudgery from the mashing or

yield of a product of acceptable quality for the international pounding stage (digestion), and improving the efficiency of

edible oil trade. The oil winning process, in summary, oil extraction. Small mechanical, motorized digesters have

involves the reception of fresh fruit bunches from the been developed in most oil palm cultivating African

plantations, sterilizing and threshing of bunches to free the countries. Palm oil processors of all sizes go through these

palm fruit, mashing the fruit and pressing out the crude palm unit operational stages. They differ in the level of

oil. The oil is further treated to purify and dry it for storage mechanization of each unit operation and the

and export (FAO, 2014; Federal Ministry of Agriculture and interconnecting materials transfer mechanisms that make the

Rural Development, 2015). system batch or continuous. The scale of operations differs

at the level of process and product quality control that may

Large-scale plants, featuring all stages required to be achieved by the method of mechanization adopted (Singh

produce palm oil to international standards, are generally et al., 2013; FAO, 2014).

handling from 3 to 60 tonnes of FFB/hr. The large

installations have mechanical handling systems (bucket and There are several works done on oil palm processing

screw conveyers, pumps and pipelines) and operate and extraction. Ezeoha et al. (2012) reviewed literature on

continuously, depending on the availability of FFB. Boilers, the problems and prospects of indigenous design and

fuelled by fibre and shell, produce superheated steam, used manufacture of palm kernel oil screw press in Nigeria; while

to generate electricity through turbine generators. The lower Akande et al. (2013) examined the level oil palm production

pressure steam from the turbine is used for heating purposes mechanization in selected local government areas of Oyo

throughout the factory. Most processing operations are and Osun States, Nigeria. Oke (2002) evaluated palm oil

automatically controlled and routine sampling and analysis processing in Egbedore LGA of Osun State, Nigeria. Oil

IJISRT21JUL093 www.ijisrt.com 1305

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

palm resources have been undergoing different ways of II. MATERIALS AND METHODS

being extracted and processed as recognised by different

studies but most of these studies did not undergo The study was carried out in communities in Akwa

quantification in terms of methodological approach used; Ibom, Imo and Rivers State, Southern Nigeria. They are

and also most of the studies have been restricted to a located geographically within latitude 4o 02’ 00’’N and 6o

particular region aside the Niger Delta. The present study is 00’ 00’’N and longitude 6o 00’ 00’’E and 8o 30’00’’E

examining the extraction and processing methods for palm (Figure 1). The study areas experience a tropical climate

oil in the core Niger Delta, Nigeria with a view to adopting consisting of rainy season (usually from April to November)

quantification approach. and dry season (December to March). High temperatures

and humidity as well as marked wet and dry seasons

characterize the climate of the area (Kuruk, 2004).

Figure 1: Study Area States

The geology is basically sedimentary and is dominated remaining 46 wards were obtained from the 3 LGAs in

by the geology of arcuate Niger delta; composed of an Rivers State. The total number of wards of 114 was

overall classic sequence which reaches a maximum considered high for the study. Thus, a sample size of 50%

thickness of 9-12 kilometers (lbe, 1988). The vegetation of was determined from the total number of each ward in each

the area is characterized by mangrove forests, brackish LGA. In other words, half of the size of each total number of

swamp forests and rain forests. The study adopted the cross wards (50%) was used as criteria for selecting oil palm

sectional research design (Schmidt and Kohlmann, 2008). farmers and processors as participants for the study. In each

The study involved using primary data acquired from the selected ward, ten (10) oil palm farmers and processors were

field surveys using structured questionnaire which was selected to give a total of 560 respondents for the study.

administered on the sampled oil palm producers and Thus, based on the number of wards, the sample size for the

business men and women in the study areas. The population study was 560 respondents. The sampling procedure

of study involved all oil palm processors in three LGAs employed multi-stage sampling, purposive sampling and

under each three States (that is; Akwa Ibom (Esit Eket, Nsit random sampling techniques. Oil palm agricultural zones

Ubium and Ibesikpo), Imo (Ezinihitte Mbaise, Obowo and namely; Akwa Ibom, Imo and Rivers States were

Aboh Mbaise) and Rivers States (Ikwerre, Etche and purposively selected among Niger Delta member states

Emohua)). The study area was divided into wards and a total because of the intensity of oil palm processing activities in

of 114 wards were obtained for the study whereby, 34 wards these areas and also that oil palm processing is largely a

were recorded for the 3 LGAs in Akwa Ibom, another 34 rural based enterprise (Onoh and Peter-Onoh, 2012; Eze et

wards were obtained from 3 LGAs in Imo State; while the al., 2014; Uche et al., 2017). Thus, rural communities as

IJISRT21JUL093 www.ijisrt.com 1306

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

grouped by wards in each LGA under each state were used bracket of between 46 and 55 years; while the remaining

as the study areas where questionnaire administrations were 9.4% of sampled respondents are 56 years and above. Thus,

carried out for the study in line with the study objectives. more respondents within the age bracket of 26 and 55 years

Descriptive statistics in form of frequency and percentages were sampled for the study with majority (49.1%) being

were used for the data analyses. contributed from sampled oil palm farmers from Imo State.

III. RESULTS AND DISCUSSIONS The information for the level of education revealed

that 5.5% sampled respondents had primary level education;

Socio-economic Characteristics of Sampled Respondents 59.2% of sampled respondents had secondary level

The information displayed on Table 1 describes the education; 23.9% of respondents have tertiary level of

socio-economic characteristics of sampled respondents. In education; while the remaining 11.5% of sampled

Akwa Ibom State, it was revealed that 26.0% oil palm respondents have other forms of education that teaches them

farmer were males while 74.0% were females; in Imo State, to read and write. The occupational status of respondents for

27.3% respondents were males while 72.7% were females; the study indicated that 30.9% are farmers; 60.3% of the

however, least number of males (24.4%) were sampled from respondents are oil palm traders; while the remaining 8.8%

Rivers State with highest number of females of 75.6%. The of respondents are oil palm businessmen/women or retailers.

distribution revealed that more female oil palm The average monthly income of sampled respondents

farmers/traders/retailers were sampled for the study. The showed that 0.4% earn on the average #30,000; 4.4% of

information for the age distribution of sampled respondents respondents earn between #31,000 and #45,000; 18.3% of

revealed that 12.4% of sampled respondents were between sampled respondents earn on the average between #46,000

the age bracket of 26 and 35 years; 44.5% of sampled and #60,000; 47.7% of sampled respondents earn between

respondents were between the age bracket of 36 and 45 #61,000 and #80,000; while the remaining 29.2% of

years; 33.8% of sampled respondents falls within the age sampled respondents earn at least #81,000 and above.

Table 1: Socio-economic Characteristics of Sampled Respondents

State

Socio-economic Status Akwa Ibom Imo Rivers Total

Gender Male 39 44 52 135

26.0% 27.3% 24.4% 25.8%

Female 111 117 161 389

74.0% 72.7% 75.6% 74.2%

Age 26-35 years 15 20 30 65

10.0% 12.4% 14.1% 12.4%

36-45 years 69 79 85 233

46.0% 49.1% 39.9% 44.5%

46-55 years 51 49 77 177

34.0% 30.4% 36.2% 33.8%

56 years and above 15 13 21 49

10.0% 8.1% 9.9% 9.4%

Level of Education Primary 15 3 11 29

10.0% 1.9% 5.2% 5.5%

Secondary 87 100 123 310

58.0% 62.1% 57.7% 59.2%

Tertiary 32 41 52 125

21.3% 25.5% 24.4% 23.9%

Others 16 17 27 60

10.7% 10.6% 12.7% 11.5%

Occupation Farmer 49 47 66 162

32.7% 29.2% 31.0% 30.9%

Oil Palm Trader 91 98 127 316

60.7% 60.9% 59.6% 60.3%

Business/Retailer 10 16 20 46

6.7% 9.9% 9.4% 8.8%

Average monthly #31,000 - #60,000 0 2 0 2

income 0.0% 1.2% 0.0% 0.4%

#61,000 - #90,000 2 19 2 23

1.3% 11.8% 0.9% 4.4%

#91,000 - #120,000 27 41 28 96

IJISRT21JUL093 www.ijisrt.com 1307

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

18.0% 25.5% 13.1% 18.3%

#121,000 - #150,000 74 67 109 250

49.3% 41.6% 51.2% 47.7%

#151,000 and above 47 32 74 153

31.3% 19.9% 34.7% 29.2%

Methods of Extraction and Processing of Oil Palm presented on Table 3. The results revealed that among LGAs

Products in the Study Area in Akwa Ibom State, Ibesikpo (11.6%) utilizes more of less

than 1 hectare of land for oil palm business; Aboh Mbaise

Land Area (hectares) Utilized for Oil Palm Production (11.1%) also showed that more oil palm farmers utilizes less

The land area (hectares) utilized for oil palm than 1 hectare of land; 18.5% was indicated for oil palm

production among sampled States is presented on Table 2. It farmers in Etche LGA with less than 1 hectare of land.

was revealed that more of Rivers oil palm producers However, in general, the study sampled more oil palm

(42.9%) (43.5%) and (37.7%) utilizes less than 1 hectare, 1 farmers in Ibesikpo and Ezinihitte LGAs with land area

hectare and between 1 and 2 hectares of land for oil palm utilization of more than 4 hectares in the study area. The

production in the study area. However, more oil palm information on Table 4 further shows the analysis for land

producers were sampled in the LGAs in Rivers State due to utilization among sampled oil palm producers in the study

higher number of wards. For land area space between 3 and area. The column analysis revealed that in the study area

4 hectares and above 4 hectares showed slightly lower land 36.1% of oil palm producers utilizes less than 1 hectare of

utilization for LGAs in Rivers State (32.6%) and (28.6%) land; 36.8% of oil palm farmers utilizes at least an hectare of

against Akwa Ibom (32.6% and 37.1%) and Imo States land; 11.6% of oil palm farmers occupied a land space of

(34.8% and 34.3%) which may be due to the cost of land in between 1 and 2 hectares; while the remaining 8.8% and

Rivers state which is usually higher in Rivers State than the 6.7% of sampled oil palm producers have between 3 and 4

other states. hectares and above 4 hectares of land for oil palm

cultivation in the study area.

In the same analysis, land utilization for oil palm

production was compared across LGAs and this was

Table 2: Land Area (Hectares) Utilized for Oil palm Production

State

Hectares of Land Used Akwa Ibom Imo Rivers Total

Less than 1 hectare 53 55 81 189

28.0% 29.1% 42.9% 100.0%

I hectare 51 58 84 193

26.4% 30.1% 43.5% 100.0%

Between 1 and 2 hectares 18 20 23 61

29.5% 32.8% 37.7% 100.0%

Between 3 and 4 hectares 15 16 15 46

32.6% 34.8% 32.6% 100.0%

Above 4 hectares 13 12 10 35

37.1% 34.3% 28.6% 100.0%

Total 150 161 213 524

28.6% 30.7% 40.6% 100.0%

Table 3: Hectares of Land Utilized for Oil palm Production (Row)

LGAs

Akwa Ibom Imo Rivers

Esit Nsit Aboh

Land Area (Hectares) Eket Ubium Ibesikpo Ezinihitte Obowo Mbaise Ikwerre Etche Emohua Total

Less than 1 hectare 15 16 22 18 16 21 24 35 22 189

7.9% 8.5% 11.6% 9.5% 8.5% 11.1% 12.7% 18.5% 11.6% 100.0%

I hectare 17 18 16 22 16 20 27 32 25 193

8.8% 9.3% 8.3% 11.4% 8.3% 10.4% 14.0% 16.6% 13.0% 100.0%

Between 1 and 2 7 6 5 6 6 8 6 8 9 61

hectares

11.5% 9.8% 8.2% 9.8% 9.8% 13.1% 9.8% 13.1% 14.8% 100.0%

IJISRT21JUL093 www.ijisrt.com 1308

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Between 3 and 4 5 4 6 6 6 4 6 5 4 46

hectares

10.9% 8.7% 13.0% 13.0% 13.0% 8.7% 13.0% 10.9% 8.7% 100.0%

Above 4 hectares 4 3 6 6 5 1 3 3 4 35

11.4% 8.6% 17.1% 17.1% 14.3% 2.9% 8.6% 8.6% 11.4% 100.0%

Total 48 47 55 58 49 54 66 83 64 524

9.2% 9.0% 10.5% 11.1% 9.4% 10.3% 12.6% 15.8% 12.2% 100.0%

Table 4: Hectares of Land Utilized for Oil palm Production (Column)

Land Area (Hectares)

Less than 1 Between 1 and Between 3 and Above 4

State LGAs hectare I hectare 2 hectares 4 hectares hectares Total

Akwa Ibom Esit Eket 15 17 7 5 4 48

31.3% 35.4% 14.6% 10.4% 8.3% 100.0%

Nsit Ubium 16 18 6 4 3 47

34.0% 38.3% 12.8% 8.5% 6.4% 100.0%

Ibesikpo 22 16 5 6 6 55

40.0% 29.1% 9.1% 10.9% 10.9% 100.0%

Imo Ezinihitte 18 22 6 6 6 58

31.0% 37.9% 10.3% 10.3% 10.3% 100.0%

Obowo 16 16 6 6 5 49

32.7% 32.7% 12.2% 12.2% 10.2% 100.0%

Aboh Mbaise 21 20 8 4 1 54

38.9% 37.0% 14.8% 7.4% 1.9% 100.0%

Rivers Ikwerre 24 27 6 6 3 66

36.4% 40.9% 9.1% 9.1% 4.5% 100.0%

Etche 35 32 8 5 3 83

42.2% 38.6% 9.6% 6.0% 3.6% 100.0%

Emohua 22 25 9 4 4 64

34.4% 39.1% 14.1% 6.3% 6.3% 100.0%

Total 189 193 61 46 35 524

36.1% 36.8% 11.6% 8.8% 6.7% 100.0%

Oil Palm Production Process method of boiling palm fruits. Plate 3 describes the modern

The oil palm production processing normally follows method of heating up the palm fruits before being processed

the steps displayed on Table 5. The first process is the and transferred to the Clarification Tank (the whole process

softening of the palm fruits which is being is automated but only need a controller that monitors the

pounded/skimmed into paste like product after which the oil process). Plate 4 showed a local clarification tank that

extraction process starts; and the final stage is the separates the oil from the fibre and nuts. Plate 5 and Plate 6

clarification stage which is basically for removing of describes the modern and local method of oil clarification

impurities and the separation of particles from the extracted process that separates palm oil from the fibre and nuts.

oil palm. Plate 1 and Plate 2 gives a clear picture of the local

Table 5: Processing Steps of Palm oil products

Process Methods

Local (Native) Modern (Automated)

Softening of the palm fruits Boiling of palm fruits in a big pot using Palm fruits are heated up in a container using

by heating firewood pressured heaters

Maceration Pounding Skimming

Oil Extraction A Colander pounds the oil palm paste Palm oil extracting Machine called Pioneer Mill

which is mixed water and heated to release (Revolver Press)

oil

Clarification A manually wheeled clarification tank An automated giant sized clarification tank

(Removal of impurities)

IJISRT21JUL093 www.ijisrt.com 1309

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Plate 1: Local heating method: Boiling of palm fruits with firewood

Plate 2: Local method of boiling palm fruits

Plate 3: Palm fruits Heater and Processor Machine that is connected to the Clarification Tank

IJISRT21JUL093 www.ijisrt.com 1310

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Plate 4: Local Oil extractor which pound the paste to release the oil

Plate 5: A modern Clarification tank (Large scale business)

Plate 6: A local Clarification Tank (Small scale business)

IJISRT21JUL093 www.ijisrt.com 1311

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Extraction Methods

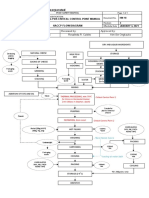

The information on Figure 2 reveals the typical process of palm oil extraction. The actual palm oil extraction process starts

from the bunch threshing (which is the separation of the bunch from the nuts); to fruit digestion (process of releasing the palm oil

in the fruit through rupture of breaking down of oil bearing cells); to pulp pressing (pressing stage that involves extracting the oil

out of the digested palm pulp); to oil clarification (removing impurities from the palm oil); and packing the oil that comes out of

the clarification process.

BUNCH

RECEPTION

BUNCH

STERILIZATION

BUNCH

THRESHING Empty Bunches

FRUIT

DIGESTION

PULP NUT & FIB R E

PRESSING NUT RECOVERY

OIL NUT DRYING

CLARIFICATION

OIL DRYING NUT CRACKING

KERNEL

OIL PACKING SEPARATION Shells

Kernels

KERNEL

STORAGE

Figure 2: Chart of Palm Oil Extraction (also include the extraction of palm kernel oil)

Extraction Methods across Sampled LGAs was observed that the pioneer methods were practiced

The extraction methods across LGAs are displayed on among oil palm farmers/producers/business men and women

Table 6. The distribution revealed that native extraction who have between 3, 4 and above 4 hectares of land devoted

methods were by 69.5% sampled oil palm producers; 29.6% for oil palm production. However, oil palm farmers with less

of sampled oil palm producers utilize the squeeze press than 1 hectare of land devoted for oil palm business utilizes

methods; while the remaining 1.0% of sampled oil palm the native and squeeze method of oil extraction (native

producers utilizes the pioneer mill method. Thus, only 2 methods (47.5%) and squeeze press (10.3%)). These

(3.6%) from the total sampled oil palm producers in the observations are similar for oil palm producers who devoted

three (3) LGAs under Akwa Ibom use the pioneer mill in between 1 and 2 hectares for oil palm production (native

Ibesikpo LGA; 1 which represents 1.7% of the total methods (42.6%) and squeeze press (24.5%)).

population of sampled oil palm producers in the three (3)

LGAs under Imo State utilize the pioneer mill in Ezinihitte Furthermore, the scales of individual oil palm producer

LGA; while 3.0% from the total sampled oil palm farmers with their extraction methods are displayed on Table 8. The

under Rivers State utilizes the pioneer mill in Ikwerre LGA. study indicated majority of sampled oil palm producers

The squeeze press method was being practiced by 29.6% in (98.6%) which totaled 68.9% from the overall total who

the study area of which the utilization showed slight employed the native method of extracting oil run a small

variations in frequency of usage across LGAs. The cross scale oil palm production business. The population of 55.5%

tabulation between hectares of land utilized by oil palm of oil palm producers who practiced the squeeze press

producers and extraction methods is displayed on Table 7. It method operates their oil palm production on a medium

IJISRT21JUL093 www.ijisrt.com 1312

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

scale basis. Lastly, 0.5% of oil palm producers who utilizes total 14.1% from the overall total are on a large scale oil

the native method, and 43.2% who utilize the squeeze palm production in the study area.

method and 100.0% who utilizes the pioneer mill which

Table 6: Cross Tabulation of Methods Applied for Oil Extraction for Oil Palm with LGAs

Extraction Methods

LGAs Native method Squeeze press Pioneer Mill (Revolver Press) Total

Akwa Ibom Esit Eket 27 21 0 48

56.3% 43.8% 0.0% 100.0%

Nsit Ubium 31 16 0 47

66.0% 34.0% 0.0% 100.0%

Ibesikpo 39 14 2 55

70.9% 25.5% 3.6% 100.0%

Imo Ezinihitte 35 22 1 58

60.3% 37.9% 1.7% 100.0%

Obowo 32 17 0 49

65.3% 34.7% 0.0% 100.0%

Aboh Mbaise 44 10 0 54

81.5% 18.5% 0.0% 100.0%

Rivers Ikwerre 39 25 2 66

59.1% 37.9% 3.0% 100.0%

Etche 70 13 0 83

84.3% 15.7% 0.0% 100.0%

Emohua 47 17 0 64

73.4% 26.6% 0.0% 100.0%

Total 364 155 5 524

69.5% 29.6% 1.0% 100.0%

Table 7: Cross Tabulation of Extraction Methods and Hectares of Land Utilized for Oil Palm farming and Production

Extraction Methods

Pioneer Mill

Native (Revolver

Hectares of Land Utilized method Squeeze press Press) Total

Less than 1 hectare 173 16 0 189

47.5% 10.3% 0.0% 36.1%

I hectare 155 38 0 193

42.6% 24.5% 0.0% 36.8%

Between 1 and 2 hectares 32 29 0 61

8.8% 18.7% 0.0% 11.6%

Between 3 and 4 hectares 1 41 4 46

0.3% 26.5% 80.0% 8.8%

Above 4 hectares 3 31 1 35

0.8% 20.0% 20.0% 6.7%

Total 364 155 5 524

100.0% 100.0% 100.0% 100.0%

Table 8: Cross Tabulation of Scale Utilized by Oil palm producers and Methods Applied for Extraction

Extraction Methods

Pioneer Mill

Scale Utilized Native method Squeeze press (Revolver Press) Total

Small Scale 359 2 0 361

98.6% 1.3% 0.0% 68.9%

Medium scale 3 86 0 89

0.8% 55.5% 0.0% 17.0%

Large scale 2 67 5 74

0.5% 43.2% 100.0% 14.1%

Total 364 155 5 524

100.0% 100.0% 100.0% 100.0%

IJISRT21JUL093 www.ijisrt.com 1313

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

IV. DISCUSSION OF FINDINGS Engineering. 2013-Special Issue - 2nd International

Conference on Engineering and Technology Research,

Findings revealed that more females were found in the 4(9):36-39.

occupation of extracting and processing of oil palm [5]. Bassey, O.I. (2016). Overview of oil palm production

products. This is agreement to the study of Walker (2010) in Nigeria; Comparative social and environmental

who reported that women play an important role in the impacts; Case of Ekong Anaku Community in Cross

production, storage and commercialization of the red palm River State, Nigeria. Institute of Social Science,

oil. Majority of the methods for extracting and processing Erasmus University Rotterdam.

oil palm resources were native methods. This may be [6]. Bello, R.S., Bello, M.B., Essien, B.A., Saidu, M.J.

attributed to the simple way that this kind of extraction (2015). Economic Potentials of Oil Palm Production

method demands. Although, it is simple but tedious and in UDI, Enugu State. Science Journal of Business

inefficient (Adeniyi et al., 2014; Bello et al., 2015). Kwasi and Management, 3(5-1): 16-20.

(2002) reported that pounding (digestion) and oil extraction [7]. Eze, S.O., Nwoha, V.U. & Adiele, C.S. (2014). Oil

are the most tedious and essential operations in traditional Palm Processing Among Farmers in Imo State:

palm fruit processing; therefore, early efforts concentrated Implications for Market Orientation and

on these tasks. In small-scale processing, digestion, that is, Entrepreneurship in Extension Practice in Nigeria.

the breaking up of the oil-bearing cells of the palm fruits’ Journal of Agriculture, Extension and Rural

mesocarp, is the most labour intensive activity. The general Development, 2(7): 114-120

traditional method of oil extraction consists of steeping the [8]. Ezeoha, S.L, Akubuo . C.O. and Ani, A.O. (2012):

pounded fruit mash in hot or cold water; removing fibre and Indigenous Design and Manufacture of Palm Kernel

nuts in small baskets and hand squeezing; filtering out Oil Screw Press in Nigeria: Problems and Prospects.

residual fibre from the oil/water emulsion in perforated International Journal of Applied Agricultural Research

metal colanders or baskets; boiling and skimming palm oil 7(2):67-82

from the oil/water mixture and drying the recovered oil [9]. FAO (2002): “Food and Agricultural Organization of

(Poku, 1998). United Nations” Publications Rome 2002. pp: 225-

255.

V. CONCLUSION AND RECOMMENDATIONS [10]. Federal Ministry of Agriculture and Rural

Development (2015). National programme for food

The study concluded that the major method of security (NPFC). Expansion Phase Project Report

extracting and processing oil palm in Imo, Rivers and Akwa 2006-2015

Ibom States in Nigeria was native methods and majority of [11]. Food and Agriculture Organization (FAO) (2014).

land utilized was maximum of one hectare with small scale Global forest resources assessment 2010, Food and

utilization with respect to oil palm producers and methods Agriculture Organization of the United Nations. Rome,

applied for extraction. The study therefore recommended Italy.

that government should support the oil palm [12]. Ibe, A.C., (1988). Coastline Erosion in Nigeria. Ibadan

farmers/producers with loans and adequate credit facilities University Press, Ibadan Nigeria.

that will aid crude oil palm extractions and productions [13]. Kuruk, P., (2004). Customary Water Laws and

because of its socio-economic benefits to rural livelihoods Practices: Nigeria

and food production processes in the study area and the http://www.fao.org/legal/advserv/FAOIUCNcs/Nigeria

increasing demands of crude oil palm. .pdf.

[14]. Kwaski, P. (2002). “Small-scale palm oil processing in

REFERENCES Africa”. FAO Agricultural Services Bulletin, 148 (3).

[15]. Modebe, S. (1978). The Feasibility Study of Olumo

[1]. Adebiyi, H.O., Oladimeji, A. B., & Gambo, M. D. Agro-Allied Farm.Retrieved May, 2012,

(2017). Prevention of environmental degradation in [16]. Oke, O. E. (2002). Evaluation of Palm Oil Processing

Nigeria: a strategy towards sustainable development. in Egbedore LGA of Osun State, Nigeria. An

International Journal of Sciences, Engineering & Unpublished M.Sc Thesis submitted to the Department

Environmental Technology, 2 (3), 17-24. of Agricultural Engineering, Obafemi Awolowo

[2]. Adeniyi O. R.Ogunsola G.O.Oluwusi D. (2014): University, Ile-Ife, Nigeria.

Methods of Palm Oil Processing in Ogun State, [17]. Onoh, P.A., & Peter-Onoh, C.A. (2012). Adoption of

Nigeria: A Resource Use Efficiency Assessment. improved oil palm production technology among

American International Journal of Contemporary farmers in Aboh Mbaise Local Government Area of

Research, 4(8):173-179. Imo State. International Journal of Agriculture and

[3]. Agriculture Organization of Nigeria, (2019). Oil Palm. Rural Development, 15(2): 966-971

Available at: [18]. Onoja, A.O. and A.I. Achike (2015) 'Large-Scale Land

https://www.agriculturenigeria.com/user/senceagric/ Acquisitions by Foreign Investors in West Africa:

Retrieved 2019-11-05 Learning Points', Consilience: The Journal of

[4]. Akande F., Oriola K. , Oniya O., and, Bolaji G. Sustainable Development 14(2): 173-188.

(2013): Level of Oil Palm Production Mechanization [19]. PIND (2011) Foundation for Partnership Initiatives

in Selected Local Government Areas of Oyo and Osun in the Niger Delta. A report on Palm Oil Value

States, Nigeria. Innovative Systems Design and Chain Analysis in the Niger Delta.

IJISRT21JUL093 www.ijisrt.com 1314

Volume 6, Issue 7, July – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

[20]. Poku, K. (1998). Oil Palm Smallholder Development:

Processing Technology Mission Report presented on

FAO Project TCP/MLW/6612. p.250

[21]. Singh, R.; Ong-Abdullah, M.; Low, E.-T.L.; Manaf,

M.A.A.; Rosli, R.; Nookiah, R.; Ooi, L.C.-L.; Ooi, S.-

E.; Chan, K.-L.; Halim, M.A.; Azizi, N. (2013). "Oil

palm genome sequence reveals divergence of

interfertile species in Old and New worlds". Nature.

500 (7462): 335–339.

[22]. Uche, C., Etowa, E.B. & Anele, P.C. (2017).

Economic Analysis of Palm Oil Processing in Ikwerre

and Etche Local Government Areas of Rivers State,

Nigeria. Applied Tropical Agriculture, 22 (1): 5-8.

[23]. Walker, A., (2010): “Oil palm in Africa”.

http//:.oilpalmafrica.wordpress.com. Accessed: May

26, 2012 (www.nifor.org) Official website of the

Nigeria Institute for Oil palm Research. Accessed:

April, 12, 2012

IJISRT21JUL093 www.ijisrt.com 1315

You might also like

- Economic Analysis of Processing and Marketing of Palm Oil in Afikpo NorthDocument8 pagesEconomic Analysis of Processing and Marketing of Palm Oil in Afikpo NorthMajesty100% (1)

- Procedure Text-How To Extract Palm Oil From Palm Fruit at HomeDocument2 pagesProcedure Text-How To Extract Palm Oil From Palm Fruit at HomeRestu Hasibuan100% (1)

- Pome 4 PDFDocument13 pagesPome 4 PDFHafiz Maulud100% (1)

- Design and Analysis of Energy Efficient IntegratedDocument9 pagesDesign and Analysis of Energy Efficient IntegratedAbyan100% (1)

- Value Chain Analysis of Super Pure Vegetable Oil Management EssayDocument10 pagesValue Chain Analysis of Super Pure Vegetable Oil Management Essaygauravsharm4100% (1)

- Palm Oil Mill Bio RefinerDocument21 pagesPalm Oil Mill Bio Refinerajeculture100% (1)

- Characterization of Bio-Oil: A By-Product From Slow Pyrolysis of Oil Palm Empty Fruit BunchesDocument6 pagesCharacterization of Bio-Oil: A By-Product From Slow Pyrolysis of Oil Palm Empty Fruit BunchesMochamad Bhadawi100% (1)

- W B6 ICCL 2013 Cuypers Biopile v20131002Document25 pagesW B6 ICCL 2013 Cuypers Biopile v20131002Rodrigo Salgueiro Llanos100% (1)

- EKOGRID Presentation With Selected Cases-190412 PDFDocument31 pagesEKOGRID Presentation With Selected Cases-190412 PDFMuhammad ZiyaadNo ratings yet

- Bioresource Technology: Mailin Misson, Roslindawati Haron, Mohd Fadhzir Ahmad Kamaroddin, Nor Aishah Saidina AminDocument7 pagesBioresource Technology: Mailin Misson, Roslindawati Haron, Mohd Fadhzir Ahmad Kamaroddin, Nor Aishah Saidina Aminwidianingsih100% (1)

- Penentuan Minyak Mentah Di Sumatera Selatan: Oil Losses Dan Faktor Koreksi Pada Jalur Pipa PengirimanDocument6 pagesPenentuan Minyak Mentah Di Sumatera Selatan: Oil Losses Dan Faktor Koreksi Pada Jalur Pipa PengirimanNia dewi100% (1)

- Guidelines For Soil and Groundwater Sampling - Brownfields/Voluntary Cleanup ProgramDocument3 pagesGuidelines For Soil and Groundwater Sampling - Brownfields/Voluntary Cleanup ProgramStiharu100% (1)

- Water Sampling and Preservation Techniques: A.Gnanavelu CPCB, BangaloreDocument32 pagesWater Sampling and Preservation Techniques: A.Gnanavelu CPCB, BangaloreKashif Md 3NA16CV413100% (1)

- Hazardous Waste Control L3Document5 pagesHazardous Waste Control L3Reno Valencia Perez100% (1)

- Pesticides in SoilDocument33 pagesPesticides in Soildani100% (1)

- Risk Analysis Template 35Document2 pagesRisk Analysis Template 35Abobakr Elomda100% (1)

- Biopile Design and Construction 1996 TM 2189Document132 pagesBiopile Design and Construction 1996 TM 2189Botnaru Vladimir100% (1)

- Waste in USADocument6 pagesWaste in USARavi Sankar100% (1)

- Biosafety and Biosecurity Lec. 3Document14 pagesBiosafety and Biosecurity Lec. 3Ali Alhadi100% (1)

- Risk Matrix, Consequence and Likelihood Tables: Appendix ThreeDocument2 pagesRisk Matrix, Consequence and Likelihood Tables: Appendix Threekent kent100% (1)

- New Automobile Depreciation: Years ValueDocument22 pagesNew Automobile Depreciation: Years Valueroyalb100% (4)

- Modern Oil Palm CultivationDocument12 pagesModern Oil Palm CultivationLip Hock Chan100% (1)

- Calculator - Leasing Vs (1) (1) - PurchasingDocument2 pagesCalculator - Leasing Vs (1) (1) - PurchasingTomer Saban100% (1)

- Anjali Exim - 5 TonDocument15 pagesAnjali Exim - 5 TonAjay Jain100% (1)

- Soils and Rocks Schedules and Chain of Custody SheetsDocument3 pagesSoils and Rocks Schedules and Chain of Custody SheetsJajat Sudrajat100% (1)

- Soil Investigations and Evaluation 3Document4 pagesSoil Investigations and Evaluation 3jassim mohammed100% (1)

- Indonesian Palm Oil Smallholders - Briefing PaperDocument11 pagesIndonesian Palm Oil Smallholders - Briefing PaperSri Wahyudi100% (1)

- Composting of Waste From Palm Oil Mill: A Sustainable Waste Management PracticeDocument15 pagesComposting of Waste From Palm Oil Mill: A Sustainable Waste Management Practiceaufa100% (1)

- TH THDocument1 pageTH THBudi Ariyadi100% (1)

- Project Title: Project Proposal: EMD/EPD 452 Final Year Project Project Proposal Semester I, 2014-15Document13 pagesProject Title: Project Proposal: EMD/EPD 452 Final Year Project Project Proposal Semester I, 2014-15Imran Kai100% (1)

- Case Study Palm Oil Refinery NewDocument2 pagesCase Study Palm Oil Refinery NewFong Leong Chee 馮亮智100% (2)

- Sampling Soils and Contaminated Media With Hand-Operated Bucket AugersDocument4 pagesSampling Soils and Contaminated Media With Hand-Operated Bucket AugersMPS KALIBARU100% (1)

- Well Design Constr For Monitoring GWContam Sites1Document95 pagesWell Design Constr For Monitoring GWContam Sites1EstefaniaSantos100% (1)

- Bio Oil Empty Fruit BunchesDocument8 pagesBio Oil Empty Fruit Bunchesegananta100% (1)

- PoramDocument58 pagesPoramHendrawan Darmalim100% (1)

- Composting of Waste From Palm Oil Mill A Sustainable WasteDocument14 pagesComposting of Waste From Palm Oil Mill A Sustainable WasteKai Yuan Teo100% (1)

- Electrokinetic RemediationDocument22 pagesElectrokinetic RemediationBunani ParfaitNo ratings yet

- Advance in Bioefuel Production From Oil Palm and Palm Oil Processing WastesDocument15 pagesAdvance in Bioefuel Production From Oil Palm and Palm Oil Processing WastesMiftahFakhriansyah100% (1)

- Introduction To Oil Palm & Palm Oil Milling-IntroductionDocument11 pagesIntroduction To Oil Palm & Palm Oil Milling-Introductionjneokl100% (1)

- Engineering Proposal and Quotation: 50T/D Continuous Refining Workshop EquipmentDocument26 pagesEngineering Proposal and Quotation: 50T/D Continuous Refining Workshop EquipmentMuhammad aliNo ratings yet

- Coconut Lecture PresentationDocument49 pagesCoconut Lecture PresentationAmoako DerrickNo ratings yet

- WYG Environmental (Ireland) Ltd. Water Sampling Protocol: 1) Site ObservationsDocument15 pagesWYG Environmental (Ireland) Ltd. Water Sampling Protocol: 1) Site ObservationsLeni Marlina100% (1)

- Edible Oil.Document9 pagesEdible Oil.Bilal RiazNo ratings yet

- Edible OilDocument51 pagesEdible Oilashish100% (3)

- Dry Separation TechnologyDocument15 pagesDry Separation Technologyamirul amirNo ratings yet

- Wenzhou Bangcheng Grain and Oil Machinery Co.,Ltd: 20T/D Soybean & Sunflower Oil Full Continuous Refinery Plant QuotationDocument3 pagesWenzhou Bangcheng Grain and Oil Machinery Co.,Ltd: 20T/D Soybean & Sunflower Oil Full Continuous Refinery Plant QuotationMuhammad aliNo ratings yet

- Tugas Latihan Membuat Jurnal PACDocument8 pagesTugas Latihan Membuat Jurnal PACAhey AhoyNo ratings yet

- Sensors: Dissolved Gas Analysis Equipment For Online Monitoring of Transformer Oil: A ReviewDocument21 pagesSensors: Dissolved Gas Analysis Equipment For Online Monitoring of Transformer Oil: A ReviewBaSant Kohli100% (1)

- Development of A Palm Fruit Bunch Chopper and Spikelet StripperDocument7 pagesDevelopment of A Palm Fruit Bunch Chopper and Spikelet Stripperinventionjournals100% (1)

- Palm Oil Mill EffluentDocument6 pagesPalm Oil Mill Effluentankitsaxena123100% (2)

- Mass and Energy Balance of Palm OilDocument10 pagesMass and Energy Balance of Palm OilMuhammad Junaid100% (2)

- Palm OilDocument8 pagesPalm OilHadiBiesNo ratings yet

- Alemu Integrated Farms LTD: Palm Oil Plantation Odholu Gboji, Ahoada-West Ahoada - Mbiama HighwayDocument36 pagesAlemu Integrated Farms LTD: Palm Oil Plantation Odholu Gboji, Ahoada-West Ahoada - Mbiama HighwayTolu Fasakin100% (2)

- Activated Carbon From PKSDocument14 pagesActivated Carbon From PKSVelan Raveendhran100% (2)

- Improving Energy Efficiency at Palm Oil Mill IndusDocument9 pagesImproving Energy Efficiency at Palm Oil Mill IndusReynaldi 25No ratings yet

- ISCC Guidance WR From Palm Oil Mills V3.0Document13 pagesISCC Guidance WR From Palm Oil Mills V3.0Henry XieNo ratings yet

- Chapter One 1.1 Background of The StudyDocument23 pagesChapter One 1.1 Background of The StudyUshie IsraelNo ratings yet

- 2023 Global Market Report Palm OilDocument46 pages2023 Global Market Report Palm OilOmo RusdianaNo ratings yet

- A Comparative Study of Chemical Analysis of Palm Kernel OilDocument41 pagesA Comparative Study of Chemical Analysis of Palm Kernel OilAhmad Jaelani ManurungNo ratings yet

- Analysis of Opaque, Peel-Off and Flex Rejects in the Electro Plating Process Using the Six Sigma Dmaic MethodDocument18 pagesAnalysis of Opaque, Peel-Off and Flex Rejects in the Electro Plating Process Using the Six Sigma Dmaic MethodInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Study to Effect of Reminiscence Therapy on Psychological Well-Being among Elderly Residing in Selected Old Age HomeDocument5 pagesA Study to Effect of Reminiscence Therapy on Psychological Well-Being among Elderly Residing in Selected Old Age HomeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Application of Project Management using CPM (Critical Path Method) and Pert (Project Evaluation and Review Technique) in the Nava House Bekasi Cluster Housing Development ProjectDocument12 pagesApplication of Project Management using CPM (Critical Path Method) and Pert (Project Evaluation and Review Technique) in the Nava House Bekasi Cluster Housing Development ProjectInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Comprehensive Review on the Therapeutic Potential of PectinDocument6 pagesA Comprehensive Review on the Therapeutic Potential of PectinInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Application of the Economic Order Quantity (EOQ) Method on the Supply of Chemical Materials in the Laboratory of PT. Fajar Surya Wisesa TbkDocument15 pagesApplication of the Economic Order Quantity (EOQ) Method on the Supply of Chemical Materials in the Laboratory of PT. Fajar Surya Wisesa TbkInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Rare Complication: Cardiac Arrest and Pulmonary Embolism in Polyarteritis NodosaDocument5 pagesA Rare Complication: Cardiac Arrest and Pulmonary Embolism in Polyarteritis NodosaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Integrated Border Security System on Human Trafficking in Bangladesh: The Mediating Effect of the Use of Advanced TechnologyDocument12 pagesThe Impact of Integrated Border Security System on Human Trafficking in Bangladesh: The Mediating Effect of the Use of Advanced TechnologyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quality Control to Reduce Appearance Defects at PT. Musical InstrumentDocument11 pagesQuality Control to Reduce Appearance Defects at PT. Musical InstrumentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Forecasting PM10 Concentrations Using Artificial Neural Network in Imphal CityDocument10 pagesForecasting PM10 Concentrations Using Artificial Neural Network in Imphal CityInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis of Carton Packaging Quality Control Using Statistical Quality Control Methods at PT XYZDocument10 pagesAnalysis of Carton Packaging Quality Control Using Statistical Quality Control Methods at PT XYZInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Quizlet's Usefulness for Vocabulary Learning: Perceptions of High-Level and Low-Level Chinese College EFL LearnersDocument5 pagesQuizlet's Usefulness for Vocabulary Learning: Perceptions of High-Level and Low-Level Chinese College EFL LearnersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Enhancing Estimating the Charge Level in Electric Vehicles: Leveraging Force Fluctuation and Regenerative Braking DataDocument6 pagesEnhancing Estimating the Charge Level in Electric Vehicles: Leveraging Force Fluctuation and Regenerative Braking DataInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Entrepreneurial Adult Education as a Catalyst for Youth Employability in Disadvantaged AreasDocument9 pagesEntrepreneurial Adult Education as a Catalyst for Youth Employability in Disadvantaged AreasInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Role of Leadership Training in Developing Effective Police SupervisorsDocument17 pagesThe Role of Leadership Training in Developing Effective Police SupervisorsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Health Care - An Android Application Implementation and Analyzing user Experience Using PythonDocument7 pagesHealth Care - An Android Application Implementation and Analyzing user Experience Using PythonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Intrusion Detection System with Ensemble Machine Learning Approaches using VotingClassifierDocument4 pagesIntrusion Detection System with Ensemble Machine Learning Approaches using VotingClassifierInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Synthetic and Natural Vitamin C Modulation of Leaded Paint-Induced Nephrotoxicity of Automobile Painters in Ile-Ife, Nigeria.Document21 pagesSynthetic and Natural Vitamin C Modulation of Leaded Paint-Induced Nephrotoxicity of Automobile Painters in Ile-Ife, Nigeria.International Journal of Innovative Science and Research TechnologyNo ratings yet

- Visitor Perception Related to the Quality of Service in Todo Tourism VillageDocument10 pagesVisitor Perception Related to the Quality of Service in Todo Tourism VillageInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Gravity Investigations Applied to the Geological Framework Study of the Mambasa Territory in Democratic Republic of CongoDocument9 pagesGravity Investigations Applied to the Geological Framework Study of the Mambasa Territory in Democratic Republic of CongoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Developing Digital Fluency in Early Education: Narratives of Elementary School TeachersDocument11 pagesDeveloping Digital Fluency in Early Education: Narratives of Elementary School TeachersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A New Model of Rating to Evaluate Start-ups in Emerging Indian MarketDocument7 pagesA New Model of Rating to Evaluate Start-ups in Emerging Indian MarketInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Proof of Concept Using BLE to Optimize Patients Turnaround Time (PTAT) in Health CareDocument14 pagesA Proof of Concept Using BLE to Optimize Patients Turnaround Time (PTAT) in Health CareInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Financial Prudence as Determinant of Employees’ Interest in Graduate StudyDocument13 pagesFinancial Prudence as Determinant of Employees’ Interest in Graduate StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Design and Implementation of Software-Defined ReceiverDocument8 pagesDesign and Implementation of Software-Defined ReceiverInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Optimizing Bio-Implant Materials for Femur Bone Replacement:A Multi-Criteria Analysis and Finite Element StudyDocument5 pagesOptimizing Bio-Implant Materials for Femur Bone Replacement:A Multi-Criteria Analysis and Finite Element StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Crop Monitoring System with Water Moisture Levels Using ControllerDocument8 pagesCrop Monitoring System with Water Moisture Levels Using ControllerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Inclusive Leadership in the South African Police Service (SAPS)Document26 pagesInclusive Leadership in the South African Police Service (SAPS)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Naturopathic Approaches to Relieving Constipation: Effective Natural Treatments and TherapiesDocument9 pagesNaturopathic Approaches to Relieving Constipation: Effective Natural Treatments and TherapiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fahfi/Mochaina Illegal Gambling Activities and its Average Turnover within Limpopo ProvinceDocument8 pagesFahfi/Mochaina Illegal Gambling Activities and its Average Turnover within Limpopo ProvinceInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Year Wise Analysis and Prediction of Gold RatesDocument8 pagesYear Wise Analysis and Prediction of Gold RatesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- SLA-Answerscript-Group BrownDocument4 pagesSLA-Answerscript-Group BrownMaria MuntarinNo ratings yet

- Flow Diagram Blocks 2021Document1 pageFlow Diagram Blocks 2021Jude ColumnaNo ratings yet

- Cbieenss 10Document5 pagesCbieenss 10Ayusman100% (1)

- Mushroom Stew With Creamy Polenta - SCRAPS by Carolina GelenDocument1 pageMushroom Stew With Creamy Polenta - SCRAPS by Carolina GelenChristina ChelaruNo ratings yet

- NEONATAL NUTRITION Pro PIT 3Document69 pagesNEONATAL NUTRITION Pro PIT 3Andi Dewi PratiwiNo ratings yet

- Flexible Packaging: Changing Dynamics of Indian Packaging MarketDocument24 pagesFlexible Packaging: Changing Dynamics of Indian Packaging Marketggudayakumar100% (1)

- Coyote Grill Menu Feb 09Document5 pagesCoyote Grill Menu Feb 09support_local_flavor100% (1)

- AgranaDocument24 pagesAgranaYun LINo ratings yet

- Armfield: Develop With UsDocument2 pagesArmfield: Develop With UsjuansalvadorgarciaheNo ratings yet

- Myanmar Food Security AssessmentDocument6 pagesMyanmar Food Security AssessmentThe Guardian100% (7)

- Toefl Skills 5-10 PracticeDocument10 pagesToefl Skills 5-10 PracticeDaniel Eduardo Lopez FigueroaNo ratings yet

- Narrative Text Reall FixxxDocument4 pagesNarrative Text Reall FixxxCayla Alicia CherynNo ratings yet

- The Pittston Dispatch 06-19-2011Document82 pagesThe Pittston Dispatch 06-19-2011The Times LeaderNo ratings yet

- Tempeh SummaryDocument9 pagesTempeh SummaryLovely TinaNo ratings yet

- Nutrition Crossword Puzzle: Answer KeyDocument1 pageNutrition Crossword Puzzle: Answer KeyAlejandraNo ratings yet

- AP M10 Ch9 Respiration Worksheet2Document5 pagesAP M10 Ch9 Respiration Worksheet2Jakie Ubina0% (1)

- CENE A U3 4 TestADocument5 pagesCENE A U3 4 TestAIsabella AmigoNo ratings yet

- 1 Unit-01 Inglés IiDocument19 pages1 Unit-01 Inglés IiVictor Amir Suyon CoronadoNo ratings yet

- ATK and MATK Boosters SheetDocument156 pagesATK and MATK Boosters SheetDonato Vergara IIINo ratings yet

- Maryline Gen SCO - White Refined Cane Sugar ICUMSA45, Brazil Origin, 50000MT X 12 Months, CIF Lome or Abidjan Port 16012023Document2 pagesMaryline Gen SCO - White Refined Cane Sugar ICUMSA45, Brazil Origin, 50000MT X 12 Months, CIF Lome or Abidjan Port 16012023Citizen KoumNo ratings yet

- ĐỀ KTHKI ANH 6 LEDocument5 pagesĐỀ KTHKI ANH 6 LEOanh_PTNo ratings yet

- GRADIENT 30 TMDocument2 pagesGRADIENT 30 TMJatan JoshiNo ratings yet

- 2nd Quarter Test TLE 10Document2 pages2nd Quarter Test TLE 10Rowena Gonzales87% (15)

- IcebergDocument7 pagesIcebergPatricia DillonNo ratings yet

- HRM Skills Competition (Choi)Document12 pagesHRM Skills Competition (Choi)ROGEL SONo ratings yet

- Islcollective Worksheets Elementary A1 Intermediate b1 Elementary School Writing Present Simple Co House or Flat 107959173153f095d049b6c9 82577967Document3 pagesIslcollective Worksheets Elementary A1 Intermediate b1 Elementary School Writing Present Simple Co House or Flat 107959173153f095d049b6c9 82577967adlesor_n1No ratings yet

- Azna Catering PackageDocument10 pagesAzna Catering PackageM Irfan SidikNo ratings yet

- PW Nelson& Salmo Sept27Document56 pagesPW Nelson& Salmo Sept27Pennywise PublishingNo ratings yet

- Class: Dicotyledonae: 1. Annona Squamosa-Custard Apple 2. A.reticulata 3. Annona MuricataDocument3 pagesClass: Dicotyledonae: 1. Annona Squamosa-Custard Apple 2. A.reticulata 3. Annona MuricataDani MathewNo ratings yet

- On The Farm - Hard Word Search (Places)Document2 pagesOn The Farm - Hard Word Search (Places)zfmf025366No ratings yet