Professional Documents

Culture Documents

Part Revalidation Summary

Part Revalidation Summary

Uploaded by

Chetan PatilOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part Revalidation Summary

Part Revalidation Summary

Uploaded by

Chetan PatilCopyright:

Available Formats

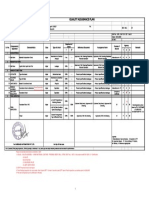

Supplier Self Part Revalidation

Audit Ref No:(As

Supplier Name: Lumax Industries Ltd. Supp Code: 7200422

given by AL)

Part No. &

Part Name: S/A OF HEADLAMP AND FDI-LH BOYO2413 / A Batch Code:

Drg Ver.

Supplier Contact Name: Mr. Shashi Patil Contact Mob: 8975423200 Insp Date: 11.02.2020

Part Revalidation Summary

Total Number Of Parameters: 16 No of Parameters Checked: 16 OK: 16 NOK: 0 NOK (CTQ Parameters): 0

Remarks: All CTQ Parameters shall meet Drg / Standard specifications Audit Score (in %) 100

A) Dimensional Aspects (including GD&T like Parallelism, Roundness etc.)

Tolerance Actual Measured Samples

Method of Inspection Status

S.No. Parameter Specification Special Characteristics (CC / SC) Remarks

(Instrument) (OK/NG)

Min Max S1 S2 S3 S4 S5

1 Center distance 143.5 ± 1.0 mm 142.5 144.5 CC Vernier 143.12 143.19 143.14 143.13 143.18 OK

2 Dimension Ø 11.0 ± 0.2 ( Hole 3 10.8 11.2 SC Vernier 10.86 10.89 10.84 10.87 10.84 OK

Nos. ) mm

3 Bulb (Osram Make ) 12 v 55/ 60 w CC Bulb Testing Unit OK OK OK OK OK OK

4 Bulb (Osram Make ) 12 v 21w CC Bulb Testing Unit OK OK OK OK OK OK

5 Bulb (Osram Make ) 12 v 4w CC Bulb Testing Unit OK OK OK OK OK OK

6 Leak test (tested for the sealed CC Leak Testing Unit OK OK OK OK OK OK

beam at 0.2 bar pressure

7 Leveling motor and aiming CC Bulb Testing Stage OK OK OK OK OK OK

Checks sequentially

for the lamps working

8 Light testing CC Bulb Testing Stage OK OK OK OK OK OK and poke yoke

( current consumption

based) for wrong

lamp assy in place.

Main Beam :- White / Red :- Found OK

9 Wire assly CC VISUAL / BULB TESTING UNIT Dip Beam :- Yellow :- Found OK

Earth :- Brown :- Found OK OK

Parking :- White / Black :- Found OK

10 E marking details ( GLASS ) SC VISUAL OK OK OK OK OK OK

11 E marking details ( FDI ) SC VISUAL OK OK OK OK OK OK

B) Surface Finish, If applicable (e.g: Ra Value etc)

1.NO FLASHES OUTSIDE OF LENS

2.REFLECTOR SURFACE SHOULD BE METALLISED & COVER WITH TOP COAT METAL.

3.KOH & TAPE TEST SHOULD BE OK.

4.12 V MOTOR WORKING WITH AIMING

5.100% LEAKAGE TESTING ON ASSLY WITH PRESSURE 0.2 BAR (- VE)

SEALED BEAM & FDI UNIT

C) Performance Characteristics, if applicable (e.g:Proof pressure, Continuity check,etc)

1 Bulb (Osram Make ) 12 v 55/ 60 w CC Bulb Testing Unit OK OK OK OK OK

2 Bulb (Osram Make ) 12 v 21w CC Bulb Testing Unit OK OK OK OK OK

3 Bulb (Osram Make ) 12 v 4w CC Bulb Testing Unit OK OK OK OK OK

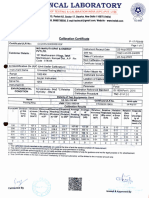

D) Material / Chemical Property (MTR: RM, Surface & Core Hardness, Microstructure etc). Attach the test report

a) Raw material Ref Standard Element C% : 0.05 Si% :- Mn% :- 0.30 P% :- 0.012 s% :- 0.008 Cr% :- ---- Cu%&Sn% Remarks

b) Surface Hardness

c) Microstructure

d) Actual Weight

E) Mechanical Properties Inspection

S.No. Parameters Specification Actual Observed values Remarks

a) Tensile Strength 350 T.C 318.18

b) Yield strength 210 T.C 187.08

c) Elongation 38 T.C 38.1

d) Weight 2.043 2.00 3.00 Weight Scale 2.045 2.043 2.043 2.045 2.052 OK

F) Surface Protection/ Coating, If applicable

S.No. Parameter Specification Actual Measured Values Remarks

a) Plating Thickness ( Powder Coating ) 50 - 60 Micron 50 60 CC DFT METER

b) Salt Spray Test (attch report) Third Party Found OK :- Report Attached

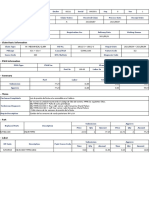

c) Special Packing Instruction

G) Visual Inspection

S.No. Parameter Specific Requirement, If any Remarks

a) Burrs & Chips Free from burr , Chips etc VISUAL OK OK OK OK OK OK

b) Sharp Edges, Blow Holes VISUAL OK OK OK OK OK OK

c) Scratch & Damages VISUAL OK OK OK OK OK OK

d) RPO (oil) Application N.A. N.A. N.A. N.A. N.A. N.A. N.A. N.A.

Summary:-

Total No. of Parameters: 16 Total No. of Parameter Verified: 16 OK: Not Ok:

No. of Parameters verified with in-house facility: 11 No. of Parameters verified with Out Source facility: 05 0

Conclusion :-

Note : No NC allowed for Major / Critical Parameters

Name Sign Name Signature

Supplier Rep: AL-SQ Engr:

Supplier Rep: AL-SQ Engr:

Mr.Shashi Patil

You might also like

- ARRI Lighting General CatalogDocument192 pagesARRI Lighting General CatalogchaytorNo ratings yet

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- Incandescent and FlourescentDocument83 pagesIncandescent and FlourescentArniel SomilNo ratings yet

- Supplier Self Part RevalidationDocument2 pagesSupplier Self Part RevalidationChetan PatilNo ratings yet

- Supplier Self Part RevalidationDocument2 pagesSupplier Self Part RevalidationChetan PatilNo ratings yet

- Part Re-Validation Report: Dighvijay Plastics & Allied Products PVT LTDDocument5 pagesPart Re-Validation Report: Dighvijay Plastics & Allied Products PVT LTDArun .vNo ratings yet

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocument3 pagesVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNo ratings yet

- MBA01161Document5 pagesMBA01161Arun .vNo ratings yet

- Sample ADDC Approved METER SCHEDULEDocument1 pageSample ADDC Approved METER SCHEDULEMubasher AhmedNo ratings yet

- FJP14213Document5 pagesFJP14213Arun .vNo ratings yet

- FJP14313Document5 pagesFJP14313Arun .vNo ratings yet

- CSP123D000021410 15 07 2023 (36) SRKDocument1 pageCSP123D000021410 15 07 2023 (36) SRKpmmahobaNo ratings yet

- FV549913Document6 pagesFV549913Arun .vNo ratings yet

- Apl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)Document1 pageApl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)devanshbhuvansht.823No ratings yet

- Qa3 MCR BW211D-40 (5402)Document1 pageQa3 MCR BW211D-40 (5402)nanda adisNo ratings yet

- Giwi RT 373Document2 pagesGiwi RT 373Aris BulaongNo ratings yet

- Cs-Rites-Door Link Mechanism (Single Link)Document3 pagesCs-Rites-Door Link Mechanism (Single Link)sohelNo ratings yet

- 10 MM AS0480104Document1 page10 MM AS0480104mamdouhNo ratings yet

- 1.11111 Hyu Flo Flu Steel: Tensile Test Impact Test (L) Chemical Composition Yield Bend MN S Cu Ni Mo CR NB SNDocument1 page1.11111 Hyu Flo Flu Steel: Tensile Test Impact Test (L) Chemical Composition Yield Bend MN S Cu Ni Mo CR NB SNyugandharNo ratings yet

- Claim VIN Information: Currency: USDDocument1 pageClaim VIN Information: Currency: USDLEONARDO DIEGO ALBINAGORTA PAREDESNo ratings yet

- 43-Utm Load Cell Tensile Calibration CartificateDocument1 page43-Utm Load Cell Tensile Calibration CartificateCustomer SupportNo ratings yet

- 1802 Brida Ac WN 6 X 150 SCH STD SWDocument1 page1802 Brida Ac WN 6 X 150 SCH STD SWAlejandro L MagnusNo ratings yet

- Claim VIN Information: Currency: USDDocument1 pageClaim VIN Information: Currency: USDLeonardo Albinagorta ParedesNo ratings yet

- Apl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)Document1 pageApl Apollo Tubes Limited Unit-Iii: Works-Vill-Kudavali Plot No-M-1, Murbad, 421401, Thane (MS)devanshbhuvansht.823No ratings yet

- Sky Mqap1Document1 pageSky Mqap1Kumara SubramanianNo ratings yet

- TC Rungta 02Document1 pageTC Rungta 02pmmahobaNo ratings yet

- Ot 27031Document1 pageOt 27031LEONARDO DIEGO ALBINAGORTA PAREDESNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- MTC 5Document1 pageMTC 5Muthazhagan SaravananNo ratings yet

- Auto On Off Ball Valve Suresales - Commented - QAP - REV-01Document1 pageAuto On Off Ball Valve Suresales - Commented - QAP - REV-01Deepak UpadhyayNo ratings yet

- 65-Muffle Furnace Calibration CartificateDocument1 page65-Muffle Furnace Calibration CartificateCustomer SupportNo ratings yet

- (A Division of Testing & Calibration India (Opc) Pvt. LTD)Document1 page(A Division of Testing & Calibration India (Opc) Pvt. LTD)santanushee8No ratings yet

- PQR PT Bse WPS 07Document2 pagesPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraNo ratings yet

- AL-905-R-11202 Spec AG01 Rev. T02Document3 pagesAL-905-R-11202 Spec AG01 Rev. T02altipatlarNo ratings yet

- Motor Itp For Package ItemsDocument1 pageMotor Itp For Package ItemsZulfequar R. Ali KhanNo ratings yet

- QA-033 Outgoing Inspection Checklist Rev.GDocument1 pageQA-033 Outgoing Inspection Checklist Rev.GChoo Wei MingNo ratings yet

- Lifting Equipment Thorough Examination Register: Almansoori Inspection ServicesDocument5 pagesLifting Equipment Thorough Examination Register: Almansoori Inspection ServicesRanjithNo ratings yet

- Reporting PPM D155A-6 Baskhara Sinar SaktiDocument9 pagesReporting PPM D155A-6 Baskhara Sinar SaktiCandy 888No ratings yet

- Control Plan-StampingDocument2 pagesControl Plan-StampingVipin Jangra100% (1)

- Part Re-Validation ReportDocument8 pagesPart Re-Validation ReportArun .vNo ratings yet

- Testi: OrationDocument1 pageTesti: OrationSusil Kumar SahooNo ratings yet

- Claim VIN Information: Currency: USDDocument1 pageClaim VIN Information: Currency: USDLeonardo Albinagorta ParedesNo ratings yet

- Claim VIN Information: Currency: USDDocument1 pageClaim VIN Information: Currency: USDLEONARDO DIEGO ALBINAGORTA PAREDESNo ratings yet

- MBA01007Document8 pagesMBA01007Arun .vNo ratings yet

- NDT UtDocument1 pageNDT UtMohd AshifNo ratings yet

- Inspection Report: 0M-84150C Assy Suction Pipe To Coil C223C4-3-1Document1 pageInspection Report: 0M-84150C Assy Suction Pipe To Coil C223C4-3-1NAGRAJNo ratings yet

- Pdir F2L09399Document1 pagePdir F2L09399Shankar JadhavNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOshekarNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- Marathan Motor India PVT LTD.: Joint Inspection ReportDocument2 pagesMarathan Motor India PVT LTD.: Joint Inspection ReportRishi GautamNo ratings yet

- AWS SEISMIC SPECIMEN KIT Blank WorksheetsDocument5 pagesAWS SEISMIC SPECIMEN KIT Blank WorksheetsA. champNo ratings yet

- 3) Minda Industries (AW2W)Document2 pages3) Minda Industries (AW2W)VikasNo ratings yet

- 12mm Diameter ReportsDocument2 pages12mm Diameter ReportsPRASAD THOMBARENo ratings yet

- MBA01015Document8 pagesMBA01015Arun .vNo ratings yet

- Examination Data Sheet: Walter TostoDocument3 pagesExamination Data Sheet: Walter TostoasdasdasdasdNo ratings yet

- 3827-E10-067 - High Performance Butterfly Valve - BDocument2 pages3827-E10-067 - High Performance Butterfly Valve - BMohamed Elsaid El ShallNo ratings yet

- 2211J5444 90mm WeldablesDocument1 page2211J5444 90mm WeldablesChethan Nagaraju KumbarNo ratings yet

- Ultrasonic Laminations Test Report BatamDocument2 pagesUltrasonic Laminations Test Report Batamvinsensius rasaNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- Claim VIN Information: Currency: USDDocument1 pageClaim VIN Information: Currency: USDLeonardo Albinagorta ParedesNo ratings yet

- Lumax Quality System: Gauge TypeDocument4 pagesLumax Quality System: Gauge TypeHarkesh KumarNo ratings yet

- Handbook of Microwave Component Measurements: with Advanced VNA TechniquesFrom EverandHandbook of Microwave Component Measurements: with Advanced VNA TechniquesRating: 4 out of 5 stars4/5 (1)

- Evergreen Catalog 2020Document77 pagesEvergreen Catalog 2020WinSajeewaNo ratings yet

- Lamps Catalog For 2 Wheelers PDFDocument28 pagesLamps Catalog For 2 Wheelers PDFB manjunatg50% (2)

- ORBIK: The Light Experts Vol. 2Document40 pagesORBIK: The Light Experts Vol. 2Jane Uymatiao0% (1)

- CAT03 - LEDS AstralPool - Proyectores LumiPlus EN - AP - v02 - 2015Document11 pagesCAT03 - LEDS AstralPool - Proyectores LumiPlus EN - AP - v02 - 2015Robert PerezNo ratings yet

- M-Light Range: Led Headlights, Marker & Tail LightsDocument12 pagesM-Light Range: Led Headlights, Marker & Tail LightsjovanicmarijaNo ratings yet

- Ford Escort MK1 Originalprospekt RS 2000 EnglischDocument8 pagesFord Escort MK1 Originalprospekt RS 2000 EnglischHenrique CorreiaNo ratings yet

- Philips Accent LightingDocument37 pagesPhilips Accent LightingCecila Torrez BenitezNo ratings yet

- 18.5W PAR30 LED: Lamp Type Watts CRI LumensDocument2 pages18.5W PAR30 LED: Lamp Type Watts CRI LumensDidier AlvarezNo ratings yet

- Rotorcraft PresentationDocument22 pagesRotorcraft PresentationLloyd FrancisNo ratings yet

- L&B General LightingDocument588 pagesL&B General LightingPatricia Vargas VillegasNo ratings yet

- Halo Lighting Power Trac Lighting Catalog 1989Document100 pagesHalo Lighting Power Trac Lighting Catalog 1989Alan Masters100% (1)

- Vtac Samsung Catalogue PDFDocument92 pagesVtac Samsung Catalogue PDFEduardo Mesa PérezNo ratings yet

- DDE Price ListDocument5 pagesDDE Price ListgaloriNo ratings yet

- Acs2 PDFDocument4 pagesAcs2 PDFToto SukisnoNo ratings yet

- Elektronapon Philips CenDocument18 pagesElektronapon Philips CenVlada VlaNo ratings yet

- Led Lamp CatalogDocument52 pagesLed Lamp CatalogAprilihardini LaksmiNo ratings yet

- Catalog Q4Document628 pagesCatalog Q4AIIOT SSSNo ratings yet

- Technical Theatre Program: Types of Lights Blocking Light Plan Video MappingDocument18 pagesTechnical Theatre Program: Types of Lights Blocking Light Plan Video MappingAnna WILLIAMSONNo ratings yet

- Aqua Electrical Equipment PDFDocument14 pagesAqua Electrical Equipment PDFBambang YuwonoNo ratings yet

- Saso Certification: LEDVANCE, Parkring 29 - 33, 85748 Garching SASO Registration / 23rd of October 2017 1Document42 pagesSaso Certification: LEDVANCE, Parkring 29 - 33, 85748 Garching SASO Registration / 23rd of October 2017 1Abdelrahman HassanNo ratings yet

- Juno Lighting Price Book Trac-Master & Vector 10-1987Document12 pagesJuno Lighting Price Book Trac-Master & Vector 10-1987Alan MastersNo ratings yet

- Types of Light FixturesDocument9 pagesTypes of Light FixturesJohn Michael CastilloNo ratings yet

- LED Lamps BrochureDocument32 pagesLED Lamps BrochureYuliia BukharovaNo ratings yet

- NVC Tranditional Lighting V4Document67 pagesNVC Tranditional Lighting V4THEARY THUNNo ratings yet

- Lighting in LandscapeDocument85 pagesLighting in LandscapeAnu AlrejaNo ratings yet

- TEATRO 2009: Price List March 2009Document20 pagesTEATRO 2009: Price List March 2009John SmithNo ratings yet

- Juno Lighting Down-Lites Downlighting Catalog 6-86Document32 pagesJuno Lighting Down-Lites Downlighting Catalog 6-86Alan MastersNo ratings yet

- MEGAMAN LED Light Source Product Guide 2023Document66 pagesMEGAMAN LED Light Source Product Guide 2023qxnh625rjmNo ratings yet