Professional Documents

Culture Documents

Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)

Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)

Uploaded by

felipeCopyright:

Available Formats

You might also like

- Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni)Document1 pageClassifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni)Joni HartonoNo ratings yet

- Kiswel K-309LTDocument1 pageKiswel K-309LTOmer IkhlasNo ratings yet

- Classifications: For Atmospheric Corrosion Resisting SteelDocument1 pageClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongNo ratings yet

- Classifications: For 560mpa Low Temperature Service Steel (1.5% Ni)Document1 pageClassifications: For 560mpa Low Temperature Service Steel (1.5% Ni)BHARANINo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- Solid1 8Document1 pageSolid1 8ANo ratings yet

- Filcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- DATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Document2 pagesDATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Dries VandezandeNo ratings yet

- Datasheet FOXcore 308L T0 DG Cored WireDocument1 pageDatasheet FOXcore 308L T0 DG Cored WireAHRAKNo ratings yet

- Avesta Tig 316-SiDocument1 pageAvesta Tig 316-SiMarco Andres Gonzalez SaavedraNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Filcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Tetra V 309L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra V 309L-G: Technical Data Sheet Cored Welding WireawNo ratings yet

- En 1011 2 Welding RecommendationsDocument2 pagesEn 1011 2 Welding RecommendationsRam TN100% (1)

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Ok Tubrod 14.30a PDFDocument1 pageOk Tubrod 14.30a PDFqaNo ratings yet

- Shield - Bright 2209 FCAW (!)Document2 pagesShield - Bright 2209 FCAW (!)rajNo ratings yet

- B - Boehler EMK 6 - de - en - 5 PDFDocument1 pageB - Boehler EMK 6 - de - en - 5 PDFburakNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014HoangNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- Product Data Sheet Ok Aristorod 12.50: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Ok Aristorod 12.50: G 'Gas-Shielded Metal-Arc Welding'João GuilhermeNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Inertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsDocument1 pageInertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsEdison CheongNo ratings yet

- Your Reliable Welding Business Partner Worldwide"Document70 pagesYour Reliable Welding Business Partner Worldwide"Anonymous SLI4aGNo ratings yet

- BOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WireDocument2 pagesBOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WirebrayanNo ratings yet

- Classifications: Ferritic Stainless Welding Wire (Muffler, 18%Cr-Ti)Document1 pageClassifications: Ferritic Stainless Welding Wire (Muffler, 18%Cr-Ti)Chung LêNo ratings yet

- CSF-81T en 2014Document1 pageCSF-81T en 2014NGUYEN VINHNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- ALTIGDocument5 pagesALTIGbokugairuNo ratings yet

- Indura Em12k-H400Document2 pagesIndura Em12k-H400Rodrigo CarizNo ratings yet

- FICHA Técnica Weld 71T-1 PDFDocument2 pagesFICHA Técnica Weld 71T-1 PDFCarlos Padilla67% (3)

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- Electrodes Hilchrome 308rDocument1 pageElectrodes Hilchrome 308rManu NistorNo ratings yet

- Weld 71 TDocument1 pageWeld 71 TGanesh HileNo ratings yet

- Bohler Ti 52Document1 pageBohler Ti 52Anonymous nKOyHbNo ratings yet

- MIP Bohler Welding Austria 63Document1 pageMIP Bohler Welding Austria 63thod3rNo ratings yet

- Kms-308Lsi: Gmaw Solid Wire For Stainless SteelDocument1 pageKms-308Lsi: Gmaw Solid Wire For Stainless SteelStefanoTampieriNo ratings yet

- Minfm67089 Astm A1011 Ss Grade 250 Type 1Document4 pagesMinfm67089 Astm A1011 Ss Grade 250 Type 1أبومحمدالزياتNo ratings yet

- Valve Material SpecificationDocument5 pagesValve Material Specificationapi-9572051No ratings yet

- CHS29 9Document1 pageCHS29 9sulis setiawanNo ratings yet

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocument1 pageBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNo ratings yet

- AFROX Stainless Steel 98Document1 pageAFROX Stainless Steel 98Branko FerenčakNo ratings yet

- Tig Welding W19 12 3 LSiDocument2 pagesTig Welding W19 12 3 LSiKoen BidlotNo ratings yet

- Fio Fluxado Mx-100tDocument1 pageFio Fluxado Mx-100tFilipe CordeiroNo ratings yet

- Product Data Sheet - OK Tigrod 13.09 PDFDocument2 pagesProduct Data Sheet - OK Tigrod 13.09 PDFarman pangestuNo ratings yet

- Er308l PDFDocument1 pageEr308l PDFnargissuhailNo ratings yet

- Hyundai Welding Co., LTDDocument3 pagesHyundai Welding Co., LTDblahNo ratings yet

- ER316LDocument1 pageER316LslowmosquitoNo ratings yet

- Product Data Sheet OK 61.35: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.35: E 'Manual Metal-Arc Welding'C7 TGNo ratings yet

- Item5 LNT316LDocument1 pageItem5 LNT316LVVan TanNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Endohedral Metallofullerenes: Fullerenes with Metal InsideFrom EverandEndohedral Metallofullerenes: Fullerenes with Metal InsideNo ratings yet

- Orca Share Media1661901265298 6970519124644998154Document6 pagesOrca Share Media1661901265298 6970519124644998154Mirasol QuintoNo ratings yet

- Casting PDFDocument14 pagesCasting PDFArun kumar rouniyarNo ratings yet

- 1556320638TDS - SN-501 100 RTV Neutral Silicone SealantDocument2 pages1556320638TDS - SN-501 100 RTV Neutral Silicone SealantLawrence LauNo ratings yet

- CIVL 245 Topic 3 Concrete Technology Week 3 Lecture 1 IntroductionDocument31 pagesCIVL 245 Topic 3 Concrete Technology Week 3 Lecture 1 IntroductionAsfin HaqueNo ratings yet

- Annealing PDFDocument5 pagesAnnealing PDFKamran ShakeelNo ratings yet

- CH 11Document55 pagesCH 11Anuj shuklaNo ratings yet

- 01 GTSM 2Document2 pages01 GTSM 2subash1688No ratings yet

- Presentation On UsmDocument11 pagesPresentation On UsmArshad KhanNo ratings yet

- Blanking & Piercing - Forming Questions and Answers - SanfoundryDocument4 pagesBlanking & Piercing - Forming Questions and Answers - SanfoundryrahmaNo ratings yet

- Monthly Production and ConsumptionDocument6 pagesMonthly Production and ConsumptionjekiranNo ratings yet

- DIY Car Painting TipsDocument9 pagesDIY Car Painting TipsJohn BrownNo ratings yet

- Astm A884-A884m-02 Specs For Epoxy-Coated Steel WireDocument6 pagesAstm A884-A884m-02 Specs For Epoxy-Coated Steel WireCharwin PicaoNo ratings yet

- Grinder Safety: Portable Grinders Stationary GrindersDocument7 pagesGrinder Safety: Portable Grinders Stationary GrindersbigappforfunNo ratings yet

- Silencer MaintenanceDocument1 pageSilencer MaintenancesantosNo ratings yet

- 20-Division 15-Section 15190 Packaged Sewage Treatment-Version 2.0Document13 pages20-Division 15-Section 15190 Packaged Sewage Treatment-Version 2.0Fasil ENo ratings yet

- DS Granipan F30Document1 pageDS Granipan F30faridNo ratings yet

- Multiple Batch ExtractionDocument12 pagesMultiple Batch ExtractionTuba Ahmed75% (8)

- Introduction To Micro Nanofabrication PDFDocument39 pagesIntroduction To Micro Nanofabrication PDFGauri DalviNo ratings yet

- Welding Course PDFDocument46 pagesWelding Course PDFRogerio Salvagni100% (1)

- Kester - Catalogue - Kester - Consommables Pour L'électronique - 2010Document18 pagesKester - Catalogue - Kester - Consommables Pour L'électronique - 2010ZorbanfrNo ratings yet

- Catalogo BVMDocument16 pagesCatalogo BVMLeonardo Rachen RodriguezNo ratings yet

- Physical Vapor DepositionDocument20 pagesPhysical Vapor DepositionPraveen KumarNo ratings yet

- Cytec Solutions 2013 8Document1 pageCytec Solutions 2013 8aktivrudarpNo ratings yet

- Industri NEWDocument4 pagesIndustri NEWhamdi musthofaNo ratings yet

- Types of ReboilersDocument12 pagesTypes of ReboilersRuchit PatelNo ratings yet

- Gtaw 03Document40 pagesGtaw 03பத்மநாபன் ஶ்ரீநிவாஸன்No ratings yet

- Astm A743 PDFDocument6 pagesAstm A743 PDFzafarbadal100% (2)

- Alloy A286 Ams 5731 Ams 5732 Ams 5737Document2 pagesAlloy A286 Ams 5731 Ams 5732 Ams 5737gowtham raju buttiNo ratings yet

- Apcothane CF 678Document1 pageApcothane CF 678Santaj TechnologiesNo ratings yet

- PhET Sandwich Stoichiometry CHDocument4 pagesPhET Sandwich Stoichiometry CHAli Ahmed AlyammahiNo ratings yet

Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)

Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)

Uploaded by

felipeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)

Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni-Mo)

Uploaded by

felipeCopyright:

Available Formats

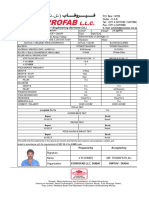

Flux Cored Welding Wire

K-316LT

Austenitic Stainless welding wire (Low C, 18%Cr-8%Ni-Mo)

Classifications

EN ISO 17633-A:2008 : T 19 12 3 L P C(M) 1 KS D 3612 : YF-316LC

EN ISO 17633-B:2008 : TS316L-FB1 JIS Z 3323 : TS316L-FB1

AWS A5.22-15 : E316LT1-1/4

Description

K-316LT is designed for MAG welding of low carbon 18%Cr-12%Ni-2%Mo stainless steels and this wire

has low carbon content which gives good resistance to most types of corrosion of the weld metal (AISI

316L, 316Ti)

Wire is a titania type of flux cored wire for all-position welding and the weld metal contains optimum

ferrite contents in their austenitic structures, therefore their weldability is excellent with lower crack

susceptibility.

Wire has self-detaching slag, spray-like arc transfer, excellent weldability and increased creep resistance

at elevated temperature

Welding positions Polarity & shielding gas

CO2: 100% CO2,

Mix: Ar+20% CO2 (15~25 /min)

DCEP (DC+)

Typical chemical composition of all-weld metal (%)

Shielding gas C Si Mn Cr Ni Mo FN

CO2 0.03 0.60 1.15 19.50 12.70 2.40

3~8 & 8~12

Mix 0.03 0.65 1.20 19.70 12.70 2.40

Typical mechanical properties of all-weld metal

Y.S T.S El. IV (J)

(MPa) (MPa) (%) -60 -105 Remarks

AWS A5.22 min. 390 min. 485 min. 30 ! 27

EN ISO 17633-B min. 320 min. 510 min. 25 ! 27

Example 420 560 38 50 38 CO2

430 570 38 52 40 Mix

Notes on usage and welding condition Package

Refer to page 303 for more information on usage Dia. (mm) 0.9 1.2 1.6

When heat input is excessive, base metal will be Spool (kg) 5, 12.5, 15

bended or distorted due to the bad heat conductivity.

Therefore, perform welding with selecting proper

heat input

Approvals

Shielding gas ABS BV DNV LR KR NK RINA RS CCS

CO2 E316LT1-1 UP 316L MS BF 316L S CHE RW 316LG(C) KW 316LG(C) 316LS A-6 316L

321

You might also like

- Classifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni)Document1 pageClassifications: Austenitic Stainless Welding Wire (Low C, 18%Cr-8%Ni)Joni HartonoNo ratings yet

- Kiswel K-309LTDocument1 pageKiswel K-309LTOmer IkhlasNo ratings yet

- Classifications: For Atmospheric Corrosion Resisting SteelDocument1 pageClassifications: For Atmospheric Corrosion Resisting Steelhuynh thanh truongNo ratings yet

- Classifications: For 560mpa Low Temperature Service Steel (1.5% Ni)Document1 pageClassifications: For 560mpa Low Temperature Service Steel (1.5% Ni)BHARANINo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- Solid1 8Document1 pageSolid1 8ANo ratings yet

- Filcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord D: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- DATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Document2 pagesDATASHEET WELDING CONSUMABLE - ESAB OK Tubrod 15.15-Rev14Dries VandezandeNo ratings yet

- Datasheet FOXcore 308L T0 DG Cored WireDocument1 pageDatasheet FOXcore 308L T0 DG Cored WireAHRAKNo ratings yet

- Avesta Tig 316-SiDocument1 pageAvesta Tig 316-SiMarco Andres Gonzalez SaavedraNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- Filcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsDocument2 pagesFilcord C: MIG/MAG Solid wires-TIG Rods C-MN and Low-Alloy SteelsPavelNo ratings yet

- Tetra V 309L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra V 309L-G: Technical Data Sheet Cored Welding WireawNo ratings yet

- En 1011 2 Welding RecommendationsDocument2 pagesEn 1011 2 Welding RecommendationsRam TN100% (1)

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Ok Tubrod 14.30a PDFDocument1 pageOk Tubrod 14.30a PDFqaNo ratings yet

- Shield - Bright 2209 FCAW (!)Document2 pagesShield - Bright 2209 FCAW (!)rajNo ratings yet

- B - Boehler EMK 6 - de - en - 5 PDFDocument1 pageB - Boehler EMK 6 - de - en - 5 PDFburakNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014HoangNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- Product Data Sheet Ok Aristorod 12.50: G 'Gas-Shielded Metal-Arc Welding'Document2 pagesProduct Data Sheet Ok Aristorod 12.50: G 'Gas-Shielded Metal-Arc Welding'João GuilhermeNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Inertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsDocument1 pageInertfil 308lsi: MIG-MAG Wires Stainless and Heat Resistant SteelsEdison CheongNo ratings yet

- Your Reliable Welding Business Partner Worldwide"Document70 pagesYour Reliable Welding Business Partner Worldwide"Anonymous SLI4aGNo ratings yet

- BOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WireDocument2 pagesBOHLER E 71T-1C/1M: GMAW Rutile Flux Cored WirebrayanNo ratings yet

- Classifications: Ferritic Stainless Welding Wire (Muffler, 18%Cr-Ti)Document1 pageClassifications: Ferritic Stainless Welding Wire (Muffler, 18%Cr-Ti)Chung LêNo ratings yet

- CSF-81T en 2014Document1 pageCSF-81T en 2014NGUYEN VINHNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- ALTIGDocument5 pagesALTIGbokugairuNo ratings yet

- Indura Em12k-H400Document2 pagesIndura Em12k-H400Rodrigo CarizNo ratings yet

- FICHA Técnica Weld 71T-1 PDFDocument2 pagesFICHA Técnica Weld 71T-1 PDFCarlos Padilla67% (3)

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- Electrodes Hilchrome 308rDocument1 pageElectrodes Hilchrome 308rManu NistorNo ratings yet

- Weld 71 TDocument1 pageWeld 71 TGanesh HileNo ratings yet

- Bohler Ti 52Document1 pageBohler Ti 52Anonymous nKOyHbNo ratings yet

- MIP Bohler Welding Austria 63Document1 pageMIP Bohler Welding Austria 63thod3rNo ratings yet

- Kms-308Lsi: Gmaw Solid Wire For Stainless SteelDocument1 pageKms-308Lsi: Gmaw Solid Wire For Stainless SteelStefanoTampieriNo ratings yet

- Minfm67089 Astm A1011 Ss Grade 250 Type 1Document4 pagesMinfm67089 Astm A1011 Ss Grade 250 Type 1أبومحمدالزياتNo ratings yet

- Valve Material SpecificationDocument5 pagesValve Material Specificationapi-9572051No ratings yet

- CHS29 9Document1 pageCHS29 9sulis setiawanNo ratings yet

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocument1 pageBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNo ratings yet

- AFROX Stainless Steel 98Document1 pageAFROX Stainless Steel 98Branko FerenčakNo ratings yet

- Tig Welding W19 12 3 LSiDocument2 pagesTig Welding W19 12 3 LSiKoen BidlotNo ratings yet

- Fio Fluxado Mx-100tDocument1 pageFio Fluxado Mx-100tFilipe CordeiroNo ratings yet

- Product Data Sheet - OK Tigrod 13.09 PDFDocument2 pagesProduct Data Sheet - OK Tigrod 13.09 PDFarman pangestuNo ratings yet

- Er308l PDFDocument1 pageEr308l PDFnargissuhailNo ratings yet

- Hyundai Welding Co., LTDDocument3 pagesHyundai Welding Co., LTDblahNo ratings yet

- ER316LDocument1 pageER316LslowmosquitoNo ratings yet

- Product Data Sheet OK 61.35: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.35: E 'Manual Metal-Arc Welding'C7 TGNo ratings yet

- Item5 LNT316LDocument1 pageItem5 LNT316LVVan TanNo ratings yet

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

- Endohedral Metallofullerenes: Fullerenes with Metal InsideFrom EverandEndohedral Metallofullerenes: Fullerenes with Metal InsideNo ratings yet

- Orca Share Media1661901265298 6970519124644998154Document6 pagesOrca Share Media1661901265298 6970519124644998154Mirasol QuintoNo ratings yet

- Casting PDFDocument14 pagesCasting PDFArun kumar rouniyarNo ratings yet

- 1556320638TDS - SN-501 100 RTV Neutral Silicone SealantDocument2 pages1556320638TDS - SN-501 100 RTV Neutral Silicone SealantLawrence LauNo ratings yet

- CIVL 245 Topic 3 Concrete Technology Week 3 Lecture 1 IntroductionDocument31 pagesCIVL 245 Topic 3 Concrete Technology Week 3 Lecture 1 IntroductionAsfin HaqueNo ratings yet

- Annealing PDFDocument5 pagesAnnealing PDFKamran ShakeelNo ratings yet

- CH 11Document55 pagesCH 11Anuj shuklaNo ratings yet

- 01 GTSM 2Document2 pages01 GTSM 2subash1688No ratings yet

- Presentation On UsmDocument11 pagesPresentation On UsmArshad KhanNo ratings yet

- Blanking & Piercing - Forming Questions and Answers - SanfoundryDocument4 pagesBlanking & Piercing - Forming Questions and Answers - SanfoundryrahmaNo ratings yet

- Monthly Production and ConsumptionDocument6 pagesMonthly Production and ConsumptionjekiranNo ratings yet

- DIY Car Painting TipsDocument9 pagesDIY Car Painting TipsJohn BrownNo ratings yet

- Astm A884-A884m-02 Specs For Epoxy-Coated Steel WireDocument6 pagesAstm A884-A884m-02 Specs For Epoxy-Coated Steel WireCharwin PicaoNo ratings yet

- Grinder Safety: Portable Grinders Stationary GrindersDocument7 pagesGrinder Safety: Portable Grinders Stationary GrindersbigappforfunNo ratings yet

- Silencer MaintenanceDocument1 pageSilencer MaintenancesantosNo ratings yet

- 20-Division 15-Section 15190 Packaged Sewage Treatment-Version 2.0Document13 pages20-Division 15-Section 15190 Packaged Sewage Treatment-Version 2.0Fasil ENo ratings yet

- DS Granipan F30Document1 pageDS Granipan F30faridNo ratings yet

- Multiple Batch ExtractionDocument12 pagesMultiple Batch ExtractionTuba Ahmed75% (8)

- Introduction To Micro Nanofabrication PDFDocument39 pagesIntroduction To Micro Nanofabrication PDFGauri DalviNo ratings yet

- Welding Course PDFDocument46 pagesWelding Course PDFRogerio Salvagni100% (1)

- Kester - Catalogue - Kester - Consommables Pour L'électronique - 2010Document18 pagesKester - Catalogue - Kester - Consommables Pour L'électronique - 2010ZorbanfrNo ratings yet

- Catalogo BVMDocument16 pagesCatalogo BVMLeonardo Rachen RodriguezNo ratings yet

- Physical Vapor DepositionDocument20 pagesPhysical Vapor DepositionPraveen KumarNo ratings yet

- Cytec Solutions 2013 8Document1 pageCytec Solutions 2013 8aktivrudarpNo ratings yet

- Industri NEWDocument4 pagesIndustri NEWhamdi musthofaNo ratings yet

- Types of ReboilersDocument12 pagesTypes of ReboilersRuchit PatelNo ratings yet

- Gtaw 03Document40 pagesGtaw 03பத்மநாபன் ஶ்ரீநிவாஸன்No ratings yet

- Astm A743 PDFDocument6 pagesAstm A743 PDFzafarbadal100% (2)

- Alloy A286 Ams 5731 Ams 5732 Ams 5737Document2 pagesAlloy A286 Ams 5731 Ams 5732 Ams 5737gowtham raju buttiNo ratings yet

- Apcothane CF 678Document1 pageApcothane CF 678Santaj TechnologiesNo ratings yet

- PhET Sandwich Stoichiometry CHDocument4 pagesPhET Sandwich Stoichiometry CHAli Ahmed AlyammahiNo ratings yet