Professional Documents

Culture Documents

LPT Procedure

LPT Procedure

Uploaded by

vijay padaleCopyright:

Available Formats

You might also like

- Painting - Training PPT 1Document24 pagesPainting - Training PPT 1vijay padale83% (6)

- Peneterant Testing For NDT - Procedure Details - Latest FinalDocument8 pagesPeneterant Testing For NDT - Procedure Details - Latest FinalAlam MD Sazid100% (1)

- Shockey - Precast Parking Structure Guide PDFDocument47 pagesShockey - Precast Parking Structure Guide PDFChanduthewilderNo ratings yet

- To Be Known Know The Gas Cutting Sets. Hazards & Precautions Risk AssessmentDocument17 pagesTo Be Known Know The Gas Cutting Sets. Hazards & Precautions Risk AssessmentRaja GuruNo ratings yet

- LPT ProcedureDocument8 pagesLPT ProcedurequalityNo ratings yet

- Pneumatic Test ProcedureDocument4 pagesPneumatic Test Procedurevijay padaleNo ratings yet

- RNS - NDT - PT - 001 Rev.0Document8 pagesRNS - NDT - PT - 001 Rev.0Goutam Kumar Deb100% (1)

- Liquid Dye Penetrant Test Inspection NDT Sample ProcedureDocument7 pagesLiquid Dye Penetrant Test Inspection NDT Sample ProcedureAnonymous gFcnQ4go100% (2)

- Peneterant Testing For NDT Procedure Details LatestDocument7 pagesPeneterant Testing For NDT Procedure Details LatestAlam MD SazidNo ratings yet

- WIweld10 Dye Penetrant Examination Rev 00Document3 pagesWIweld10 Dye Penetrant Examination Rev 00Gautam KumarNo ratings yet

- Dye Penetrant Inspection ProcedureDocument6 pagesDye Penetrant Inspection ProcedureRidoNo ratings yet

- Liquid Dye Penetrant Test Inspection Sample ProcedureDocument8 pagesLiquid Dye Penetrant Test Inspection Sample Procedureم.ذكى فضل ذكىNo ratings yet

- STS QAC SOP 009 - 01 Liquid Penetrant Test ProcedureDocument6 pagesSTS QAC SOP 009 - 01 Liquid Penetrant Test Proceduremohd as shahiddin jafriNo ratings yet

- Procedure For Liquid Penetrant ExaminationDocument12 pagesProcedure For Liquid Penetrant ExaminationShashank ParmarNo ratings yet

- Pneumatic Test ProcedureDocument3 pagesPneumatic Test Procedurevijay padale50% (2)

- Procedure For LPTDocument8 pagesProcedure For LPTmd quasid rabbaniNo ratings yet

- Hydro Test ProcedureDocument6 pagesHydro Test Procedurevijay padaleNo ratings yet

- Penetrating Dye ProcedureDocument7 pagesPenetrating Dye ProcedureScribdTranslationsNo ratings yet

- BK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsDocument69 pagesBK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsPanneer SelvamNo ratings yet

- PT Procedure Rev01EDocument14 pagesPT Procedure Rev01ETrương Ngọc SơnNo ratings yet

- DPT ProcedureDocument4 pagesDPT ProcedureRohit Attri100% (1)

- Hydrostatic Test ProcedureDocument7 pagesHydrostatic Test ProcedurequalityNo ratings yet

- TUV SUD - PT Procedure Rev.05Document13 pagesTUV SUD - PT Procedure Rev.05HassanNo ratings yet

- Procedure For DYE PENETRANT TestingDocument10 pagesProcedure For DYE PENETRANT TestingKarrar Talib100% (1)

- Dye Penetrant Inspection ProcedureDocument13 pagesDye Penetrant Inspection ProcedureHafidzManaf100% (1)

- PT-Liquid Penetrant Testing Procedure R01 - 2 2Document12 pagesPT-Liquid Penetrant Testing Procedure R01 - 2 2George Ogbeche100% (1)

- 014-DP TestDocument4 pages014-DP TestBinod DavisNo ratings yet

- BIX Dye Penetrant ProcedureDocument7 pagesBIX Dye Penetrant ProcedureEduard Abastillas100% (2)

- Liquid Penetrant Examination Procedure For Asme CodeDocument15 pagesLiquid Penetrant Examination Procedure For Asme Codeshabbir626100% (1)

- Specification PTDocument11 pagesSpecification PTDomingos OliveiraNo ratings yet

- LPT Written ProcedureDocument8 pagesLPT Written ProcedureManikantaSumanthNo ratings yet

- DPTDocument12 pagesDPTAMIT SHAH100% (2)

- SCTPL Q SP 002 A1 Vaccum Box Testing ProcedureDocument6 pagesSCTPL Q SP 002 A1 Vaccum Box Testing ProcedureKandula Raju100% (1)

- PT ProcedureDocument14 pagesPT Procedureefmartin21No ratings yet

- PT Procedure GeneralDocument9 pagesPT Procedure Generalvsnaiduqc100% (1)

- PT Non Fluorecent R2Document12 pagesPT Non Fluorecent R2edo ramadhanNo ratings yet

- Liquid Penetrant Testing - Level 1 (Practical)Document1 pageLiquid Penetrant Testing - Level 1 (Practical)Farrukh NazNo ratings yet

- Dye Penetrant Inspection ProcedureDocument14 pagesDye Penetrant Inspection Proceduretankimsin100% (1)

- Pro 805Document8 pagesPro 805sorsanbarNo ratings yet

- 03-MS - Liquid Penetration Test - LudhianaDocument7 pages03-MS - Liquid Penetration Test - LudhianaAbhishek Kumar VishwakarmaNo ratings yet

- Welding Dye PenetrantDocument12 pagesWelding Dye Penetrantarun manchekarNo ratings yet

- LPT SopDocument7 pagesLPT SopQUALITYNo ratings yet

- 04-MS - Tank Vacuum Box Test - LudhianaDocument8 pages04-MS - Tank Vacuum Box Test - LudhianaAbhishek Kumar VishwakarmaNo ratings yet

- 6-Penetrant Test ProcedureDocument3 pages6-Penetrant Test ProcedureSezgin CkllıNo ratings yet

- Approval of LPT ProcedureDocument14 pagesApproval of LPT ProcedureimranNo ratings yet

- Pneumatic Test ProcedureDocument5 pagesPneumatic Test ProcedureBharat BhoirNo ratings yet

- LPT Procedure AsiplDocument10 pagesLPT Procedure Asipltushartech009No ratings yet

- Procedure For Liquid Penetrant Testing: Omnifab Engineers Pvt. LTDDocument10 pagesProcedure For Liquid Penetrant Testing: Omnifab Engineers Pvt. LTDgayaprasad2310No ratings yet

- Liquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Document12 pagesLiquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Anas PratamaNo ratings yet

- Liquid Penetrant Testing Generic Procedure: Procedure No. BCE/LPT/001-2021/Rev.0Document11 pagesLiquid Penetrant Testing Generic Procedure: Procedure No. BCE/LPT/001-2021/Rev.0BCE DeNo ratings yet

- Hydro Test ProcedureDocument5 pagesHydro Test ProcedureBharat BhoirNo ratings yet

- PR-QAQC-05-Liquid Penentrant Testing ProcedureDocument12 pagesPR-QAQC-05-Liquid Penentrant Testing Procedurevanthien0196No ratings yet

- Dye Penetrant Testing ProcedureDocument5 pagesDye Penetrant Testing ProcedureTabish Shaikh50% (2)

- Construction Leak Test ProcedureDocument6 pagesConstruction Leak Test Procedurezack zeeartNo ratings yet

- Fired Pressure VesselDocument27 pagesFired Pressure VesselAmir ZamriNo ratings yet

- TUV SUD - MT Procedure Rev.05Document11 pagesTUV SUD - MT Procedure Rev.05HassanNo ratings yet

- DPT Acceptance Code ReferenceDocument5 pagesDPT Acceptance Code ReferenceMidhun K Chandrabose100% (2)

- PT - ExWI-NDT-22110 Rev.00 - ASME CodeDocument17 pagesPT - ExWI-NDT-22110 Rev.00 - ASME CodeCherdchai nuntariNo ratings yet

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&AFrom EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&ANo ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- 05) MSM QF-MR-05 Equipment MasterDocument4 pages05) MSM QF-MR-05 Equipment Mastervijay padaleNo ratings yet

- Chem-Wps - PQR - WPQ-004 CS-SS 08-08 GtawDocument5 pagesChem-Wps - PQR - WPQ-004 CS-SS 08-08 Gtawvijay padaleNo ratings yet

- Chem-Pqr - WPQ-010 CS-CS 50NB-50NB GtawDocument3 pagesChem-Pqr - WPQ-010 CS-CS 50NB-50NB Gtawvijay padaleNo ratings yet

- UT Procedure of WeldsDocument10 pagesUT Procedure of Weldsvijay padaleNo ratings yet

- Hydro Test ProcedureDocument6 pagesHydro Test Procedurevijay padaleNo ratings yet

- Pneumatic Test ProcedureDocument4 pagesPneumatic Test Procedurevijay padaleNo ratings yet

- Approved - Passivation Procedure - Date18.02.2021Document6 pagesApproved - Passivation Procedure - Date18.02.2021vijay padaleNo ratings yet

- Pneumatic Test ProcedureDocument3 pagesPneumatic Test Procedurevijay padale50% (2)

- ?di' FQ: Procedure For Radiographic Examination Welds Unique Sery'CesDocument33 pages?di' FQ: Procedure For Radiographic Examination Welds Unique Sery'Cesvijay padaleNo ratings yet

- Pickling & Passivation Procedure MainDocument6 pagesPickling & Passivation Procedure Mainvijay padale100% (3)

- Section - 079129 - Penetration SealsDocument6 pagesSection - 079129 - Penetration SealsBikash BhattaraiNo ratings yet

- Steelmaster 120Sb: Technical Data SheetDocument4 pagesSteelmaster 120Sb: Technical Data SheetkalstarNo ratings yet

- Shell Permeability PresentationDocument29 pagesShell Permeability Presentationbilalabbasi1990No ratings yet

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- Watertite R 1000Document2 pagesWatertite R 1000Alexi ALfred H. TagoNo ratings yet

- Airseal Installation Instruction - enDocument4 pagesAirseal Installation Instruction - enkamendrix kamendrixNo ratings yet

- Welding Wire CatalogDocument10 pagesWelding Wire CatalogElvis MaljanovicNo ratings yet

- The Platinum Foil TechniqueDocument15 pagesThe Platinum Foil Techniqueaziz2007No ratings yet

- Packaging Materials and Handling Technique: Dr. Ranjeet SinghDocument48 pagesPackaging Materials and Handling Technique: Dr. Ranjeet Singharon demagiba100% (1)

- Influence of The Age and Drying Process On Pore Structure and Sorption Isotherms of Hardened Cement PasteDocument16 pagesInfluence of The Age and Drying Process On Pore Structure and Sorption Isotherms of Hardened Cement PasteBambus PrometeNo ratings yet

- Is 14959 2 2001 PDFDocument13 pagesIs 14959 2 2001 PDFGarima GuptaNo ratings yet

- Dipshikha Meti SchoolDocument13 pagesDipshikha Meti SchoolNasrinNaharTuliNo ratings yet

- PLUMBINGDocument5 pagesPLUMBINGhadjie ansayNo ratings yet

- Cooling Water Treatment and Periodical Test of The Cooling WaterDocument4 pagesCooling Water Treatment and Periodical Test of The Cooling WaterGaurav MaithilNo ratings yet

- TDS - Titanpro 6331Document1 pageTDS - Titanpro 6331Ilham HidayatNo ratings yet

- Exhaust Rim E722 - Epoxy - PDSDocument5 pagesExhaust Rim E722 - Epoxy - PDSSpace MuskNo ratings yet

- Tapcon: SCOTS AnchorsDocument2 pagesTapcon: SCOTS Anchorsblessed cccNo ratings yet

- Carrier Oil Shelf LifeDocument3 pagesCarrier Oil Shelf LifeAna ThesecretiveNo ratings yet

- G7 Science Q1 - Week 6-Unsaturated and Saturated SolutionDocument14 pagesG7 Science Q1 - Week 6-Unsaturated and Saturated SolutionJessa-Bhel AlmueteNo ratings yet

- Description: Polystyrene (PS)Document5 pagesDescription: Polystyrene (PS)Murilo SanchesNo ratings yet

- .Study of Mechanical Properties of Concrete With Zeolite Powder and Steel SlagDocument7 pages.Study of Mechanical Properties of Concrete With Zeolite Powder and Steel Slagalaa albalahNo ratings yet

- Chemistry Investigatory Project OnDocument15 pagesChemistry Investigatory Project OnjibinNo ratings yet

- Kennedy Solid Wedge Series 100Document1 pageKennedy Solid Wedge Series 100vineethNo ratings yet

- Electrochemical Recovery of Gold From ConcentrateDocument9 pagesElectrochemical Recovery of Gold From ConcentrateAlexander Opazo PérezNo ratings yet

- Cycom-977-3 CM en PDFDocument5 pagesCycom-977-3 CM en PDFSeçkin MartinNo ratings yet

- Collector Beads CatalogDocument34 pagesCollector Beads Catalogsudhanshu_12juneNo ratings yet

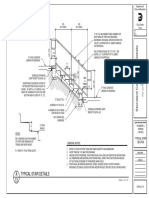

- Typical Stair DetailsDocument1 pageTypical Stair DetailsM IQbalNo ratings yet

- Preliminary EstimateDocument558 pagesPreliminary Estimatesurendra_pangaNo ratings yet

LPT Procedure

LPT Procedure

Uploaded by

vijay padaleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LPT Procedure

LPT Procedure

Uploaded by

vijay padaleCopyright:

Available Formats

NON DESTRUCTIVE EXAMINATION PROCEDURE

Doc No. :

QA/CHEM/NDEP/LPT

NDE PROCEDURE LIQUID PENETRANT TESTING REV No. : 00 DATE :

27.07.2021

1. Scope

This Test method covers procedures for penetrant examination of butt and fillet weld with the

associated Heat Effected Zone (HAZ) on the parent metal and components. They are non-

destructive testing methods for detecting discontinuities that are open to the surface such as

cracks, porosity and lack of fusion by liquid penetrant testing conducted in accordance with the

requirements ofthe referenced Codes and Standards.

2. Purpose

The purpose of this procedure is to explain the method of applying the liquid penetration non-

destructive test.

3. References

ASME Code Section V -applicable edition/addenda.

ASME Code Section VIII, Div1-applicable edition/addenda.

ANSI/ASME 831.1, 831.3 applicable edition/addenda.

AWS 01.1 - applicable edition.

ASTM-E165-Standard Test Method for Liquid Penetrant Examination.

Clients specification requirements for acceptance criteria.

CEE Written Practice

Note: In case of conflict between Code requirements and Client's specifications, Code

requirements shall prevail.

4. Definitions

PT : Penetrant Examination

5. Responsibilities

The NDT Inspector shall be responsible for conducting and reporting the results of inspection in

accordance with project contract.

6. Personnel Qualification

6.1 All personnel involved in Penetrant Examinations shall be qualified in accordance with the

Requirements of code.

6.2 When the written practice is revised, the certification of NDE personnel remains valid to the

requirements of the previous revision until the expiry date of the personnel qualification

certificate; then, recertification to the requirements of the new revision is required.

6.3 The certification of personnel shall be checked by the QNQC Manager prior to work

commencement.

Prepared By Approved By

Reviewed

12-08-2021

Mr. Vijaykumar Padale

QA DEPT.

LEVEL-II (RT, LPT, MPT, VT)

CHEMSEPT PVT LTD.

NON DESTRUCTIVE EXAMINATION PROCEDURE

Doc No. :

QA/CHEM/NDEP/LPT

NDE PROCEDURE LIQUID PENETRANT TESTING REV No. : 00 DATE :

27.07.2021

7. Procedure

This procedure shall be demonstrated prior to use in accordance with the requirements of T-

150, ASME Code Sec. V. The procedure qualification record shall be attached to this

procedure.

7.1 Equipment:

7.1.1 Solvent Removable Visible Dye Penetrant materials consist of:

a) Penetrant.

b) Penetrant remover/ cleaner .

c) Developer. ·

d) Lint free cloth.

e) Light meter capable of measuring visible light intensity in lux I foot candles (f.c.). The light meter

shall meet the calibration requirement of T-660 of ASME Code Section V

7.2 Materials:

7.2.1 Only materials of a recognized commercial quality shall be used as identified by the

manufacturers name i.e. Dyglo or FerroChem or as specified by the client.

7.2.2 Penetrant materials of the same family group shall be used; mix between family groups is

prohibited.

7.2.3 Certification of contaminant content shall be provided by manufacturers for all liquid

penetrant materials used on nickel base alloys, austenitic or duplex stainless steels, and titanium.

These certifications shall include the penetrant manufacturers' batch numbers and the test results

obtained in accordance with Mandatory Appendix II of Article 6, ASME Code Sec. V. These

records shall be maintained as required by the referencing Code Section.

7.3 Surface Condition:

7.3.1 Generally satisfactory results may be obtained when the surface of the part is in the as-

welded, as rolled, as-cast, or as forged condition. Surface preparation by grinding, machining, or

other methods may be necessary where surface irregularities could mask indications of

unacceptable discontinuities.

Precautions shall be made with the mechanical cleaning not to close the discontinuities open to

the surface. Etching of the cleaned surfaces may be necessary to open the discontinuities.

7.3.2 Prior to all liquid penetrant inspections, the surface to be examined and all adjacent areas

within at least 25mm (1") shall be dry and free of dirt, grease, lint, scale, welding flux, weld spatter,

Prepared By Approved By

Approved

12-08-2021

Mr. Vijaykumar Padale

QA DEPT.

LEVEL-II (RT, LPT, MPT, VT)

CHEMSEPT PVT LTD.

NON DESTRUCTIVE EXAMINATION PROCEDURE

Doc No. :

QA/CHEM/NDEP/LPT

NDE PROCEDURE LIQUID PENETRANT TESTING REV No. : 00 DATE :

27.07.2021

oil and other extraneous matters that could obscure surface openings or otherwise interfere with

the examination.

7.3.3 Typical cleaning agents that may be used are detergents, organic solvents , descaling

solutions and paint removers. Degreasing and ultrasonic cleaning methods may also be used.

7.4 Method :

7.4.1Surface Cleaning process:

a) Solvent cleaning method: On removal of any rust, scale, welding flux, spatter, and in general,

inorganic soils, the surfaces to be inspected shall be cleaned, with solvent cleaner and then finally

with a dry lint free cloth.

7.4.2 Application of penetrant:

a) After the area has been cleaned, dried and the temperature of the surface and penetrant are

within the range of 40° F (5° C) to 125° F (52° C), the penetrant shall be Brushed I sprayed

directly to the surface to be inspected by means of aerosol container I brush, so that the entire

area under inspection is completely covered.

b) After application, excess penetrant shall be allowed to drain (care being taken to prevent pools

of penetrant forming on the test area) while allowing for minimum penetration (dwell) time

stated in accordance with (ASME V.Article24, SE165) unless otherwise specified by the client

in a more restrictive manner.

c) The length of time the penetrant must remain on the part to allow proper penetration should be

as recommended by the penetrant manufacturer (dwell time shall not exceed the maximum

recommended by the manufacturer).

7.4.3 Excess Penetrant removal:

a) After the specified dwell time has been elapsed, any penetrant remaining on the surface shall

be removed with a dry or slightly moistened cloth of solvent cleaner, taking care to minimize

removal of penetrant from possible discontinuity.

b) Flushing the surface with solvent cleaner, following the application of the penetrant and prior to

developing is prohibited.

7.4.4 Drying after removal of excess penetrant:

Prepared By Approved By

Reviewed

12-08-2021

Mr. Vijaykumar Padale

QA DEPT.

LEVEL-II (RT, LPT, MPT, VT)

CHEMSEPT PVT LTD.

NON DESTRUCTIVE EXAMINATION PROCEDURE

Doc No. :

QA/CHEM/NDEP/LPT

NDE PROCEDURE LIQUID PENETRANT TESTING REV No. : 00 DATE :

27.07.2021

a) The drying process shall be accomplished by normal evaporation. Drying time shall only be that

necessary to adequately dry the part.

7.4.5 Application o& the developer:

a) Apply the non-aqueous wet developer directly to the area being inspected, by Brushing

spraying from the aerosol container.

b) The non-aqueous developer evaporates rapidly at room temperature and therefore does not

require the use of a dryer.

c) Areas being inspected shall be sprayed in such a manner so as to assure complete coverage

with a thin, even film of developer.

d) Dipping or flooding parts with non-aqueous developer is prohibited.

e) Developing dwell time shall not be less than 10 min., The maximum permitted developing time is 1

hour for no aqueous developers as stated in accordance with (ASME-V.Article24, SE-165) unless

otherwise specified by the client. in a more restrictive manner.

7.5 Examination:

7.5.1 shall be carried out after the applicable developer dwell time to allow for bleed out

of penetrant from discontinuities into the developer coating. It is good practice to

observe the bleed out while applying the developer as an aid in interpreting and

evaluating indications.

7.5.2 Visible penetrant indications can be inspected in natural or artificial white light. A

minimum intensity at the inspection surface of 100 foot candles (1000 Lux) is required.

7.5.3The light source, technique used, and light level verification is required to be

demonstrated, one time, documented, and maintained on file.

7.6 Evaluation of indications:

7.6.1 All indications shall be evaluated in accordance with the referencing code or

Specification.

7.6.2 Relevant indications are those that result from mechanical discontinuities:

a) Linear indications are those indications in which the length is more than three times the

Prepared By Approved By

Reviewed

12-08-2021

Mr. Vijaykumar Padale

QA DEPT.

LEVEL-II (RT, LPT, MPT, VT)

CHEMSEPT PVT LTD.

NON DESTRUCTIVE EXAMINATION PROCEDURE

Doc No. :

QA/CHEM/NDEP/LPT

NDE PROCEDURE LIQUID PENETRANT TESTING REV No. : 00 DATE :

27.07.2021

width.

b) Rounded indication or indications which are circular or elliptical with lengths less

than three times the width.

c) Any questionable or doubtful indications shall be re-tested to verify whether or not

actual defects are present.

d) Localized surface imperfections may occur, such as machine marks, surface

conditions, or incomplete bond between base metal and cladding, may produce similar

indications which are not relevant to the detection of unacceptable discontinuities.

7.7 Acceptance Criteria:

7.7.1 Acceptance criteria for specific Code as below.

ASME SEC VIII 01

Indications > 1/16" (1.5 mm) shall be considered as relevant. The following indications shall be

rejectable:

1. Relevant linear indication >1/16" (1.Smm)

2. Relevant rounded indications > 3/16" (5 mm)

3. Four or more rounded indications in a line separated by 1/16" or less (edge to edge).

7.8 Post cleaning:

7.8.1 Upon completion of the test, in cases where residual penetrant or developer could

interfere with subsequent processing or with service requirements, a suitable technique, such as a

water rinse or solvent soak for cleaning may be employed.

7.9 Documentation:

7.9.1 Non-rejectable indications shall be recorded as specified by the referencing Code Section.

7.9.2 Rejectable indications shall be recorded. As a minimum, the type of indications (linear or rounded),

location and extent (length or diameter or aligned) shall be recorded.

8. Records

Liquid Penetrant Examination shall be documented on Liquid Penetrant Examination Doc:

IR/LPTR/01, REV.00

Prepared By Approved By

Reviewed

12-08-2021

Mr. Vijaykumar Padale

QA DEPT.

LEVEL-II (RT, LPT, MPT, VT)

CHEMSEPT PVT LTD.

NON DESTRUCTIVE EXAMINATION PROCEDURE

Doc No. :

QA/CHEM/NDEP/LPT

NDE PROCEDURE LIQUID PENETRANT TESTING REV No. : 00 DATE :

27.07.2021

LPT REPORT

Client: P.O No.:

Equipment: SO No.:

Drawing No./Rev: QAP No.

Report No: IR/LPTR/01, REV.00 Inspected By:

TECHNIQUE Visible Solvent Removable Stage

STANDARD ASME sec V & VIII Div 1 Surface Condition-

Dwell Time 10 Min Developing Time 10 Min Surface Temp.-

Examination Extant: 100%

Penetrant Make, Batch no-, Exp-Date

Developer Make, Batch no-, Exp-Date

Cleaner Make, Batch no-, Exp-Date

RESULTS

Sr. Observation Remark

Tag No. Description

No

1

2

Note NRI no recordable indication.

Prepared By Approved By

Format Reviewed

12-08-2021

Mr. Vijaykumar Padale

QA DEPT.

LEVEL-II (RT, LPT, MPT, VT)

CHEMSEPT PVT LTD.

You might also like

- Painting - Training PPT 1Document24 pagesPainting - Training PPT 1vijay padale83% (6)

- Peneterant Testing For NDT - Procedure Details - Latest FinalDocument8 pagesPeneterant Testing For NDT - Procedure Details - Latest FinalAlam MD Sazid100% (1)

- Shockey - Precast Parking Structure Guide PDFDocument47 pagesShockey - Precast Parking Structure Guide PDFChanduthewilderNo ratings yet

- To Be Known Know The Gas Cutting Sets. Hazards & Precautions Risk AssessmentDocument17 pagesTo Be Known Know The Gas Cutting Sets. Hazards & Precautions Risk AssessmentRaja GuruNo ratings yet

- LPT ProcedureDocument8 pagesLPT ProcedurequalityNo ratings yet

- Pneumatic Test ProcedureDocument4 pagesPneumatic Test Procedurevijay padaleNo ratings yet

- RNS - NDT - PT - 001 Rev.0Document8 pagesRNS - NDT - PT - 001 Rev.0Goutam Kumar Deb100% (1)

- Liquid Dye Penetrant Test Inspection NDT Sample ProcedureDocument7 pagesLiquid Dye Penetrant Test Inspection NDT Sample ProcedureAnonymous gFcnQ4go100% (2)

- Peneterant Testing For NDT Procedure Details LatestDocument7 pagesPeneterant Testing For NDT Procedure Details LatestAlam MD SazidNo ratings yet

- WIweld10 Dye Penetrant Examination Rev 00Document3 pagesWIweld10 Dye Penetrant Examination Rev 00Gautam KumarNo ratings yet

- Dye Penetrant Inspection ProcedureDocument6 pagesDye Penetrant Inspection ProcedureRidoNo ratings yet

- Liquid Dye Penetrant Test Inspection Sample ProcedureDocument8 pagesLiquid Dye Penetrant Test Inspection Sample Procedureم.ذكى فضل ذكىNo ratings yet

- STS QAC SOP 009 - 01 Liquid Penetrant Test ProcedureDocument6 pagesSTS QAC SOP 009 - 01 Liquid Penetrant Test Proceduremohd as shahiddin jafriNo ratings yet

- Procedure For Liquid Penetrant ExaminationDocument12 pagesProcedure For Liquid Penetrant ExaminationShashank ParmarNo ratings yet

- Pneumatic Test ProcedureDocument3 pagesPneumatic Test Procedurevijay padale50% (2)

- Procedure For LPTDocument8 pagesProcedure For LPTmd quasid rabbaniNo ratings yet

- Hydro Test ProcedureDocument6 pagesHydro Test Procedurevijay padaleNo ratings yet

- Penetrating Dye ProcedureDocument7 pagesPenetrating Dye ProcedureScribdTranslationsNo ratings yet

- BK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsDocument69 pagesBK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsPanneer SelvamNo ratings yet

- PT Procedure Rev01EDocument14 pagesPT Procedure Rev01ETrương Ngọc SơnNo ratings yet

- DPT ProcedureDocument4 pagesDPT ProcedureRohit Attri100% (1)

- Hydrostatic Test ProcedureDocument7 pagesHydrostatic Test ProcedurequalityNo ratings yet

- TUV SUD - PT Procedure Rev.05Document13 pagesTUV SUD - PT Procedure Rev.05HassanNo ratings yet

- Procedure For DYE PENETRANT TestingDocument10 pagesProcedure For DYE PENETRANT TestingKarrar Talib100% (1)

- Dye Penetrant Inspection ProcedureDocument13 pagesDye Penetrant Inspection ProcedureHafidzManaf100% (1)

- PT-Liquid Penetrant Testing Procedure R01 - 2 2Document12 pagesPT-Liquid Penetrant Testing Procedure R01 - 2 2George Ogbeche100% (1)

- 014-DP TestDocument4 pages014-DP TestBinod DavisNo ratings yet

- BIX Dye Penetrant ProcedureDocument7 pagesBIX Dye Penetrant ProcedureEduard Abastillas100% (2)

- Liquid Penetrant Examination Procedure For Asme CodeDocument15 pagesLiquid Penetrant Examination Procedure For Asme Codeshabbir626100% (1)

- Specification PTDocument11 pagesSpecification PTDomingos OliveiraNo ratings yet

- LPT Written ProcedureDocument8 pagesLPT Written ProcedureManikantaSumanthNo ratings yet

- DPTDocument12 pagesDPTAMIT SHAH100% (2)

- SCTPL Q SP 002 A1 Vaccum Box Testing ProcedureDocument6 pagesSCTPL Q SP 002 A1 Vaccum Box Testing ProcedureKandula Raju100% (1)

- PT ProcedureDocument14 pagesPT Procedureefmartin21No ratings yet

- PT Procedure GeneralDocument9 pagesPT Procedure Generalvsnaiduqc100% (1)

- PT Non Fluorecent R2Document12 pagesPT Non Fluorecent R2edo ramadhanNo ratings yet

- Liquid Penetrant Testing - Level 1 (Practical)Document1 pageLiquid Penetrant Testing - Level 1 (Practical)Farrukh NazNo ratings yet

- Dye Penetrant Inspection ProcedureDocument14 pagesDye Penetrant Inspection Proceduretankimsin100% (1)

- Pro 805Document8 pagesPro 805sorsanbarNo ratings yet

- 03-MS - Liquid Penetration Test - LudhianaDocument7 pages03-MS - Liquid Penetration Test - LudhianaAbhishek Kumar VishwakarmaNo ratings yet

- Welding Dye PenetrantDocument12 pagesWelding Dye Penetrantarun manchekarNo ratings yet

- LPT SopDocument7 pagesLPT SopQUALITYNo ratings yet

- 04-MS - Tank Vacuum Box Test - LudhianaDocument8 pages04-MS - Tank Vacuum Box Test - LudhianaAbhishek Kumar VishwakarmaNo ratings yet

- 6-Penetrant Test ProcedureDocument3 pages6-Penetrant Test ProcedureSezgin CkllıNo ratings yet

- Approval of LPT ProcedureDocument14 pagesApproval of LPT ProcedureimranNo ratings yet

- Pneumatic Test ProcedureDocument5 pagesPneumatic Test ProcedureBharat BhoirNo ratings yet

- LPT Procedure AsiplDocument10 pagesLPT Procedure Asipltushartech009No ratings yet

- Procedure For Liquid Penetrant Testing: Omnifab Engineers Pvt. LTDDocument10 pagesProcedure For Liquid Penetrant Testing: Omnifab Engineers Pvt. LTDgayaprasad2310No ratings yet

- Liquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Document12 pagesLiquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Anas PratamaNo ratings yet

- Liquid Penetrant Testing Generic Procedure: Procedure No. BCE/LPT/001-2021/Rev.0Document11 pagesLiquid Penetrant Testing Generic Procedure: Procedure No. BCE/LPT/001-2021/Rev.0BCE DeNo ratings yet

- Hydro Test ProcedureDocument5 pagesHydro Test ProcedureBharat BhoirNo ratings yet

- PR-QAQC-05-Liquid Penentrant Testing ProcedureDocument12 pagesPR-QAQC-05-Liquid Penentrant Testing Procedurevanthien0196No ratings yet

- Dye Penetrant Testing ProcedureDocument5 pagesDye Penetrant Testing ProcedureTabish Shaikh50% (2)

- Construction Leak Test ProcedureDocument6 pagesConstruction Leak Test Procedurezack zeeartNo ratings yet

- Fired Pressure VesselDocument27 pagesFired Pressure VesselAmir ZamriNo ratings yet

- TUV SUD - MT Procedure Rev.05Document11 pagesTUV SUD - MT Procedure Rev.05HassanNo ratings yet

- DPT Acceptance Code ReferenceDocument5 pagesDPT Acceptance Code ReferenceMidhun K Chandrabose100% (2)

- PT - ExWI-NDT-22110 Rev.00 - ASME CodeDocument17 pagesPT - ExWI-NDT-22110 Rev.00 - ASME CodeCherdchai nuntariNo ratings yet

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&AFrom EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&ANo ratings yet

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- 05) MSM QF-MR-05 Equipment MasterDocument4 pages05) MSM QF-MR-05 Equipment Mastervijay padaleNo ratings yet

- Chem-Wps - PQR - WPQ-004 CS-SS 08-08 GtawDocument5 pagesChem-Wps - PQR - WPQ-004 CS-SS 08-08 Gtawvijay padaleNo ratings yet

- Chem-Pqr - WPQ-010 CS-CS 50NB-50NB GtawDocument3 pagesChem-Pqr - WPQ-010 CS-CS 50NB-50NB Gtawvijay padaleNo ratings yet

- UT Procedure of WeldsDocument10 pagesUT Procedure of Weldsvijay padaleNo ratings yet

- Hydro Test ProcedureDocument6 pagesHydro Test Procedurevijay padaleNo ratings yet

- Pneumatic Test ProcedureDocument4 pagesPneumatic Test Procedurevijay padaleNo ratings yet

- Approved - Passivation Procedure - Date18.02.2021Document6 pagesApproved - Passivation Procedure - Date18.02.2021vijay padaleNo ratings yet

- Pneumatic Test ProcedureDocument3 pagesPneumatic Test Procedurevijay padale50% (2)

- ?di' FQ: Procedure For Radiographic Examination Welds Unique Sery'CesDocument33 pages?di' FQ: Procedure For Radiographic Examination Welds Unique Sery'Cesvijay padaleNo ratings yet

- Pickling & Passivation Procedure MainDocument6 pagesPickling & Passivation Procedure Mainvijay padale100% (3)

- Section - 079129 - Penetration SealsDocument6 pagesSection - 079129 - Penetration SealsBikash BhattaraiNo ratings yet

- Steelmaster 120Sb: Technical Data SheetDocument4 pagesSteelmaster 120Sb: Technical Data SheetkalstarNo ratings yet

- Shell Permeability PresentationDocument29 pagesShell Permeability Presentationbilalabbasi1990No ratings yet

- MFF Spect. Blind 6 CL 150Document1 pageMFF Spect. Blind 6 CL 150Mohamed RaafatNo ratings yet

- Watertite R 1000Document2 pagesWatertite R 1000Alexi ALfred H. TagoNo ratings yet

- Airseal Installation Instruction - enDocument4 pagesAirseal Installation Instruction - enkamendrix kamendrixNo ratings yet

- Welding Wire CatalogDocument10 pagesWelding Wire CatalogElvis MaljanovicNo ratings yet

- The Platinum Foil TechniqueDocument15 pagesThe Platinum Foil Techniqueaziz2007No ratings yet

- Packaging Materials and Handling Technique: Dr. Ranjeet SinghDocument48 pagesPackaging Materials and Handling Technique: Dr. Ranjeet Singharon demagiba100% (1)

- Influence of The Age and Drying Process On Pore Structure and Sorption Isotherms of Hardened Cement PasteDocument16 pagesInfluence of The Age and Drying Process On Pore Structure and Sorption Isotherms of Hardened Cement PasteBambus PrometeNo ratings yet

- Is 14959 2 2001 PDFDocument13 pagesIs 14959 2 2001 PDFGarima GuptaNo ratings yet

- Dipshikha Meti SchoolDocument13 pagesDipshikha Meti SchoolNasrinNaharTuliNo ratings yet

- PLUMBINGDocument5 pagesPLUMBINGhadjie ansayNo ratings yet

- Cooling Water Treatment and Periodical Test of The Cooling WaterDocument4 pagesCooling Water Treatment and Periodical Test of The Cooling WaterGaurav MaithilNo ratings yet

- TDS - Titanpro 6331Document1 pageTDS - Titanpro 6331Ilham HidayatNo ratings yet

- Exhaust Rim E722 - Epoxy - PDSDocument5 pagesExhaust Rim E722 - Epoxy - PDSSpace MuskNo ratings yet

- Tapcon: SCOTS AnchorsDocument2 pagesTapcon: SCOTS Anchorsblessed cccNo ratings yet

- Carrier Oil Shelf LifeDocument3 pagesCarrier Oil Shelf LifeAna ThesecretiveNo ratings yet

- G7 Science Q1 - Week 6-Unsaturated and Saturated SolutionDocument14 pagesG7 Science Q1 - Week 6-Unsaturated and Saturated SolutionJessa-Bhel AlmueteNo ratings yet

- Description: Polystyrene (PS)Document5 pagesDescription: Polystyrene (PS)Murilo SanchesNo ratings yet

- .Study of Mechanical Properties of Concrete With Zeolite Powder and Steel SlagDocument7 pages.Study of Mechanical Properties of Concrete With Zeolite Powder and Steel Slagalaa albalahNo ratings yet

- Chemistry Investigatory Project OnDocument15 pagesChemistry Investigatory Project OnjibinNo ratings yet

- Kennedy Solid Wedge Series 100Document1 pageKennedy Solid Wedge Series 100vineethNo ratings yet

- Electrochemical Recovery of Gold From ConcentrateDocument9 pagesElectrochemical Recovery of Gold From ConcentrateAlexander Opazo PérezNo ratings yet

- Cycom-977-3 CM en PDFDocument5 pagesCycom-977-3 CM en PDFSeçkin MartinNo ratings yet

- Collector Beads CatalogDocument34 pagesCollector Beads Catalogsudhanshu_12juneNo ratings yet

- Typical Stair DetailsDocument1 pageTypical Stair DetailsM IQbalNo ratings yet

- Preliminary EstimateDocument558 pagesPreliminary Estimatesurendra_pangaNo ratings yet