Professional Documents

Culture Documents

100%(1)100% found this document useful (1 vote)

690 viewsStone Pitching 22

Stone Pitching 22

Uploaded by

Deven PatleThis document describes a dry stone pitching engineering method for bank protection. It involves selecting stones of appropriate size and shape, laying them carefully according to several steps, and adding a protective steel plate net. This method is an improvement over prior techniques by strictly controlling the stone selection and layout, significantly enhancing the protective capabilities of dry stone pitching bank protection structures.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- A Civil Engg. Final Year Training Report On Residential Building Construction.Document71 pagesA Civil Engg. Final Year Training Report On Residential Building Construction.Monu Khand84% (261)

- Asphalt Institute MS2 - 6th Edition PDFDocument147 pagesAsphalt Institute MS2 - 6th Edition PDFDeven Patle75% (4)

- Jones - Larry.sheet PileDocument19 pagesJones - Larry.sheet PileJessie Radaza Tutor100% (1)

- Chapter 5 Coffer DamDocument8 pagesChapter 5 Coffer Dambipul bhattataiNo ratings yet

- Morth 2100 Open FoundationsDocument6 pagesMorth 2100 Open FoundationsRameshNo ratings yet

- What Is Meant by Charactyeristic Strength of ConcreteDocument4 pagesWhat Is Meant by Charactyeristic Strength of ConcretemmabeeNo ratings yet

- Gujarat SORDocument67 pagesGujarat SORbnarendrababu19No ratings yet

- Technal Submittal For Ug Tank Water ProofingDocument43 pagesTechnal Submittal For Ug Tank Water ProofingArunashish Mazumdar100% (3)

- Water ReticulationDocument49 pagesWater ReticulationMuhammad Hanafi50% (2)

- Bentonite Cavities in Diaphragm WallsDocument113 pagesBentonite Cavities in Diaphragm Wallsrasanavaneethan100% (2)

- 9.1 Formwork Notes-1Document4 pages9.1 Formwork Notes-1RahulSinghRajput100% (2)

- Types of PavementDocument10 pagesTypes of Pavementmohsen.911.mkNo ratings yet

- Safe Bearing Capacity of Soil at SiteDocument3 pagesSafe Bearing Capacity of Soil at SiteTravel With EvonNo ratings yet

- Selection of Retaining Walls in Hill Areas - Indian StandardsDocument14 pagesSelection of Retaining Walls in Hill Areas - Indian Standardsnimm1962100% (1)

- R R MasonryDocument10 pagesR R MasonryVedachalam ManiNo ratings yet

- Modified R-Wall PDFDocument9 pagesModified R-Wall PDFujjawaldaharwalNo ratings yet

- Testing of Sand Quality at Construction Site For ConcreteDocument6 pagesTesting of Sand Quality at Construction Site For ConcreteHussamAlmustafaNo ratings yet

- Beams IS 13920 2016Document12 pagesBeams IS 13920 2016TEJ BAHADUR KARKINo ratings yet

- Earthwork & Engineering Backfilling MaterialsDocument47 pagesEarthwork & Engineering Backfilling MaterialsAHMAD YAGHINo ratings yet

- Box Culvert Estimate 3/53/0Document69 pagesBox Culvert Estimate 3/53/0veevimalNo ratings yet

- Method of Statement - Junction ChamberDocument9 pagesMethod of Statement - Junction ChamberLaksri JayathilakeNo ratings yet

- Construction of Hill Roads and AnswersDocument67 pagesConstruction of Hill Roads and AnswersIqbal BaigNo ratings yet

- Replacement of Coarse Aggregate by Cinder Aggregate in Light Weight Concrete.Document27 pagesReplacement of Coarse Aggregate by Cinder Aggregate in Light Weight Concrete.Parashu Ram Neo100% (1)

- RD - PROTECTION WORKDocument34 pagesRD - PROTECTION WORKMuthusamy ArumugamNo ratings yet

- Ground Improvement TechniquesDocument30 pagesGround Improvement TechniquesNaveen Natarajan100% (1)

- Cracks Repair in PQCDocument3 pagesCracks Repair in PQCNeeraj SharmaNo ratings yet

- MJB-MNB Estimate & BOQDocument14 pagesMJB-MNB Estimate & BOQsujeetNo ratings yet

- Boq-Rehabilition of Football Stadium and New ConstructionDocument12 pagesBoq-Rehabilition of Football Stadium and New ConstructionAcharya Madridista SunilNo ratings yet

- PQC Cracks Repair 1Document3 pagesPQC Cracks Repair 1Deven PatleNo ratings yet

- Types of Failures in Flexible and Rigid PavementsDocument6 pagesTypes of Failures in Flexible and Rigid PavementsTrisha Mae Jamili PetillaNo ratings yet

- Pmgsy Circular About Rural Road GeometryDocument16 pagesPmgsy Circular About Rural Road Geometryprasadnn2001100% (1)

- Rubble Soling: 50mm Thick Stone Dust/ Sand/ Murum/ Soil BedDocument1 pageRubble Soling: 50mm Thick Stone Dust/ Sand/ Murum/ Soil Bedsaurabh dasNo ratings yet

- Aggregate Impact Value (Is: 2386 (Part-Iv) )Document19 pagesAggregate Impact Value (Is: 2386 (Part-Iv) )ajit karandikarNo ratings yet

- (LECT - 19,20) Prestressed Concrete Poles, Piles, SleepersDocument28 pages(LECT - 19,20) Prestressed Concrete Poles, Piles, SleepersSushil Mundel100% (1)

- Soil Stabilisation - 10 SlidesDocument10 pagesSoil Stabilisation - 10 SlidesMarko MarkiniNo ratings yet

- Ac-Corroguard: Inhibitor Solution For Reinforcement BarDocument1 pageAc-Corroguard: Inhibitor Solution For Reinforcement BarbhagwatpatilNo ratings yet

- Permeable Spur Doc 1Document22 pagesPermeable Spur Doc 1Anonymous MAQrYFQDzVNo ratings yet

- Filter Media SpecificationsDocument1 pageFilter Media SpecificationsVarshil Parikh100% (1)

- Design and Cost Estimation of PavementsDocument1 pageDesign and Cost Estimation of PavementsDharma banothuNo ratings yet

- CC Road PDFDocument222 pagesCC Road PDFPhani PitchikaNo ratings yet

- Short Panel Concrete Pavement and White ToppingDocument41 pagesShort Panel Concrete Pavement and White ToppingsombansNo ratings yet

- DSR PuneDocument5 pagesDSR PunedigvijayjagatapNo ratings yet

- Toll Plaza Structure - Technical SpecificationsDocument3 pagesToll Plaza Structure - Technical SpecificationsNeeraj SinghNo ratings yet

- Construction of Short Paneled Concrete Pavement On ADocument28 pagesConstruction of Short Paneled Concrete Pavement On ARajib ChattarajNo ratings yet

- Pradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Document4 pagesPradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Lucky TraderNo ratings yet

- River TrainingDocument8 pagesRiver Trainingnandi_scrNo ratings yet

- Consistency Test of Cement: ResultsDocument11 pagesConsistency Test of Cement: Resultsnira365No ratings yet

- Beam and Block Floor Systems PDFDocument3 pagesBeam and Block Floor Systems PDFdamindaNo ratings yet

- Design & Cost Analysis of Self-Compacting Concrete For Mivan ShutteringDocument5 pagesDesign & Cost Analysis of Self-Compacting Concrete For Mivan Shutteringraj221No ratings yet

- General Notes For RoadDocument2 pagesGeneral Notes For RoadEngr Sayyar Ahmad100% (1)

- Cement Concrete PavementDocument8 pagesCement Concrete Pavementgtarun22guptaNo ratings yet

- Accurate Technical Interpretation of Clause-11.3 of Is-456-2000 For Stripping of FormworkDocument2 pagesAccurate Technical Interpretation of Clause-11.3 of Is-456-2000 For Stripping of FormworkalibaazizNo ratings yet

- WBM Construction ProceduresDocument8 pagesWBM Construction ProceduresYedla NeelakanteshwarNo ratings yet

- Cement Mortar PlasterDocument5 pagesCement Mortar PlasterMani Appa100% (1)

- Morth DLCDocument9 pagesMorth DLCAmit AbhangNo ratings yet

- L-1 Bituminous Mix DesignDocument86 pagesL-1 Bituminous Mix DesignrajibchattarajNo ratings yet

- Civil Engineering Material Lecture NotesDocument4 pagesCivil Engineering Material Lecture Notes11520035No ratings yet

- Types of MixesDocument68 pagesTypes of MixesVinamraMishraNo ratings yet

- RE Wall COnstructionDocument2 pagesRE Wall COnstructionAkshay Agatkar100% (2)

- PQC and DLC AnalysisDocument6 pagesPQC and DLC AnalysisLalkiran VaddeNo ratings yet

- 2500 River Training WorkDocument11 pages2500 River Training WorkGoanengineer100% (1)

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1No ratings yet

- Civil Work ResearchDocument15 pagesCivil Work ResearchKarissa LimosNo ratings yet

- ScienceDirect - Quay WallsDocument15 pagesScienceDirect - Quay WallsYayoi IshikawaNo ratings yet

- Chapter 15Document12 pagesChapter 15Aziz Khan Kakar100% (1)

- Batch SlipDocument2 pagesBatch SlipDeven PatleNo ratings yet

- CALIBRATION OF HM PlantDocument3 pagesCALIBRATION OF HM PlantDeven PatleNo ratings yet

- Different Methodologies For Repair of Cracks in PQC in Concrete PavementsDocument26 pagesDifferent Methodologies For Repair of Cracks in PQC in Concrete PavementsDeven PatleNo ratings yet

- Construction Methodology and QAPDocument7 pagesConstruction Methodology and QAPDeven PatleNo ratings yet

- Ten Percent Fine ValueDocument1 pageTen Percent Fine ValueDeven PatleNo ratings yet

- Viscosity TestDocument1 pageViscosity TestDeven Patle100% (2)

- Methodology For PQC (00) Toll Plaza L&TDocument4 pagesMethodology For PQC (00) Toll Plaza L&TDeven PatleNo ratings yet

- 2.1 Inspection Test PlanDocument26 pages2.1 Inspection Test PlanDeven Patle50% (2)

- Sieve Size Excel 1 PDFDocument1 pageSieve Size Excel 1 PDFDeven PatleNo ratings yet

- Core Cutting FormatDocument1 pageCore Cutting FormatDeven PatleNo ratings yet

- Sieve Size Excel 1 PDFDocument1 pageSieve Size Excel 1 PDFDeven PatleNo ratings yet

- Ac-Pqc-Injecto: Low Viscous Epoxy Injection ResinDocument2 pagesAc-Pqc-Injecto: Low Viscous Epoxy Injection ResinDeven Patle0% (1)

- Open Ended Lab Report: STEN 2002 Civil Engineering MaterialsDocument17 pagesOpen Ended Lab Report: STEN 2002 Civil Engineering MaterialsDeven PatleNo ratings yet

- Foundation Substructure CodeDocument64 pagesFoundation Substructure CodeDeven PatleNo ratings yet

- PQC Cracks Repair 1Document3 pagesPQC Cracks Repair 1Deven PatleNo ratings yet

- QC Frequency Test Plan (5th Revision)Document42 pagesQC Frequency Test Plan (5th Revision)Deven PatleNo ratings yet

- PQC Cracks Repair 2 PDFDocument5 pagesPQC Cracks Repair 2 PDFDeven PatleNo ratings yet

- Frequently Asked Questions (Faqs) About Ground Granulated Blastfurnace Slag (GGBS)Document6 pagesFrequently Asked Questions (Faqs) About Ground Granulated Blastfurnace Slag (GGBS)Deven PatleNo ratings yet

- Soil Improvement Technique and LimitationsDocument4 pagesSoil Improvement Technique and LimitationsMuhammad SyafiqNo ratings yet

- FoundationDocument5 pagesFoundationAnna Rose LoboNo ratings yet

- CE 470-Lect-18 (Estimating The Sizes of Cantilever Retaining Walls) (Read-Only) PDFDocument17 pagesCE 470-Lect-18 (Estimating The Sizes of Cantilever Retaining Walls) (Read-Only) PDFJamal RkhNo ratings yet

- Retaining Structure Design For KNDocument11 pagesRetaining Structure Design For KNberkely19No ratings yet

- Construction Method Statement and Structural Report London W10 5BZDocument29 pagesConstruction Method Statement and Structural Report London W10 5BZAtilla AkdoganNo ratings yet

- S5.3 - Deep Excavation Works Close To The Existing MRT Tunnel in Soft Marine Clay - KonoDocument10 pagesS5.3 - Deep Excavation Works Close To The Existing MRT Tunnel in Soft Marine Clay - KonofreezefreezeNo ratings yet

- SOR Detailed Estimate ROB ROUGHDocument29 pagesSOR Detailed Estimate ROB ROUGHMinhaj Ahmed khanNo ratings yet

- Overcoming Soil Uncertainty in Prediction of Construction and Industrial VibrationsDocument20 pagesOvercoming Soil Uncertainty in Prediction of Construction and Industrial VibrationslrbolNo ratings yet

- 50ft Deep Excavation Design Example - Deep ExcavationDocument7 pages50ft Deep Excavation Design Example - Deep ExcavationAdrian FrantescuNo ratings yet

- Geosense Brochure 2011 V1.2Document46 pagesGeosense Brochure 2011 V1.2jnfNo ratings yet

- Hill RoadsDocument69 pagesHill RoadsHarish joshiNo ratings yet

- 06 Chapter 7 - Lateral Earth Pressure-M PDFDocument62 pages06 Chapter 7 - Lateral Earth Pressure-M PDFogeboy sangcopanNo ratings yet

- Changes DC-Cantilever For Windows Date Version ChangeDocument7 pagesChanges DC-Cantilever For Windows Date Version ChangeGanea Marius BogdanNo ratings yet

- HAT Pile - Technical Report On Hat+H Sheet PilesDocument46 pagesHAT Pile - Technical Report On Hat+H Sheet Pilesedward the iiiNo ratings yet

- Copia Di CH-Albania - TR - Rraeshen-Kalimash Highway Paramesh Structure 2009Document3 pagesCopia Di CH-Albania - TR - Rraeshen-Kalimash Highway Paramesh Structure 2009Snopi DeGrauNo ratings yet

- Department of Public Works and HighwaysDocument7 pagesDepartment of Public Works and HighwaysZA TarraNo ratings yet

- Geotechnical QuizDocument41 pagesGeotechnical QuizAminulIslamNo ratings yet

- CCSP Method EnglishDocument14 pagesCCSP Method EnglishSuperdanzNo ratings yet

- Guidance On The Structural Use of Plastic Sheet Piling in Highway ApplicationsDocument30 pagesGuidance On The Structural Use of Plastic Sheet Piling in Highway ApplicationsIvanSmithNo ratings yet

- Tablon Retaining Wall Ht. - Clark - With WindDocument27 pagesTablon Retaining Wall Ht. - Clark - With WindclarkgaguiNo ratings yet

- Lateral Earth PressureDocument34 pagesLateral Earth PressureTimothy Charles YabutNo ratings yet

- (GT-PPT) Deep Excavation Presentation 20150317Document12 pages(GT-PPT) Deep Excavation Presentation 20150317Laurenz Luigi CruzNo ratings yet

- Important Notice: Community, Storing All or Part of The Content (Electronically orDocument43 pagesImportant Notice: Community, Storing All or Part of The Content (Electronically orS Sathiyaruban100% (1)

Stone Pitching 22

Stone Pitching 22

Uploaded by

Deven Patle100%(1)100% found this document useful (1 vote)

690 views2 pagesThis document describes a dry stone pitching engineering method for bank protection. It involves selecting stones of appropriate size and shape, laying them carefully according to several steps, and adding a protective steel plate net. This method is an improvement over prior techniques by strictly controlling the stone selection and layout, significantly enhancing the protective capabilities of dry stone pitching bank protection structures.

Original Description:

Stone pitching methodology very useful in structure works.

Original Title

stone pitching 22

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document describes a dry stone pitching engineering method for bank protection. It involves selecting stones of appropriate size and shape, laying them carefully according to several steps, and adding a protective steel plate net. This method is an improvement over prior techniques by strictly controlling the stone selection and layout, significantly enhancing the protective capabilities of dry stone pitching bank protection structures.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

100%(1)100% found this document useful (1 vote)

690 views2 pagesStone Pitching 22

Stone Pitching 22

Uploaded by

Deven PatleThis document describes a dry stone pitching engineering method for bank protection. It involves selecting stones of appropriate size and shape, laying them carefully according to several steps, and adding a protective steel plate net. This method is an improvement over prior techniques by strictly controlling the stone selection and layout, significantly enhancing the protective capabilities of dry stone pitching bank protection structures.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

Description

Dry stone pitching engineering method

Technical field

The present invention relates to road and bridge construction field, particularly dry stone

pitching engineering method.

Background technology

Bank protection refers to as preventing that side slope from being washed away, and that does

on domatic variously paves and plant.Section, bridge site place, the concave bank on

riverbank is met year by year and is subject to current scour, can make riverbank constantly

cave in.For protection bridge and embankment safety, must build protective structure at

concave bank.In addition, cause that river flows to and change because establishing bridge,

concave bank and while jeopardizing farmland and villages and small towns, also must build

protective structure on riverbank.This building is called again shore protection

conventionally.The form of shore protection has direct protection and protection

indirectly.Directly protection is that riverbank side slope is directly reinforced, to resist

washing away and scour of current.The builds such as conventional jackstone, dry-laid

rubble, mortar flag stone, gabion and fascine.Indirectly protection is applicable to the wider

or protection larger section of length, riverbed, can build groynes, longitudinal dike and

lattice dam etc., and current are chosen from riverbank.

Function according to bank protection can generally be divided into two kinds by it: be only

(A) the slope protection work of weather resistance and antiscour; this protection work is not

born lateral earth pressure; as shotcrete bank protection; gridiron plant growing protection

slope; plant growing protection slopes etc. all belong to this type of, are only applicable to

mild and stablize in the side slope of fricton-tight anxiety.(B) provide the native bank

protection of gear of skid resistance, roughly can divide into: (a) rigidity deadweight type

retaining wall (as: masonry retaining wall, gravity retaining wall, lean on wall type retaining

wall, cantilever sheet pile wall, counterfort retaining wall), (b) flexible deadweight type

retaining wall (as: gabion retaining wall, crib retaining wall, the formula of putting more

energy into retaining wall), (c) anchor Rods In Tied Double Retaining Walls (as: the pull-

type lattice beam retaining wall of anchor, the pull-type campshed retaining wall of anchor).

Wherein masonry retaining wall is with stone laid dry or grouts the masonry forming, and

current masonry retaining wall is careful not to the screening in early stage of stone-laying,

easily causes protective capacities to decline.

Summary of the invention

In order to overcome above-mentioned the deficiencies in the prior art, the object of the

present invention is to provide dry stone pitching engineering method, sternly select stone-

laying type and specification, significantly improve the protective capacities of dry stone

pitching.

To achieve these goals, the technical solution used in the present invention is:

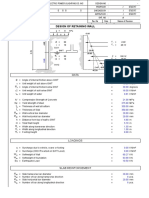

Dry stone pitching engineering method, comprises the steps:

Step 1, adopts ashlar and cobble masonry as stone-laying body, and wherein in ashlar, rubble

is block, and interior thickness is more than or equal to 20cm, and in cobble masonry, cobble

thickness is less than or equal to 30cm, between the ratio 1.0-1.5 of length and thickness;

Step 2, carries out smooth compacting by domatic downstream, by smooth-going domatic

finishing;

Step 3, is transported to filler position by the piece stone of choosing and carries out filler;

Step 4, on the work plane of having built by laying bricks or stones, arranges protective guard

with 2mm steel plate net, and 2mm steel plate protective screening is set in inner side.

Meanwhile, also can adopt interior thickness is the little rubble stuff up a crack of 5-15cm,

and the consumption of little rubble is the 0.1-10% of this place's masonry weight.

The present invention compared with prior art, by sternly selecting stone-laying type and

specification, has significantly improved the protective capacities of dry stone pitching.

The specific embodiment

Below in conjunction with embodiment, the present invention is carried out to more detailed

explanation.

Dry stone pitching engineering method, comprises the steps:

Step 1, adopt ashlar and cobble masonry as stone-laying body, wherein in ashlar, rubble is

block, interior thickness is more than or equal to 20cm, also can adopt interior thickness is the

little rubble stuff up a crack of 5-15cm, the consumption of little rubble is the 0.1-10% of this

place's masonry weight, and in cobble masonry, cobble thickness is less than or equal to

30cm, between the ratio 1.0-1.5 of length and thickness;

Step 2, carries out smooth compacting by domatic downstream, by smooth-going domatic

finishing;

Step 3, is transported to filler position by the piece stone of choosing and carries out filler;

Step 4, on the work plane of having built by laying bricks or stones, arranges protective guard

with 2mm steel plate net, and 2mm steel plate protective screening is set in inner side.

To checking and accepting according to " code for construction and acceptance of masonry

structure engineering " with the bank protection of this engineering method construction,

element project qualification rate reaches 100%, and acceptance rate reaches more than 85%.

You might also like

- A Civil Engg. Final Year Training Report On Residential Building Construction.Document71 pagesA Civil Engg. Final Year Training Report On Residential Building Construction.Monu Khand84% (261)

- Asphalt Institute MS2 - 6th Edition PDFDocument147 pagesAsphalt Institute MS2 - 6th Edition PDFDeven Patle75% (4)

- Jones - Larry.sheet PileDocument19 pagesJones - Larry.sheet PileJessie Radaza Tutor100% (1)

- Chapter 5 Coffer DamDocument8 pagesChapter 5 Coffer Dambipul bhattataiNo ratings yet

- Morth 2100 Open FoundationsDocument6 pagesMorth 2100 Open FoundationsRameshNo ratings yet

- What Is Meant by Charactyeristic Strength of ConcreteDocument4 pagesWhat Is Meant by Charactyeristic Strength of ConcretemmabeeNo ratings yet

- Gujarat SORDocument67 pagesGujarat SORbnarendrababu19No ratings yet

- Technal Submittal For Ug Tank Water ProofingDocument43 pagesTechnal Submittal For Ug Tank Water ProofingArunashish Mazumdar100% (3)

- Water ReticulationDocument49 pagesWater ReticulationMuhammad Hanafi50% (2)

- Bentonite Cavities in Diaphragm WallsDocument113 pagesBentonite Cavities in Diaphragm Wallsrasanavaneethan100% (2)

- 9.1 Formwork Notes-1Document4 pages9.1 Formwork Notes-1RahulSinghRajput100% (2)

- Types of PavementDocument10 pagesTypes of Pavementmohsen.911.mkNo ratings yet

- Safe Bearing Capacity of Soil at SiteDocument3 pagesSafe Bearing Capacity of Soil at SiteTravel With EvonNo ratings yet

- Selection of Retaining Walls in Hill Areas - Indian StandardsDocument14 pagesSelection of Retaining Walls in Hill Areas - Indian Standardsnimm1962100% (1)

- R R MasonryDocument10 pagesR R MasonryVedachalam ManiNo ratings yet

- Modified R-Wall PDFDocument9 pagesModified R-Wall PDFujjawaldaharwalNo ratings yet

- Testing of Sand Quality at Construction Site For ConcreteDocument6 pagesTesting of Sand Quality at Construction Site For ConcreteHussamAlmustafaNo ratings yet

- Beams IS 13920 2016Document12 pagesBeams IS 13920 2016TEJ BAHADUR KARKINo ratings yet

- Earthwork & Engineering Backfilling MaterialsDocument47 pagesEarthwork & Engineering Backfilling MaterialsAHMAD YAGHINo ratings yet

- Box Culvert Estimate 3/53/0Document69 pagesBox Culvert Estimate 3/53/0veevimalNo ratings yet

- Method of Statement - Junction ChamberDocument9 pagesMethod of Statement - Junction ChamberLaksri JayathilakeNo ratings yet

- Construction of Hill Roads and AnswersDocument67 pagesConstruction of Hill Roads and AnswersIqbal BaigNo ratings yet

- Replacement of Coarse Aggregate by Cinder Aggregate in Light Weight Concrete.Document27 pagesReplacement of Coarse Aggregate by Cinder Aggregate in Light Weight Concrete.Parashu Ram Neo100% (1)

- RD - PROTECTION WORKDocument34 pagesRD - PROTECTION WORKMuthusamy ArumugamNo ratings yet

- Ground Improvement TechniquesDocument30 pagesGround Improvement TechniquesNaveen Natarajan100% (1)

- Cracks Repair in PQCDocument3 pagesCracks Repair in PQCNeeraj SharmaNo ratings yet

- MJB-MNB Estimate & BOQDocument14 pagesMJB-MNB Estimate & BOQsujeetNo ratings yet

- Boq-Rehabilition of Football Stadium and New ConstructionDocument12 pagesBoq-Rehabilition of Football Stadium and New ConstructionAcharya Madridista SunilNo ratings yet

- PQC Cracks Repair 1Document3 pagesPQC Cracks Repair 1Deven PatleNo ratings yet

- Types of Failures in Flexible and Rigid PavementsDocument6 pagesTypes of Failures in Flexible and Rigid PavementsTrisha Mae Jamili PetillaNo ratings yet

- Pmgsy Circular About Rural Road GeometryDocument16 pagesPmgsy Circular About Rural Road Geometryprasadnn2001100% (1)

- Rubble Soling: 50mm Thick Stone Dust/ Sand/ Murum/ Soil BedDocument1 pageRubble Soling: 50mm Thick Stone Dust/ Sand/ Murum/ Soil Bedsaurabh dasNo ratings yet

- Aggregate Impact Value (Is: 2386 (Part-Iv) )Document19 pagesAggregate Impact Value (Is: 2386 (Part-Iv) )ajit karandikarNo ratings yet

- (LECT - 19,20) Prestressed Concrete Poles, Piles, SleepersDocument28 pages(LECT - 19,20) Prestressed Concrete Poles, Piles, SleepersSushil Mundel100% (1)

- Soil Stabilisation - 10 SlidesDocument10 pagesSoil Stabilisation - 10 SlidesMarko MarkiniNo ratings yet

- Ac-Corroguard: Inhibitor Solution For Reinforcement BarDocument1 pageAc-Corroguard: Inhibitor Solution For Reinforcement BarbhagwatpatilNo ratings yet

- Permeable Spur Doc 1Document22 pagesPermeable Spur Doc 1Anonymous MAQrYFQDzVNo ratings yet

- Filter Media SpecificationsDocument1 pageFilter Media SpecificationsVarshil Parikh100% (1)

- Design and Cost Estimation of PavementsDocument1 pageDesign and Cost Estimation of PavementsDharma banothuNo ratings yet

- CC Road PDFDocument222 pagesCC Road PDFPhani PitchikaNo ratings yet

- Short Panel Concrete Pavement and White ToppingDocument41 pagesShort Panel Concrete Pavement and White ToppingsombansNo ratings yet

- DSR PuneDocument5 pagesDSR PunedigvijayjagatapNo ratings yet

- Toll Plaza Structure - Technical SpecificationsDocument3 pagesToll Plaza Structure - Technical SpecificationsNeeraj SinghNo ratings yet

- Construction of Short Paneled Concrete Pavement On ADocument28 pagesConstruction of Short Paneled Concrete Pavement On ARajib ChattarajNo ratings yet

- Pradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Document4 pagesPradhan Mantri Gram Sadak Yojana Cost Estimate For Road Construction Package CG03-234Lucky TraderNo ratings yet

- River TrainingDocument8 pagesRiver Trainingnandi_scrNo ratings yet

- Consistency Test of Cement: ResultsDocument11 pagesConsistency Test of Cement: Resultsnira365No ratings yet

- Beam and Block Floor Systems PDFDocument3 pagesBeam and Block Floor Systems PDFdamindaNo ratings yet

- Design & Cost Analysis of Self-Compacting Concrete For Mivan ShutteringDocument5 pagesDesign & Cost Analysis of Self-Compacting Concrete For Mivan Shutteringraj221No ratings yet

- General Notes For RoadDocument2 pagesGeneral Notes For RoadEngr Sayyar Ahmad100% (1)

- Cement Concrete PavementDocument8 pagesCement Concrete Pavementgtarun22guptaNo ratings yet

- Accurate Technical Interpretation of Clause-11.3 of Is-456-2000 For Stripping of FormworkDocument2 pagesAccurate Technical Interpretation of Clause-11.3 of Is-456-2000 For Stripping of FormworkalibaazizNo ratings yet

- WBM Construction ProceduresDocument8 pagesWBM Construction ProceduresYedla NeelakanteshwarNo ratings yet

- Cement Mortar PlasterDocument5 pagesCement Mortar PlasterMani Appa100% (1)

- Morth DLCDocument9 pagesMorth DLCAmit AbhangNo ratings yet

- L-1 Bituminous Mix DesignDocument86 pagesL-1 Bituminous Mix DesignrajibchattarajNo ratings yet

- Civil Engineering Material Lecture NotesDocument4 pagesCivil Engineering Material Lecture Notes11520035No ratings yet

- Types of MixesDocument68 pagesTypes of MixesVinamraMishraNo ratings yet

- RE Wall COnstructionDocument2 pagesRE Wall COnstructionAkshay Agatkar100% (2)

- PQC and DLC AnalysisDocument6 pagesPQC and DLC AnalysisLalkiran VaddeNo ratings yet

- 2500 River Training WorkDocument11 pages2500 River Training WorkGoanengineer100% (1)

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1No ratings yet

- Civil Work ResearchDocument15 pagesCivil Work ResearchKarissa LimosNo ratings yet

- ScienceDirect - Quay WallsDocument15 pagesScienceDirect - Quay WallsYayoi IshikawaNo ratings yet

- Chapter 15Document12 pagesChapter 15Aziz Khan Kakar100% (1)

- Batch SlipDocument2 pagesBatch SlipDeven PatleNo ratings yet

- CALIBRATION OF HM PlantDocument3 pagesCALIBRATION OF HM PlantDeven PatleNo ratings yet

- Different Methodologies For Repair of Cracks in PQC in Concrete PavementsDocument26 pagesDifferent Methodologies For Repair of Cracks in PQC in Concrete PavementsDeven PatleNo ratings yet

- Construction Methodology and QAPDocument7 pagesConstruction Methodology and QAPDeven PatleNo ratings yet

- Ten Percent Fine ValueDocument1 pageTen Percent Fine ValueDeven PatleNo ratings yet

- Viscosity TestDocument1 pageViscosity TestDeven Patle100% (2)

- Methodology For PQC (00) Toll Plaza L&TDocument4 pagesMethodology For PQC (00) Toll Plaza L&TDeven PatleNo ratings yet

- 2.1 Inspection Test PlanDocument26 pages2.1 Inspection Test PlanDeven Patle50% (2)

- Sieve Size Excel 1 PDFDocument1 pageSieve Size Excel 1 PDFDeven PatleNo ratings yet

- Core Cutting FormatDocument1 pageCore Cutting FormatDeven PatleNo ratings yet

- Sieve Size Excel 1 PDFDocument1 pageSieve Size Excel 1 PDFDeven PatleNo ratings yet

- Ac-Pqc-Injecto: Low Viscous Epoxy Injection ResinDocument2 pagesAc-Pqc-Injecto: Low Viscous Epoxy Injection ResinDeven Patle0% (1)

- Open Ended Lab Report: STEN 2002 Civil Engineering MaterialsDocument17 pagesOpen Ended Lab Report: STEN 2002 Civil Engineering MaterialsDeven PatleNo ratings yet

- Foundation Substructure CodeDocument64 pagesFoundation Substructure CodeDeven PatleNo ratings yet

- PQC Cracks Repair 1Document3 pagesPQC Cracks Repair 1Deven PatleNo ratings yet

- QC Frequency Test Plan (5th Revision)Document42 pagesQC Frequency Test Plan (5th Revision)Deven PatleNo ratings yet

- PQC Cracks Repair 2 PDFDocument5 pagesPQC Cracks Repair 2 PDFDeven PatleNo ratings yet

- Frequently Asked Questions (Faqs) About Ground Granulated Blastfurnace Slag (GGBS)Document6 pagesFrequently Asked Questions (Faqs) About Ground Granulated Blastfurnace Slag (GGBS)Deven PatleNo ratings yet

- Soil Improvement Technique and LimitationsDocument4 pagesSoil Improvement Technique and LimitationsMuhammad SyafiqNo ratings yet

- FoundationDocument5 pagesFoundationAnna Rose LoboNo ratings yet

- CE 470-Lect-18 (Estimating The Sizes of Cantilever Retaining Walls) (Read-Only) PDFDocument17 pagesCE 470-Lect-18 (Estimating The Sizes of Cantilever Retaining Walls) (Read-Only) PDFJamal RkhNo ratings yet

- Retaining Structure Design For KNDocument11 pagesRetaining Structure Design For KNberkely19No ratings yet

- Construction Method Statement and Structural Report London W10 5BZDocument29 pagesConstruction Method Statement and Structural Report London W10 5BZAtilla AkdoganNo ratings yet

- S5.3 - Deep Excavation Works Close To The Existing MRT Tunnel in Soft Marine Clay - KonoDocument10 pagesS5.3 - Deep Excavation Works Close To The Existing MRT Tunnel in Soft Marine Clay - KonofreezefreezeNo ratings yet

- SOR Detailed Estimate ROB ROUGHDocument29 pagesSOR Detailed Estimate ROB ROUGHMinhaj Ahmed khanNo ratings yet

- Overcoming Soil Uncertainty in Prediction of Construction and Industrial VibrationsDocument20 pagesOvercoming Soil Uncertainty in Prediction of Construction and Industrial VibrationslrbolNo ratings yet

- 50ft Deep Excavation Design Example - Deep ExcavationDocument7 pages50ft Deep Excavation Design Example - Deep ExcavationAdrian FrantescuNo ratings yet

- Geosense Brochure 2011 V1.2Document46 pagesGeosense Brochure 2011 V1.2jnfNo ratings yet

- Hill RoadsDocument69 pagesHill RoadsHarish joshiNo ratings yet

- 06 Chapter 7 - Lateral Earth Pressure-M PDFDocument62 pages06 Chapter 7 - Lateral Earth Pressure-M PDFogeboy sangcopanNo ratings yet

- Changes DC-Cantilever For Windows Date Version ChangeDocument7 pagesChanges DC-Cantilever For Windows Date Version ChangeGanea Marius BogdanNo ratings yet

- HAT Pile - Technical Report On Hat+H Sheet PilesDocument46 pagesHAT Pile - Technical Report On Hat+H Sheet Pilesedward the iiiNo ratings yet

- Copia Di CH-Albania - TR - Rraeshen-Kalimash Highway Paramesh Structure 2009Document3 pagesCopia Di CH-Albania - TR - Rraeshen-Kalimash Highway Paramesh Structure 2009Snopi DeGrauNo ratings yet

- Department of Public Works and HighwaysDocument7 pagesDepartment of Public Works and HighwaysZA TarraNo ratings yet

- Geotechnical QuizDocument41 pagesGeotechnical QuizAminulIslamNo ratings yet

- CCSP Method EnglishDocument14 pagesCCSP Method EnglishSuperdanzNo ratings yet

- Guidance On The Structural Use of Plastic Sheet Piling in Highway ApplicationsDocument30 pagesGuidance On The Structural Use of Plastic Sheet Piling in Highway ApplicationsIvanSmithNo ratings yet

- Tablon Retaining Wall Ht. - Clark - With WindDocument27 pagesTablon Retaining Wall Ht. - Clark - With WindclarkgaguiNo ratings yet

- Lateral Earth PressureDocument34 pagesLateral Earth PressureTimothy Charles YabutNo ratings yet

- (GT-PPT) Deep Excavation Presentation 20150317Document12 pages(GT-PPT) Deep Excavation Presentation 20150317Laurenz Luigi CruzNo ratings yet

- Important Notice: Community, Storing All or Part of The Content (Electronically orDocument43 pagesImportant Notice: Community, Storing All or Part of The Content (Electronically orS Sathiyaruban100% (1)