Professional Documents

Culture Documents

MS-1000-Material Specifications For Steel

MS-1000-Material Specifications For Steel

Uploaded by

ALEX MURPHYCopyright:

Available Formats

You might also like

- GMW14400 May2007 PDFDocument9 pagesGMW14400 May2007 PDFAkmal NizametdinovNo ratings yet

- Sae Ams 5518M-2014Document5 pagesSae Ams 5518M-2014Mehdi Mokhtari100% (1)

- Sae 1008Document4 pagesSae 1008ALEX MURPHYNo ratings yet

- Aisi 1010 Carbon Steel (Uns g10100)Document5 pagesAisi 1010 Carbon Steel (Uns g10100)spiderblackNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Material Specification: 23dec2015 01sep1961Document2 pagesMaterial Specification: 23dec2015 01sep1961Chuanxiang Weinong (川香味浓)No ratings yet

- G-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Document7 pagesG-00-1169 - Grade Designation For Low Carbon Hot Rolled Steel Sheets Used in Automotive Applications - Rev 4Prince Ali50% (2)

- Carraro India LTD Steel Mill Standard Rev 08Document7 pagesCarraro India LTD Steel Mill Standard Rev 08SUNDARNo ratings yet

- Lanka Alluminium - Profile Catlogue - CD PDFDocument152 pagesLanka Alluminium - Profile Catlogue - CD PDFfixfixitNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Metallic Material Specification: Title: 4140 Mod / 4145 Mod, 125 KSI YS, 285-340 BHNDocument5 pagesMetallic Material Specification: Title: 4140 Mod / 4145 Mod, 125 KSI YS, 285-340 BHNReginaldo SantosNo ratings yet

- Astm A588 1979 PDFDocument4 pagesAstm A588 1979 PDFNuno Telmo LopesNo ratings yet

- Cr-Product Manual - PDFDocument28 pagesCr-Product Manual - PDFThơ Thẫn ThờNo ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelKarimulla ShaikNo ratings yet

- Electrode Booklet F Web 93Document1 pageElectrode Booklet F Web 93satnamNo ratings yet

- Consumables To Match Cast & Wrought Alloy 800: Astm Bs en & DinDocument3 pagesConsumables To Match Cast & Wrought Alloy 800: Astm Bs en & Dinankitniranjan1390No ratings yet

- C 70 SuperthermDocument2 pagesC 70 SuperthermMandeep SinghNo ratings yet

- Fairfield Atlas Limited Shinoli Metallurgical Technical Delivery Specification TDS No: TDS/ P 0110790 Rev No: 02 Page No: 1 of 3Document4 pagesFairfield Atlas Limited Shinoli Metallurgical Technical Delivery Specification TDS No: TDS/ P 0110790 Rev No: 02 Page No: 1 of 3Andras StegerNo ratings yet

- Scope: 4.1. Significance and UseDocument3 pagesScope: 4.1. Significance and UsepathinathanNo ratings yet

- 20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelDocument5 pages20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelzhenyupanNo ratings yet

- User'S Guide: Tel: 0427-2382236 / 2383836, Fax: 238 3249 / 2383063Document50 pagesUser'S Guide: Tel: 0427-2382236 / 2383836, Fax: 238 3249 / 2383063suheilbugsNo ratings yet

- Steel Table GuideDocument11 pagesSteel Table Guidemanoj983@gmail.comNo ratings yet

- Hastelloy X / Alloy X / UNS N06002 / DIN 2.4619Document3 pagesHastelloy X / Alloy X / UNS N06002 / DIN 2.4619SamkitNo ratings yet

- Interlloy Grade 1045 Carbon Steel BarDocument3 pagesInterlloy Grade 1045 Carbon Steel BarPRASHANT KANTENo ratings yet

- 7 Tool Steels1Document12 pages7 Tool Steels1ontc0109No ratings yet

- Alluminium GradesDocument4 pagesAlluminium GradesAnjani kumarNo ratings yet

- 1 Scope: SpecificationDocument2 pages1 Scope: Specificationrahul vermaNo ratings yet

- Alloy SteelDocument33 pagesAlloy SteelDhana LakshmiNo ratings yet

- Material Specification Sheet En8D CoilsDocument1 pageMaterial Specification Sheet En8D CoilsMahesh Kumar BandariNo ratings yet

- Aluminium Alloy 6061 - Composition, Properties, Temper and ApplicationsDocument4 pagesAluminium Alloy 6061 - Composition, Properties, Temper and ApplicationsMadhu SudanNo ratings yet

- Chromium Steel Rolls: Hitachi Metals America, LTDDocument2 pagesChromium Steel Rolls: Hitachi Metals America, LTDHariNo ratings yet

- Component Details:: Fairfield Atlas LimitedDocument3 pagesComponent Details:: Fairfield Atlas LimitedAndras StegerNo ratings yet

- Rail Specification S & CorrosionDocument94 pagesRail Specification S & CorrosionGowthami Priya HanumuthuNo ratings yet

- Specification For Galvanized Steel: Raw Material SpecificationsDocument2 pagesSpecification For Galvanized Steel: Raw Material SpecificationsAnonymous aBZfewNo ratings yet

- EC 1350-O Product Specification Rev.0Document3 pagesEC 1350-O Product Specification Rev.0serkan temelNo ratings yet

- Ind0116 - FDocument4 pagesInd0116 - Frajit kumarNo ratings yet

- GMM Mag.Document1 pageGMM Mag.Ehsan KhanNo ratings yet

- Product Manual: BarrettDocument52 pagesProduct Manual: Barrettbrajendra1020No ratings yet

- Lecture-1, Maraging SteelsDocument30 pagesLecture-1, Maraging Steelssatish chinthamNo ratings yet

- B 169 - B 169M - 95 - Qje2os9cmty5ts1sruqDocument7 pagesB 169 - B 169M - 95 - Qje2os9cmty5ts1sruqHimanshu KashyapNo ratings yet

- Heat Treat 2Document5 pagesHeat Treat 2gawaNo ratings yet

- Maraging 350 SpecDocument1 pageMaraging 350 SpecHeidarianNo ratings yet

- DATA SHEET - WD-Alloy718Document2 pagesDATA SHEET - WD-Alloy718MTB ENGNo ratings yet

- Material Data Sheet: Casting Material: Stainless Steel CF8MDocument9 pagesMaterial Data Sheet: Casting Material: Stainless Steel CF8MakshayNo ratings yet

- z3T - Maraging Steel 1-2709 (EOS MS1)Document1 pagez3T - Maraging Steel 1-2709 (EOS MS1)martinm3tNo ratings yet

- Aisi 304 Stainless SteelDocument3 pagesAisi 304 Stainless SteelfarhadNo ratings yet

- Armco Pure Iron PDFDocument12 pagesArmco Pure Iron PDFsmith willNo ratings yet

- As 3678 Steel Grade 350Document3 pagesAs 3678 Steel Grade 350gsoaresrj80No ratings yet

- Metallic Material SpecificationDocument8 pagesMetallic Material SpecificationReginaldo SantosNo ratings yet

- En 8Document1 pageEn 8Devendera TripathiNo ratings yet

- Forging - Case Hardening For 1.5%Ni-Cr-Mo SteelsDocument8 pagesForging - Case Hardening For 1.5%Ni-Cr-Mo SteelsJaison JoseNo ratings yet

- Inconel 82 PDFDocument1 pageInconel 82 PDFMiguel MorenoNo ratings yet

- fm82 1Document1 pagefm82 1harikrishnanNo ratings yet

- 8-AluminiumSheet Coil PlateandTreadplateDocument9 pages8-AluminiumSheet Coil PlateandTreadplatejerimiah_manzonNo ratings yet

- LM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical CompositionDocument3 pagesLM4 Aluminium Casting Alloy (Al - Si5Cu3) : Chemical Compositiona.suleimanNo ratings yet

- Electrode Booklet F Web 97Document1 pageElectrode Booklet F Web 97satnamNo ratings yet

- Alloy Steel Astm A217 Grade Wc6 1Document1 pageAlloy Steel Astm A217 Grade Wc6 1didi sudiNo ratings yet

- 6271-ECF-11 ITAR EAR Conflict Matl CertificationDocument2 pages6271-ECF-11 ITAR EAR Conflict Matl CertificationALEX MURPHYNo ratings yet

- Melling Products - Supplier ExpectationsDocument1 pageMelling Products - Supplier ExpectationsALEX MURPHYNo ratings yet

- Supplier Code of ConductDocument3 pagesSupplier Code of ConductALEX MURPHYNo ratings yet

- UntitledDocument28 pagesUntitledALEX MURPHYNo ratings yet

- Pur-Man-0001 Rev 20.0)Document24 pagesPur-Man-0001 Rev 20.0)ALEX MURPHYNo ratings yet

- QP-I.6-007 Rev CDocument1 pageQP-I.6-007 Rev CALEX MURPHYNo ratings yet

- Do You Supply Similar Materials?: SAE J1392 Grade 070ZH Hot-RolledDocument4 pagesDo You Supply Similar Materials?: SAE J1392 Grade 070ZH Hot-RolledALEX MURPHYNo ratings yet

- Senior PLC Code of ConductDocument19 pagesSenior PLC Code of ConductALEX MURPHYNo ratings yet

- Plating Specification: DSP-01-Duplex NickelDocument4 pagesPlating Specification: DSP-01-Duplex NickelALEX MURPHYNo ratings yet

- Melling Tool Company Supplier Quality Manual: Supply Chain Vision StatementDocument21 pagesMelling Tool Company Supplier Quality Manual: Supply Chain Vision StatementALEX MURPHYNo ratings yet

- Do You Supply Similar Materials?: SAE J1392 Grade 070XL Hot-RolledDocument4 pagesDo You Supply Similar Materials?: SAE J1392 Grade 070XL Hot-RolledALEX MURPHYNo ratings yet

- Melling Tool Company Supplier Quality Manual: Supply Chain Vision StatementDocument22 pagesMelling Tool Company Supplier Quality Manual: Supply Chain Vision StatementALEX MURPHYNo ratings yet

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDocument2 pagesAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionALEX MURPHYNo ratings yet

- JIS G4051 Grade S45C: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument4 pagesJIS G4051 Grade S45C: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearALEX MURPHYNo ratings yet

- Melling Supplier Quality Manual Rev 12Document21 pagesMelling Supplier Quality Manual Rev 12ALEX MURPHYNo ratings yet

- Sae 1010Document3 pagesSae 1010ALEX MURPHY50% (2)

- Do You Supply Similar Materials?: ASTM A830 Grade 1008Document3 pagesDo You Supply Similar Materials?: ASTM A830 Grade 1008ALEX MURPHYNo ratings yet

- Do You Supply Similar Materials?: SAE J404 Grade 4130Document3 pagesDo You Supply Similar Materials?: SAE J404 Grade 4130ALEX MURPHYNo ratings yet

- SAE J403 Grade 1055: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearDocument4 pagesSAE J403 Grade 1055: Matmatch Is Trusted by 2 Million+ Engineers and Product Developers Each YearALEX MURPHYNo ratings yet

- Do You Supply Similar Materials?: SAE J1392 Grade 070ZL Hot-RolledDocument4 pagesDo You Supply Similar Materials?: SAE J1392 Grade 070ZL Hot-RolledALEX MURPHYNo ratings yet

- Minfc1664 Astm A519 Grade 1010Document4 pagesMinfc1664 Astm A519 Grade 1010ALEX MURPHYNo ratings yet

- PN AR.01033 Test Methods For Monitoring of Cleaning ProcessesDocument16 pagesPN AR.01033 Test Methods For Monitoring of Cleaning ProcessesALEX MURPHYNo ratings yet

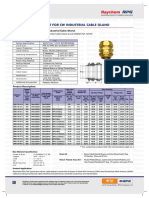

- In USA and Canada Contact:-: Toll Free 1-888-454-2688 or 201-986-1131 Fax: 201-986-7886 WebDocument5 pagesIn USA and Canada Contact:-: Toll Free 1-888-454-2688 or 201-986-1131 Fax: 201-986-7886 WebALEX MURPHYNo ratings yet

- Engineering Material Specification: Date Action RevisionsDocument3 pagesEngineering Material Specification: Date Action RevisionsALEX MURPHY100% (1)

- PmL.00227 Stanzteile Stamped PartsDocument8 pagesPmL.00227 Stanzteile Stamped PartsALEX MURPHYNo ratings yet

- Metallurgy Module One Notes CompleteDocument45 pagesMetallurgy Module One Notes CompleteMutai Daniel50% (2)

- Eastern Refinery Limited: Furnace Fuel To F1101Document2 pagesEastern Refinery Limited: Furnace Fuel To F1101Kaisar JamilNo ratings yet

- FabricationDocument7 pagesFabricationg-ipgp23271000No ratings yet

- Mindanao Polytechnic College General Santos City Midterm Exam - Engineering Materials (Fme 5) DEADLINE: MAY 31, 2021 (6:00 P.M.), MONDAYDocument3 pagesMindanao Polytechnic College General Santos City Midterm Exam - Engineering Materials (Fme 5) DEADLINE: MAY 31, 2021 (6:00 P.M.), MONDAYkeith tambaNo ratings yet

- ASTM A325 - Portland BoltDocument3 pagesASTM A325 - Portland BoltHector BalderaNo ratings yet

- A 240 - A 240M - 04 Qti0mc0wneeDocument12 pagesA 240 - A 240M - 04 Qti0mc0wneeEduardoNo ratings yet

- Steel-Grits ROTOCASTDocument8 pagesSteel-Grits ROTOCASTSama UmateNo ratings yet

- DURMAT Flux Cored Wires For Wear Protection Rev 10 RedDocument28 pagesDURMAT Flux Cored Wires For Wear Protection Rev 10 RedandreasNo ratings yet

- Astm A 463-A 463M-02Document6 pagesAstm A 463-A 463M-02Anton Thomas Punzalan100% (4)

- Chapter 4 Kaedah Penunjuk Bentuk Permukaan Ukuran Had Terima Fit Simbol Bentuk PermukaanDocument21 pagesChapter 4 Kaedah Penunjuk Bentuk Permukaan Ukuran Had Terima Fit Simbol Bentuk PermukaanhaziqismailNo ratings yet

- Fixed Tank Cleaning Machine Pm-10Document89 pagesFixed Tank Cleaning Machine Pm-10Mustafa YıldırımNo ratings yet

- Screw Thread Calculations - Roy MechDocument6 pagesScrew Thread Calculations - Roy Mechangelo collaNo ratings yet

- SteelMint Daily Report As On 08 Mar 2021Document17 pagesSteelMint Daily Report As On 08 Mar 2021manish367No ratings yet

- Bollard Guide TrelleborgDocument9 pagesBollard Guide Trelleborgcost_engineer100% (2)

- Choosing The Right RacewayDocument6 pagesChoosing The Right RacewayAngela Sofia Rosas GarcesNo ratings yet

- AU0087 MC Mill Circuit BrochureFINAL - v2 - LoresDocument8 pagesAU0087 MC Mill Circuit BrochureFINAL - v2 - LoresEDDY PINONo ratings yet

- Environment Degradation of Materials - 1Document27 pagesEnvironment Degradation of Materials - 1NSHIMIYIMANA Jean d'AmourNo ratings yet

- Jis G4308Document13 pagesJis G4308ATULNo ratings yet

- Alloy Steel Seamless Pipes ASTM A335 P5Document6 pagesAlloy Steel Seamless Pipes ASTM A335 P5amin.qcNo ratings yet

- Colored Gold - WikipediaDocument30 pagesColored Gold - Wikipediashehalan nilumindaNo ratings yet

- Threaded Accessories: Fig. B3188 - Standard U-Bolt With 4 Hex Nuts Fig. B3188C - Standard Plastic Coated U-BoltDocument2 pagesThreaded Accessories: Fig. B3188 - Standard U-Bolt With 4 Hex Nuts Fig. B3188C - Standard Plastic Coated U-BoltJulio César MaltezNo ratings yet

- Plate Design For Husky Manifold Systems - V6.0-English PDFDocument29 pagesPlate Design For Husky Manifold Systems - V6.0-English PDFSSMNo ratings yet

- GlassDocument33 pagesGlassNeerajaNo ratings yet

- Astm A312Document12 pagesAstm A312Ruth Sarai YañezNo ratings yet

- MIL-R-5031 - B (Rods and Wire, Welding, Corrosion and Heat Resistant Alloys) (Notice 1)Document1 pageMIL-R-5031 - B (Rods and Wire, Welding, Corrosion and Heat Resistant Alloys) (Notice 1)ccorp00890% (1)

- WN - Welding Neck Flange Ansi b16.5, Facing - RF, FF, and RTJDocument2 pagesWN - Welding Neck Flange Ansi b16.5, Facing - RF, FF, and RTJindikumaNo ratings yet

- General GrindingDocument28 pagesGeneral GrindingRavi Arjun Kumar100% (1)

- Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape Metal (Fox Chapel Publishing) Over 400 Step-by-Step Photos to Help You Learn Hands-On Welding and Avoid Common Mistakes - Andrew PearceDocument6 pagesFarm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape Metal (Fox Chapel Publishing) Over 400 Step-by-Step Photos to Help You Learn Hands-On Welding and Avoid Common Mistakes - Andrew Pearcecazikoce0% (1)

- 40°C To + 100°C - 50°C To + 135°C: Product ApplicationDocument1 page40°C To + 100°C - 50°C To + 135°C: Product Applicationaleem ycNo ratings yet

- Application of Refractory Metals and AlloysDocument36 pagesApplication of Refractory Metals and Alloysbugoff700No ratings yet

MS-1000-Material Specifications For Steel

MS-1000-Material Specifications For Steel

Uploaded by

ALEX MURPHYOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS-1000-Material Specifications For Steel

MS-1000-Material Specifications For Steel

Uploaded by

ALEX MURPHYCopyright:

Available Formats

Page 1 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:0301-CR-ST-FQ-T2-S2-No.3

Mtl Group:Stainless Steel Material: 0301

Mtl Spec Code:22

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Forming Quality Temper: Half Hard Surface : Bright

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 666 Addnl. Spec: SAE J405

Exception:

Grain Size: Note: Thickness +/- .001 Width +/- .005.

Hardness: This material is specified by yield strength (110,000 lbs/ins).

Fitness Note: Fitness For Use: This material must be fit for forming. The end product will be utilized in an

occupant restraint system as a spring.

Std Min Max Std Min Max

Carbon . . . 0.150 Silicon . . . 1.000

Manganese . : 2.000 Nickel . . . 6.000 8.000

Phosphorus . 0.045 Chromium . . 16.000 18.000

Sulphur . . . 0.030 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 2 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:050 XF-1P-ST-SQ-TT-AR-No.3

Mtl Group:High Strength Steel Material: 050 XF

Mtl Spec Code: 18

Final Processing: Hot rolled followed by one pass cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Not Specified Surface : As Rolled

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A1008/A 1008M 04b HSLAS-F Addnl. Spec:

Exception: Substitution of 050 XF Material- Per SAE J1392 is acceptable.

Grain Size: Note:

Hardness:

This material is specified by yield strength.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.150 Silicon . . .

Manganese . : 1.650 Nickel . . . 0.200

Phosphorus . 0.020 Chromium . . 0.150

Sulphur . . . 0.025 Molybdenum : 0.060

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 3 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description: 050 XF-HR-ST-SQ-TT-PO-No.3

Mtl Group: High Strength Steel Material: 050 XF

Mtl Spec Code:1

Final Processing: Hot rolled. Mtl Form: Strip

Quality: Special Quality Temper: Not Specified Surface : Pickled & Oiled

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM 1008/A 1008M 04b Addnl. Spec:

Exception: Substitution of 050 XLF Material- Per SAE J1392 is acceptable.

Grain Size: Note:

Hardness:

This material is specified by yield strength.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.150 Silicon . . .

Manganese . : 1.650 Nickel . . . 0.200

Phosphorus . 0.020 Chromium . . 0.150

Sulphur . . . 0.025 Molybdenum : 0.060

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 4 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description: 060 XF-1P-ST-SQ-TT-AR-No.3

Mtl Group: High Strength Steel Material: 060 XF

Mtl Spec Code: 2

Final Processing: Hot rolled followed by one pass cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Not Specified Surface : As Rolled

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 1008/A 1008M 04b HSLA-F Addnl. Spec:

Exception: Substitution of 060 XLF Material- Per SAE J1392 is acceptable.

Grain Size: Note:

Hardness:

This material is specified by yield strength.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processes. The end

product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.150 Silicon . . .

Manganese . : 1.650 Nickel . . . 0.200

Phosphorus . 0.020 Chromium . . 0.150

Sulphur . . . 0.025 Molybdenum : 0.060

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 5 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:060 XF-HC-ST-SQ-TT-PO-No.3

Mtl Group:High Strength Steel Material:060 XF

Mtl Spec Code:34

Final Processing: Hot or Cold Rolled Mtl Form: Strip

Quality: Special Quality Temper: Not Specified Surface : Pickled & Oiled

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A1011/A 1011M HSLA-F Addnl. Spec: ASTM A1008/A 1008M

Exception: Substitution of 080 XLF Material- Per SAE J1392 is acceptable.

Grain Size: Note:

Hardness:

This material is specified by yield strength.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.150 Silicon . . .

Manganese . : 1.650 Nickel . . . 0.200

Phosphorus . 0.020 Chromium . . 0.150

Sulphur . . . 0.025 Molybdenum : 0.060

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 6 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:060 XF-HR-ST-SQ-TT-PO-No.3

Mtl Group:High Strength Steel Material: 060 XF

Mtl Spec Code:3

Final Processing: Hot rolled. Mtl Form: Strip

Quality: Special Quality Temper: Not Specified Surface : Pickled & Oiled

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A1011/A 1011M 04a HSLA-F Addnl. Spec:

Exception: Substitution of 080 XLF Material- Per SAE J1392 is acceptable.

Grain Size: Note:

Hardness:

This material is specified by yield strength.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.150 Silicon . . .

Manganese . : 1.650 Nickel . . . 0.200

Phosphorus . 0.020 Chromium . . 0.150

Sulphur . . . 0.025 Molybdenum : 0.060

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 7 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:080 XF-HR-ST-SQ-TT-PO-No.3

Mtl Group:High Strength Steel Material: 080 XF

Mtl Spec Code: 35

Final Processing: Hot rolled. Mtl Form: Strip

Quality: Special Quality Temper: Not Specified Surface : Pickled & Oiled

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A1011/A 1011M 04a HSLAS-F Addnl. Spec:

Exception: Substitution of 080 XLF Material- Per SAE J1392 is acceptable.

Grain Size: Note:

Hardness:

This material is specified by yield strength.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.150 Silicon . . .

Manganese . : 1.650 Nickel . . . 0.200

Phosphorus . 0.020 Chromium . . 0.150

Sulphur . . . 0.025 Molybdenum : 0.160

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 8 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1008-CR-SH-CQ-AR-AR-N/A

Mtl Group:Low Carbon Steel Material: 1008

Mtl Spec Code:33

Final Processing: Cold rolled. Mtl Form: Sheet

Quality: Commercial Quality Temper: As Rolled Surface : As Rolled

Edge Condition: Not Applicable

Gen Spec: ASTM A 109 Addnl. Spec: Composition per X1.1 ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

60 - 75 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.100 Silicon . . .

Manganese . : 0.250 0.500 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 9 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description: 1008-CR-ST-CQ-T2-PO-No.3

Mtl Group:Low Carbon Steel Material:1008

Mtl Spec Code:44

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Half Hard Surface : Pickled & Oiled

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 109 Addnl. Spec: Composition per X1.1 ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

60 - 75 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.100 Silicon . . .

Manganese . : 0.250 0.500 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 10 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1008-CR-ST-CQ-T4-S1-No.3

Mtl Group:Low Carbon Steel Material:1008

Mtl Spec Code: 37

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Skin Rolled Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 109 Addnl. Spec: Composition per X1.1 ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

B65 Max

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processes. The end

product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.100 Silicon . . .

Manganese . : 0.500 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 11 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1008-HR-ST-CQ-T3-S1-No.3

Mtl Group:Low Carbon Steel Material:1008

Mtl Spec Code:42

Description: 1008-HR-ST-CQ-T3-S1-No.3 Mtl Group: Low Carbon Steel Material: 1008

Final Processing: Hot rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: As Rolled Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 569/A 569M Addnl. Spec: Composition per ASTM A682

Exception:

Grain Size: Note:

Hardness:

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processes. The end

product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.100 Silicon . . .

Manganese . : 0.500 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 12 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1010-1P-ST-CQ-T3-S1-No.3

Mtl Group:Low Carbon Steel Material: 1010

Mtl Spec Code: 21

Final Processing: Hot rolled followed by one pass cold rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Quarter Hard Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A109 Addnl. Spec: Compostion per ASTM A568/A568M.

Exception: No Exception.

Grain Size: Note:

Hardness:

60-75 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processes

The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.080 0.130 Silicon . . .

Manganese . : 0.300 0.600 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 13 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1010-CR-SH-CQ-AR-AR-N/A

Mtl Group:Low Carbon Steel Material:1010

Mtl Spec Code:32

Final Processing: Cold rolled. Mtl Form: Sheet

Quality: Commercial Quality Temper: As Rolled Surface : As Rolled

Edge Condition: Not Applicable

Gen Spec: ASTM A 109 Addnl. Spec: Composition per X1.1 ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

60 - 75 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.080 0.130 Silicon . . .

Manganese . : 0.300 0.600 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 14 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1010-CR-ST-CQ-T2-PO-No.3

Mtl Group:Low Carbon Steel Material:1010

Mtl Spec Code:45

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Half Hard Surface : Pickled & Oiled

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 569/A 569M Addnl. Spec: Composition per ASTM A682

Exception: No Exceptions

Grain Size: Note:

Hardness:

60 - 75 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.080 0.130 Silicon . . .

Manganese . : 0.300 0.600 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 15 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1010-CR-ST-CQ-T3-S1-No.3

Mtl Group:Low Carbon Steel Material:1010

Mtl Spec Code:4

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Quarter Hard Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 109 Addnl. Spec: Composition per X1.1 ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

60 - 75 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.080 0.130 Silicon . . .

Manganese . : 0.300 0.600 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 16 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1010-CR-ST-CQ-T4-S1-No.3

Mtl Group:Low Carbon Steel Material:1010

Mtl Spec Code:5

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Skin Rolled Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 109 Addnl. Spec: Composition per X1.1 ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

HRB 65 Max

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.080 0.130 Silicon . . .

Manganese . : 0.300 0.600 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 17 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1010-CR-ST-CQ-T4-S2-No.3

Mtl Group:Low Carbon Steel Material:1010

Mtl Spec Code:19

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Skin Rolled Surface : Bright

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 109 Addnl. Spec: Composition per X1.1 ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

Fitness

Fitness Note:

Std Min Max Std Min Max

Carbon . . . 0.080 0.130 Silicon . . .

Manganese . : 0.300 0.600 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 18 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1010-HR-ST-CQ-T3-S1-No.3

Mtl Group:Low Carbon Steel Material:1010

Mtl Spec Code:6

Final Processing: Hot rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Quarter Hard Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 569/A 569M Addnl. Spec: Composition per ASTM A682

Exception: No Exceptions

Grain Size: Note:

Hardness:

60 - 75 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.080 0.130 Silicon . . .

Manganese . : 0.300 0.600 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 19 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1018-HR-SH-CQ-T3-S1-No.3

Mtl Group:Low Carbon Steel Material:1018

Mtl Spec Code: 38

Final Processing: Hot rolled. Mtl Form: Sheet

Quality: Commercial Quality Temper: Quarter Hard Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 109 Addnl. Spec: Coposition per X1.1 ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

70 - 85 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.140 0.200 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 20 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1020-CR-ST-CQ-T2-PO-No.3

Mtl Group:Low Carbon Steel Material:1020

Mtl Spec Code:46

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Half Hard Surface : Pickled & Oiled

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 109 Addnl. Spec: Composition per X1.1 ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

70 - 85 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.170 0.230 Silicon . . .

Manganese . : 0.300 0.600 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 21 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1020-CR-ST-CQ-T2-S1-No.3

Mtl Group:Low Carbon Steel Material:1020

Mtl Spec Code:7

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Half Hard Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 109 Addnl. Spec: Composition per X1.1 ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

70 - 85 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.170 0.230 Silicon . . .

Manganese . : 0.300 0.600 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 22 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1020-HR-SH-CQ-T3-S1-No.3

Mtl Group:Low Carbon Steel Material:1020

Mtl Spec Code:39

Final Processing: Hot rolled. Mtl Form: Sheet

Quality: Commercial Quality Temper: Quarter Hard Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 109 Addnl. Spec: Composition per ASTM A568/A568M

Exception: No Exceptions

Grain Size: Note:

Hardness:

70 - 85 HRB

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.170 0.230 Silicon . . .

Manganese . : 0.300 0.600 Nickel . . .

Phosphorus . 0.030 Chromium . .

Sulphur . . . 0.035 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 23 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1040-CR-ST-CQ-SA-S1-No.3

Mtl Group:Medium Carbon Steel Material:1040

Mtl Spec Code:8

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Spheroidize Annealed Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 684/684M Addnl. Spec: Composition per ASTM A682

Exception:

Grain Size: Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: Per ASTM A684/684M, Figure 2.

Fitness

Fitness Note:

Std Min Max Std Min Max

Carbon . . . 0.370 0.440 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 24 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1040-HR-ST-CQ-IN-S1-No.3

Mtl Group:Medium Carbon Steel Material:1040

Mtl Spec Code:9

Final Processing: Hot rolled. Mtl Form: Strip

Quality: Commercial Quality Temper: Intermediate Hardness Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 569/A 569M Addnl. Spec: Composition per ASTM A682

Exception:

Grain Size: Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: HRB 90 Max.

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.370 0.440 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure:

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 25 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1050-1P-ST-SQ-SA-S1-No.1

Mtl Group:High Carbon Steel Material:1050

Mtl Spec Code:27

Final Processing: Hot rolled followed by one pass cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Spheroidize Annealed Surface : Dull

Edge Condition: Round edge.

Gen Spec: ASTM A 749/749M Addnl. Spec:

Exception: Substitution of cold rolled material per IMMI Spec 1050 CR ST-SQ-SA-S1 is acceptable.

Grain Size: 6-9 Grain Size Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: Per ASTM A684/684M, Figure 2.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.480 0.550 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 26 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1050-1P-ST-SQ-SA-S1-No.3

Mtl Group:High Carbon Steel Material:1050

Mtl Spec Code:10

Final Processing: Hot rolled followed by one pass cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Spheroidize Annealed Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 749/749M Addnl. Spec:

Exception: Substitution of cold rolled material per IMMI Spec 1050 CR ST-SQ-SA-S1 is acceptable.

Grain Size: 6-9 Grain Size Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: Per ASTM A684/684M, Figure 2.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.480 0.550 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 27 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1050-1P-ST-SQ-SA-S1-No.4

Mtl Group:High Carbon Steel Material:1050

Mtl Spec Code:29

Final Processing: Hot rolled followed by one pass cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Spheroidize Annealed Surface : Dull

Edge Condition: Round edge produced by edge rolling.

Gen Spec: ASTM A 749/749M Addnl. Spec:

Exception: Substitution of cold rolled material per IMMI Spec 1050 CR ST-SQ-SA-S1 is acceptable.

Grain Size: 6-9 Grain Size Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: Per ASTM A684/684M, Figure 2.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.480 0.550 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 28 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1050-CR-ST-SQ-SA-AR-No.3

Mtl Group:High Carbon Steel Material:1050

Mtl Spec Code:20

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Spheroidize Annealed Surface : As Rolled

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 684/684M Addnl. Spec: Composition per ASTM A682

Exception:

Grain Size: 6-9 Grain Size Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: Per ASTM A684/684M, Figure 2.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.480 0.550 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 29 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1050-CR-ST-SQ-SA-S1-No.3

Mtl Group:High Carbon Steel Material:1050

Mtl Spec Code: 11

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Spheroidize Annealed Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 684/684M Addnl. Spec: Composition per ASTM A682

Exception:

Grain Size: 6-9 Grain Size Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: Per ASTM A684/684M, Figure 2.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.480 0.550 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 30 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1050-CR-ST-SQ-SA-S2-No.3

Mtl Group:High Carbon Steel Material:1050

Mtl Spec Code:12

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Spheroidize Annealed Surface : Bright

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 684/684M Addnl. Spec: Composition per ASTM A682

Exception:

Grain Size: 6-9 Grain Size Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: Per ASTM A684/684M, Figure 2.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.480 0.550 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 31 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1050-CRG-ST-SQ-SA-S1-No.3

Mtl Group:High Carbon Steel Material:1050

Mtl Spec Code:30

Final Processing: CRS Followed by Additional Pass or Passes for Gage Control Mtl Form: Strip

Quality: Special Quality Temper: Spheroidize Annealed Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 684/684M Addnl. Spec: Composition per ASTM A682

Exception: Substitution of aluminum killed material is acceptable.

Grain Size: 6-9 Grain Size Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: Per ASTM A684/684M, Figure 2.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.480 0.550 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 32 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1050-HR-SH-SQ-SA-PO-No.3

Mtl Group:High Carbon Steel Material:1050

Mtl Spec Code:40

Final Processing: Hot rolled. Mtl Form: Sheet

Quality: Special Quality Temper: Spheroidize Annealed Surface :

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 684/684M Addnl. Spec: Composition per ASTM A682

Exception: No Exceptions.

Grain Size: Al Killed 6-9 Grain S Note: Grain size of the material should be predominately equiaxed with t

ize he range specified above. Grain size shall be determined in accord

ance with ASTM E112.

Hardness: Per ASTM A684/A684M, Figure 2.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.480 0.550 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or disintegrat

ing plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 33 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1050-HR-ST-SQ-SA-S1-No.3

Mtl Group:High Carbon Steel Material:1050

Mtl Spec Code:36

Final Processing: Hot rolled. Mtl Form: Strip

Quality: Special Quality Temper: Spheroidize Annealed Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 684/684M Addnl. Spec: Composition per ASTM A682

Exception:

Grain Size: 6-9 Grain Size Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: Per ASTM A684/684M, Figure 2.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.480 0.550 Silicon . . .

Manganese . : 0.600 0.900 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.050 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 34 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1050M-CR-ST-SQ-SA-S2-No.3

Mtl Group:High Carbon Steel Material:1050M

Mtl Spec Code:17

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Spheroidize Annealed Surface : Bright

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 684/684M Addnl. Spec:

Exception: Inclusion content (sulphides, alumina, silicates, and oxides) to be no greater than rating #2 (lig

ht) per ASTM E45.

Grain Size: 5 Grain Size Max. Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: HRB 76 Max.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, and plating processe

s. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.470 0.550 Silicon . . . 0.020

Manganese . : 0.450 0.750 Nickel . . .

Phosphorus . 0.020 Chromium . .

Sulphur . . . 0.020 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 35 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1095-CR-ST-SQ-SA-S1-No.3

Mtl Group:High Carbon Steel Material:1095

Mtl Spec Code:13

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Spheroidize Annealed Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 684/684M Addnl. Spec: Composition per ASTM A682

Exception: No Exceptions

Grain Size: Note: NOTE: Grain size of the material should be predominately equiaxed

with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: HRB 90 Max.

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.900 1.040 Silicon . . . 0.150 0.300

Manganese . : 0.300 0.500 Nickel . . .

Phosphorus . 0.035 Chromium . .

Sulphur . . . 0.040 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 36 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1141-CR-BR-SQ-A-AR-N/A

Mtl Group:Medium Carbon Steel Material:1141

Mtl Spec Code:14

Final Processing: Cold rolled. Mtl Form: Bar

Quality: Special Quality Temper: Annealed Surface : As Rolled

Edge Condition: Not Applicable

Gen Spec: ASTM A 29 /A 29M Addnl. Spec:

Exception: No Exceptions

Grain Size: Si Killed, 6-9 Grain Note: NOTE: Grain size of the material should be predominately equiaxed

Size with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: 85 HRB MAX

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.370 0.450 Silicon . . . 0.200

Manganese . : 1.350 1.650 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.080 0.130 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 37 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:1144-CR-BR-SQ-A-AR-N/A

Mtl Group:Medium Carbon Steel Material:1144

Mtl Spec Code: 31

Final Processing: Cold rolled. Mtl Form: Bar

Quality: Special Quality Temper: Annealed Surface : As Rolled

Edge Condition: Not Applicable

Gen Spec: ASTM A 29 /A 29M Addnl. Spec:

Exception: No Exceptions

Grain Size: Si Killed, 6-9 Grain Note: NOTE: Grain size of the material should be predominately equiaxed

Size with the range as specified above. Grain size shall be determine

d in accordance with ASTM E112.

Hardness: 85 HRB MAX

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.400 0.480 Silicon . . .

Manganese . : 1.350 1.650 Nickel . . .

Phosphorus . 0.040 Chromium . .

Sulphur . . . 0.240 0.330 Molybdenum :

Aluminum . . Boron . . . .

Microstructure: NOTE: Minimum 90% spheroidal carbide structure with no evidence of lamellar pearlite or dis

integrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 38 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:4130-CR-BR-SQ-AN-AR-N/A

Mtl Group:Alloy Steel Material: 4130

Mtl Spec Code:47

Final Processing: Cold rolled. Mtl Form: Bar

Quality: Special Quality Temper: Annealed Surface : As Rolled

Edge Condition: Not Applicable

Gen Spec: ASTM A 505 Addnl. Spec: ASTM 506

Exception: No Exceptrions

Grain Size: 6 -9 Grain Size Note: Grain size of the material should be predominately equiaxed with t

he range specified above. Grain size shall be determined in accord

ance with ASTM E112.

Hardness: 85 HRB Max

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.

Std Min Max Std Min Max

Carbon . . . 0.280 0.330 Silicon . . . 0.150 0.350

Manganese . : 0.400 0.600 Nickel . . .

Phosphorus . 0.035 Chromium . . 0.800 1.100

Sulphur . . . 0.035 Molybdenum : 0.150 0.250

Aluminum . . Boron . . . .

Microstructure: Minimum 90% spheroidal carbide structure with no evidence of lamellar or disintegrating plates.

Material shall be free of pits, laminations and any other surface imperfections, consistent with industry

standards for the quality specified, which may be detrimental in the manufacture of the product for which the

material is intended. Continuous cast material is preferred.

Steel mill heat number, chemistry and master coil number used to manufacture the component lot number of each shipment must be certified

per IMMI Procedure QA-33.

IMMI Bringing Safety to People™

Page 39 of 44

Material Specifications for Steel

Revision Date: June 9, 2010

Description:4130-CR-ST-SQ-AN-S1-No.3

Mtl Group:Alloy Steel Material:4130

Mtl Spec Code:41

Final Processing: Cold rolled. Mtl Form: Strip

Quality: Special Quality Temper: Annealed Surface : Dull

Edge Condition: Approx. square edge by slitting, not filing.

Gen Spec: ASTM A 505 Addnl. Spec: ASTM 506

Exception: No Exceptrions

Grain Size: 6 -9 Grain Size Note: Grain size of the material should be predominately equiaxed with t

he range specified above. Grain size shall be determined in accord

ance with ASTM E112.

Hardness: 85 HRB Max

Fitness

Fitness Note: Fitness For Use: This material must be fit for blanking, forming, heat treating, and p

lating processes. The end product will be utilized in an occupant restraint system.