Professional Documents

Culture Documents

A320-25-1BWX R00 Dt. 12.03.21

A320-25-1BWX R00 Dt. 12.03.21

Uploaded by

Pradeep K sCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A320-25-1BWX R00 Dt. 12.03.21

A320-25-1BWX R00 Dt. 12.03.21

Uploaded by

Pradeep K sCopyright:

Available Formats

A318/A319/A320/A321

SERVICE BULLETIN

CONF ALL

AIRBUS

2, ROND POINT EMILE DEWOITINE

31700 BLAGNAC

FRANCE

The content of this document is the property of Airbus. All rights including copyrights are reserved.

It is supplied in confidence and commercial security on its contents must be maintained.

It must not be used for any purpose other than that for which it is supplied, nor may information

contained in it be disclosed to unauthorized persons.

It must not be reproduced in whole or in part without permission in writing from the owners of the

copyright. Requests for reproduction of any data in this document and the media authorized for it must

be addressed to Airbus.

ATA SYSTEM: 25

TITLE: EQUIPMENT/FURNISHINGS - BUFFET AND GALLEY - REPLACE GALLEY

G1 AND G5 AND INSTALL NEW FLOOR PANELS

MODIFICATION No.:

168687K39692

REV 00 Mar 12/21 A320-25-1BWX

Page 1

A318/A319/A320/A321

SERVICE BULLETIN

SUMMARY

ATA SYSTEM: 25

TITLE: EQUIPMENT/FURNISHINGS - BUFFET AND GALLEY - REPLACE GALLEY

G1 AND G5 AND INSTALL NEW FLOOR PANELS

SUMMARY

This summary is for information only and is not approved for modification of the aircraft.

A. MODIFICATIONS

MODIFICATION CLASSIFICATION

MAJOR None

MINOR 168687K39692

NOTE: As per EASA IR 21, a minor change is one that has no appreciable effect on the

mass, balance, structural strength, reliability, operational characteristics affecting

the airworthiness of the product. All other changes are major changes.

B. REASON

(1) History

This Service Bulletin is issued further to an operator’s request.

(2) Objective/Action

This Service Bulletin details the work necessary to replace the existing AEROSUD

galleys G1 and G5 by BUCHER galleys.

This includes the installation of new floor panel for additional hardpoint of galley G5,

new certified catering and adaptation of Non Textile Floor (NTF).

(3) Advantages

Accomplishment of this Service Bulletin fulfills the operator’s request.

(4) Operational/Maintenance Consequences

The Operational/Maintenance Consequences of this Service Bulletin are covered by

the update of the affected publications detailed in "PLANNING INFORMATION".

C. GENERAL EVALUATION

EVALUATION TABLE

COMPLIANCE OPTIONAL COST SAVING NO

A/C OPERATION YES VENDOR SB NO

AFFECTED

CANCELS INSPECTION SB NO ETOPS AFFECTED NO

PAX COMFORT AFFECTED NO POTENTIAL AD NO

RELIABILITY AFFECTED NO STRUCTURAL LIFE EXTENSION NO

LIFE LIMIT NO LINE MAINTENANCE AFFECTED NO

NOTE: Service Bulletin for convenience or option.

D. MAINTENANCE CONFIGURATION

No specific aircraft maintenance configuration required.

REV 00 Mar 12/21 A320-25-1BWX

Page 2

A318/A319/A320/A321

SERVICE BULLETIN

SUMMARY

E. MATERIAL PRICE INFORMATION

(1) Modification

(a) Task set A320-A-25-XX-1BWX-01000-93AA-A Modification

MATERIAL PRICE INFORMATION TABLE

QTY

MATERIAL SET PRICE PER A/C MAIN PARTS

PER A/C

Part kit 251BWXD02R01 1 See SB Panel

Part kit 251BWXD03R02 1 See SB Coverings tapes

Part kit 251BWXD05R01 1 See SB Beam, angles

Equipment See SB See Note Galleys, bushings, kits,

heaters, ovens

NOTE: Price information to be obtained from the given supplier.

F. APPLICABILITY

This Service Bulletin is applicable to this (these) operator(s):

IGO

NOTE: This Service Bulletin is written for the operators listed above. The modification in

this Service Bulletin can be done by other operators. If other operators want to do

this modification, use the RFC/RMO procedure and write to:

AIRBUS

2 ROND POINT EMILE DEWOITINE

31700 BLAGNAC

FRANCE

G. CONCURRENT REQUIREMENTS

None

H. NATURE OF THE WORK

(1) Modification

(a) Task set A320-A-25-XX-1BWX-01000-93AA-A Modification

AIRCRAFT YES

EQUIPMENT YES

I. MANPOWER

(1) Modification

(a) Task set A320-A-25-XX-1BWX-01000-93AA-A Modification

MANPOWER

TOTAL MAN-HOURS 46.50 h

ELAPSED TIME (HOURS) 25.00 h

REV 00 Mar 12/21 A320-25-1BWX

Page 3

A318/A319/A320/A321

SERVICE BULLETIN

ATA SYSTEM: 25

TITLE: EQUIPMENT/FURNISHINGS - BUFFET AND GALLEY - REPLACE GALLEY

G1 AND G5 AND INSTALL NEW FLOOR PANELS

1. PLANNING INFORMATION

A. APPLICABILITY

NOTE: This/These modification(s) is/are applicable by Service Bulletin only.

(1) Models

ON A/C 04481

320-232

CONF ALL

(2) Applicability by MSN

04481

(3) MSN by configuration

MSN CONFIGURATION

04481 001

(4) Configuration definition

Configuration 001

CONF 001 is applicable for all the aircraft affected by this Service Bulletin as a

standard configuration.

CONF 001 retrofits following modifications: 168687K39692.

B. CONCURRENT REQUIREMENTS

None

C. REASON

(1) History

This Service Bulletin is issued further to an operator’s request.

(2) Objective/Action

This Service Bulletin details the work necessary to replace the existing AEROSUD

galleys G1 and G5 by BUCHER galleys.

This includes the installation of new floor panel for additional hardpoint of galley G5,

new certified catering and adaptation of Non Textile Floor (NTF).

(3) Advantages

Accomplishment of this Service Bulletin fulfills the operator’s request.

(4) Operational/Maintenance Consequences

The Operational/Maintenance Consequences of this Service Bulletin are covered by

the update of the affected publications detailed in "PLANNING INFORMATION".

D. DESCRIPTION

NOTE: The listed tasks are not in sequence with the work steps.

REV 00 Mar 12/21 A320-25-1BWX

Page 4

A318/A319/A320/A321

SERVICE BULLETIN

To accomplish this Service Bulletin it is necessary to:

(1) Modification

(a) Task set A320-A-25-XX-1BWX-01000-93AA-A Modification

1 Work Package 25-28 - Remove and Install the Non Textile Floor (NTF) and

the Mylar in the Cabin

2 Work Package 25-30 - Remove and Install the Galleys G1 and G5 and the

Catering in the Cabin

3 Work Package 53-40 - Install the Hardpoint under the Galley G5

4 Work Package 53-60 - Remove and Install the Floor Panel in the Cabin

5 Work Package 92-00 - Remove the Clips on the Circuit Breakers in Panel

123VU

E. COMPLIANCE

(1) Classification

OPTIONAL: Service Bulletin for convenience or option.

(2) Accomplishment Timescale

In accordance with operators' maintenance schedule.

F. APPROVAL

The technical content of this document is approved under the authority of the Design

Organisation Approval ref. EASA.21J.031.

If an aircraft listed in the applicability has a modification or repair embodied that is not

of AIRBUS origin, and which affects the content of this Service Bulletin, the operator

is responsible for obtaining approval by its airworthiness authority for any adaptation

necessary before incorporation of the Service Bulletin.

NOTE: The installation of the emergency equipment for the valid layout is under customer

responsibility and not part of this change.

G. MANPOWER

The manpower estimates given in this Service Bulletin are based on the direct labor cost to

do the work. These estimates assume that the work will be done by experienced personnel,

and may need to be revised upwards to suit operator’s circumstances. The estimates do not

include the time to prepare, plan or inspect the work. Manufacture and procurement of parts

and tools, drying times for paints, sealants, etc., and general administration work are also

not included.

(1) Modification

(a) Task set A320-A-25-XX-1BWX-01000-93AA-A Modification

PREPARATION

Job Set-up 2.00 h

PROCEDURE

Work Package 25-28 - Remove and Install the Non Textile 6.00 h

Floor (NTF) and the Mylar in the Cabin

Work Package 25-30 - Remove and Install the Galleys G1 26.00 h

and G5 and the Catering in the Cabin

REV 00 Mar 12/21 A320-25-1BWX

Page 5

A318/A319/A320/A321

SERVICE BULLETIN

Work Package 53-40 - Install the Hardpoint under the 1.00 h

Galley G5

Work Package 53-60 - Remove and Install the Floor Panel in 2.00 h

the Cabin

Work Package 92-00 - Remove the Clips on the Circuit 0.25 h

Breakers in Panel 123VU

PREPARATION FOR TEST

Energize Electrical Network 0.25 h

TEST

Test 5.00 h

CLOSE-UP

Close-up 4.00 h

TOTAL MAN-HOURS 46.50 h

ELAPSED TIME (HOURS) 25.00 h

H. WEIGHT AND BALANCE

The weight and balance estimates given in this Service Bulletin are based on the

Manufacturer's Empty Weight (MEW) and do not include operator's items. The definition of

MEW and operator's items is given in the Weight and Balance Manual (WBM), Ref. WBM.

Manufacturer's Empty Weight +0.404 kg (+0.891 lb)

Effect on Balance +13.246 kg.m (+95.808 lb.ft)

I. ELECTRICAL LOAD DATA

(1) Alternating Current (AC) Load Changes

The values listed in the table(s) show the increase (+) or decrease (-) of the electrical

load resulting from the accomplishment of this Service Bulletin.

(a) Circuit Breaker Data

Busbar: FIN 1XPA ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 1MC Existing

Designation: FWD GALLEY/FEEDER C

Nominal Power (Differential Value): +943 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +188.6 +471.5

Start +188.6 +471.5

Roll +188.6 +471.5

Take Off +188.6 +660.1

Climb +660.1 +660.1

Cruise +660.1 +660.1

Descent +188.6 +660.1

Landing +188.6 +471.5

Taxi +188.6 +471.5

REV 00 Mar 12/21 A320-25-1BWX

Page 6

A318/A319/A320/A321

SERVICE BULLETIN

(b) Circuit Breaker Data

Busbar: FIN 1XPB ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 1MC Existing

Designation: FWD GALLEY/FEEDER C

Nominal Power (Differential Value): +897 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +179.4 +448.5

Start +179.4 +448.5

Roll +179.4 +448.5

Take Off +179.4 +627.9

Climb +627.9 +627.9

Cruise +627.9 +627.9

Descent +179.4 +627.9

Landing +179.4 +448.5

Taxi +179.4 +448.5

(c) Circuit Breaker Data

Busbar: FIN 1XPC ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 1MC Existing

Designation: FWD GALLEY/FEEDER C

Nominal Power (Differential Value): +897 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +179.4 +448.5

Start +179.4 +448.5

Roll +179.4 +448.5

Take Off +179.4 +627.9

Climb +627.9 +627.9

Cruise +627.9 +627.9

Descent +179.4 +627.9

Landing +179.4 +448.5

Taxi +179.4 +448.5

(d) Circuit Breaker Data

Busbar: FIN 2XPA ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 2MC Existing

Designation: FWD GALLEY/FEEDER D

Nominal Power (Differential Value): +1322.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

REV 00 Mar 12/21 A320-25-1BWX

Page 7

A318/A319/A320/A321

SERVICE BULLETIN

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +264.5 +661.25

Start +264.5 +661.25

Roll +264.5 +661.25

Take Off +264.5 +925.75

Climb +925.75 +925.75

Cruise +925.75 +925.75

Descent +264.5 +925.75

Landing +264.5 +661.25

Taxi +264.5 +661.25

(e) Circuit Breaker Data

Busbar: FIN 2XPB ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 2MC Existing

Designation: FWD GALLEY/FEEDER D

Nominal Power (Differential Value): +1322.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +264.5 +661.25

Start +264.5 +661.25

Roll +264.5 +661.25

Take Off +264.5 +925.75

Climb +925.75 +925.75

Cruise +925.75 +925.75

Descent +264.5 +925.75

Landing +264.5 +661.25

Taxi +264.5 +661.25

(f) Circuit Breaker Data

Busbar: FIN 2XPC ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 2MC Existing

Designation: FWD GALLEY/FEEDER D

Nominal Power (Differential Value): +1437.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +287.5 +718.75

Start +287.5 +718.75

Roll +287.5 +718.75

Take Off +287.5 +1006.25

REV 00 Mar 12/21 A320-25-1BWX

Page 8

A318/A319/A320/A321

SERVICE BULLETIN

Flight Configuration Value (VA) Operational Value (VA) Max

Climb +1006.25 +1006.25

Cruise +1006.25 +1006.25

Descent +287.5 +1006.25

Landing +287.5 +718.75

Taxi +287.5 +718.75

(g) Circuit Breaker Data

Busbar: FIN 1XPA ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 16MC Existing

Designation: FWD GALLEY/FEEDER F

Nominal Power (Differential Value): +402.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +80.5 +201.25

Start +80.5 +201.25

Roll +80.5 +201.25

Take Off +80.5 +281.75

Climb +281.75 +281.75

Cruise +281.75 +281.75

Descent +80.5 +281.75

Landing +80.5 +201.25

Taxi +80.5 +201.25

(h) Circuit Breaker Data

Busbar: FIN 1XPB ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 16MC Existing

Designation: FWD GALLEY/FEEDER F

Nominal Power (Differential Value): +402.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +80.5 +201.25

Start +80.5 +201.25

Roll +80.5 +201.25

Take Off +80.5 +281.75

Climb +281.75 +281.75

Cruise +281.75 +281.75

Descent +80.5 +281.75

Landing +80.5 +201.25

Taxi +80.5 +201.25

REV 00 Mar 12/21 A320-25-1BWX

Page 9

A318/A319/A320/A321

SERVICE BULLETIN

(i) Circuit Breaker Data

Busbar: FIN 1XPC ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 16MC Existing

Designation: FWD GALLEY/FEEDER F

Nominal Power (Differential Value): +402.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +80.5 +201.25

Start +80.5 +201.25

Roll +80.5 +201.25

Take Off +80.5 +281.75

Climb +281.75 +281.75

Cruise +281.75 +281.75

Descent +80.5 +281.75

Landing +80.5 +201.25

Taxi +80.5 +201.25

(j) Circuit Breaker Data

Busbar: FIN 2XPA ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 3MC Existing

Designation: AFT GALLEY/FEEDER A

Nominal Power (Differential Value): +3967.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +793.5 +1983.75

Start +793.5 +1983.75

Roll +793.5 +1983.75

Take Off +793.5 +2777.25

Climb +2777.25 +2777.25

Cruise +2777.25 +2777.25

Descent +793.5 +2777.25

Landing +793.5 +1983.75

Taxi +793.5 +1983.75

(k) Circuit Breaker Data

Busbar: FIN 2XPB ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 3MC Existing

Designation: AFT GALLEY/FEEDER A

Nominal Power (Differential Value): +3967.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

REV 00 Mar 12/21 A320-25-1BWX

Page 10

A318/A319/A320/A321

SERVICE BULLETIN

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +793.5 +1983.75

Start +793.5 +1983.75

Roll +793.5 +1983.75

Take Off +793.5 +2777.25

Climb +2777.25 +2777.25

Cruise +2777.25 +2777.25

Descent +793.5 +2777.25

Landing +793.5 +1983.75

Taxi +793.5 +1983.75

(l) Circuit Breaker Data

Busbar: FIN 2XPC ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 3MC Existing

Designation: AFT GALLEY/FEEDER A

Nominal Power (Differential Value): +4082.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +816.5 +2041.25

Start +816.5 +2041.25

Roll +816.5 +2041.25

Take Off +816.5 +2857.75

Climb +2857.75 +2857.75

Cruise +2857.75 +2857.75

Descent +816.5 +2857.75

Landing +816.5 +2041.25

Taxi +816.5 +2041.25

(m) Circuit Breaker Data

Busbar: FIN 1XPA ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 12MC Existing

Designation: AFT GALLEY/FEEDER B

Nominal Power (Differential Value): +954.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +190.9 +477.25

Start +190.9 +477.25

Roll +190.9 +477.25

Take Off +190.9 +668.15

REV 00 Mar 12/21 A320-25-1BWX

Page 11

A318/A319/A320/A321

SERVICE BULLETIN

Flight Configuration Value (VA) Operational Value (VA) Max

Climb +668.15 +668.15

Cruise +668.15 +668.15

Descent +190.9 +668.15

Landing +190.9 +477.25

Taxi +190.9 +477.25

(n) Circuit Breaker Data

Busbar: FIN 1XPB ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 12MC Existing

Designation: AFT GALLEY/FEEDER B

Nominal Power (Differential Value): +897 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +179.4 +448.5

Start +179.4 +448.5

Roll +179.4 +448.5

Take Off +179.4 +627.9

Climb +627.9 +627.9

Cruise +627.9 +627.9

Descent +179.4 +627.9

Landing +179.4 +448.5

Taxi +179.4 +448.5

(o) Circuit Breaker Data

Busbar: FIN 1XPC ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 12MC Existing

Designation: AFT GALLEY/FEEDER B

Nominal Power (Differential Value): +897 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +179.4 +448.5

Start +179.4 +448.5

Roll +179.4 +448.5

Take Off +179.4 +627.9

Climb +627.9 +627.9

Cruise +627.9 +627.9

Descent +179.4 +627.9

Landing +179.4 +448.5

Taxi +179.4 +448.5

REV 00 Mar 12/21 A320-25-1BWX

Page 12

A318/A319/A320/A321

SERVICE BULLETIN

(p) Circuit Breaker Data

Busbar: FIN 1XPA ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 14MC Existing

Designation: AFT GALLEY/FEEDER E

Nominal Power (Differential Value): +2311.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +462.3 +1155.75

Start +462.3 +1155.75

Roll +462.3 +1155.75

Take Off +462.3 +1618.05

Climb +1618.05 +1618.05

Cruise +1618.05 +1618.05

Descent +462.3 +1618.05

Landing +462.3 +1155.75

Taxi +462.3 +1155.75

(q) Circuit Breaker Data

Busbar: FIN 1XPB ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 14MC Existing

Designation: AFT GALLEY/FEEDER E

Nominal Power (Differential Value): +2185 VA

Intermittent: YES Sheddable: NO Clipped: NO

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +437 +1092.5

Start +437 +1092.5

Roll +437 +1092.5

Take Off +793.5 +1529.5

Climb +1529.5 +1529.5

Cruise +1529.5 +1529.5

Descent +437 +1529.5

Landing +437 +1092.5

Taxi +437 +1092.5

(r) Circuit Breaker Data

Busbar: FIN 1XPC ATA/SubATA: 2456 Electrical Panel 123VU

Circuit Breaker: FIN 14MC Existing

Designation: AFT GALLEY/FEEDER E

Nominal Power (Differential Value): +2196.5 VA

Intermittent: YES Sheddable: NO Clipped: NO

REV 00 Mar 12/21 A320-25-1BWX

Page 13

A318/A319/A320/A321

SERVICE BULLETIN

Effects on electrical loads

Flight Configuration Value (VA) Operational Value (VA) Max

Ground +439.3 +1098.25

Start +439.3 +1098.25

Roll +439.3 +1098.25

Take Off +439.3 +1537.55

Climb +1537.55 +1537.55

Cruise +1537.55 +1537.55

Descent +439.3 +1537.55

Landing +439.3 +1098.25

Taxi +439.3 +1098.25

(2) Direct Current (DC) Load Changes

Not changed

J. REFERENCES

To accomplish this Service Bulletin, refer to:

- 251BWXTOP001 sheet 01(A00)

- D2507028108200 sheet BOM(AD)

- D2507028108200 sheet 20(AD)

(1) Modification

(a) Task set A320-A-25-XX-1BWX-01000-93AA-A Modification

AIRCRAFT MAINTENANCE MANUAL (AMM)

06-20-00, Page Block 001 06-31-53, Page Block 001

Task 12-34-24-869-002 Task 20-21-11-911-001

Task 24-41-00-861-002 Task 25-28-42-000-001

Task 25-28-42-400-001

Task 25-28-43-000-001 Task 25-31-42-000-001

Task 25-28-43-400-001 Task 25-31-42-400-001

Task 25-33-45-000-001 Task 25-35-00-710-015

Task 25-33-45-400-001 Task 25-35-00-710-023

Task 25-35-19-400-001 Task 25-35-27-000-001

Task 25-35-27-400-001

Task 53-00-00-000-801

Task 53-00-00-400-801

ELECTRICAL STANDARD PRACTICES MANUAL (ESPM)

20-55-00

IN SERVICE INFORMATION (ISI)

00.00.00135

REV 00 Mar 12/21 A320-25-1BWX

Page 14

A318/A319/A320/A321

SERVICE BULLETIN

STRUCTURAL REPAIR MANUAL (SRM)

51-24-00 51-40-00

51-42-00 51-43-00

51-44-00 51-75-12

DESIGN DRAWINGS SHEET(S)

251BWXM92001 sheet 01(A00)

D2528602505600 sheet 48

D2528602543200 sheet 48

D2528602543400 sheet 48

D2528887503800 sheet 36

D2528887504000 sheet 37

D2537031113000 sheets 87 to 91

D2537031203200 sheet 15

D5347229500000 sheet 01

D5367504502000 sheets 16 to 17

WEIGHT AND BALANCE MANUAL (WBM)

STANDARDS MANUAL (SM)

CONSUMABLE MATERIAL LIST (CML)

K. PUBLICATION AFFECTED

AIRCRAFT MAINTENANCE MANUAL (AMM)

CABIN CREW OPERATING MANUAL (CCOM)

ILLUSTRATED PART CATALOG (IPC)

STRUCTURAL REPAIR MANUAL (SRM)

This Service Bulletin has an impact on flight operations documentation. Refer to ISI

00.00.00135 paragraph "Flight Operations Products" for further information on the update

of affected Flight Operations Products.

Technical queries should be addressed through TechRequest on AirbusWorld using "Technical

Data/Support to report Service Bulletins" form.

L. INDUSTRY SUPPORT INFORMATION

Industry Support terms must be agreed between the Customer and AIRBUS in accordance

with the RFC (or RFC/RMO) procedure.

REV 00 Mar 12/21 A320-25-1BWX

Page 15

A318/A319/A320/A321

SERVICE BULLETIN

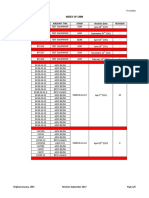

2. MATERIAL INFORMATION

A. MATERIAL APPLICABILITY

Material for task set A320-A-25-XX-1BWX-01000-93AA-A Modification

MATERIAL QTY SEE NOTES

Consumables See SB

Referenced consumables See SB

Part kit 251BWXD02R01 1

Part kit 251BWXD03R02 1

Part kit 251BWXD05R01 1

Equipment See SB

Referenced parts See SB

B. TOOLING

No tools

C. CONSUMABLES

Consumables for task set A320-A-25-XX-1BWX-01000-93AA-A Modification

ITEM REFERENCE CML DESCRIPTION DRAWING SEE NOTES

Silicone Sealant - Non

06BQD1 Textile Floor Jointing One

part

Non Hardening Jointing

06LCG9

Putty - Medium Temp. Area

14RCB1 Cord - Welding PVC

Referenced consumables for task set A320-A-25-XX-1BWX-01000-93AA-A

Modification

To accomplish this Service Bulletin it is necessary to use the consumable materials listed in:

Ref. AMM Task 25-28-42-000-001

Ref. AMM Task 25-28-42-400-001

Ref. AMM Task 25-28-43-000-001

Ref. AMM Task 25-28-43-400-001

Ref. AMM Task 25-31-42-400-001

Ref. AMM Task 25-33-45-400-001

Ref. AMM Task 53-00-00-400-801

D. LIST OF NEW PARTS

Part kit 251BWXD02R01

Availability

NOTE(S)

Sales terms must be agreed between the Customer and AIRBUS in accordance with

the RFC (or RFC/RMO) procedure.

Procurement address

NOTE(S)

REV 00 Mar 12/21 A320-25-1BWX

Page 16

A318/A319/A320/A321

SERVICE BULLETIN

The AIRBUS material is included in the commercial offer and as such will be supplied

by AIRBUS Upgrade Services. To facilitate the material reception, Airline Customers

are requested to contact:

- AIRBUS Upgrade Services

- Attn. Sales Manager

ITEM PART No. QTY (UM) KEYWORD DRAWING SEE NOTES

Work package 53-60

0074 E5367175605200 1 PANEL D5367504502000

0376 ABS5006-4G 0.500 (m) TAPE D5367504502000

0402 ABS0376-3-35 109 SCREW D5367504502000

0405 EN6131-3C1 17 NUT D5367504502000

0409 EN6131-3C2 46 NUT D5367504502000

NOTE(S)

Refer to the AIRBUS Ref. SM if you find part numbers of hardware components which

you cannot identify. The SM will give you the correct part number to part number

relationship.

Part kit 251BWXD03R02

Availability

NOTE(S)

Sales terms must be agreed between the Customer and AIRBUS in accordance with

the RFC (or RFC/RMO) procedure.

Procurement address

NOTE(S)

The AIRBUS material is included in the commercial offer and as such will be supplied

by AIRBUS Upgrade Services. To facilitate the material reception, Airline Customers

are requested to contact:

- AIRBUS Upgrade Services

- Attn. Sales Manager

ITEM PART No. QTY (UM) KEYWORD DRAWING SEE NOTES

Work package 25-28

0010 ABS5768A500 18 (m) TAPE D2528602505600

0000 497B67830WTBY 2.500 (m2) COVERING D2528602543200

0000 497B67830WTBZ 3 (m2) COVERING D2528602543400

0000 ABS5093B485 8 (m) FOIL D2528887503800

0000 ABS5093B485 9 (m) FOIL D2528887504000

Part kit 251BWXD05R01

Availability

NOTE(S)

Sales terms must be agreed between the Customer and AIRBUS in accordance with

the RFC (or RFC/RMO) procedure.

Procurement address

REV 00 Mar 12/21 A320-25-1BWX

Page 17

A318/A319/A320/A321

SERVICE BULLETIN

NOTE(S)

The AIRBUS material is included in the commercial offer and as such will be supplied

by AIRBUS Upgrade Services. To facilitate the material reception, Airline Customers

are requested to contact:

- AIRBUS Upgrade Services

- Attn. Sales Manager

ITEM PART No. QTY (UM) KEYWORD DRAWING SEE NOTES

Work package 53-40

0000 D5347229800000 1 BEAM D5347229500000

0002 D5347217124200 1 ANGLE D5347229500000

0004 D5347217124400 1 ANGLE D5347229500000

0648 EN6081AD6-05 6 RIVET D5347229500000

0865 DAN6-6-5 3 PIN D5347229500000

0906 NSA5075-6 3 COLLAR D5347229500000

0916 DAN12-6 8 COLLAR D5347229500000

0974 DAN7-6-4 8 PIN D5347229500000

NOTE(S)

Refer to the AIRBUS Ref. SM if you find part numbers of hardware components which

you cannot identify. The SM will give you the correct part number to part number

relationship.

Equipment for task set A320-A-25-XX-1BWX-01000-93AA-A Modification

Procurement address

NOTE(S)

Sales terms must be agreed between the Customer and AIRBUS in accordance with

the RFC (or RFC/RMO) procedure.

Equipment procurement conditions are defined in the commercial offer. For any

assistance, Airline Customers are requested to contact:

- AIRBUS Upgrade Services

- Attn. Sales Manager

ITEM PART No. QTY (UM) KEYWORD DRAWING SEE NOTES

Work package 25-30

0001 1311000-100 1 GALLEY D2537031113000 (1)

0002 1315000-100 1 GALLEY D2537031113000 (1)

0020 LN9424A63 0.03 (kg) WIRE D2537031113000 (1)

0024 NAS1291C3M 4 NUT D2537031113000 (1)

0025 NAS1801-3-8 4 SCREW D2537031113000 (1)

0026 NAS1149F0332P 4 WASHER D2537031113000 (1)

0028 DAN1174 0.004 (kg) VARNISH D2537031113000 (1)

0033 DA4-653-3SF8-71 0.3 (kg) SEALANT D2537031113000 (1)

0034 DA4-653-3S2 0.3 (kg) ADHESIVE D2537031113000 (1)

0035 DA4-653-3S2TRAN 0.6 (kg) ADHESIVE D2537031113000 (1)

REV 00 Mar 12/21 A320-25-1BWX

Page 18

A318/A319/A320/A321

SERVICE BULLETIN

ITEM PART No. QTY (UM) KEYWORD DRAWING SEE NOTES

0036 DA4-653-3H2 0.06 (kg) PRIMER D2537031113000 (1)

0038 10987425 0.016 (kg) GREASE D2537031113000 (1)

0040 NAS1611-317 18 PACKING D2537031113000 (1)

0041 A2537040622400 18 BUSHING D2537031113000 (1)

0050 NSA935807-20 4 CLAMP D2537031113000 (1)

0051 NSA935808C01 3 WASHER D2537031113000 (1)

0052 NAS1726-3E 5 NUT D2537031113000 (1)

0054 AS21919WCH13 2 CLAMP D2537031113000 (1)

0055 NAS1149C0332R 2 WASHER D2537031113000 (1)

0056 AS21919WCH05 4 CLAMP D2537031113000 (1)

0057 NAS1149CN816R 1 WASHER D2537031113000 (1)

0058 NAS1801-3-7 1 SCREW D2537031113000 (1)

0059 MS21919WCH5 2 CLAMP D2537031113000 (1)

0063 NAS1801-08-10 3 SCREW D2537031113000 (1)

0064 NSA5159-23 1 STUD D2537031113000 (1)

0065 NSA5527-03-06 1 SPACER D2537031113000 (1)

0101 1311085 1 KIT D2537031113000 (1)

0102 1311086 1 KIT D2537031113000 (1)

0103 1311049 1 KIT D2537031113000 (1)

0104 1311047 1 KIT D2537031113000 (1)

0105 1311048 1 KIT D2537031113000 (1)

0106 1311095 1 KIT D2537031113000 (1)

0107 1311051 1 KIT D2537031113000 (1)

0108 1311076 1 KIT D2537031113000 (1)

0109 1311072 1 KIT D2537031113000 (1)

0110 1311090 1 KIT D2537031113000 (1)

0111 0046085 1 KIT D2537031113000 (1)

0112 1311094 1 KIT D2537031113000 (1)

0201 1315102 1 KIT D2537031113000 (1)

0202 1315123 1 KIT D2537031113000 (1)

0203 1315122 1 KIT D2537031113000 (1)

0204 1315056 1 KIT D2537031113000 (1)

0205 1315051 1 KIT D2537031113000 (1)

0206 1315053 1 KIT D2537031113000 (1)

0207 1315045 1 KIT D2537031113000 (1)

0208 1315046 1 KIT D2537031113000 (1)

0209 1315047 1 KIT D2537031113000 (1)

0210 1315048 1 KIT D2537031113000 (1)

0211 1315092 1 KIT D2537031113000 (1)

0212 1315088 1 KIT D2537031113000 (1)

0213 1315085 1 KIT D2537031113000 (1)

REV 00 Mar 12/21 A320-25-1BWX

Page 19

A318/A319/A320/A321

SERVICE BULLETIN

ITEM PART No. QTY (UM) KEYWORD DRAWING SEE NOTES

0214 1315093 1 KIT D2537031113000 (1)

0215 1315095 1 KIT D2537031113000 (1)

0216 1315109 1 KIT D2537031113000 (1)

0217 1315116 1 KIT D2537031113000 (1)

0218 0046075 1 KIT D2537031113000 (1)

0001 4360004-80-0018 4 HEATER D2537031203200 (1)

0005 4310000-00-55 6 OVEN D2537031203200 (1)

NOTE(S)

Refer to the AIRBUS Ref. SM if you find part numbers of hardware components which

you cannot identify. The SM will give you the correct part number to part number

relationship.

(1): The components listed above are not an AIRBUS Kit, the required parts must be

ordered as necessary through the given channel.

Referenced parts for task set A320-A-25-XX-1BWX-01000-93AA-A Modification

To accomplish this Service Bulletin it is necessary to use the expendable parts listed in:

Ref. AMM Task 25-31-42-400-001

Ref. AMM Task 25-33-45-400-001

E. LIST OF EXISTING PARTS

No parts

REV 00 Mar 12/21 A320-25-1BWX

Page 20

A318/A319/A320/A321

SERVICE BULLETIN

3. ACCOMPLISHMENT INSTRUCTIONS

Task set A320-A-25-XX-1BWX-01000-93AA-A (A320-A-25-XX-1BWX-01ZZZ-93AZ-A)

Modification

WARNING: MAKE SURE THAT YOU OBEY ALL THE REMARKS AND SAFETY PRECAUTIONS

AS GIVEN IN THE RELATED INSTALLATION DRAWINGS.

WARNING: MAKE SURE THAT YOU OBEY ALL THE WARNINGS AND ALL THE CAUTIONS

INCLUDED IN THE REFERENCED PROCEDURES.

CAUTION: ALWAYS OBEY THE PRECAUTIONS THAT FOLLOW TO KEEP ELECTRICAL

WIRING IN A SATISFACTORY CONDITION (ELECTRICALLY AND MECHANICALLY

SERVICEABLE). WHEN YOU DO A MAINTENANCE WORK, REPAIRS OR

MODIFICATIONS, ALWAYS KEEP ELECTRICAL WIRING, COMPONENTS AND

THE WORK AREA AS CLEAN AS POSSIBLE. TO DO THIS:

- PUT PROTECTION, SUCH AS PLASTIC SHEETING, CLOTHS, ETC., AS

NECESSARY ON WIRING AND COMPONENTS.

- REGULARLY REMOVE ALL SHAVINGS, UNWANTED MATERIAL AND

OTHER CONTAMINATION.

THESE PRECAUTIONS WILL DECREASE THE RISK OF CONTAMINATION AND

DAMAGE TO THE ELECTRICAL WIRING INSTALLATION.

IF THERE IS CONTAMINATION, REFER TO Ref. ESPM 20-55-00.

NOTE: The accomplishment instructions of this Service Bulletin include procedures given in

other documents or in other sections of the Service Bulletin. When the words “refer to”

are used and the operator has a procedure accepted by the local authority he belongs to,

the accepted alternative procedure can be used. When the words “in accordance with”

are used then the given procedure must be followed.

NOTE: The access and close-up instructions, not comprising return to service tests, in this

Service Bulletin do not constitute or affect the technical intent of the Service Bulletin.

Operators can therefore, as deemed necessary, omit or add access and/or close-up steps

to add flexibility to their maintenance operations as long as the technical intent of the

Service Bulletin is met within the set parameters.

NOTE: Manual titles given in the accomplishment instructions are referred to by acronyms. Refer

to paragraph 1.J., References, for the definition of acronyms.

NOTE: This Service Bulletin contains the instructions for the on-aircraft maintenance necessary

to ensure the continued airworthiness of the aircraft.

For any deviations to the instructions, contact AIRBUS for further instructions and

approval.

NOTE: The listed tasks are not in sequence with the work steps. The operator can change the

sequence.

NOTE: Discarded parts must be managed at the operator's discretion.

A. TASK SET ASSOCIATED INFORMATION

Task Manpower

TOTAL MAN-HOURS 46.50 h

ELAPSED TIME (HOURS) 25.00 h

B. PREPARATION

(1) Task A320-A-25-XX-1BWX-01001-540A-A (A320-A-25-XX-1BWX-01ZZZ-540Z-A)

Job Set-up

REV 00 Mar 12/21 A320-25-1BWX

Page 21

A318/A319/A320/A321

SERVICE BULLETIN

Job Set-Up Information

Manpower/Resources/Skills

Man-hours 2.00 h

Minimum Number of person 2

Elapsed Time 1.00 h

Referenced Information

Manuals/Drawings References/Sheets

Task 12-34-24-869-002

Task 25-28-42-000-001

AMM

Task 25-31-42-000-001

Task 25-33-45-000-001

Procedure

NOTE: For the basic Aircraft configuration, refer to AMM Chapter “Introduction -

Aircraft status for maintenance" in Manual Front Matter section.

(a) Make sure that the aircraft is electrically grounded, refer to Ref. AMM Task 12-34-

24-869-002.

(b) Do the job set-up procedure specified in the removal of the forward galley unit,

G1, refer to Ref. AMM Task 25-31-42-000-001.

(c) Do the job set-up procedure specified in the removal of the AFT galley unit, G5,

refer to Ref. AMM Task 25-33-45-000-001.

(d) Do the job set-up procedure specified in the removal of the Non-Textile Floor

(NTF) covering, refer to Ref. AMM Task 25-28-42-000-001.

C. PROCEDURE

(1) Task A320-A-25-XX-1BWX-01001-920A-A (A320-A-25-XX-1BWX-01ZZZ-920Z-A)

Work Package 25-28 - Remove and Install the Non Textile Floor (NTF) and

the Mylar in the Cabin

Job Set-Up Information

Working Area

Impacted Zone Access / Work Location

220 Work location From Frame 12 to Frame 16

260 Work location From Frame 68 to Frame 70

Manpower/Resources/Skills

Man-hours 6.00 h

Minimum Number of person 2

Elapsed Time 3.00 h

Skills Cabin

REV 00 Mar 12/21 A320-25-1BWX

Page 22

A318/A319/A320/A321

SERVICE BULLETIN

Material necessary to do the job

Consumables

ITEM REFERENCE CML DESCRIPTION DRAWING SEE NOTES

Silicone Sealant - Non

06BQD1 Textile Floor Jointing One

part

14RCB1 Cord - Welding PVC

Part kit 251BWXD03R02

Referenced Information

Manuals/Drawings References/Sheets

06-20-00, Page Block 001

06-31-53, Page Block 001

Task 25-28-42-000-001

AMM

Task 25-28-42-400-001

Task 25-28-43-000-001

Task 25-28-43-400-001

CML CONSUMABLE MATERIAL LIST (CML)

D2528602505600 sheet 48

D2528602543200 sheet 48

D2528602543400 sheet 48

D2528887503800 sheet 36

D2528887504000 sheet 37

Procedure

(a) Standard practices

1 If you find process and material specifications that you do not know in

the design drawings, refer to the cross-reference list in the Process and

Material Specification (PMS).

2 For the identification of zones, refer to Ref. AMM 06-20-00, Page Block 001.

3 For the Frame (FR) identification, refer to Ref. AMM 06-31-53, Page Block

001.

4 For the specification of Material application codes given in this Service

Bulletin, refer to the Ref. CML.

(b) Remove and install the NTF in the cabin between Frame 12 and Frame 16 and

between Frame 68 and Frame 70.

Refer to Ref. AMM Task 25-28-42-000-001, Ref. AMM Task 25-28-42-400-001, Ref.

AMM Task 25-28-43-000-001 and Ref. AMM Task 25-28-43-400-001

Refer to this/these drawing(s):

Ref. D2528887503800 sheet 36

Ref. D2528887504000 sheet 37

Ref. D2528602505600 sheet 48

Ref. D2528602543200 sheet 48

Ref. D2528602543400 sheet 48

NOTE: Drawings D2528887503800 and D2528887504000 contains these

consumable materials:

REV 00 Mar 12/21 A320-25-1BWX

Page 23

A318/A319/A320/A321

SERVICE BULLETIN

Silicone Sealant - Non 06BQD1

Textile Floor Jointing

One part

Cord - Welding PVC 14RCB1

(2) Task A320-A-25-XX-1BWX-02001-920A-A (A320-A-25-XX-1BWX-02ZZZ-920Z-A)

Work Package 25-30 - Remove and Install the Galleys G1 and G5 and the

Catering in the Cabin

Job Set-Up Information

Working Area

Impacted Zone Access / Work Location

220 Work location From Frame 12 to Frame 16

260 Work location From Frame 68 to Frame 70

Manpower/Resources/Skills

Man-hours 26.00 h

Minimum Number of person 2

Elapsed Time 13.00 h

Skills Cabin

Material necessary to do the job

Equipment

ITEM PART No. QTY (UM) KEYWORD DRAWING SEE NOTES

Work package 25-30

0001 1311000-100 1 GALLEY D2537031113000 (1)

0002 1315000-100 1 GALLEY D2537031113000 (1)

0020 LN9424A63 0.03 (kg) WIRE D2537031113000 (1)

0024 NAS1291C3M 4 NUT D2537031113000 (1)

0025 NAS1801-3-8 4 SCREW D2537031113000 (1)

0026 NAS1149F0332P 4 WASHER D2537031113000 (1)

0028 DAN1174 0.004 (kg) VARNISH D2537031113000 (1)

0033 DA4-653-3SF8-71 0.3 (kg) SEALANT D2537031113000 (1)

0034 DA4-653-3S2 0.3 (kg) ADHESIVE D2537031113000 (1)

0035 DA4-653-3S2TRAN 0.6 (kg) ADHESIVE D2537031113000 (1)

0036 DA4-653-3H2 0.06 (kg) PRIMER D2537031113000 (1)

0038 10987425 0.016 (kg) GREASE D2537031113000 (1)

0040 NAS1611-317 18 PACKING D2537031113000 (1)

0041 A2537040622400 18 BUSHING D2537031113000 (1)

0050 NSA935807-20 4 CLAMP D2537031113000 (1)

0051 NSA935808C01 3 WASHER D2537031113000 (1)

0052 NAS1726-3E 5 NUT D2537031113000 (1)

0054 AS21919WCH13 2 CLAMP D2537031113000 (1)

0055 NAS1149C0332R 2 WASHER D2537031113000 (1)

0056 AS21919WCH05 4 CLAMP D2537031113000 (1)

0057 NAS1149CN816R 1 WASHER D2537031113000 (1)

REV 00 Mar 12/21 A320-25-1BWX

Page 24

A318/A319/A320/A321

SERVICE BULLETIN

Equipment

ITEM PART No. QTY (UM) KEYWORD DRAWING SEE NOTES

0058 NAS1801-3-7 1 SCREW D2537031113000 (1)

0059 MS21919WCH5 2 CLAMP D2537031113000 (1)

0063 NAS1801-08-10 3 SCREW D2537031113000 (1)

0064 NSA5159-23 1 STUD D2537031113000 (1)

0065 NSA5527-03-06 1 SPACER D2537031113000 (1)

0101 1311085 1 KIT D2537031113000 (1)

0102 1311086 1 KIT D2537031113000 (1)

0103 1311049 1 KIT D2537031113000 (1)

0104 1311047 1 KIT D2537031113000 (1)

0105 1311048 1 KIT D2537031113000 (1)

0106 1311095 1 KIT D2537031113000 (1)

0107 1311051 1 KIT D2537031113000 (1)

0108 1311076 1 KIT D2537031113000 (1)

0109 1311072 1 KIT D2537031113000 (1)

0110 1311090 1 KIT D2537031113000 (1)

0111 0046085 1 KIT D2537031113000 (1)

0112 1311094 1 KIT D2537031113000 (1)

0201 1315102 1 KIT D2537031113000 (1)

0202 1315123 1 KIT D2537031113000 (1)

0203 1315122 1 KIT D2537031113000 (1)

0204 1315056 1 KIT D2537031113000 (1)

0205 1315051 1 KIT D2537031113000 (1)

0206 1315053 1 KIT D2537031113000 (1)

0207 1315045 1 KIT D2537031113000 (1)

0208 1315046 1 KIT D2537031113000 (1)

0209 1315047 1 KIT D2537031113000 (1)

0210 1315048 1 KIT D2537031113000 (1)

0211 1315092 1 KIT D2537031113000 (1)

0212 1315088 1 KIT D2537031113000 (1)

0213 1315085 1 KIT D2537031113000 (1)

0214 1315093 1 KIT D2537031113000 (1)

0215 1315095 1 KIT D2537031113000 (1)

0216 1315109 1 KIT D2537031113000 (1)

0217 1315116 1 KIT D2537031113000 (1)

0218 0046075 1 KIT D2537031113000 (1)

0001 4360004-80-0018 4 HEATER D2537031203200 (1)

0005 4310000-00-55 6 OVEN D2537031203200 (1)

NOTE(S)

(1): The components listed above are not an AIRBUS Kit, the required parts must be

ordered as necessary through the given channel.

REV 00 Mar 12/21 A320-25-1BWX

Page 25

A318/A319/A320/A321

SERVICE BULLETIN

Referenced Information

Manuals/Drawings References/Sheets

06-20-00, Page Block 001

06-31-53, Page Block 001

Task 25-31-42-000-001

Task 25-31-42-400-001

AMM Task 25-33-45-000-001

Task 25-33-45-400-001

Task 25-35-19-400-001

Task 25-35-27-000-001

Task 25-35-27-400-001

D2537031113000 sheets 87 to 91

D2537031203200 sheet 15

Procedure

(a) Standard practices

1 If you find process and material specifications that you do not know in

the design drawings, refer to the cross-reference list in the Process and

Material Specification (PMS).

2 For the identification of zones, refer to Ref. AMM 06-20-00, Page Block 001.

3 For the Frame (FR) identification, refer to Ref. AMM 06-31-53, Page Block

001.

(b) Remove and install the galleys G1 (FIN 6475MM) and G5 (FIN 6483MM) in the

cabin between Frame 12 and Frame 16 and between Frame 68 and Frame 70

and install the kits in the galleys G1 and G5.

Refer to Ref. AMM Task 25-31-42-000-001, Ref. AMM Task 25-33-45-000-001, Ref.

AMM Task 25-31-42-400-001 and Ref. AMM Task 25-33-45-400-001

NOTE: If the Ref. AMM Task 25-31-42-400-001 and Ref. AMM Task 25-33-45-400-

001 are not available in the latest AMM operator’s issue, refer to Ref.

Appendix Advance Copy of AMM Tasks.

Refer to this/these drawing(s):

Ref. D2537031113000 sheets 87 to 91

NOTE: All emergency equipment installed in the galleys G1 and G5 are

removed with the galleys.

(c) Remove the catering equipment and install ovens and water heaters in the new

galleys G1 and G5 between Frame 12 and Frame 16 and between Frame 68 and

Frame 70.

Refer to Ref. AMM Task 25-35-27-000-001, Ref. AMM Task 25-35-19-400-001 and

Ref. AMM Task 25-35-27-400-001

NOTE: If the Ref. AMM Task 25-35-19-400-001 and Ref. AMM Task 25-35-27-400-

001 are not available in the latest AMM operator’s issue, refer to Ref.

Appendix Advance Copy of AMM Tasks.

Refer to this/these drawing(s):

Ref. D2537031203200 sheet 15

(3) Task A320-A-25-XX-1BWX-01001-720A-A (A320-A-25-XX-1BWX-01ZZZ-720Z-A)

Work Package 53-40 - Install the Hardpoint under the Galley G5

REV 00 Mar 12/21 A320-25-1BWX

Page 26

A318/A319/A320/A321

SERVICE BULLETIN

Job Set-Up Information

Working Area

Impacted Zone Access / Work Location

260 Work location From Frame 68 to Frame 69

Manpower/Resources/Skills

Man-hours 1.00 h

Minimum Number of person 1

Elapsed Time 1.00 h

Skills Cabin

Material necessary to do the job

Part kit 251BWXD05R01

Referenced Information

Manuals/Drawings References/Sheets

06-20-00, Page Block 001

AMM 06-31-53, Page Block 001

Task 20-21-11-911-001

51-24-00

51-40-00

51-42-00

SRM

51-43-00

51-44-00

51-75-12

D5347229500000 sheet 01

Procedure

(a) Standard practices

1 If you find process and material specifications that you do not know in

the design drawings, refer to the cross-reference list in the Process and

Material Specification (PMS).

2 For the identification of zones, refer to Ref. AMM 06-20-00, Page Block 001.

3 For the Frame (FR) identification, refer to Ref. AMM 06-31-53, Page Block

001.

4 Remove and install fasteners in accordance with Ref. SRM 51-42-00.

5 Get alternative and substitute fastener data in accordance with Ref. SRM

51-43-00.

6 If alternative and substitute fasteners have to be used, you must make

sure that the associated nut/collar are compatible in accordance with Ref.

SRM 51-40-00.

7 If the length of any fastener specified in this Service Bulletin does not

meet installation standards given in SRM Chapter 51, then a fastener of

the same specification, or an approved substitute, with a length which

meets the installation standards given in SRM Chapter 51 may be used. In

addition, washers may be installed for fastener grip length in accordance

with SRM Chapter 51.

REV 00 Mar 12/21 A320-25-1BWX

Page 27

A318/A319/A320/A321

SERVICE BULLETIN

8 Repair the paint coating in accordance with Ref. SRM 51-75-12.

9 Apply sealant in accordance with Ref. SRM 51-24-00.

10 Get fastener hole diameters and drill data in accordance with Ref. SRM 51-

44-00.

11 To torque tighten the standard threaded fasteners, refer to Ref. AMM Task

20-21-11-911-001.

(b) Install the hardpoint on the floor under the galley G5 between Frame 68 and

Frame 69.

Refer to this/these drawing(s):

Ref. D5347229500000 sheet 01

(4) Task A320-A-25-XX-1BWX-03001-920A-A (A320-A-25-XX-1BWX-03ZZZ-920Z-A)

Work Package 53-60 - Remove and Install the Floor Panel in the Cabin

Job Set-Up Information

Working Area

Impacted Zone Access / Work Location

260 Work location From Frame 68 to Frame 70

Manpower/Resources/Skills

Man-hours 2.00 h

Minimum Number of person 1

Elapsed Time 2.00 h

Skills Cabin

Material necessary to do the job

Consumables

ITEM REFERENCE CML DESCRIPTION DRAWING SEE NOTES

Non Hardening Jointing

06LCG9

Putty - Medium Temp. Area

Part kit 251BWXD02R01

Referenced Information

Manuals/Drawings References/Sheets

06-20-00, Page Block 001

06-31-53, Page Block 001

AMM

Task 53-00-00-000-801

Task 53-00-00-400-801

CML CONSUMABLE MATERIAL LIST (CML)

D5367504502000 sheets 16 to 17

Procedure

(a) Standard practices

1 If you find process and material specifications that you do not know in

the design drawings, refer to the cross-reference list in the Process and

Material Specification (PMS).

2 For the identification of zones, refer to Ref. AMM 06-20-00, Page Block 001.

REV 00 Mar 12/21 A320-25-1BWX

Page 28

A318/A319/A320/A321

SERVICE BULLETIN

3 For the Frame (FR) identification, refer to Ref. AMM 06-31-53, Page Block

001.

4 For the specification of Material application codes given in this Service

Bulletin, refer to the Ref. CML.

(b) Remove and install the floor panel in the cabin between Frame 68 and Frame 70.

Refer to Ref. AMM Task 53-00-00-000-801 and Ref. AMM Task 53-00-00-400-801

Refer to this/these drawing(s):

Ref. D5367504502000 sheets 16 to 17

NOTE: Drawing D5367504502000 contains this consumable material:

Non Hardening Jointing 06LCG9

Putty - Medium Temp.

Area

(5) Task A320-A-25-XX-1BWX-01001-520A-A (A320-A-25-XX-1BWX-01ZZZ-520Z-A)

Work Package 92-00 - Remove the Clips on the Circuit Breakers in Panel

123VU

Job Set-Up Information

Working Area

Impacted Zone Access / Work Location

210 Work location Electrical Panel 123VU

Manpower/Resources/Skills

Man-hours 0.25 h

Minimum Number of person 1

Elapsed Time 0.25 h

Skills Cabin

Referenced Information

Manuals/Drawings References/Sheets

06-20-00, Page Block 001

AMM

06-31-53, Page Block 001

251BWXM92001 sheet 01(A00)

Procedure

(a) Standard practices

1 For the identification of zones, refer to Ref. AMM 06-20-00, Page Block 001.

2 For the Frame (FR) identification, refer to Ref. AMM 06-31-53, Page Block

001.

(b) Remove 3 clips on circuit breaker 2MC in position AD04, circuit breaker 3MC in

position AF04 and circuit breaker 12MC in position AD09 in Panel 123VU.

Refer to this/these drawing(s):

Ref. 251BWXM92001 sheet 01(A00)

D. PREPARATION FOR TEST

(1) Task A320-A-25-XX-1BWX-01001-761A-A (A320-A-25-XX-1BWX-01ZZZ-761Z-A)

Energize Electrical Network

REV 00 Mar 12/21 A320-25-1BWX

Page 29

A318/A319/A320/A321

SERVICE BULLETIN

Job Set-Up Information

Manpower/Resources/Skills

Man-hours 0.25 h

Minimum Number of person 1

Elapsed Time 0.25 h

Referenced Information

Manuals/Drawings References/Sheets

AMM Task 24-41-00-861-002

Procedure

(a) Energize the aircraft electrical circuits, refer to Ref. AMM Task 24-41-00-861-002.

E. TEST

(1) Task A320-A-25-XX-1BWX-01001-320A-A (A320-A-25-XX-1BWX-01ZZZ-320Z-A)

Test

Job Set-Up Information

Manpower/Resources/Skills

Man-hours 5.00 h

Minimum Number of person 2

Elapsed Time 2.50 h

Referenced Information

Manuals/Drawings References/Sheets

Task 25-31-42-400-001

Task 25-33-45-400-001

AMM

Task 25-35-00-710-015

Task 25-35-00-710-023

Procedure

(a) Do the test after the installation of the forward galley unit, refer to Ref. AMM Task

25-31-42-400-001.

NOTE: If the Ref. AMM Task 25-31-42-400-001 is not available in the latest AMM

operator’s issue, refer to Ref. Appendix Advance Copy of AMM Tasks.

(b) Do the test after the installation of the AFT galley unit, refer to Ref. AMM Task 25-

33-45-400-001.

NOTE: If the Ref. AMM Task 25-33-45-400-001 is not available in the latest AMM

operator’s issue, refer to Ref. Appendix Advance Copy of AMM Tasks.

(c) Do the test after the installation of the oven, refer to Ref. AMM Task 25-35-00-

710-015.

NOTE: If the Ref. AMM Task 25-35-00-710-015 is not available in the latest AMM

operator’s issue, refer to Ref. Appendix Advance Copy of AMM Tasks.

REV 00 Mar 12/21 A320-25-1BWX

Page 30

A318/A319/A320/A321

SERVICE BULLETIN

(d) Do the test after the installation of water boiler/heater, refer to Ref. AMM Task

25-35-00-710-023.

NOTE: If the Ref. AMM Task 25-35-00-710-023 is not available in the latest AMM

operator’s issue, refer to Ref. Appendix Advance Copy of AMM Tasks.

F. CLOSE-UP

(1) Task A320-A-25-XX-1BWX-01001-740A-A (A320-A-25-XX-1BWX-01ZZZ-740Z-A)

Close-up

Job Set-Up Information

Manpower/Resources/Skills

Man-hours 4.00 h

Minimum Number of person 2

Elapsed Time 2.00 h

Referenced Information

Manuals/Drawings References/Sheets

Task 25-28-42-400-001

AMM Task 25-31-42-400-001

Task 25-33-45-400-001

Procedure

(a) Make sure that the work areas are clean and clear of tools and other items of

equipment.

(b) Do the close-up procedure specified in the installation of the Non-Textile Floor

(NTF) covering, refer to Ref. AMM Task 25-28-42-400-001.

(c) Do the close-up procedure specified in the installation of the forward galley unit,

refer to Ref. AMM Task 25-31-42-400-001.

NOTE: If the Ref. AMM Task 25-31-42-400-001 is not available in the latest AMM

operator’s issue, refer to Ref. Appendix Advance Copy of AMM Tasks.

(d) Do the close-up procedure specified in the installation of the AFT galley unit,

refer to Ref. AMM Task 25-33-45-400-001.

NOTE: If the Ref. AMM Task 25-33-45-400-001 is not available in the latest AMM

operator’s issue, refer to Ref. Appendix Advance Copy of AMM Tasks.

(e) Put the aircraft back to its initial configuration.

G. ADMINISTRATIVE

(1) Task A320-A-25-XX-1BWX-01001-90AA-A (A320-A-25-XX-1BWX-01ZZZ-90AZ-A)

Administrative

Procedure

Confirm in the applicable aircraft records that you have completed all the work defined

in this Service Bulletin task set as required.

REV 00 Mar 12/21 A320-25-1BWX

Page 31

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

APPENDIX

A. GLOSSARY

GLOSSARY

ACRONYM FULL FORM

ATA Air Transport Association of America

EASA European Aviation Safety Agency

IR Implementing Rules

NTF Non Textile Floor

RFC Request For Change

RMO Retrofit Modification Offer

REV 00 Mar 12/21 A320-25-1BWX

Page 32

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

B. Advance Copy of AMM Tasks

Advance Copy of AMM Tasks

Refer to this (these) Figure(s) for the AMM task(s) which is (are) not available in the latest

operator’s issue:

- Ref. Fig. AMM TASK 25-31-42-400-001 - Installation of the Forward Galley Unit

- Ref. Fig. AMM TASK 25-33-45-400-001 - Installation of the Aft Galley Unit

- Ref. Fig. AMM TASK 25-35-19-400-001 - Installation of the Oven

- Ref. Fig. AMM TASK 25-35-27-400-001 - Installation of the Water Boiler/Heater

- Ref. Fig. AMM TASK 25-35-00-710-015 - Operational Test of the Oven

- Ref. Fig. AMM TASK 25-35-00-710-023 - Operational Test of the Water Boiler/Heater

REV 00 Mar 12/21 A320-25-1BWX

Page 33

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

CONF ALL

** ON A/C ALL

TASK 25-31-42-400-001-A

Installation of the Forward Galley Unit

WARNING: BE CAREFUL WHEN YOU USE CONSUMABLE MATERIALS. OBEY THE MATERIAL

MANUFACTURER'S INSTRUCTIONS AND YOUR LOCAL REGULATIONS.

WARNING: BE CAREFUL WHEN YOU REMOVE OR INSTALL THIS EQUIPMENT. THIS EQUIPMENT

IS

S HEAVY (MORE THAN 12 KG (26.5 LB)) AND CAN CAUSE INJURY AND/OR

DAMAGE.

FIN : 6475MM

1. Reason for the job

Self Explanatory

NOTE: More than one person is necessary for this procedure.

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific 1 SCRAPER - NON METALLIC

No specific AR WARNING NOTICE(S)

B. Consumable Materials

REFERENCE DESIGNATION

(Material No. 03GBB1) Synthetic Oil base Grease-General Purpose Clay Thickened -

(Material No. 05BAJ1) Threadlocking Adhesive-- High strength -

(Material No. 06CMD9) Silicone Adhesive Sealant-General Purpose One part legacy

(Material No. 08BAA9) Non Aqueous Cleaner-General - -

(Material No. 14QFB1) Wire-Locking Dia: 0.8 mm CRES Nickel Alloy -

(Material No. 14SBA1) Textile-Lint free Cotton -

C. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

220 FWD CAB UTILITY AREAS

D. Expendable Parts

FIG.ITEM DESIGNATION IPC-CSN

52 PACKINGS 25-31-01-65-030

62 PACKINGS 25-31-01-65-030

ICN-A320-A-25XX1BWX-A-FAPE3-026LV-A-001-01

Figure ICN-A320-A-25XX1BWX-A-FAPE3-026LV-A-001-01 SHEET 1/15

REV 00 Mar 12/21 AMM TASK 25-31-42-400-001 - A320-25-1BWX

Installation of the Forward Galley Unit Page 34

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

CONF ALL

E. Referenced Information

REFERENCE DESIGNATION

(Ref. 12-15-38-613-001-A). Fill the Potable Water Tank System (Aircraft

Electrical Power Available)

(Ref. 12-24-38-680-001-A). Draining of the Potable Water System (with

Electrical Power)

(Ref. 12-33-21-618-001-A-01). Pre-conditioning through the HP Ground

Connection

(Ref. 12-33-21-618-001-A-02). Pre-conditioning with the APU

(Ref. 20-21-11-911-001-A). Tightening Torques for Standard Threaded

Fasteners

(Ref. 20-28-00-912-802-A). Electrical Bonding - General Maintenance

Procedure

(Ref. 21-23-00-720-002-A). Functional Test of an Air Extraction Point

(Ref. 24-42-00-861-001-A). Energize the Ground Service Network from the

External Power

(Ref. 24-42-00-862-001-A). De-energize the Ground Service Network Supplied

from the External Power

(Ref. 25-23-41-000-001-A). Removal of the Ceiling Panels

(Ref. 25-23-41-400-001-A). Installation of the Ceiling Panels

(Ref. 25-23-42-000-001-A). Removal of the Ceiling Panels - Forward Utility

Area

(Ref. 25-23-45-000-002-A). Removal of the Door Frame Linings from the Right

Forward Passenger/Crew Door

(Ref. 25-23-45-400-007-A). Installation of the Door Frame Linings on the

Right Forward Passenger/Crew Door

(Ref. 25-26-41-000-001-A). Removal of the Forward Curtain Rail

(Ref. 25-26-41-400-001-A). Installation of the Forward Curtain Rail

(Ref. 25-31-42-000-001-A). Removal of the Forward Galley Unit

(Ref. 25-35-00-010-001-A). Removal of the Galley Equipment

(Ref. 25-35-19-400-001-A). Installation of the Oven

(Ref. 25-35-25-400-001-A). Installation of the Hot Cup

(Ref. 25-35-27-400-001-A). Installation of the Water Boiler/Heater

(Ref. 38-10-00-614-001-A). Pressurization of the Potable Water System from

a Ground Air Supply

(Ref. 38-10-00-614-002-A). Depressurization of the Potable Water System

(Ref. 52-51-11-000-001-A). Removal of the Cockpit Door

(Ref. 52-51-11-400-001-A). Installation of the Cockpit Door

(Ref. 53-16-11-000-001-A). Removal of the Mount Fitting at FR14

(Ref. 53-16-11-400-001-A). Installation of the Mount Fitting at FR14

Upper and Lower Attachments of the Forward Galley Unit - G1

Splitlines of the Forward Galley Unit - G1 SHEET 1

Supply Connections of the Forward Galley Unit - G1 SHEET 1

Electrical Connections of the Forward Galley Unit - G1

ICN-A320-A-25XX1BWX-A-FAPE3-026LW-A-001-01

Figure ICN-A320-A-25XX1BWX-A-FAPE3-026LW-A-001-01 SHEET 2/15

REV 00 Mar 12/21 AMM TASK 25-31-42-400-001 - A320-25-1BWX

Installation of the Forward Galley Unit Page 35

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

CONF ALL

3. Job Set-up

Subtask 25-31-42-860-051-GK

A. Aircraft Maintenance Configuration

(1) Make sure that the ground service network is

energized (Ref. AMM TASK 24-42-00-861-001).

(2) Make sure that the potable water system is depressurized (Ref. AMM TASK

38-10-00-614-002).

(3) Make sure that the potable water system is drained (Ref. AMM TASK 12-24-

38-680-001).

(4) On the overhead panel, on AIR COND panel 30VU:

(a) Make sure that these pushbutton switches are released:

· APU BLEED pushbutton switch (the ON legend is off)

· All the ENG BLEED pushbutton switches (the OFF legends are on)

· PACK 1 and PACK 2 pushbutton switches (the OFF legends are on).

(b) Make sure that the WARNING NOTICE(S) is (are) in position to tell

persons not to operate these pushbutton switches.

(5) On the HP and LP ground-air connectors:

(a) Make sure that the WARNING NOTICE(S) is (are) in position to tell

persons not to connect the ground air supply.

(6) On the water service panel:

(a) Make sure that the WARNING NOTICE(S) is (are) in position to tell

persons not to do the servicing of the potable water system.

(7) Make sure that all applicable doors are open to let you get access to

all the parts that you must install/ connect.

(8) If necessary, remove the contents of the galley.

(9) Make sure that all the items of non-electrical equipment are removed

from the galley.

(10) Make sure that the items of equipment are removed (Ref. AMM TASK 25-35-

00-010-001).

(11) Make sure that the curtain(s) and the curtain rail(s) are removed (Ref.

AMM TASK 25-26-41-000-001).

(12) Make sure that the ceiling panels and the door frame linings in the

area of the galley are removed (Ref. AMM TASK 25-23-41-000-001) and

(Ref. AMM TASK 25-23-45-000-002).

(13) If necessary, remove the forward utility-area ceiling-panels (Ref. AMM

TASK 25-23-42-000-001).

(14) Make sure that the cockpit door is removed (Ref. AMM TASK 52-51-11-000-001).

(15) If a cockpit door camera is installed, make sure that the

hinge-mount fitting is removed (Ref. AMM TASK 53-16-11-000-001).

ICN-A320-A-25XX1BWX-A-FAPE3-026LX-A-001-01

Figure ICN-A320-A-25XX1BWX-A-FAPE3-026LX-A-001-01 SHEET 3/15

REV 00 Mar 12/21 AMM TASK 25-31-42-400-001 - A320-25-1BWX

Installation of the Forward Galley Unit Page 36

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

CONF ALL

Subtask 25-31-42-865-060-A

B. Make sure that this(these) circuit breaker(s) is(are) open, safetied and tagged:

PANEL DESIGNATION FIN LOCATION

122VU ELEC/GALLEY/CNTOR 7MC S28

122VU ELEC/GALY & CAB/CTL 1XA S26

122VU AIR COND/LAV/GALLEY VENT 5HU U21

CTL/EXTRACT FAN/CTL

122VU AIR COND/LAV/GALLEY VENT 6HU U19

CTL/EXTRACT FAN/SPLY

123VU FWD GALLEY/FEEDER F 16MC AC10

123VU FWD GALLEY/FEEDER D 2MC AD04

123VU FWD GALLEY/FEEDER C 1MC AE10

Subtask 25-31-42-560-050-B

C. Preparation of the Replacement Component

NOTE: To move the galley through the aircraft door, it is necessary to

disconnect the galley splitline (Ref. AMM TASK 25-31-42-000-001).

Subtask 25-31-42-210-050-B

D. Preparation for Installation

(1) Clean the component interfaces and the adjacent area.

(2) Do a visual inspection of the component interface and/or the adjacent area.

(3) Make sure that the parts retained from the removed component are clean and in

the correct condition.

4. Procedure

Subtask 25-31-42-420-050-CC

WARNING: BE CAREFUL WHEN YOU USE CONSUMABLE MATERIALS. OBEY THE MATERIAL

MANUFACTURER'S INSTRUCTIONS AND YOUR LOCAL REGULATIONS.

A. Connect the Galley Splitline

NOTE: This procedure is only necessary if the galley was removed from the

aircraft.

(1) Unless specified, torque all nuts, bolts and screws (Ref. AMM TASK 20-21-11-

911-001).

(2) Install the floor fittings:

(Ref. Fig. Upper and Lower Attachments of the Forward Galley Unit - G1)

WARNING: BE CAREFUL WHEN YOU USE CONSUMABLE MATERIALS. OBEY THE MATERIAL

MANUFACTURER'S INSTRUCTIONS AND YOUR LOCAL REGULATIONS.

(a) Apply the Synthetic Oil base Grease-General Purpose Clay Thickened -

(Material No. 03GBB1) to the bushing (63) and put them in position.

(b) Install the new IPC -CSN (25-31-01-65-030) PACKINGS (62).

(c) Apply the Threadlocking Adhesive-- High strength - (Material No.

05BAJ1) to the threads of the bolt (61).

(d) Install the bolt (61).

(e) Apply the Synthetic Oil base Grease-General Purpose Clay Thickened -

(Material No. 03GBB1) to the bushing (53) and put them in position.

(f) Install the new IPC -CSN (25-31-01-65-030) PACKINGS (52).

ICN-A320-A-25XX1BWX-A-FAPE3-026LY-A-001-01

Figure ICN-A320-A-25XX1BWX-A-FAPE3-026LY-A-001-01 SHEET 4/15

REV 00 Mar 12/21 AMM TASK 25-31-42-400-001 - A320-25-1BWX

Installation of the Forward Galley Unit Page 37

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

CONF ALL

(g) Put the floor fittings (54) in position.

(h) Apply the Threadlocking Adhesive-- High strength - (Material No.

05BAJ1) to the threads of the bolt (48).

(i) Install the bushings (50) and (51), the washers (49) and the bolts (48).

(j) Put the shims (55) in position as identified during the removal procedure.

WARNING: SUPPORT THE UNIT/ASSEMBLY. THE UNIT/ASSEMBLY IS HEAVY. IF YOU DO NOT

SUPPORT IT, IT WILL FALL. THIS CAN CAUSE INJURY TO PERSONS, AND/OR

DAM-AGE TO EQUIPMENT.

(3) Connect the galley at the splitline:

(Ref. Fig. Splitlines of the Forward Galley Unit - G1 SHEET 1)

NOTE: This procedure is only necessary if the galley was

removed from the aircraft. NOTE: The splitline screws and

bolts are painted red.

(a) Prevent damage to the component interfaces and the adjacent area.

(b) Carefully put the galley modules (80) and (84) in position.

(c) Install the washers (86) and the screws (87).

(d) Install the screws (85), (88) and (89).

(e) Install all the remaining splitline screws as necessary.

(f) Remove the PLUG-BLANKING from each disconnected line end.

(g) Connect the exhaust air pipe (81) to the pipe end (83) and tighten the

clamp (82).

(4) Seal the splitline joints of the galley:

WARNING: BE CAREFUL WHEN YOU USE CONSUMABLE MATERIALS. OBEY THE MATERIAL

MANUFACTURER'S INSTRUCTIONS AND YOUR LOCAL REGULATIONS.

(a) Remove the used sealant of the splitline joints with a SCRAPER - NON

METALLIC.

(b) Clean the splitline joints with the Non Aqueous Cleaner-General - -

(Material No.08BAA9) and a lint-free cloth Textile-Lint free Cotton -

(Material No.14SBA1).

(c) Apply the new Silicone Adhesive Sealant-General

Purpose One part legacy (Material No. 06CMD9) into

all the splitline joints.

Subtask 25-31-42-420-051-DM

B. Installation of the Forward Galley Unit G1

WARNING: BE CAREFUL WHEN YOU USE CONSUMABLE MATERIALS. OBEY THE MATERIAL

MANUFACTURER'S INSTRUCTIONS AND YOUR LOCAL REGULATIONS.

(1) Unless specified, torque all nuts, bolts and screws (Ref. AMM TASK 20-21-11-

911-001).

(2) Install the upper and the lower attachments:

(Ref. Fig. Upper and Lower Attachments of the Forward Galley Unit - G1)

WARNING: SUPPORT THE UNIT/ASSEMBLY. THE UNIT/ASSEMBLY IS HEAVY. IF YOU DO

NOT SUPPORT IT, IT WILL FALL. THIS CAN CAUSE INJURY TO PERSONS,

AND/ OR DAMAGE TO EQUIPMENT.

ICN-A320-A-25XX1BWX-A-FAPE3-026LZ-A-001-01

Figure ICN-A320-A-25XX1BWX-A-FAPE3-026LZ-A-001-01 SHEET 5/15

REV 00 Mar 12/21 AMM TASK 25-31-42-400-001 - A320-25-1BWX

Installation of the Forward Galley Unit Page 38

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

CONF ALL

(a) Prevent damage to the component interfaces and the adjacent area.

(b) Carefully move the galley onto the shims (55), the floor fittings (54) and

the bolt (61).

(c) Put the shims (56) and (57) in position as recorded during the removal.

(d) Install the special washers (58), the washers (59) and the screws (60).

(e) Install the wheel guides (46) with the screws (47).

(f) Put the tie rods (43) in their correct positions on the aircraft

structure and install the quick-release pins (42).

(g) If necessary, adjust the tie rods (43):

WARNING: USE PROTECTIVE GOGGLES AND GLOVES WHEN YOU REMOVE OR IN-

STALL LOCKWIRE. EACH TIME YOU CUT LOCKWIRE, REMOVE AND DIS-

CARD IT IMMEDIATELY. LOOSE LOCKWIRE CAN CUT YOU OR MAKE YOU

BLIND, AND/OR CAN CAUSE DAMAGE.

1 Remove and discard the lockwire from the locknuts (44).

2 Loosen the locknuts (44).

3 Hold the tie rod end that is not installed.

4 Turn the tie rod barrel (45) until you can install the quick-release

pin (42) easily.

5 Tighten the locknuts (44).

6 Do a check of the tie rods (43) for the correct installation:

· Put a short piece of the lockwire stainless steel 0,8mm DIA,

Wire-Locking Dia: 0.8 mm CRES Nickel Alloy - (Material No.

14QFB1), into the safety hole at the tie rod ends.

· Make sure that the lockwire does not go through the safety holes.

· If it does, install a new tie rod.

7 Safety the locknuts (44) with the lockwire stainless steel 0,8mm

DIA, Wire-Locking Dia: 0.8 mm CRES Nickel Alloy - (Material No.

14QFB1).

(3) Connect the potable water connections:

(Ref. Fig. Supply Connections of the Forward Galley Unit - G1 SHEET 1)

WARNING: MAKE SURE THAT THE POTABLE WATER SYSTEM IS DEPRESSURIZED. A

PRESSURIZED SYSTEM CAN CAUSE INJURY TO PERSONS WHEN THEY DO

WORK ON IT.

WARNING: MAKE SURE THAT THE EQUIPMENT YOU USE FOR THIS PROCEDURE IS CLEAN AND

APPROVED FOR THE POTABLE WATER SYSTEM. IF NOT IT CAN CAUSE

CONTAMINATION OF THE POTABLE WATER SYSTEM.

WARNING: DO NOT DO WORK ON THE TOILET WASTE SYSTEM AND THE POTABLE WATER

SYSTEM AT THE SAME TIME. THIS WILL PREVENT CONTAMINATION OF THE

POTABLE WATER SYSTEM. SUCH CONTAMINATION CAN BE DANGEROUS TO HEALTH.

(a) Remove the PLUG-BLANKING from each disconnected line end.

(b) Connect the potable water pipe (33) to the fitting (31) and tighten the nut

(32).

(4) Connect the waste water connections:

(a) Remove the PLUG-BLANKING from each disconnected line end.

(b) Connect the waste water hose (28) to the pipe (30) and tighten the clamps

(29).

ICN-A320-A-25XX1BWX-A-FAPE3-026M0-A-001-01

Figure ICN-A320-A-25XX1BWX-A-FAPE3-026M0-A-001-01 SHEET 6/15

REV 00 Mar 12/21 AMM TASK 25-31-42-400-001 - A320-25-1BWX

Installation of the Forward Galley Unit Page 39

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

CONF ALL

(c) Connect the fresh air hose (24) to the pipe (22) and tighten the clamp

(23).

(5) Connect the ventilation connections:

(a) Remove the PLUG-BLANKING from each disconnected line end.

(b) Connect the exhaust air hose (27) to the pipe (25) and tigthen the clamps

(26).

(c) Put the pelmet (20) in position and install the screws (21).

(6) Connect the electrical connections:

(Ref. Fig. Electrical Connections of the Forward Galley Unit - G1)

(a) Put the bonding straps (14) in position and install the washers (13),

the bolts (12) and the nuts (11) (Ref. AMM TASK 20-28-00-912-802).

(b) Put the clamps (8) in position and install the washer (9) and the screw

(10).

(c) Put the clamps (1) in position and install the washers (2) and the nuts

(3).

(d) Connect the electrical wires:

CAUTION: REFER TO THE MATCH MARKS MADE DURING THE REMOVAL WHEN YOU CONNECT

THE ELECTRICAL WIRES.

IF YOU MAKE AN ERROR WHEN YOU CONNECT THE WIRES YOU WILL

CAUSE DAMAGE TO EQUIPMENT.

1 Refer to the match marks and connect the electrical wires (7) with the

nuts (6).

2 Install the cover (4) with the screws (5).

WARNING: USE PROTECTIVE GOGGLES AND GLOVES WHEN YOU REMOVE OR IN-

STALL LOCKWIRE. EACH TIME YOU CUT LOCKWIRE, REMOVE AND DIS-

CARD IT IMMEDIATELY. LOOSE LOCKWIRE CAN CUT YOU OR MAKE YOU

BLIND, AND/OR CAN CAUSE DAMAGE.

3 Safety the screws (5) with new lockwire stainless steel 0.8mm

DIA, Wire-Locking Dia: 0.8 mm CRES Nickel Alloy - (Material No.

14QFB1).

(7) Install all the decorative material removed during

the removal procedure. Subtask 25-31-42-410-053-AA

C. Preparation for the Test

(1) Make sure that the work area is clean and clear of tools and other items.

(2) Install the galley electrical equipment that follows, if removed:

(a) The oven (Ref. AMM TASK 25-35-19-400-001)

(b) The hot cup (Ref. AMM TASK 25-35-25-400-001)

(c) The water boiler (Ref. AMM TASK 25-35-27-400-001).

Subtask 25-31-42-720-050-B

D. Do the test of the bonding of the galley and the galley electrical equipment

(Ref. AMM TASK 20-28-00-912-802).

ICN-A320-A-25XX1BWX-A-FAPE3-026M1-A-001-01

Figure ICN-A320-A-25XX1BWX-A-FAPE3-026M1-A-001-01 SHEET 7/15

REV 00 Mar 12/21 AMM TASK 25-31-42-400-001 - A320-25-1BWX

Installation of the Forward Galley Unit Page 40

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

CONF ALL

Subtask 25-31-42-865-061-A

E. Remove the safety clip(s) and the tag(s) and close this(these) circuit

breaker(s):

PANEL DESIGNATION FIN LOCATION

122VU ELEC/GALLEY/CNTOR 7MC S28

122VU ELEC/GALY & CAB/CTL 1XA S26

122VU AIR COND/LAV/GALLEY VENT 5HU U21

CTL/EX-TRACT FAN/CTL

122VU AIR COND/LAV/GALLEY VENT 6HU U19

CTL/EXTRACT FAN/SPLY

123VU FWD GALLEY/FEEDER F 16MC AC10

123VU FWD GALLEY/FEEDER D 2MC AD04

123VU FWD GALLEY/FEEDER C 1MC AE10

Subtask 25-31-42-942-050-A

F. Safety Precautions

(1) Remove the warning notice(s) from:

· AIR COND panel 30VU

· The HP and LP ground air-connectors

· The water service panel. Subtask 25-31-42-613-050-B

G. Fill the potable water system (Ref. AMM TASK 12-15-38-613-001).

Subtask 25-31-42-710-050-N

H. Operational Test of the Galley Systems

(1) Do a check of the air supply and air exhaust system:

(a) Do the pre-conditioning with the APU (Ref. AMM TASK 12-33-21-618-

001), or the HP ground connection (Ref. AMM TASK 12-33-21-618-001).

(b) Do the functional test of an air extraction point (Ref. AMM TASK 21-

23-00-720-002), do not de-energise the electrical circuits when the

test is complete.

(c) Turn the air outlet clockwise until it is in the closed position.

(d) Air must not come out from the air outlet.

(e) Examine all the air hoses and the connections for leaks.

(f) Repair all leaks.

(g) Turn the air outlet counterclockwise until it is in the open position.

(h) Make sure that different airflow is possible when you turn the air outlet.

(2) Do a check of the potable water and drain system:

(a) Pressurize the potable water system (Ref. AMM TASK 38-10-00-614-001).

(b) Examine all the potable water hoses for leaks.

(c) Repair all leaks.

(d) Depressurize the potable water system (Ref. AMM TASK 38-10-00-614-002).

ICN-A320-A-25XX1BWX-A-FAPE3-026M2-A-001-01

Figure ICN-A320-A-25XX1BWX-A-FAPE3-026M2-A-001-01 SHEET 8/15

REV 00 Mar 12/21 AMM TASK 25-31-42-400-001 - A320-25-1BWX

Installation of the Forward Galley Unit Page 41

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

CONF ALL

(3) Do an operational test of the galley electrical system:

(a) On the galley control panel, make sure that all the circuit breakers are

closed.

ACTION RESULT

1.In the flight compartment, on On the galley control panel:

the overhead panel 35VU:

· Push (on) the pushbutton switch · The POWER indicator light comes

2XA GALLEY. on.

2.On the galley control panel: In the galley:

· Set the WORKLIGHT switch to the · The galley worklight comes on

BRIGHT position. brightly.

· Set the WORKLIGHT switch to the · The galley worklight comes on

DIM position. dimmed.

ICN-A320-A-25XX1BWX-A-FAPE3-026M3-A-001-01

Figure ICN-A320-A-25XX1BWX-A-FAPE3-026M3-A-001-01 SHEET 9/15

REV 00 Mar 12/21 AMM TASK 25-31-42-400-001 - A320-25-1BWX

Installation of the Forward Galley Unit Page 42

A318/A319/A320/A321

SERVICE BULLETIN

APPENDIX

CONF ALL

Z220

A

A

B

FR20

GALLEY 1

6475MM

FR12

C

EXAMPLE

D

46

B

EXAMPLE

47

42

43

44

45

ICN-A320-A-25XX1BWX-A-FAPE3-026M4-A-001-01

Figure ICN-A320-A-25XX1BWX-A-FAPE3-026M4-A-001-01 SHEET 10/15

REV 00 Mar 12/21 AMM TASK 25-31-42-400-001 - A320-25-1BWX