Professional Documents

Culture Documents

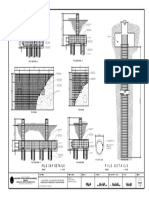

Piles Resting On Rocks

Piles Resting On Rocks

Uploaded by

Vince GarciaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piles Resting On Rocks

Piles Resting On Rocks

Uploaded by

Vince GarciaCopyright:

Available Formats

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Bearing capacity of embedded piles in rocks considering their

contribution to friction

Capacidad portante de pilotes empotrados en rocas

considerando su aporte a fricción

1

Gilberto Quevedo *

* Universidad Central Marta Abreu de Las Villas, Villa Clara. CUBA

Fecha de Recepción: 07/06/2014

Fecha de Aceptación: 17/05/2015

PAG 189-199

Abstract

This article has the objective to show a study of different existing theories that consider the friction contribution of embedded piles in rock. It initially summarizes the

adopted criteria for such theories and the coefficient ranges considered for the application of their basic expressions. The results of these theoretical analyses were

applied in the solution of the foundations of a hotel, and its marine, built on the beach in the city of Varadero, Cuba. The study area presented a high geologic and

engineering complexity, with highly variable stratification characteristics together with distinct soil and rock properties, where the presence of a calcareous stratum

stands out in the deposit. The calcareous layer is found in a variable depth within the strata and has a quality ranging from very poor to good, where all the pile tips

were founded. In order to obtain the bearing capacities from the designed piles, it was necessary to take into account their friction contribution within the rock,

which was done by validating the existing theories through the execution of in situ pile load tests, combined with the use of theoretical models. This exercise allowed

the establishment of practical coefficient values that were required by the theories in such particular site conditions. It was finally possible to yield design solutions for

the deep foundations of this case history, which comprised over 2000 driven piles..

Keywords: Piles in rock, bearing capacities, friction contribution, in situ pile load tests

Resumen

Este artículo tiene como objetivo mostrar el estudio realizado de diferentes teorías existentes para considerar el aporte a fricción de pilotes empotrado en roca. Para ello se

resume inicialmente los criterios considerados en dichas teorías y los intervalos de los coeficientes que las mismas consideran para la aplicación de sus expresiones

básicas. Los resultados de este análisis teórico fueron aplicados en la solución de las cimentaciones sobre pilote de un hotel y su marina construido en la playa de

Varadero, Cuba. La zona de estudio presentaba una alta complejidad ingeniero geológica, con una estratificación muy variables y propiedades de los suelos y las rocas de

la misma igualmente variable, destacándose la presencia de un estrato de calcarenita, que aparece a una profundidad variable y con una calidad desde buena hasta muy

mala, donde siempre se empotraron los pilotes. Para la obtención de la capacidad portante de muchos de los pilotes, fue necesario tomar en cuenta el aporte a fricción en

la roca, validándose las teorías existente a partir de la realización de pruebas de carga in-situ, combinadas con el empleo de los modelos teóricos, llegando a establecer

los valores de los coeficientes que las mismas utilizan para las condiciones del caso de estudio. A partir de todo ello fue que se pudo dar solución a las cimentaciones

sobre pilotes del caso de estudio, la comprendía más de 2000 pilotes hincados.

Palabras clave: Pilotes en rocas, capacidad resistente, aporte a fricción, pruebas de carga

In international literature, there are several works

1. Introduction studying this issue, including among the most recent: Serrano

(2008), Perez Carballo (2010) and Olmo (2011). All these

As known classical theories of Soil and Foundation

studies agree that there are two groups of theories to establish

Mechanics state, when a pile manages to become embedded

ultimate resistance to friction in piles in rock τult

in rock at least one time its diameter, that pile will work with

support only at the tip and its friction contribution will not be

• Theories that consider the τult as a linear function of

taken into account, on the basis that the displacements at the

the compressive strength of rock Rc

tip of the pile will be negligible and thus pile-rock friction will .

• Theories that consider the τult as a quadratic function

not be generated. The above statement is true when the piles

of the compressive strength of rock Rc

rest on high quality rocks. However, for cases where the piles .

are supported by low quality rocks, where they can be

In this research, all these theories were studied,

embedded in rock several times their diameter, the above

establishing basic expressions and intervals of the coefficients

statement is not true, and it is necessary to take the friction

proposed therein. This study was necessary to apply to the

contribution within the rock into account when determining

solution of the foundations over piles in a hotel on the beach

the ultimate bearing capacity of the pile.

in Varadero, Cuba. The engineering geological conditions of

the area were very complex and variable, together with the

existing soil and rock properties. This can be simplified in a

stratification consisting of a series of soft soils, with variable

1 thickness of fill, peat, silt and other very loose soils, none of

Corresponding author:

which contribute to the bearing capacity of the piles, and a

Ingeniero Civil en 1977 en el Instituto Politecnico "José A. Echeverría" Habana, stratum of calcarenite, which appears at different depths and

Cuba. Doctor en ciencias técnicas (PhD) en 1887 en el Instituto de la

Construcción de Moscú. Doctor en Ciencias (Dr.Sc) en la Habana en 2002.

with very variable quality, from good to very poor. There, the

Profesor titular desde el 1992, Investigador Titular desde 1999. Decano de la piles achieve embedded length (EL) from only 1.5 times its

Facultad de Construcciones de la UCLV desde 2008 diameter to more than 14 times its diameter, depending on

E-mail: quevedo@uclv.edu.cu the quality of the rock.

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 189

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

To determine the bearing capacity of piles, laboratory studies in order to obtain the main physical and

determinations for existing models, including the analyzed mechanical properties of soils and rocks.

theories that consider the friction contribution within the rock The following types of soil and rocks, of varying

where necessary, were combined with in situ pile load tests, thickness, positions, and engineering properties, were found

which served to calibrate the models and set the interval at in the general zone:

which coefficients taken into account in the conditions for the

case study could vary. A very good engineering calibration of • Fill stratum, always on the surface but with different

the models was achieved, and from it the resistant capabilities capacities

of the piles, for various conditions of support, were • Peat stratum, with low thickness

established. This allowed for a significant reduction in the • Silt strum, with low thickness

length of piles, resulting in cost savings for construction.

Stratum composed of a combination of various loose soils,

2. Characterization of the engineering which may or may not be present in different

geology of the study area • areas of the building

• Calcarenite stratum, which is present at very variable

In order to characterize the engineering geological depths and qualities, from good from very poor

conditions of the study area, which was necessary for the

determination of the bearing capacity of the piles, several in Figure 1 shows two photos of these soils during

situ studies were carried out by the companies GeoCuba sample collection in the field, where the fill characteristics

(2008) and ENIA (2010, 2011). This research included and especially the different qualities of calcarenite, with

surveys, description of strata, geophysical studies, and variable RQD values, can be observed.

Figure 1. Photos of the fill samples and calcarenite collected during exploration

fill

calcarenite

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 190

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

For the purposes of this study, stratification can be According to Pérez Carballo (2010), the expressions

simplified to two zones, the first of which is composed of fill, proposed by the main authors are those that are shown in the

peat, silt, and other loose soils that may or may not be following formulas:

present, which is formed by soft soils that do not contribute to

the bearing capacity of piles. The second zone is composed Ø Thorne 𝜏!"# = (0.05~0.1) ∙ 𝜎! (2)

of calcarenite, with different thickness and quality, which is Ø Poulos and Davis 𝜏!"# = 0.15 ∙ 𝜎! (3)

what actually contributes to the tip and friction, accordingly. Ø Australian Code 𝜏!"# = 0.15 ∙ 𝜎! (4)

As previously mentioned, the quality of calcarenite is Ø Hooly and Lefroy 𝜏!"# = 0.3 ∙ 𝜎! (5)

very variable, and can be grouped, based on the study of all Ø Spanish Technical Code 𝜏!"# = 0.1~0.4 ∙ 𝜎! (6)

the geological engineering research done, into 3 groups: Ø Theories that consider the τult as a quadratic function

of the compressive strength of rock Rc.

• Good quality calcarenite, with an average value of

Rc=9000 kPa The general expression posed by this theory to obtain

• Poor quality calcarenite, with an average value of the ultimate friction resistance of pile in rock is defined by

Rc=1650 kPa Formula 7.

• Very poor quality calcarenite, with a value of

Rc=1000 kPa 𝜏!"# = 𝛼 ∙ 𝜎! ! (7)

The tested piles were always embedded, with different All the authors of these studies agree that k=0.5, so

EL embedded lengths, in calcarenite, with one of the above what varies in each one is the range of values of α that were

qualities. The result was when it was embedded in poor or considered. According to Pérez Carballo (2010), the

very poor quality calcarenite, it was necessary to consider the expressions proposed by the main authors are those that are

contribution to friction, whereas when it was embedded in shown in the following formulas:

good quality calcarenite, only the contribution in the tip was

taken into consideration. Ø Rosenberg and Journaux 𝜏!"# = 0.4 ∙ 𝜎! !.! (8)

Ø Hovarth and Hovarth 𝜏!"# = (0.2~0.3) ∙ 𝜎! !.! (9)

Ø Fleming 𝜏!"# = 0.45 ∙ 𝜎! !.! (10)

3. Analysis of different theories to take Ø Hooley and Lefroy 𝜏!"# = 0.15 ∙ 𝜎! !.! (11)

Ø AASHO Manual 𝜏!"# = (0.21~0.26) ∙ 𝜎! !.! (12)

into account the contribution to Ø Carubba 𝜏!"# = (0.10~0.25) ∙ 𝜎! !.! (13)

friction of embedded piles in rock

All previous theories can be expressed by Formula 7,

considering the following variation intervals for variables k

As was outlined in the introduction of the article, in

international literature, there are several works studying this and α.

issue, including among the most recent: Serrano (2008),

If K=1 then α takes the values of α = 0.05~0.4

Perez Carballo (2010) and Olmo (2011). All these studies

agree that there are two groups of theories to establish If K=0.5 then α takes the values of α = 0.10~0.45

ultimate resistance to friction in piles in rock τul

4. Determination of bearing capacity

t

• Theories that consider the 𝜏!"# as a linear function of piles.

of the compressive strength of rock Rc.

The procedure for determining the bearing capacity of

The general expression posed by this theory to obtain piles, given the complexity of the study area, is set forth in

the ultimate friction resistance of pile in rock is defined by Figure 2.

Formula 1.

.

𝜏!"# = 𝛼 ∙ 𝜎! (1)

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 191

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Figure 2. Proposed methodology to determine the bearing capacity of piles

From the above methodology, there has already been 5 steps of the methodology defined in Figure 2, it was

a very general overview of the first 3 steps in Sections 1 and 2 determined that 8 in-situ load tests were needed for piles of

of this article. While we will not analyze those related to steps different lengths and embedded with different EL embedded

4 and 5, due to the length of the article, we note that 36 pile lengths, in calcarenite of different qualities. In this article we

driving tests were initially conducted, controlled for various will discuss the results of 5 load tests: one of a pile embedded

conditions of pile length and stratification characteristics. in very poor quality calcarenite, two of piles embedded in

From the results of these tests, it was possible to have an poor quality calcarenite, and two of a pile embedded in good

initial approximation of the bearing capacity of the piles, with quality calcarenite.

the application of different formulas of dynamic methods. The load tests were performed on individual piles,

Together with the initial geological engineering applying three load cells of 1000 kN capacity each, and

characterization of the area, this made it possible to placing a reaction pile above them, always greater than the

determine the piles that needed to be tested in situ load applied to the pile. Figure 3 shows 2 photos of the

characteristics of the load tests.

4.1 Conducting situ load tests on chosen piles

From the analysis of the results obtained from the first

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 192

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Figure 3. Photos of conducting load tests

Next we will show the results of two of the completed After unloading, a yield stress of 25.8 mm was maintained,

load tests, one with the pile embedded in poor quality corroborating the occurred failure.

calcarenite and the other embedded in good quality The second load test was carried out on Pile 006, 9 m

calcarenite. length, 7.2 m of which were driven, in a stratification whose

The first of these load tests was carried out on Pile Zone 1 had 6 m, embedding the pile 1.2 m in good quality

026, 11 m long, 9 m of which were driven, in a stratification rock. Figure 5 shows the results of the load deformation curve

whose Zone 1, composed of soft ground, with a capacity of 4 obtained from the load test.

m, embedding of 5 m in the poor quality calcarenite. Figure 4 As shown in Figure 5, the pile was able to carry a load

shows the results of the load deformation curve obtained from of up to 1902 kN, but for that load, it had almost a linear

the load test. behavior, with a final deformation of less than 10 mm. After

. As shown in Figure 4, the pile failed with an ultimate unloading, it had a yield stress of only 2 mm, which indicates

load of 1305 kN and with a final deformation of 41 mm. that it did not reach failure.

Figure 4. Results of load test on Pile 026

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 193

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Figure 5. Results of load test on Pile 006

To obtain the ultimate load reaching failure on Pile of pile foundations (Ibañez, Quevedo 2011). The result was

006, it was necessary to apply the graphic analytical method an estimated ultimate load capacity of 2300 kN, as shown in

defined in the Proposed International Standard for the design Figure 6.

Figure 6. Results of the load test on Pile 006, extended to failure

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 194

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

4.2 Determination of the bearing capacity of piles applying 𝑘!" : Factor that takes the quality of the rock into account,

theoretical models determined according to RQD

To determine the bearing capacity of the pile, 𝑑! : Factor that takes the EL embedded length of the pile in the

expressions defined in the Proposed International Standard for rock into account, determined by Formula (16).

the design of pile foundations (Ibañez, Quevedo 2011) are

utilized. As what is being determined is the ultimate vertical !"

𝑑! = (1 + 0.4 ) ≤ 3.5 (16)

bearing capacity of the pile, 𝑄!"#$ , safety factors equal to the !

unit are used in all cases. Therefore, the ultimate bearing

capacity of the pile is defined by Formula 14, shown below: where:

D: Diameter of pile

𝑄!"#$ = 𝑄!"#$% + 𝑄!"#$% (14) In the case of friction contribution in the rock

(Formula 17), everything analyzed in Section 3 of this article

where: will be included when obtaining the 𝜏!"# .

𝑄!"#$% : Ultimate vertical load capacity at tip

𝑄!"#$% : Ultimate vertical load capacity for friction 𝑄!"#$% = 𝑃! . 𝜏!"# . 𝐿𝐸 (17)

In the case of contribution at tip, Formula 15 is where:

applied, considering the contribution only when the pile is 𝑃! : Perimeter of pile

embedded in good quality rock. In the case that it is

embedded in poor quality or very poor quality rock, the

Applying these expressions and determining the

friction contribution within the rock will be considered.

deformations of the pile foundations for the classic

expressions for the same intervals of the load test, the

𝑄!"#$% = 𝐴! . 𝑅! . 𝑘!" . 𝑑! (15) theoretical models can be calibrated with the values of the

load test. Figures 7 and 8 show the results of such

wheree: adjustments for the load tests on Pile 026 and Pile 006

𝐴! : Area of pile respectively.

𝑅! : Average simple compressive strength of the rock

Figure 7. Results of the load tests and modeling of Pile 026

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 195

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Figure 8. Results of load test and modeling of Pile 006

As shown in Figures 7 and 8, the adjustments obtained Table 3 shows the good calibration achieved between

between theoretical models and load tests were very good the 𝑄!"#$ values obtained from theoretical models and the

from an engineering standpoint. 𝑄!"#$%& values obtained from load tests. In the case of piles

Table 1 shows the numerical results of adjusting the 010, 026, and 037, where the friction contribution in the rock

values of α for both methods considering the linear was considered, it was not possible to establish what method

relationship with Rc and those that considered the quadratic would be the best suited to the analyzed case: that which

relationship, for the determination of 𝑄!"#$% . considers the linear function or that which considers the

Table 2 shows the numerical results obtained in the quadratic function. However, in general, both are very well

determination of the contribution at the tip of all of the suited to the cases.

analyzed piles. Table 4 shows the intervals of values of α obtained in

Table 3 shows the numerical results obtained in the adjustments made when determining the 𝑄!"#$% for both

determining the 𝑄!"#$ by theoretical models, considering the methods, as well as the intervals obtained from the analysis of

linear and quadratic methods when determining the 𝑄!"#$% , international literature. As shown here, α intervals obtained in

and the values of the ultimate bearing capacity obtained from the investigation are among those mentioned in the literature,

the load test 𝑄!"#$%& . adjusting to their lower limits.

Table 1. Values of α and 𝑄!"#$% obtained for all the analyzed piles

Pile LE Rock Quality Rc Linear Formula 𝑄!"#$% Quadratic Formula of 𝑄!"#$%

(m) (kPa) α Qf(kN) α Qf(kN)

010 5.4 Very poor 1000.00 0.1 864.00 0.1 864.00

026 5.0 Mala 1650.00 0.09 1188.00 0.12 1233.00

037 5.7 Mala 1650.00 0.12 1806.00 0.15 1757.00

Table 2. Values of 𝑄!"#$% obtained for all the analyzed piles

Pile LE (m) Rock Quality Rc 𝑄!"#$%

(kPa) (kN)

010 5.4 Very poor 1000.00 56.00

026 5.0 Poor 1650.00 92.40

037 5.7 Poor 1650.00 92.40

006 1.2 Good 9000.00 2376.00

007 0.6 Good 9000.00 1728.00

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 196

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Table 3. Values of 𝑄!"#$ and 𝑄!"#$%& for the analyzed piles

Pile LE Rock 𝑄!"#$% 𝑄!"#$% (kN) 𝑄!"#$ (kN) 𝑄!"#$%&

(m) Quality (kN) Linear Quadratic Linear Quadratic (kN)

Formula Formula Formula Formula

010 5.4 Very poor 56.00 864.00 864.00 920.00 920.00 900.00

026 5.0 Poor 92.40 1188.00 1233.00 1280.40 1325.40 1305.00

037 5.7 Poor 92.40 1805.00 1757.00 1898.40 1850.40 1850.00

006 1.2 Good 2376.00 0.00 0.00 2376.00 2376.00 2300.00

007 0.6 Good 1728.00 0.00 0.00 1728.00 1728.00 1700.00

Table 4. Intervals of α values obtained in the investigation and proposed in the literature

Type of formula for Formula Values of α from the Obtained values of α

obtaining the τult according literature

to the Rc

Linear τult=α.Rc 0.05~0.40 0.09~0.12

Quadratic τult=α.Rck 0.10~0.40 0.10~0.15

(k=0.5)

4.3 Definition of the bearing capacity and pile length number of blows in the last foot that must be secured during

Following the methodology presented in Figure 2 and pile driving to ensure said bearing capacity

performing similar analyses to those set forth in this article for Figure 9 shows a plant of the building and the different

all the conditionals of the piles in the building, combining the zones defined as typical for piles from the geological

results of the application of the calibrated theoretical models, engineering conditions thereof, the bearing capacity of 𝑄!"#$% ,

the dynamic formulas from the results of controlled pile and the length of the piles

driving tests, and the results obtained from all the load tests Similarly, Table 5 summarizes the values of 𝑄!"#$% , the

that were carried out, and applying the appropriate safety length of the piles, and the number of blows in the last foot

coefficients, it was possible to determine the bearing capacity that must be secured during the pile driving of each of the

of the piles for all the defined zones, the pile length, and the established zones.

Figure 9. Zoning of the pile solutions, with their 𝑄!"#$% and length

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 197

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

Table 5. Values of 𝑄!"#$% , length of piles and the number of blows in the last foot that must be secured during the pile driving of

each of the established zones.

No Identifier Lenght (m) 𝑄!"#$% (kN) Number of blows/foot

1 P1 7 120 40

2 P2 11 65 20 a 25

3 P3 11 50 20 a 25

4 P4 9 120 35

5 P5 5.5 120 40

The above results brought about a rationality in the

solution of pile foundations for the analyzed building, with • From determining 𝑄!"#$% , including therein the

consequent cost savings. This allowed verification during pile friction contribution in the rock by the analyzed

driving that the obtained results were valid, having a very low methods, and the 𝑄!"#$% by classic methods, it was

loss of piles (less than 3%), with a behavior in each zone as possible to obtain a satisfactory engineering

established in the investigation. adjustment between the load deformation curves

obtained from load tests and those proposed by

theoretical methods, demonstrating the validity of

5. Conclusions the latter.

• With the application of the general methodology

• A general methodology is established to address the proposed in the solution of pile foundations of the

solution of pile foundations in highly variable and analyzed building, the following was achieved:

complex geological engineering conditions, using a rational results for the foundation, proposed zoning

combination of correct characterization of the depending on geological engineering characteristics,

different existing stratifications, and the physical and allowing to define the value of 𝑄!"#$% , the length of

mechanical properties of soils and rocks that the piles, and the minimum number of blows

compose them. Using theoretical methods of needed to secure the last foot during pile driving for

determining 𝑄!"#$ , where those that consider friction each of the zones. All of this was corroborated

contribution in rock are included as well as dynamic satisfactorily during pile driving.

formulas from the pile driving test results and in situ

load tests, 𝑄!"#$ can be put as close to reality as

possible.

• Through studying the literature about methods for

taking friction contribution in piles embedded in

rock into account, it was concluded that there are

two groups of methods. The first considers a linear

relationship between 𝜏!"# and Rc from the α

coefficient, finding that this value, according to the

different authors consulted, takes values in the range

of 0.05 ≤ α ≤ 0.4. The other considers a quadratic

relationship between 𝜏!"# and Rc from coefficient α,

finding that the value, according to the different

authors consulted, takes values in the range of 0.1≤

α ≤ 0.4.

• From the results of the load tests, it was possible to

calibrate the theories and coefficients used to

consider friction contribution in the rock, so that for

the methods that consider the linear relationship

between 𝜏!"# and Rc, the interval of variation α was

0.09 ≤ α ≤ 0.12, while for the methods that consider

the quadratic relationship, the interval was 0.1 ≤ α ≤

0.15, both being within those values defined in the

literature, always tending to their lower values.

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 198

Revista Ingeniería de Construcción RIC

Vol 30 Nº3 2015 www.ricuc.cl

ENGLISH VERSION.....................................................................................................................................................................................................................................................

6. References

Del Olmo D., Melentijevec S., Prieto L. y Olalla C. (2011). Ensayo a escala real e interpretación del comportamiento de un pilote por fuste en

roca. Revista Ingeniería Civil No 161, 2011, ISSN: 0213-8468, pag. 73-81

ENIA (2010), Informe geotécnico. Marina Gaviota Fase II. Empresa de Investigaciones Aplicada, Habana, Cuba, 2010, 36 pag.

ENIA (2011), Informe geotécnico. Marina Gaviota Fase III. Empresa de Investigaciones Aplicada, Habana, Cuba, 2011, 48 pag.

GeoCuba (2008), Informe ingeniero-geológico. Marina Gaviota Fase I. GeoCuba, Habana, Cuba, 2008, 29 pag.

Geotechnical Engineering Office. (2006), Foundation design and construction. Civil Engineering Development Department the Government of

de Hong Kong. Hong Kong 2006. 376 pag.

Ibañez L. (2002), Análisis del comportamiento geotécnico de las cimentaciones sobre pilotes sometidas a carga axial mediante la modelación

matemática. Tesis en opción al grado de Doctor en Ciencias Técnicas. Tutor: Dr. Sc. Gilberto Quevedo Sotolongo. UCLV. Cuba, 112 pag.

Ibáñez L. y Quevedo G. (2011), Propuesta de Norma Cubana para el diseño de cimentaciones sobre pilotes. Oficina Nacional de

Normalización. Habana. Cuba. 29 pag.

Paulos H. G (2000), Pile load test methods – applications and limitations. Libro de homenaje a Jiménez Salas. CEDEX p. 101-111.

Pérez Carballo P. (2010), Implementación informática para el cálculo de pilotes de hormigón “in-situ” según el código técnico de edificación.

Escuela Superior de Ingenieros de Sevilla, marzo 2010.

Randolph M.F. y Wroth (1980), Application of the failure state in undrained simple shear to the shaft capacity of driver of piles. Revista

Geotechnique. Vol 31. No 1 p. 143-157

Randolph M.F. (1994), Design methods for pile groups and piled rafts. Proceedings of the 13th International Conference on Soil Mechanics and

Foundation Engineering. New Delhi: 1-21.

Serrano A., Olalla C. y Ríos Aguilar D. (2008), Resistencia por fuste de pilotes empotrados en roca. Estudio comparativo entre distintos métodos

de cálculo y normativas. Revista Ingeniería Civil No 150, 2008, ISSN: 0213-8468, pag. 35-48

Shakhirev V. (1996), Estudio experimental del suelo durante la hinca de pilotes. Francia. Boletín de laboratorio de mecánica de suelo # 206

(Nov-Dic), p. 95-116

Sung-Min Ch. (2010), Foundation Design of the Incheon bridge. Geotechnical Engineering Journal of the SEAGS & AGSSEA. Vol 41, December

2010. ISSN 0046-5828, 16 pag.

Revista Ingeniería de Construcción Vol 30 Nº3 Diciembre de 2015 www.ricuc.cl 199

You might also like

- 003-User - Pass (Combo)Document554 pages003-User - Pass (Combo)Juan José CamachoNo ratings yet

- Rubric For Car BuyingDocument1 pageRubric For Car Buyingapi-248285683No ratings yet

- One Page Summary of My CV That Can Save Some Time.Document1 pageOne Page Summary of My CV That Can Save Some Time.NaveenNo ratings yet

- Diseño de Pilotes en RocaDocument11 pagesDiseño de Pilotes en RocaLuis VelascoNo ratings yet

- Design and Construction Approach of Marine Rock-Socketed Piles For An Oil Jetty ProjectDocument7 pagesDesign and Construction Approach of Marine Rock-Socketed Piles For An Oil Jetty ProjectVetriselvan ArumugamNo ratings yet

- Principles of Rockbolting Design PDFDocument19 pagesPrinciples of Rockbolting Design PDFRicardo Huisa BustiosNo ratings yet

- Geotechnioue: ParisDocument14 pagesGeotechnioue: ParisAMOUZOUN ChristopheNo ratings yet

- Designing Shotcrete As Primary Support in Tunnels: July 2011Document7 pagesDesigning Shotcrete As Primary Support in Tunnels: July 2011Anonymous EPSHB9tXZNo ratings yet

- J Ijrmms 2010 01 005Document9 pagesJ Ijrmms 2010 01 005Jumadil SyamNo ratings yet

- Tribology International: Patrick S.M. Dougherty, Randyka Pudjoprawoto, C. Fred Higgs IIIDocument8 pagesTribology International: Patrick S.M. Dougherty, Randyka Pudjoprawoto, C. Fred Higgs IIILuciana FigueiredoNo ratings yet

- Modelling The Deformation of UndergroundDocument12 pagesModelling The Deformation of UndergroundBal Krishna ShresthaNo ratings yet

- Project Designing A Habitat in MarsDocument13 pagesProject Designing A Habitat in MarsMarvin ItolondoNo ratings yet

- Blocktheoryanditsapplication Goodman 1995Document41 pagesBlocktheoryanditsapplication Goodman 1995Rey David SolisNo ratings yet

- Materi - Rock Mass ClassificationDocument17 pagesMateri - Rock Mass ClassificationAdella SyaviraNo ratings yet

- Belt Feeder Design: Starting Load Calculations: A.E. Maton, AustraliaDocument4 pagesBelt Feeder Design: Starting Load Calculations: A.E. Maton, AustraliaJakes100% (1)

- The Sinking of Well Foundations in Difficult Situations 28.3.07Document13 pagesThe Sinking of Well Foundations in Difficult Situations 28.3.07NehaSinghNo ratings yet

- A Study of Particle Separation in A Spiral ConcentratorDocument12 pagesA Study of Particle Separation in A Spiral ConcentratoraghilifNo ratings yet

- Haber Field 2018Document14 pagesHaber Field 2018ahmedNo ratings yet

- Pile Capacity - An Overview - ScienceDirect TopicsDocument15 pagesPile Capacity - An Overview - ScienceDirect TopicssurNo ratings yet

- Rockmass Classification RevisitedDocument10 pagesRockmass Classification RevisitedGilang RamadanNo ratings yet

- Design Principle of Rockbolting: Harshil Bhatt Manisha Meena Manik BadhwarDocument6 pagesDesign Principle of Rockbolting: Harshil Bhatt Manisha Meena Manik BadhwarMuhammad Saqib JanNo ratings yet

- RSR (Rock Structure Rating)Document7 pagesRSR (Rock Structure Rating)resky_pratama_99AdeNo ratings yet

- Reservoir Petrophysics Udom 1Document192 pagesReservoir Petrophysics Udom 1Mbarouk Shaame MbaroukNo ratings yet

- Modernizing Spatial Micro Refuse Analysis NewDocument26 pagesModernizing Spatial Micro Refuse Analysis NewBüşra Özlem YağanNo ratings yet

- Classification of Rock MassDocument4 pagesClassification of Rock MassHassan QadeerNo ratings yet

- Pile Foundations Analysis and DesignDocument10 pagesPile Foundations Analysis and DesignMarcius SegundoNo ratings yet

- Importance of Weathering in Rock EngineeringDocument16 pagesImportance of Weathering in Rock EngineeringGopal PNo ratings yet

- Particle Size Distribution For Refractory Castables - A ReviewDocument5 pagesParticle Size Distribution For Refractory Castables - A ReviewpetemberNo ratings yet

- Stiffened Thin Shell Domes: Kennethp - BuchertDocument5 pagesStiffened Thin Shell Domes: Kennethp - BuchertcmkohNo ratings yet

- Amit Kumar CE18M021 Guided by Prof P AlagusundaramoorthyDocument14 pagesAmit Kumar CE18M021 Guided by Prof P AlagusundaramoorthyAmit KumarNo ratings yet

- Empirical Estimation of Rock Mass ModulusDocument15 pagesEmpirical Estimation of Rock Mass ModulusMohammad Suriyaidulman RianseNo ratings yet

- Practical Masonry, Bricklaying and Plastering Author Thomas Kelly Paternoster RowDocument374 pagesPractical Masonry, Bricklaying and Plastering Author Thomas Kelly Paternoster RowJeremia Maghinang100% (2)

- Brzovic Villaescusa ISRMJournal 2007Document20 pagesBrzovic Villaescusa ISRMJournal 2007Rove 001No ratings yet

- Powder Technology: Stephane Ngako, Ruben Mouangue, Sebastien Caillat, Alexis Kuitche, Ernest SaragbaDocument7 pagesPowder Technology: Stephane Ngako, Ruben Mouangue, Sebastien Caillat, Alexis Kuitche, Ernest SaragbauvsarathiNo ratings yet

- Monolithic DomeDocument31 pagesMonolithic DomeAditya PatilNo ratings yet

- Principles of Rockbolting Design PDFDocument18 pagesPrinciples of Rockbolting Design PDFJaime BojorqueNo ratings yet

- A Case History of Completing. and Fracture Stimulating A Horizontal WellDocument9 pagesA Case History of Completing. and Fracture Stimulating A Horizontal WellzachNo ratings yet

- Scour in Bouldery Bed Proposed Formula (IRC PAPER NO 508)Document28 pagesScour in Bouldery Bed Proposed Formula (IRC PAPER NO 508)Ram Kumar Dhiman67% (3)

- Ukar Et Al 2019Document22 pagesUkar Et Al 2019MaxiNo ratings yet

- Experimental Investigation On The Effect of Geometric ImperfectionsDocument11 pagesExperimental Investigation On The Effect of Geometric ImperfectionsSUBHASHNo ratings yet

- SPE 97033 Rock Typing As An Effective ToDocument15 pagesSPE 97033 Rock Typing As An Effective Topavka789No ratings yet

- Performance of Piled Raft With Varying Pile Length: 50 Indian Geotechnical ConferenceDocument10 pagesPerformance of Piled Raft With Varying Pile Length: 50 Indian Geotechnical Conferenceprasun halderNo ratings yet

- Integration of Geotechnical and Structural Design in TunnellingDocument55 pagesIntegration of Geotechnical and Structural Design in Tunnellingsvs dmrNo ratings yet

- Survev of Characterization TechniquesDocument13 pagesSurvev of Characterization Techniquesmarcelodias725No ratings yet

- Behavior of Large Diameter Floating Bored Piles in Saprolitic SoilsDocument16 pagesBehavior of Large Diameter Floating Bored Piles in Saprolitic SoilsVetriselvan ArumugamNo ratings yet

- 1 s2.0 S0038080620324446 MainDocument10 pages1 s2.0 S0038080620324446 MainNadia Zaman SrutiNo ratings yet

- Analysis of Offshore Drilling's Vertical Load Using Semi-Submersible RigDocument8 pagesAnalysis of Offshore Drilling's Vertical Load Using Semi-Submersible RigSiva RamanNo ratings yet

- Behavior of Pile Groups Subjected To Vertical Loading IJERTV3IS031813Document5 pagesBehavior of Pile Groups Subjected To Vertical Loading IJERTV3IS031813Chukwuma OgbonnaNo ratings yet

- Feb03 Fractured ReservoirsDocument6 pagesFeb03 Fractured ReservoirsRoCo GeologoNo ratings yet

- IRJAES - Plan Analysis and Design of A Circular RCC SiloDocument6 pagesIRJAES - Plan Analysis and Design of A Circular RCC SiloM.RajivNo ratings yet

- SPWLA-1994-GGG - Pitfalls of Picket Plots in CarbonatesDocument25 pagesSPWLA-1994-GGG - Pitfalls of Picket Plots in CarbonatesPedroNo ratings yet

- Pillar Design PaperDocument10 pagesPillar Design PaperAnand sharmaNo ratings yet

- 02 Rock Mass Classification PDFDocument23 pages02 Rock Mass Classification PDFAlexer HXNo ratings yet

- Renewable and Sustainable Energy Reviews: Wei-Hsin Chen, Jianghong Peng, Xiaotao T. BiDocument20 pagesRenewable and Sustainable Energy Reviews: Wei-Hsin Chen, Jianghong Peng, Xiaotao T. BiCarolina Restrepo LondoñoNo ratings yet

- Revision 1-S2.0-S1674775514000225-MainDocument13 pagesRevision 1-S2.0-S1674775514000225-Mainjulio1051No ratings yet

- Evaluation of Stability and Seismic Analysis of Gravity Dam by Using Staad ProDocument9 pagesEvaluation of Stability and Seismic Analysis of Gravity Dam by Using Staad Promanga5No ratings yet

- Scaleup of Laboratory Measured Coal Permeability.: September 2008Document15 pagesScaleup of Laboratory Measured Coal Permeability.: September 2008Vinod KumarNo ratings yet

- Application of Derivatives in Real Life: AbstractDocument3 pagesApplication of Derivatives in Real Life: AbstractaliNo ratings yet

- Suction Piles: Their Position and Application TodayDocument6 pagesSuction Piles: Their Position and Application TodayfranciscoerezNo ratings yet

- 2023 L31 Rock MechanicsDocument29 pages2023 L31 Rock MechanicsDr Debasish PandaNo ratings yet

- Study of The Behaviour of Slab-Coupled T-Shaped RC Walls: October 2008Document10 pagesStudy of The Behaviour of Slab-Coupled T-Shaped RC Walls: October 2008dexter238No ratings yet

- Irregular Shaped PPT - Hopgood1986Document5 pagesIrregular Shaped PPT - Hopgood1986kandula.munikumarNo ratings yet

- Beam Column Joints of Special Moment Frames RPMDocument39 pagesBeam Column Joints of Special Moment Frames RPMVince GarciaNo ratings yet

- StrutDocument13 pagesStrutVince GarciaNo ratings yet

- Base Plate High Mast PoleeeeeDocument9 pagesBase Plate High Mast PoleeeeeVince GarciaNo ratings yet

- Baseplate EstimateDocument5 pagesBaseplate EstimateVince GarciaNo ratings yet

- Pile Cap Details Pile Details: Pc-3 Section - 2 Pc-5 Section - 2Document1 pagePile Cap Details Pile Details: Pc-3 Section - 2 Pc-5 Section - 2Vince GarciaNo ratings yet

- Foundation Plan: LegendDocument1 pageFoundation Plan: LegendVince GarciaNo ratings yet

- ReadmeDocument1 pageReadmeVince GarciaNo ratings yet

- Pile Cap Details Pedestal SectionDocument1 pagePile Cap Details Pedestal SectionVince GarciaNo ratings yet

- California Bearing RatioDocument11 pagesCalifornia Bearing RatioVince GarciaNo ratings yet

- Earthquake Forces in Rectangular TanksDocument4 pagesEarthquake Forces in Rectangular TanksVince GarciaNo ratings yet

- Given: A 40 FT Long, Simply Support W 18x35 Beam Supports A Point Load, P, at Mid-Span. TheDocument66 pagesGiven: A 40 FT Long, Simply Support W 18x35 Beam Supports A Point Load, P, at Mid-Span. TheVince GarciaNo ratings yet

- SurovekZiemian PDFDocument12 pagesSurovekZiemian PDFVince GarciaNo ratings yet

- Effective Length MethodDocument1 pageEffective Length MethodVince GarciaNo ratings yet

- What Does An Earthworm Do?: Activity Summary: Key WordsDocument2 pagesWhat Does An Earthworm Do?: Activity Summary: Key WordsKLS-KAFRABDOU KAUMEYANo ratings yet

- Nx-8035-G7 Specification: Model Nutanix: Per Node ( (2) Per Block) NX-8035-G7 (Configure To Order)Document2 pagesNx-8035-G7 Specification: Model Nutanix: Per Node ( (2) Per Block) NX-8035-G7 (Configure To Order)Nazakat MallickNo ratings yet

- Harp Exercise-Level-2-Exercise-3Document1 pageHarp Exercise-Level-2-Exercise-3Norman Rodriguez LlorandoNo ratings yet

- Thehilton Rhodes Resort: Ixia, GreeceDocument76 pagesThehilton Rhodes Resort: Ixia, GreeceThemisNo ratings yet

- Art StylesDocument34 pagesArt StylesAdrienne Dave MojicaNo ratings yet

- Functii ElementareDocument7 pagesFunctii ElementareAna GheorghitaNo ratings yet

- 23 January - UGV Working ProgrammeDocument3 pages23 January - UGV Working ProgrammeJoão Ricardo NunesNo ratings yet

- TECDIS Feature GuideDocument7 pagesTECDIS Feature GuideringboltNo ratings yet

- A Study of Arthur HoneggerDocument6 pagesA Study of Arthur Honeggermmarriuss7100% (1)

- Hailing A Taxi - English LearningDocument4 pagesHailing A Taxi - English Learningclinta1979No ratings yet

- Physics ProjectDocument11 pagesPhysics Projectadatta546No ratings yet

- Addons Free Part 1Document2 pagesAddons Free Part 1Alfa RebornNo ratings yet

- Quantum Materials Science EngineeringDocument2 pagesQuantum Materials Science Engineeringvisheshp961No ratings yet

- To Deleto4Document2 pagesTo Deleto4Paul Savvy100% (1)

- Arbor APS STT - Unit 03 - Virtual Deployment - 25jan2018Document26 pagesArbor APS STT - Unit 03 - Virtual Deployment - 25jan2018masterlinh2008No ratings yet

- 5 - 6255737462828565350 (10 Files Merged)Document307 pages5 - 6255737462828565350 (10 Files Merged)Aman PalNo ratings yet

- Ut Slides.Document114 pagesUt Slides.Y ShameyaNo ratings yet

- MN081Document7 pagesMN081TimmyJuriNo ratings yet

- TQM - 601 Module 6 - Quality Tools - Decision-Prioritization MatrixDocument20 pagesTQM - 601 Module 6 - Quality Tools - Decision-Prioritization Matrix512781No ratings yet

- QAHO1002227 PNC 4th ClsDocument2 pagesQAHO1002227 PNC 4th ClsdevNo ratings yet

- Munsaka Peter: Curriculum VitaeDocument5 pagesMunsaka Peter: Curriculum VitaePeter JacksonNo ratings yet

- Standard Filipino English Philippine EnglishDocument3 pagesStandard Filipino English Philippine EnglishChristine Breeza SosingNo ratings yet

- Part 1.2. Back PropagationDocument30 pagesPart 1.2. Back PropagationViệt HoàngNo ratings yet

- Struktol RP 17 MSDS PDFDocument7 pagesStruktol RP 17 MSDS PDFSimonNo ratings yet

- C ContentsDocument3 pagesC Contentsearle akhilNo ratings yet

- Designing and Implementing A Datawarehousing (Step1) : Chapter-4Document8 pagesDesigning and Implementing A Datawarehousing (Step1) : Chapter-4Mohamoud Farah Abdilahi AliNo ratings yet

- David Byrne - 2018-04 Mojo PDFDocument8 pagesDavid Byrne - 2018-04 Mojo PDFJuan Pablo GraciánNo ratings yet