Professional Documents

Culture Documents

MST-CO-002 (MS For BLASTING AND PAINTING)

MST-CO-002 (MS For BLASTING AND PAINTING)

Uploaded by

Delta akathehuskyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MST-CO-002 (MS For BLASTING AND PAINTING)

MST-CO-002 (MS For BLASTING AND PAINTING)

Uploaded by

Delta akathehuskyCopyright:

Available Formats

SAUDI ARABIAN OIL COMPANY

NEAT KHUFF CONDENSATE FRACTIONATION PROJECT

METHOD STATEMENT

FOR

BLASTING AND PAINTING

IN SITU VESSEL D-100

SUB CONTRACT NO: 308200

DOCUMENT NO: 308200 -MST-C0-002-Rev.0

Date :

Client : Project : Contractor :

02.03.2002

SAUDI ARAMCO NEAT KHUFF CONDENSATE DODSAL & CO.

FRACTIONATION PROJECT

SNAMPROGETTI

308200-MST-CO-002 Rev.0 Page 1 of 6

DATE OF ISSUE: 03-02-2002

NEAT KHUFF CONDENSATE FRACTIONATION PLANT

METHOD STATEMENT

FOR

BLASTING AND PAINTING

IN SITU VESSEL D-100

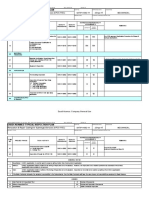

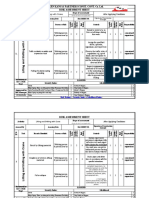

REVISION CONTROL

Revision Date of Details of Prepared by Reviewed by Approved by Approved by

Status Issue Revision DODSAL DODSAL DODSAL SP

0 03-02-2002 Initial AWM RON AB

308200-MST-CO-002 Rev.0 Page 2 of 6

DATE OF ISSUE: 03-02-2002

NEAT KHUFF CONDENSATE FRACTIONATION PLANT

308200-MST-CO-002 Rev.0 Page 3 of 6

DATE OF ISSUE: 03-02-2002

NEAT KHUFF CONDENSATE FRACTIONATION PLANT

INDEX

1.0 PURPOSE

2.0 SCOPE

3.0 REFERENCES

4.0 SAFETY

5.0 PROCEDURE

6.0 DOCUMENTATION

1.0 PURPOSE

1.1 Purpose of this Method Statement is to describe the steps to be taken for achieving

specified requirements for in situ Vessel Blasting & Painting.

2.0 SCOPE

2.1 This procedure in conjunction with the referenced Saudi Aramco and other industry

codes and standards or Saudi Aramco Engineering Procedures (SAEPS) covers

the minimum requirements for protective coating for in situ vessel that are carbon

steel unless otherwise stated.

308200-MST-CO-002 Rev.0 Page 4 of 6

DATE OF ISSUE: 03-02-2002

NEAT KHUFF CONDENSATE FRACTIONATION PLANT

3.0 REFERENCES

SAES-H-001 : Section requirements for industrial coating

SAES-H-002 : Internal and external coating for steel pipelines & piping

SAES-H-002 V : Approved Saudi Aramco Data Sheet

SAES-H-100 : Painting requirements for industrial facilities

SAES-H-101 : Approved protective coating system

SAES-H-101 V : Approved Saudi Aramco Data Sheet

SAES-H-102 : Safety requirements for painting.

FORM 175-091900 : Inspection requirements

SAEP - 316 : Qualification of coating personnel

09-SAMSS-060 : Packaging required for coating

SIS 055900 : Swedish standards for visual cleanliness for blasted steel

SSPC VIS-1 : Steel structure painting council guide to VIS 1-86-visual

standard for abrasive blast cleaned steel

SSPC PA2 : Steel structure painting council measurement of dry paint

thickness with magnetic gauges.

SSPC SPI : Steel structures painting council "Solvent cleaning".

GI 445.001 : Saudi Aramco Performance Qualification of critical coating

personnel : crew supervisor abrasive blaster, paint/ coating

applicators.

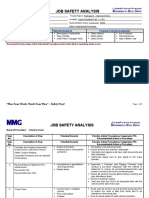

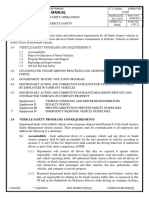

4.0 SAFETY

4.1 Minimum Safety requirements shall be in accordance with SAES-H-102 and Saudi

Aramco Construction Safety Manuals.

5.0 PROCEDURE

5.1 The Vessel D-100 to be blasted and painted shall be isolated from the rest of the

plant by means off scaffolding out the entire vessel from top to bottom and all the

way round. Making sure all scaffolding is safety tagged and signed.

5.2 The Vessel will then be enclosed fully with tarpaulins from top to bottom and all the

way round. To ensure that only the vessel D-100 is being grit blasted and not the

surrounding areas.

5.3 All Personnel shall be equiped with P.P.E. to ensure safe work practice.

5.4 The Vessel will then be blasted to the required cleanliness level. And profile

required.

308200-MST-CO-002 Rev.0 Page 5 of 6

DATE OF ISSUE: 03-02-2002

NEAT KHUFF CONDENSATE FRACTIONATION PLANT

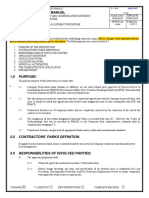

5.5 The Vessel will then be blown down by clean compressed air or by soft brushing to

ensure the correct level of cleanliness has been achieved. Also the correct profile

required has been achieved.

5.6 If the Blasted Vessel is accepted for clenliness all Welds, Bolts, Rivets, Raised

edges shall be given a stripe coat (Brush Applied) Prior to normal Painting taking

place (stripe coat not required if using inorganic zinc).

5.7 The Coating shall be holiday tested when fully cured, and any defect shall be

repaired and retested if required, If the DFT is 500 micrometer or above A Dry

spark tester shall be used instead of the wet sponge method,( Also in concurence

of the operating organization internal coating that is cathodically protected shall

not require holiday testing)

6.0 DOCUMENTATION

6.1 QC PAINT RECORDS.

6.1.1 QC paint records shall be in accordance with the approval QC records as

stated on the approved Quality Control Inspection and Test Plan

6.1.2 A daily job log shall be filled out on a daily basis by the approved crew

supervisor recording all problem areas, delays, non-compliance and

corrective actions taken.

308200-MST-CO-002 Rev.0 Page 6 of 6

DATE OF ISSUE: 03-02-2002

NEAT KHUFF CONDENSATE FRACTIONATION PLANT

You might also like

- General Instruction Manual: ContentDocument13 pagesGeneral Instruction Manual: ContentDelta akathehuskyNo ratings yet

- Olt AbencoadaDocument2 pagesOlt AbencoadaRamon ProduçõesNo ratings yet

- Scaffolders Training MatrixDocument2 pagesScaffolders Training MatrixDelta akathehuskyNo ratings yet

- Real Estate Buyers PackageDocument16 pagesReal Estate Buyers PackageTom Joseph100% (3)

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco) 710.014 Issuing Org. 3/01/2009 NEW Subject 1 OF 9Document9 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco) 710.014 Issuing Org. 3/01/2009 NEW Subject 1 OF 9Delta akathehuskyNo ratings yet

- Introduction To Derivatives and Risk Management 10th Edition Chance Test BankDocument8 pagesIntroduction To Derivatives and Risk Management 10th Edition Chance Test BankMavos OdinNo ratings yet

- MST-CO-001-01 (MS For General Painting)Document9 pagesMST-CO-001-01 (MS For General Painting)Delta akathehuskyNo ratings yet

- Apcs-113a Method StatmentDocument7 pagesApcs-113a Method StatmentNoman AhmedNo ratings yet

- Saes H 201Document9 pagesSaes H 201heartbreakkid132No ratings yet

- Dfy - Coating Quality Key PointsDocument1 pageDfy - Coating Quality Key PointsMohammed SadiqNo ratings yet

- Inspection and Test Plan FOR Coating (02260 ITP-COA-001) : Petronas Rapid Project (Package 3)Document9 pagesInspection and Test Plan FOR Coating (02260 ITP-COA-001) : Petronas Rapid Project (Package 3)Namta GeorgeNo ratings yet

- EN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete ConstructionDocument32 pagesEN131528-TCCSA-CS-M04-0003 (02) - Method Statement For Mass Concrete Construction章宇No ratings yet

- Nonmaterial Requirements: Concentrated Firefighting FoamDocument2 pagesNonmaterial Requirements: Concentrated Firefighting FoamBIPIN BALANNo ratings yet

- MasterSeal TC 244Document2 pagesMasterSeal TC 244EngTamerNo ratings yet

- Saudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Document2 pagesSaudi Aramco Inspection Checklist: Concrete Coatings Pre-Installation Inspection SAIC-H-1003 15-Nov-17Abdul HannanNo ratings yet

- SA04C2-MS-MET-AAG-00022 MS For Wrapping and Lining of CS PipeDocument16 pagesSA04C2-MS-MET-AAG-00022 MS For Wrapping and Lining of CS PipeABAID ULLAHNo ratings yet

- Sg6427-Sy-ck0p-Mtd-736-009 - Method Statement of Cable Transit & Multi Cable Transit Installation - Rev.cDocument9 pagesSg6427-Sy-ck0p-Mtd-736-009 - Method Statement of Cable Transit & Multi Cable Transit Installation - Rev.cbrian sanchezNo ratings yet

- MIP17-MS-1018 Method Statement For Installation of Sheet Pipling - Rev.0Document22 pagesMIP17-MS-1018 Method Statement For Installation of Sheet Pipling - Rev.0AmeerHamzaWarraichNo ratings yet

- 8474l-000-Jsd-2310-001-2-Protective CoatingDocument31 pages8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- Saudi Aramco Typical Inspection Plan: Renovation & Repair Coating For Submerged Service-APCS 113 A SATIP-H-002-06Document6 pagesSaudi Aramco Typical Inspection Plan: Renovation & Repair Coating For Submerged Service-APCS 113 A SATIP-H-002-06mohammad farooqNo ratings yet

- MIP17-HSE-JSA-022 For Installation of Overhead Powerlines - 2022 Rev.1 (Khursaniyah Area)Document14 pagesMIP17-HSE-JSA-022 For Installation of Overhead Powerlines - 2022 Rev.1 (Khursaniyah Area)AmeerHamzaWarraichNo ratings yet

- Logbook Data (Dec 13) 09Document18 pagesLogbook Data (Dec 13) 09Amit shahNo ratings yet

- Mip17-Ms-2012 Method of Statement For Piping Fabrication Coating and Painting in Sks Jubail Facility - Rev.1Document24 pagesMip17-Ms-2012 Method of Statement For Piping Fabrication Coating and Painting in Sks Jubail Facility - Rev.1AmeerHamzaWarraichNo ratings yet

- Satip H 002 11Document10 pagesSatip H 002 11Rauf ChaudharyNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Sa 7918 2Document2 pagesSa 7918 2junaid ShahNo ratings yet

- 8474L-000-JSD-2310-001-4-Protective Coatings PDFDocument31 pages8474L-000-JSD-2310-001-4-Protective Coatings PDFDo Quynh100% (2)

- Method Satment For Outher Tank Painting WorksDocument7 pagesMethod Satment For Outher Tank Painting WorksTri Aji100% (1)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistAnantha PadmanabhanNo ratings yet

- Tes H 107 02 R0 PDFDocument31 pagesTes H 107 02 R0 PDFUmair QayyumNo ratings yet

- Sign-A: Design NotesDocument1 pageSign-A: Design NotesMarko's Brazon'No ratings yet

- Specification FOR Piping Fabrication and InstallationDocument27 pagesSpecification FOR Piping Fabrication and Installationgc_panchaNo ratings yet

- Sky Climber SparesDocument7 pagesSky Climber SparesshambhoiNo ratings yet

- MS For AG PipingDocument15 pagesMS For AG Pipingmansih457No ratings yet

- Temporary Works of Laydown and Living Camp Area For SEPCO-III AL Taweelah RO Independent Water ProjectDocument6 pagesTemporary Works of Laydown and Living Camp Area For SEPCO-III AL Taweelah RO Independent Water ProjecteshwarNo ratings yet

- HSE-OCP-013. Cold CuttingDocument4 pagesHSE-OCP-013. Cold Cuttingibrahim0% (1)

- 01 Samss 031Document3 pages01 Samss 031Awais CheemaNo ratings yet

- Sen 1399 CSD Pur MR 052 01Document16 pagesSen 1399 CSD Pur MR 052 01Kamran JamilNo ratings yet

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final OldprabakaranNo ratings yet

- Coating Procedure For Bituminous Material Rev 01Document5 pagesCoating Procedure For Bituminous Material Rev 01moytabura96No ratings yet

- Jotun Pre-Qualified Paints As Per Norsok Systems No 1Document5 pagesJotun Pre-Qualified Paints As Per Norsok Systems No 1Sam Jose100% (1)

- O252-PI-SP-0126 - C04 - Specification For PaintingDocument26 pagesO252-PI-SP-0126 - C04 - Specification For PaintingBestun AhmedNo ratings yet

- 002-PDS-CON-009 Method Statement For Material Management at SiteDocument13 pages002-PDS-CON-009 Method Statement For Material Management at SiteMalik ZamanNo ratings yet

- Painting SpecificationDocument19 pagesPainting SpecificationArunkumar Rackan0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistJeffrey Lipata Jr.100% (1)

- Materials System SpecificationDocument11 pagesMaterials System SpecificationZubair RaoofNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- MESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167Document7 pagesMESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167sathi11189No ratings yet

- SATIP-T-492-01 Ver 08Document1 pageSATIP-T-492-01 Ver 08thezaidNo ratings yet

- BSP Project Quality Awareness Trainings (New)Document22 pagesBSP Project Quality Awareness Trainings (New)amirrulasyrafNo ratings yet

- Surface Profile Measurement by Replica Tape SSPC-SP10-Nace 2-Near - WhiteDocument5 pagesSurface Profile Measurement by Replica Tape SSPC-SP10-Nace 2-Near - WhiteClyde CoopperNo ratings yet

- On - Plot HydrotestingDocument14 pagesOn - Plot HydrotestingarunmirandaNo ratings yet

- Barcoill Hardness Test PDFDocument2 pagesBarcoill Hardness Test PDFProkopNo ratings yet

- Joint Coating Application & Pipe Coating ProcedureDocument7 pagesJoint Coating Application & Pipe Coating Proceduregst ajahNo ratings yet

- Inspectable MaterialsDocument2 pagesInspectable MaterialsMohamed RedaNo ratings yet

- QM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01Document11 pagesQM-R83-PL-4051 Procedure For Concrete Surface Preparation and Coating Rev. 01GaneshNo ratings yet

- Hempadur Quattro 17634: Product Characteristics Product SafetyDocument4 pagesHempadur Quattro 17634: Product Characteristics Product Safetyulul100% (1)

- ITP-5975-350 Rev. 7 - Soil Improvement (Incl Attachments)Document24 pagesITP-5975-350 Rev. 7 - Soil Improvement (Incl Attachments)makiNo ratings yet

- QCP 050 Concrete Finishing (Zuluf Water Supply Facilities B.I. No. 10-12322) SubmittedDocument9 pagesQCP 050 Concrete Finishing (Zuluf Water Supply Facilities B.I. No. 10-12322) SubmittedRAMAKRISHNANo ratings yet

- Job Procedure For Cable TrayDocument5 pagesJob Procedure For Cable TrayNisith SahooNo ratings yet

- Cover Sheet: Zapsib-2 ProjectDocument12 pagesCover Sheet: Zapsib-2 ProjectAkhtar AnsariNo ratings yet

- Prime Coat Data Sheet MC-70 P D SDocument1 pagePrime Coat Data Sheet MC-70 P D SRaheelHashmiNo ratings yet

- Underground Piping (U/G) : Cooling Tower PipelineDocument9 pagesUnderground Piping (U/G) : Cooling Tower PipelineMayank KumarNo ratings yet

- High Performance Coatings SpecsDocument47 pagesHigh Performance Coatings Specshasanriaz36150% (2)

- MST For Concret CoatingDocument6 pagesMST For Concret CoatingDelta akathehusky100% (1)

- Saic-H-2028Document11 pagesSaic-H-2028mominNo ratings yet

- ASTM C805 (2002) Schmidt Hammer TestDocument3 pagesASTM C805 (2002) Schmidt Hammer TestDelta akathehuskyNo ratings yet

- Concrete Finishing Level2 QualificationsDocument58 pagesConcrete Finishing Level2 QualificationsDelta akathehuskyNo ratings yet

- Concrete Finisher - AssessmentDocument1 pageConcrete Finisher - AssessmentDelta akathehuskyNo ratings yet

- AconexDocument2 pagesAconexDelta akathehuskyNo ratings yet

- Basic of Iso 9001bDocument43 pagesBasic of Iso 9001bDelta akathehuskyNo ratings yet

- Asphalt Paving DWGDocument1 pageAsphalt Paving DWGDelta akathehuskyNo ratings yet

- Appendix ADocument1 pageAppendix ADelta akathehuskyNo ratings yet

- Cable InformationDocument2 pagesCable InformationDelta akathehuskyNo ratings yet

- Insulation SeminarDocument55 pagesInsulation SeminarDelta akathehuskyNo ratings yet

- Saep 1152Document19 pagesSaep 1152Delta akathehuskyNo ratings yet

- Assessment ReportDocument1 pageAssessment ReportDelta akathehuskyNo ratings yet

- Home Safety ChecklistDocument2 pagesHome Safety ChecklistDelta akathehuskyNo ratings yet

- Pre-Interview Evaluation - (Revised 2022) - ExpatDocument3 pagesPre-Interview Evaluation - (Revised 2022) - ExpatDelta akathehuskyNo ratings yet

- Watercooler SafetyDocument14 pagesWatercooler SafetyDelta akathehuskyNo ratings yet

- General Instruction Manual: ScopeDocument10 pagesGeneral Instruction Manual: ScopeDelta akathehuskyNo ratings yet

- Assembly of Steel StructuresDocument2 pagesAssembly of Steel StructuresDelta akathehuskyNo ratings yet

- Travelling of CraneDocument3 pagesTravelling of CraneDelta akathehuskyNo ratings yet

- KCC Lifting and Shifting With CraneDocument7 pagesKCC Lifting and Shifting With CraneDelta akathehuskyNo ratings yet

- Waste ComputationDocument2 pagesWaste ComputationDelta akathehuskyNo ratings yet

- Material Order FormDocument3 pagesMaterial Order FormDelta akathehuskyNo ratings yet

- General Instruction Manual: ScopeDocument11 pagesGeneral Instruction Manual: ScopeDelta akathehuskyNo ratings yet

- General Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Document9 pagesGeneral Instruction Manual: Saudi Arabian Oil Company (Saudi Aramco)Delta akathehuskyNo ratings yet

- General Instruction Manual: ContentDocument22 pagesGeneral Instruction Manual: ContentDelta akathehuskyNo ratings yet

- Scaffolding Site Instruction Control SheetDocument21 pagesScaffolding Site Instruction Control SheetDelta akathehuskyNo ratings yet

- Gi 0002 - 718 Contractor Site Allotment ProcedureDocument12 pagesGi 0002 - 718 Contractor Site Allotment ProcedureDelta akathehuskyNo ratings yet

- General Instruction Manual: ContentDocument13 pagesGeneral Instruction Manual: ContentDelta akathehuskyNo ratings yet

- Meisei Scaffolding Materials ForecastDocument4 pagesMeisei Scaffolding Materials ForecastDelta akathehuskyNo ratings yet

- Mindray BC-2800 - Service ManualDocument108 pagesMindray BC-2800 - Service ManualAvilianaK.Bintari80% (5)

- FBC NotesDocument76 pagesFBC NotesSweatha SNo ratings yet

- Gabriel v. PangilinanDocument2 pagesGabriel v. PangilinanMit SkroNo ratings yet

- EFL IS User ManualDocument26 pagesEFL IS User Manualarupamguria05No ratings yet

- Rizki Nardianto - Tugas 1Document45 pagesRizki Nardianto - Tugas 1Rizki NardiantoNo ratings yet

- Online Examination PresentationDocument13 pagesOnline Examination PresentationFelix GathageNo ratings yet

- Thermocompressor Efficiency & PerformanceDocument4 pagesThermocompressor Efficiency & PerformancerifqizafrilNo ratings yet

- CertificateDocument1 pageCertificateNaina Umar VaishyaNo ratings yet

- The Path Is Easier: With Heat Solutions From KalsecDocument21 pagesThe Path Is Easier: With Heat Solutions From KalsecAndres RuizNo ratings yet

- Example An Op Amp Circuit Analysis LectureDocument23 pagesExample An Op Amp Circuit Analysis LectureAthiyo Martin100% (1)

- "8086 Interrupts" in (Microprocessor Systems and Interfacing)Document20 pages"8086 Interrupts" in (Microprocessor Systems and Interfacing)MUHAMMAD ABDULLAHNo ratings yet

- Impact of Green Supply Chain Management Practices On Firms ' Performance: An Empirical Study From The Perspective of PakistanDocument16 pagesImpact of Green Supply Chain Management Practices On Firms ' Performance: An Empirical Study From The Perspective of PakistansyedNo ratings yet

- CreativityDocument10 pagesCreativitySamithaDYNo ratings yet

- FTM Business Template - Margin AnalysisDocument9 pagesFTM Business Template - Margin AnalysisSofTools LimitedNo ratings yet

- Email EtiquetteDocument27 pagesEmail EtiquetteSangesh NattamaiNo ratings yet

- People of The Philippines V. Marissa Bayker G.R. No. 170192, February 10, 2016, BERSAMIN, J., FIRST DIVISION FactsDocument64 pagesPeople of The Philippines V. Marissa Bayker G.R. No. 170192, February 10, 2016, BERSAMIN, J., FIRST DIVISION FactsDonna Ingusan-BollozosNo ratings yet

- CRW85218 CRW85218 Malaysia English OIC-EH Oilfield 1016978Document13 pagesCRW85218 CRW85218 Malaysia English OIC-EH Oilfield 1016978Yong Lin Albon TiongNo ratings yet

- O & M ManualDocument131 pagesO & M Manualt_syamprasadNo ratings yet

- CLM TutorialDocument18 pagesCLM Tutorialrico.caballero7No ratings yet

- Energy Dissipation Capacity of Flexure-Dominated Reinforced Concrete MembersDocument12 pagesEnergy Dissipation Capacity of Flexure-Dominated Reinforced Concrete Members01010No ratings yet

- Drift Analysis For Lateral Stability PDFDocument5 pagesDrift Analysis For Lateral Stability PDFadriano4850No ratings yet

- Summative Test Module 4 Tle Ict CSS 9Document2 pagesSummative Test Module 4 Tle Ict CSS 9Ronaldo Oloroso Abinal Jr.No ratings yet

- CPM Lab Assignment-02Document14 pagesCPM Lab Assignment-02Muhammad NomanNo ratings yet

- Market Driven StrategyDocument43 pagesMarket Driven StrategyAhsan ShahidNo ratings yet

- PF Aquaforte Brochure - 04.04.12Document2 pagesPF Aquaforte Brochure - 04.04.12ukalNo ratings yet

- A Study of Consumer Preferences Towards FrootiDocument11 pagesA Study of Consumer Preferences Towards Frootisidyans12No ratings yet