Professional Documents

Culture Documents

QCP - Piping Press Test 11

QCP - Piping Press Test 11

Uploaded by

ziyuan wangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QCP - Piping Press Test 11

QCP - Piping Press Test 11

Uploaded by

ziyuan wangCopyright:

Available Formats

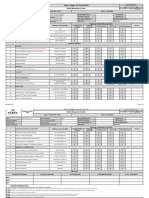

QUALITY MANAGEMENT - QUALITY CONTROL PLAN

CLIENT: KAMOA COPPER Project: KAMOA - KAKULA H = Hold Rating

LEGEND

QCP No.: Rev No.: 1

Main Contractor: CITIC Project No.: KMC-KKP-21-2145 W = Witness 1. Critical

Sub-Contractor: WHCC Enquiry: AS PER CONTRACT S = Surveillance ASME B31.3 Process Piping 2. Major X

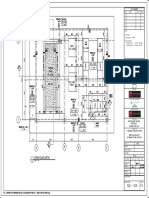

DRA-0571-PV-DC-0600-Rev2-Piping and Valve Design

INTERVENTION

Scope: PIPING Order/Scope Reference: NA R = Review Specification: 3. Minor

Criteria (003)

Description: PRESSURE TESTING Sub-Contractor Order No: NA V = Verify Applicable SANS Standard ; ISO 9001:2018 4. Other

2268-25-WG-G2-138/143/238/243

Piping Line Number: 2268-100-WG-G2-136/174/141/193/236/274/241/293 P&ID DRW Number: KAM-PID-226801-01031/01032 A = Action WBS Area: 226081 FILTER HOUSE

2268-200-WG-G2-139/142/239/242

Interventions and Control

Activity Activity Description Reference Documentation Remarks

Contractor DRA Supervisor DRA SQC ENGINEER Other (specify)

1. APPROVALS

1.1 Review and Approval of QCP QCP H H H H

Latest Revision Drawings and Drawing

1.2 Approved IFC Drawings (P&ID;Isometric) H H V V

Register

1.3 Safe Access Handover to Follow on Trades Certificate DRA-0571-SITE-FO-1003 H H V S

1.4 Approved Pressure Test Procedure. H V V V

1.5 Pressure guages calibration certificate/s. ASME Section IX 2018 H V V V

1.6 Piping Specification Spec - DRA-0571-PV-DC-0600-Rev2 H H V V

1.7 Approved Method Statement Method Statement H H V V

1.8 Received Material Inspection Receipt Inspection Report, Certificates H V V V

2. ACTIVITIES - PIPING INSTALLATION

2.1 Inspect the system to verify that openings are plugged and valves are closed. W V S S

2.2 Connect the test pump to a convenient location in the system. W V S S

2.3 Connect the water source to the test pump. W V S S

Open the main control valve to fill the system. (If the water service is not

2.4 installed or has not been flushed, fill the system through the test pump water W V S S

source.)

2.5 Fill the system slowly to avoid entrapment of air. Vent system at highest points. W V S S

Open a valve (such as the inspector’s test connection or a temporary valve) to

2.6 W V S S

vent any trapped air.

Close the valve when water flows continuously through it. No spurting of air

2.7 W V S S

observed.

When the system pressure equals that of the water source, close the supply

2.8 W V S S

valve and inspect the entire system for leaks.

2.9 Repair leaks found and repeat procedure. W V S S

If no leaks are detected, begin to increase pressure with the test pump up to

2.10 200 psi or 50 psi in excess of the static pressure when static pressure exceeds W V S S

150 psi.

Monitor the test gauge to determine that the system pressure is stable. If

2.11 pressure drops, check for leaks in the system, for open valves, or for leaks in W V S S

the test apparatus.

Once it is determined that the test pressure has stabilized, disconnect the

2.12 power to the test pump and notify the commissioning agent or authority having H W S S

jurisdiction that the 2-hour test period has begun.

QCP - PIPING PRESS TEST 11 Page 1 of 2

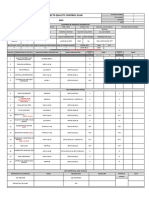

QUALITY MANAGEMENT - QUALITY CONTROL PLAN

CLIENT: KAMOA COPPER Project: KAMOA - KAKULA H = Hold Rating

LEGEND

QCP No.: Rev No.: 1

Main Contractor: CITIC Project No.: KMC-KKP-21-2145 W = Witness 1. Critical

Sub-Contractor: WHCC Enquiry: AS PER CONTRACT S = Surveillance ASME B31.3 Process Piping 2. Major X

DRA-0571-PV-DC-0600-Rev2-Piping and Valve Design

INTERVENTION

Scope: PIPING Order/Scope Reference: NA R = Review Specification: 3. Minor

Criteria (003)

Description: PRESSURE TESTING Sub-Contractor Order No: NA V = Verify Applicable SANS Standard ; ISO 9001:2018 4. Other

2268-25-WG-G2-138/143/238/243

Piping Line Number: 2268-100-WG-G2-136/174/141/193/236/274/241/293 P&ID DRW Number: KAM-PID-226801-01031/01032 A = Action WBS Area: 226081 FILTER HOUSE

2268-200-WG-G2-139/142/239/242

Interventions and Control

Activity Activity Description Reference Documentation Remarks

Contractor DRA Supervisor DRA SQC ENGINEER Other (specify)

2.13 Record the time of day and test pressure at this time. W V S S

2.14 Take photos of timer as evidence. W V S S

2.15 Hold the test pressure for 2 hours. W V S S

After the test, open the drain valve to drain the system, or, if the system is to

2.16 be commissioned immediately, relieve the test pressure and leave the water in W V S S

the system.

Disconnect the test pump and plug the outlet or test port through which the

2.17 W V S S

system was tested.

3. HANDOVER - DOCUMENTATION

Pressure / Leak Test Certificate Certificate H R R V

Safe Access Handover to Follow on Trades Certificate DRA-0571-SITE-FO-1003 H R R S

As Built Drawings / Red Line Drawings / Weld Maps DRAWINGS H R R S

Construction Completion Certificate - Piping C1 DRA-0571-SITE-FO-1006 H R R H

Review Data Dossier Data Book H R H V

Data Book Handover Data Book A V A A

Approvals

CONTRACTOR DRA Supervisor DRA SQC ENGINEER AIA / Other

Name: Wangziyuan Name: Name: Gerhard Eastes Name: Name:

Signed : Signed : Signed : Signed : Signed :

Date : 2021-08-04 Date : Date : Date : Date :

DEFINITION OF INTERVENTION POINTS:

A point of inspection in the QCP that requires the presence of the inspection organization:-

H - where the next stage of the production/construction process cannot proceed beyond this point until an inspection has been performed by the inspection organization and the required conditions indicated as met/achieved.

W - where production can proceed beyond this point if the inspection organization has not attended, provided due notice of the activity has been given to the inspection organization in terms of the relevant contract.

S - where surveillance may be performed by the inspection organization.

R - where a review of the records developed by the supplier to ensure that the relevant activity has been performed satisfactory and that contractual requirements have been met.

V - where a verification by the inspection organization to ensure that the relevant activity has been performed satisfactory and that contractual requirements have been met.

A - where the organization needs to execute an operation prior to intervention and inspection.

QCP - PIPING PRESS TEST 11 Page 2 of 2

You might also like

- Manufacturer Data RecordDocument29 pagesManufacturer Data RecordAdd Gar80% (10)

- Inspection Test Plan: 1 QA/QC Document Submission & ApprovalDocument1 pageInspection Test Plan: 1 QA/QC Document Submission & Approvalmohd as shahiddin jafri100% (2)

- ITP For Boiler ErectionDocument6 pagesITP For Boiler ErectionUmair Awan100% (2)

- Tia SafetyDocument445 pagesTia Safetydrg09100% (1)

- QCP - Piping Press Test 15Document2 pagesQCP - Piping Press Test 15ziyuan wangNo ratings yet

- QCP - Piping Press Test 19Document2 pagesQCP - Piping Press Test 19ziyuan wangNo ratings yet

- QCP - Piping Press Test 22Document3 pagesQCP - Piping Press Test 22ziyuan wangNo ratings yet

- NS2-DH01-P0ZEN-140011 - ITP For Cable Pulling and Termination - REV.CDocument8 pagesNS2-DH01-P0ZEN-140011 - ITP For Cable Pulling and Termination - REV.CAnh VàngNo ratings yet

- 5.MCS-QCP MesDocument3 pages5.MCS-QCP MesMitendra Kumar ChauhanNo ratings yet

- Asorc-Qcp 1652 ModifiedDocument22 pagesAsorc-Qcp 1652 ModifiedalkhiatNo ratings yet

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- QIP of Boiler For ErectionDocument6 pagesQIP of Boiler For ErectionUmair Awan100% (2)

- Inspection & Test PlanDocument1 pageInspection & Test PlanImran ZamanNo ratings yet

- ITP - PV Kontrol Indo RayaDocument5 pagesITP - PV Kontrol Indo RayaZulkarnain ZulkarnainNo ratings yet

- ITP Sample For Steet Strucute WorksDocument7 pagesITP Sample For Steet Strucute WorksTee Klong RungNo ratings yet

- Kc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationDocument2 pagesKc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationMitendra Kumar ChauhanNo ratings yet

- Natural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at ShopDocument3 pagesNatural Gas Transportation Development Project - Siak Riau: Inspection Test Plan (Itp) at Shopanang_priNo ratings yet

- Inspection Test Plan: Itp No: REV:1.0 DateDocument3 pagesInspection Test Plan: Itp No: REV:1.0 Datemohd as shahiddin jafriNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument10 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- QCDS-ST-001 Truck Loading Area Steel StructureDocument3 pagesQCDS-ST-001 Truck Loading Area Steel StructurejorgekarlosprNo ratings yet

- ITP & Checklist For Installtion of Conduits, Boxes Ans Switches Rev.0Document3 pagesITP & Checklist For Installtion of Conduits, Boxes Ans Switches Rev.0shameer khanNo ratings yet

- Inspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Document4 pagesInspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Delta akathehuskyNo ratings yet

- 0279STX N WM PW01 Qa Itp 0011 A02Document31 pages0279STX N WM PW01 Qa Itp 0011 A02praveen 0064No ratings yet

- Inspection Test Plan: Grinding, Build Up & ResurfaceDocument3 pagesInspection Test Plan: Grinding, Build Up & Resurfacemohd as shahiddin jafriNo ratings yet

- WE1884 - ITP For Shop Fab. of Header Coils-120813Document4 pagesWE1884 - ITP For Shop Fab. of Header Coils-120813imran100% (1)

- QCP - BuildingsDocument4 pagesQCP - BuildingsMitendra Kumar Chauhan100% (1)

- ITP - Fiber Optic CableDocument2 pagesITP - Fiber Optic CableRamy AiadNo ratings yet

- ITP Sample For Piping Assembly WorksDocument7 pagesITP Sample For Piping Assembly WorksTee Klong RungNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- Standard QAP - 4MWDocument2 pagesStandard QAP - 4MWSAEL SOLAR100% (2)

- ITP-P-001 ITP For Above Ground Piping Rev. ADocument9 pagesITP-P-001 ITP For Above Ground Piping Rev. APhong Đỗ100% (1)

- QCP Smoking SheltersDocument1 pageQCP Smoking SheltersMantshaNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Field ITP For Piping Work Rev.1 RDF 1404Document45 pagesField ITP For Piping Work Rev.1 RDF 1404Ichsan BahrilNo ratings yet

- Upvc Pipe Class DDocument4 pagesUpvc Pipe Class DnaagshreeNo ratings yet

- Civils - Trenching - ExcavationsDocument2 pagesCivils - Trenching - Excavationsmitendra singhNo ratings yet

- ITP Sample5-2-3Document2 pagesITP Sample5-2-3Mohammed Mostafa El HaddadNo ratings yet

- ITP For Drainage Pipes Installation & TestingDocument1 pageITP For Drainage Pipes Installation & TestingMurtada OmerNo ratings yet

- QIP Boiler ErectionDocument1 pageQIP Boiler Erectionshahroze mustafaNo ratings yet

- Simple LOS QAP FormatDocument1 pageSimple LOS QAP Formatmechdesign2k23No ratings yet

- Oksb-Itp-Cr2610-2022 1 Rev 00 OnshoreDocument4 pagesOksb-Itp-Cr2610-2022 1 Rev 00 OnshoreMohd Ayman YazidNo ratings yet

- Inspection Test Plan LPSDocument3 pagesInspection Test Plan LPSsafetyofficer752No ratings yet

- Qap Hot Induction BendsDocument6 pagesQap Hot Induction BendsVidyut UjalaNo ratings yet

- 15250-192-EN02-LM-001 Rev-D Load ListDocument7 pages15250-192-EN02-LM-001 Rev-D Load Listmusab shabbirNo ratings yet

- ITP For Under Ground Firewater SystemDocument4 pagesITP For Under Ground Firewater SystemjaseelNo ratings yet

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- 12 - A - GENSET, TRAFO DAN PANEL R3-Layout1Document1 page12 - A - GENSET, TRAFO DAN PANEL R3-Layout1Imam FauziNo ratings yet

- 149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Document58 pages149-158 - Zug-Header-Malinau-Sc 12 016 Rev 1 Unit 2Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- 132kV TBC CRPDocument46 pages132kV TBC CRPMeera DeviNo ratings yet

- Process Piping Inspection and Test PlanDocument6 pagesProcess Piping Inspection and Test Planmanoj thakkarNo ratings yet

- Inspection & Test Plan (Itp)Document6 pagesInspection & Test Plan (Itp)Pahlevi MattasanNo ratings yet

- Con-Pr-Re-Qual - Obr-11 R1Document29 pagesCon-Pr-Re-Qual - Obr-11 R1carla marangonNo ratings yet

- Itp-Internals R2Document2 pagesItp-Internals R2Delta akathehuskyNo ratings yet

- Itp Existing Pressure VesselDocument3 pagesItp Existing Pressure Vesselmuhammad afrizal100% (1)

- Fabrication Inspection ReportDocument1 pageFabrication Inspection ReportSalesNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- Tle-01 Dossier.Document39 pagesTle-01 Dossier.suria qaqcNo ratings yet

- J&P Projects Quality Control Plan: ? ? 0 ? Equipment & Workpack InformationDocument16 pagesJ&P Projects Quality Control Plan: ? ? 0 ? Equipment & Workpack InformationEnrico BishopNo ratings yet

- Cable Ladder InstallationDocument5 pagesCable Ladder InstallationAhmad DagamsehNo ratings yet

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- Rockfill Guidelines Part 3 - Definition of Rockfill Versus Earthfill MaterialDocument9 pagesRockfill Guidelines Part 3 - Definition of Rockfill Versus Earthfill MaterialChristian SantamariaNo ratings yet

- AUT FYP Report TemplateDocument14 pagesAUT FYP Report TemplateZain Ul AbideenNo ratings yet

- 6 Consultant WebsiteDocument3 pages6 Consultant WebsiteanoopsreNo ratings yet

- ZXMW NR8120A 8120D V2 04 02 Configuration Guide PDFDocument66 pagesZXMW NR8120A 8120D V2 04 02 Configuration Guide PDFMochamad Naquib Hasbi ZeintNo ratings yet

- Iso 31000Document14 pagesIso 31000cecilia.juwitaNo ratings yet

- Acceptance Inspection ReportDocument31 pagesAcceptance Inspection ReportstanhillNo ratings yet

- Reqirement Specification Document FOR Hospital Management SystemDocument8 pagesReqirement Specification Document FOR Hospital Management Systemlekha soniNo ratings yet

- Switching Regulator Applications: Absolute Maximum RatingsDocument6 pagesSwitching Regulator Applications: Absolute Maximum RatingsIvanilto Martins da CruzNo ratings yet

- Java ScriptDocument61 pagesJava ScriptcmjariwalaNo ratings yet

- An Introduction To EN81 The New British and European Lift StandardDocument5 pagesAn Introduction To EN81 The New British and European Lift StandardXiaofu Liu100% (1)

- Grid GIS L3 F35 - 145 - KV 0169 2016 - 07 ENDocument4 pagesGrid GIS L3 F35 - 145 - KV 0169 2016 - 07 ENiqbalmyNo ratings yet

- Hale & Borys (2013) Working To Rule or Working Safely Part 2Document11 pagesHale & Borys (2013) Working To Rule or Working Safely Part 2matt_nazriNo ratings yet

- Tech Specs of EOT CraneDocument42 pagesTech Specs of EOT CraneVicky GautamNo ratings yet

- Configuring SonicWALL Port ForwardingDocument7 pagesConfiguring SonicWALL Port ForwardingjayaprahasNo ratings yet

- AIR Brake PDFDocument50 pagesAIR Brake PDFpgp655484No ratings yet

- Section-GTR, Revision-14 - TS of RTV Coating - Annexure H - Rev 1Document5 pagesSection-GTR, Revision-14 - TS of RTV Coating - Annexure H - Rev 1shaswatNo ratings yet

- PTC Creo GearDocument6 pagesPTC Creo Gearbrpnaidu2157No ratings yet

- 1-Multinational Management in A Changing World-SDocument20 pages1-Multinational Management in A Changing World-SSego de C100% (1)

- Signal and Power Isolated RS-485 Transceiver With 15 KV ESD Protection ADM2582E/ADM2587EDocument20 pagesSignal and Power Isolated RS-485 Transceiver With 15 KV ESD Protection ADM2582E/ADM2587EvaibhavNo ratings yet

- Victrix Tera 24 PlusDocument56 pagesVictrix Tera 24 Plusadi angNo ratings yet

- Din 15020-1 1974 PDFDocument12 pagesDin 15020-1 1974 PDFJuliete Maria Taparello100% (1)

- Zebra WLAN WiNG v5 8 0 Release Notes PublicDocument39 pagesZebra WLAN WiNG v5 8 0 Release Notes PublicAdam SetyawanNo ratings yet

- As 1012.8.2-2000 Methods of Testing Concrete Method of Making and Curing Concrete - Flexure Test SpecimensDocument2 pagesAs 1012.8.2-2000 Methods of Testing Concrete Method of Making and Curing Concrete - Flexure Test SpecimensSAI Global - APACNo ratings yet

- HS80 Owners ManualDocument37 pagesHS80 Owners ManualAndy TaborNo ratings yet

- E563-11 (Reapproved 2016)Document4 pagesE563-11 (Reapproved 2016)baxterNo ratings yet

- Installation of P.GDocument1 pageInstallation of P.Gsunilkumar2685No ratings yet

- PPAP-APQP Guide B45157 - Rev-ADocument29 pagesPPAP-APQP Guide B45157 - Rev-AMoti Ben-ZurNo ratings yet

- NII Sample PT Report PDFDocument23 pagesNII Sample PT Report PDFnieltalkxNo ratings yet

- 06 Appendix ADocument6 pages06 Appendix AING. RUBENSNo ratings yet