Professional Documents

Culture Documents

A Practical Guide To Improving Steel Manufacturing Processes and Production Methods

A Practical Guide To Improving Steel Manufacturing Processes and Production Methods

Uploaded by

Junaid AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Practical Guide To Improving Steel Manufacturing Processes and Production Methods

A Practical Guide To Improving Steel Manufacturing Processes and Production Methods

Uploaded by

Junaid AliCopyright:

Available Formats

A practical guide to improving steel manufacturing

processes and production methods

Table of Contents

Overview Technology

Manufacture clean steel that meets the most stringent PGNAA and PFTNA technology...................................... 15

customer requirements.......................................................... 04 X-ray fluorescence (XRF).................................................. 16

Request quote or info ›

The metals making process................................................. 05 Near-infrared (NIR) spectroscopy.................................... 18

Quality and efficiency opportunities................................... 06 Optical emission spectrometry (OES)............................ 19

Verifying materials....................................................................07

Analyzing scrap....................................................................... 08 Equipment

Feeding process materials.................................................... 09 An overview of products available for the steel

Metal gauging...........................................................................10 making process.................................................................... 21

Energy efficiency......................................................................11 Products for monitoring raw materials in steel............ 22

Environmental (air & radiation)............................................. 12 Products for analyzing trace metals and alloying

Microalloyed and low carbon steel elements.................................................................................... 23

considerations....................................................................... 13 Gauging products for hot and cold rolling

processes................................................................................. 24

Improving furnace efficiency and reducing energy

consumption.......................................................................... 26

Environmental - Air quality monitoring............................ 27

Environmental - Radiation monitoring and soil

analysis................................................................................... 28

thermofisher.com/steel Share this eBook 2

Request quote or info ›

Overview

thermofisher.com/steel Share this eBook 3

Manufacture clean steel that meets the most

stringent customer requirements

The steel industry faces increasing demand for clean and

ultraclean steel with improved mechanical properties. With

Request quote or info ›

efficiency and sustainability in mind, steel producers also

strive to produce quality strip in a manner that maximizes mill

yield and minimizes scrap while meeting stringent customer

specifications for thickness, width, hardness, and strength.

Whether you’re producing steel from iron ore or scrap, and

your end product is several inch-thick slabs or galvanized

sheet less than a millimeter thick, the following pages introduce

technologies that will help improve each stage of the steel

manufacturing production process, from incoming raw materials

to the final coating line.

thermofisher.com/steel Share this eBook 4

The metals making process

Steel process map

Request quote or info ›

thermofisher.com/steel Share this eBook 5

Quality and efficiency opportunities

Feeding

Verifying Analyzing Metal Energy Environmental

process

materials scrap gauging efficiency air & radiation

Request quote or info ›

materials

thermofisher.com/steel Share this eBook 6

Verifying materials

Analyzing and verifying your materials –

from beginning to end

Steel manufacturing facilities meet quality standards by utilizing

Request quote or info ›

both handheld X-ray fluorescence instruments and OES metal

analyzers for examination of raw materials, slag, trace and

alloying elements throughout production.

Demanding steel plants, pure metals producers and companies

needing the best determination of all the elements turn to

the Optical Emission Spectrometers for high accuracy analysis

of iron and steel from trace to alloying element levels.

Online PGNAA elemental analyzers are used in the sinter

feed application as chemical composition is one of the most

important parameters for the efficiency of the sinter process.

Click here to watch the video on

steel raw material processing.

thermofisher.com/steel Share this eBook 7

Analyzing scrap

Using scrap metal as a raw material

Manufacturing steel from scrap yields energy and green-house

emissions savings. However, the addition of scrap into the steel

Request quote or info ›

production line is a major challenge for the industry.

Compared to the clean raw material to which manufacturers

are accustomed, post-consumer scrap is composed of an

unknown mixture of metals, alloys, and grades. It may be

contaminated by radioactive sources or other hazardous

elements.

With product quality, process integrity, safety, and regulatory

compliance at risk, steel producers can rely on handheld

x-ray fluorescence (XRF) analyzers to know the exact grade

and composition of the scrap material being introduced into

the process. Radiation monitoring portals, personal radiation

detectors, and Geiger counters should be utilized before and

after the scrap enters the facility.

thermofisher.com/steel Share this eBook 8

Feeding process materials

Raw materials quality control

Precise feeding of process materials is critical to maintaining

product quality, but measuring and ensuring steel raw material

Request quote or info ›

quality control can be challenging.

• Steel mills need belt scales with a range of conveyor speeds and

levels of accuracy.

• Weighbelt feeders provide a consistent flow for blending or batching,

from light materials at low feed rates to heavy-duty loads requiring

faster feeds.

• Online elemental analyzers help monitor and control sintering process

fluctuations, inhomogeneous mixtures, and other parameters that

affect productivity, physical and metallurgical quality, and raw material

consumption and costs.

thermofisher.com/steel Share this eBook 9

Metal gauging

Gauging metal thickness and weight

Metal thickness and coating weight gauges are used in both

hot strip and cold-rolling mills. Gauging equipment provides

Request quote or info ›

precise, real-time measurements during high-speed production

of steel plate and sheet to help you meet the tightest tolerances

while maximizing raw material use.

There are coating weight gauges to ensure coating uniformity

and product quality, thickness gauges to help increase

productivity, and profile gauges to help produce thinner,

stronger steels – which also allow in-bar correction of off-gauge

product, resulting in raw materials savings and mill optimization.

Click here to watch the video on

metal thickness and coating weight gauges.

thermofisher.com/steel Share this eBook 10

Energy efficiency

Furnace efficiency and energy

consumption

Process mass spectrometers are widely used

Request quote or info ›

in many important gas analysis applications in

iron and steel plants, including blast furnace,

basic oxygen steelmaking, coke oven gas

analysis, secondary steel process control,

fuel gas analysis and direct reduction of iron

making processes in order to improve furnace

efficiency, reduce energy consumption, and

maintain compliance with ambient air quality

monitoring and reporting requirements.

thermofisher.com/steel Share this eBook 11

Environmental (air & radiation)

Furnace efficiency and energy consumption

Continuous emissions monitoring systems (CEMS)

Comply with regulatory guidelines while meeting your own specific

Request quote or info ›

air quality monitoring needs. Thermo Scientific Continuous

Emissions Monitoring Systems (CEMS) are designed to meet

US EPA 40CFR Parts 60 and 75 standards while providing

unsurpassed sensitivity, accuracy and reliability.

Radiation detection portals & monitors

Detect illicit nuclear materials inside packages or cargo at

airports, seaports, borders, government buildings, food

storage and handling facilities, transportation stations, couriers

and freight companies with radiation monitoring devices.

thermofisher.com/steel Share this eBook 12

Microalloyed and low carbon steel

considerations

Microalloyed steels, or High Strength Low-Alloy steels (HSLA), are strengthened by adding

“micro” alloy concentrations to low-carbon mild steel.

Request quote or info ›

Low-carbon steel is used to make clutch housings, bushings and suspension components

such as brackets and control arms. Because it improves weldability, low carbon steel is also

used in decorative applications such as automotive wheel covers, and as fasteners such as

nuts, bolts, screws and washers.

Analysis of microalloying elements in steel Improving Low Carbon Steel Production in Specialty

Some handheld XRF analyzes provide excellent trace and Steel Processes

micro element precision and sensitivity for microalloyed steel While much of the world’s steel is still produced in primary

analysis. Given appropriate sample preparation, the analyzer steel processes, the need for steel with greater durability and

is able to quickly and reliably verify whether the levels of corrosion resistance has led to the increased use of vacuum

microalloying elements are in agreement with the mill test degassing processes. Fast and continuous gas analysis of

report and meet the chemical composition requirements per the furnace exhaust gas by process mass spectrometers is

specification. important to secondary steel production.

thermofisher.com/steel Share this eBook 13

Request quote or info ›

Technology

thermofisher.com/steel Share this eBook 14

PGNAA and PFTNA technology

Prompt gamma neutron activation analysis and pulsed fast thermal neutron activation are based

on a subatomic reaction between a low energy neutron and the nucleus of an atom. When a

thermal, or rather low energy neutron (<0.025 eV) approaches near enough to, or collides with,

Request quote or info ›

a nucleus of an atom, an interaction between the neutron and the nucleus takes place. Energy

from the neutron is transferred to the nucleus and temporarily elevates it to an excited energy

state. The energy is then released, nearly instantaneously, in the form of a gamma ray. The

gamma-ray given off has a distinct energy associated with the atom from which it was released.

In essence the gamma-ray emitted is like a “fingerprint” of the element. The emitted gamma-

rays are detected and an energy spectrum generated which can then be analyzed for elemental

composition.

Click here to learn more about PGNAA and PFTNA.

thermofisher.com/steel Share this eBook 15

X-ray fluorescence (XRF)

XRF (X-ray fluorescence) is a non-destructive analytical technique used to determine the

elemental composition of materials. XRF analyzers determine the chemistry of a sample by

measuring the fluorescent (or secondary) X-ray emitted from a sample when it is excited

Request quote or info ›

by a primary X-ray source. Each of the elements present in a sample produces a set of

characteristic fluorescent X-rays (“a fingerprint”) that is unique for that specific element, which

is why XRF spectroscopy is an excellent technology for qualitative and quantitative analysis of

material composition.

The X-ray fluorescence process

• A solid or a liquid sample is irradiated with high energy X-rays from a controlled X-ray tube.

• When an atom in the sample is struck with an X-ray of sufficient energy (greater than the atom’s K or

L shell binding energy), an electron from one of the atom’s inner orbital shells is dislodged.

• The atom regains stability, filling the vacancy left in the inner orbital shell with an electron from one of

the atom’s higher energy orbital shells.

• The electron drops to the lower energy state by releasing a fluorescent X-ray. The energy of this

X-ray is equal to the specific difference in energy between two quantum states of the electron. The

measurement of this energy is the basis of XRF analysis.

Click here to download the eBook:

XRF Technology in the Field

thermofisher.com/steel Share this eBook 16

X-ray fluorescence (XRF)

Request quote or info ›

Click here to download the eBook:

XRF Technology in the Lab

thermofisher.com/steel Share this eBook 17

Near-infrared (NIR) spectroscopy

A spectroscopic method that uses the near-infrared region of the electromagnetic spectrum,

and is based on overtones and combinations of bond vibrations in molecules.

Request quote or info ›

Click here to learn more about NIR Spectroscopy

thermofisher.com/steel Share this eBook 18

Optical emission spectrometry (OES)

OES enables you to perform rapid elemental analysis of solid metallic samples with optical

emission spectrometry using Arc/Spark excitation. This technique meets the most demanding

analysis needs of the metals industry from production control to R&D, from incoming material

Request quote or info ›

inspection to scrap sorting.

Read how OES provides

ultra-fast methods allowing

characterization of inclusion

during steel production.

thermofisher.com/steel Share this eBook 19

Request quote or info ›

Equipment

thermofisher.com/steel Share this eBook 20

An overview of products available for the

steel making process

Request quote or info ›

Click here to download the infographic:

The Iron and Steel Manufacturing Process.

thermofisher.com/steel Share this eBook 21

Products for monitoring raw materials in steel

Request quote or info ›

CB Omni Fusion Online Ramsey Conveyor Belt Ramsey Weighbelt MOLA/MOLA-LS (Limited

Elemental Analyzer Scale Systems Feeders Source) Moisture Online

The CB Omni analyzer for sinter Ramsey belt scale systems monitor Accurately control process material Analyzers

measures sinter feed chemistry on- steel raw material feed to crushers, feed rates. Weighbelt Feeders help Designed for harsh industrial

line and provides minute by minute, mills, screens, preparation plants, reduce material waste, maintain applications, these rugged

reliable chemical analysis data to and coal-fired power plants to help blend consistency, increase profits, instruments use patented neutron

enable control of basicity in real time. ensure precise feeding of process and meet customer specifications. backscatter, pulse mode, ion

Gain significant economic benefits materials and maintain product chamber technology to non-

for the iron ore sintering process and quality. intrusively measure the moisture

the blast furnace. content in metallurgical grade coke

and/or iron ore pellets.

Product details › Product details › Product details › Product details ›

thermofisher.com/steel Share this eBook 22

Products for analyzing trace metals and alloying

elements

Request quote or info ›

ARL iSpark Series Niton XL5 Handheld ARL easySpark ARL 9900 Explorer 4 Analyzer

Optical Emission XRF Analyzer Metal Analyzer Simultaneous- for Industrial

Spectrometer Handheld XRF Designed for small to mid- Sequential XRF Manufacturing

Obtain precise analyzers deliver accurate size foundries and metals Series Monitor the quality of

spectrochemical analysis metal and alloy analysis for processing companies, incoming material and

Drive process control

of metals for quality material verification. or as back-up instrument, finished product with

laboratory efficiencies in iron

control and production in this bench top OES improved inclusion analysis

and steel applications with

primary metals production, analyzer performs fast, and process control.

this complete laboratory

foundries, fabricators in accurate and reliable

workflow automation

the automotive, aviation elemental analysis of solid

solution.

and appliance industries, metal samples from trace to

contract laboratories and percent level.

metal recycling industries.

Product details › Product details › Product details › Product details › Product details ›

thermofisher.com/steel Share this eBook 23

Gauging products for hot and cold rolling processes

Non-contact Non-contact metals Non-contact On-line non-contact Non-contact paint

thickness gauges thickness gauges thickness gauges contact thickness thickness gauges

Request quote or info ›

for aluminum rolling for hot strip mills for cold rolling and gauges

mills process lines

RM 210 AS SIPRO Simultaneous RM 210 CM Strip Laser TX Optical RM 300 EL and

Aluminum Thickness Profile Gauge Thickness Gauge Thickness Gauge PROSIS™ Coating

Gauge Thermo Scientific non- Thermo Scientific Thermo Scientific optical Weight Gauges

Thermo Scientific non- contact thickness thickness gauges for thickness gauges provide Thermo Scientific paint

contact thickness gauges gauges for hot strip cold rolling and process accurate on-line non-contact thickness gauges provides

provide reliable, repeatable mills provide reliable, lines provide accurate, thickness measurements for fast, accurate and reliable

process control data to high-speed repeatable non-contact thickness a variety of sheet processing profile measurement of

ensure product uniformity, process control data measurement of flat sheet applications in the steel and multilayer paint and organic

and increase output. Get to identify operating steel in every type of aluminum industries. coatings, providing essential

accurate, non-contact issues, ensure product processing line. information to optimize your

thickness measurement uniformity, and increase production process.

of aluminum and aluminum output.

alloys with gauges specially

designed for aluminum cold

strip and foil mills.

Product details › Product details › Product details › Product details › Product details ›

thermofisher.com/steel Share this eBook 24

Gauging products for hot and cold rolling

processes

Hot coating weight Non-contact Metals coating Basis weight Measurement and

gauges metallic coating weight gauge sensor control system

Request quote or info ›

gauges

RM 310 EH Hot RM 315 EC Cold Cold Coating Weight Beta Plus Basis 21PlusHD

Coating Weight Coating Weight Gauges Weight Sensor Measurement and

Gauges Gauges Thermo Scientific coating Save raw materials, improve Control System

Thermo Scientific hot Thermo Scientific metallic weight gauges have yields, and produce higher Thermo Scientific™

coating weight gauges coating gauge provides employed the physics quality products with basis 21PlusHD allows

significantly improves fast, accurate, non- of x-ray fluorescence to weight transmission sensors manufacturers of coated

coating weight control by contact measurement provide accurate and for extrusion coating, products or extrusion

reducing the dead time of coatings applied to reliable on line measurement nonwovens, roofing and coated products to maintain

between the air knives and flat sheet products, of zinc, tin and other metallic building products. the high performance

measurement, resulting in helping to ensure coating coatings. characteristics of critical

raw material savings and a uniformity, product quality layers, such as adhesion or

reduction in scrap. and raw materials savings. barrier layers.

Product details › Product details › Product details › Product details › Product details ›

thermofisher.com/steel Share this eBook 25

Improving furnace efficiency and reducing energy

consumption

Request quote or info ›

PrimaPRO Process Mass Spectrometer Prima BT Bench Top Mass Spectrometer

The combination of fast, accurate MS gas analysis for gas efficiency, heat Achieve high scanning speeds and reproducible measurements with the

and mass balances and hydrogen analysis, with advanced process control Thermo Scientific Prima BT Bench Top Mass Spectrometer. Specifically

and mathematical modeling, can reduce coke consumption by up to 100 kg designed for process development laboratories, this process gas analyzer is

per ton and increase iron production. Process Mass Spectrometers provide a highly precise, multi-port magnetic sector gas analyzer.

fast, accurate, comprehensive gas analysis, enabling integrated steel mills

and mini-mills to efficiently monitor primary and secondary conversion

methods.

Product details › Product details ›

thermofisher.com/steel Share this eBook 26

Environmental - Air quality monitoring

Request quote or info ›

Ambient Gas Monitoring Continuous Emissions Monitoring Systems (CEMS)

We offer a variety of analyzers for the ambient monitoring of the criteria Comply with regulatory guidelines while meeting your own specific air quality

pollutant gases, including CO, NOX, SO2, and others such as CH4 and monitoring needs. These systems are designed to meet US EPA 40CFR

CO2. Parts 60 and 75 standards while providing unsurpassed sensitivity, accuracy

and reliability.

Product details › Product details ›

thermofisher.com/steel Share this eBook 27

Environmental - Radiation monitoring and soil

analysis

Request quote or info ›

ASM IV Series Automatic Niton XL5 Handheld XRF RadEye GR Grapple RadEye SPRD Personal

Scrap Monitoring System Analyzer Monitoring System Radiation Detector

Detect radioactive contamination in The Thermo Scientific Niton XL5 This wireless radiation detection The pocket-sized Thermo Scientific

scrap metal before it even enters Handheld XRF Analyzer enable system is designed to be installed RadEye SPRD Personal Radiation

the supply chain with an automatic to measure heavy metal in soils on a grapple to monitor scrap metal, Detector alerts workers to potential

scrap monitoring system. around currently running and former preventing radioactive contaminated radiation exposure at greater

metallurgic plants. scrap metal from making its way into distances without increasing false

the steel making process. alarms so they can respond quickly

and decisively to real radiation

threats.

Product details › Product details › Product details › Product details ›

thermofisher.com/steel Share this eBook 28

Additional resources

White Paper Infographic Application Note Application Note Infographic

Request quote or info ›

High Speed The Iron and Steel Improving Low Application of 10 Reasons (and

Archiving of Manufacturing Carbon Steel On-line Elemental Places) Recyclers

Thickness and Process Production in Analysis for Control Need Radiation

Profile Data in the Specialty Steel of Sinter Feed Detection

View this process map

Hot Strip Mill of the complete range of

Processes Basicity Contaminated scrap metal

This paper describes a technologies that improve The need for refined steel The basicity of sinter feed can result in expensive plant

stereoscopic x-ray profile each stage of the steel with greater durability and material is an important decontamination and shut

gauge with the ability to manufacturing production resistance to heat and parameter in the efficient down. Multiple points of

determine both the cross- process, from incoming raw corrosion has led to the operation of the sintering inspection are needed to

thickness profile and the materials to the final coating increased use of vacuum and iron making process. ensure processed materials

physical position of the strip line. degassing processes, are free from radiation.

in space. such as VOD and RH, in

secondary steel production.

Download › Download › Download › Download › Download ›

thermofisher.com/steel Share this eBook 29

Additional resources

Brochure Video Video Poster Web Page

Request quote or info ›

Optimize Your The Iron Ore Hot and Cold Rolling Ultra-Fast Inclusion PGNAA/PFTNA

Metals Production Sintering Process Processes in Steel Analysis with Spark- Technology

Process Manufacturing OES The CB Omni analyzer

The production of high-

Shifts in steel production quality sinter is crucial for Metal thickness and Spark OES for the analysis uses Prompt Gamma

require producers to assuring consistent, stable coating weight gauges of solid steel samples Neutron Activation Analysis

be aware of, and willing furnace productivity with provide precise, real-time allows performing various (PGNAA) or Pulsed Fast

to adopt, the latest a low consumption of measurements during high- types of inclusion related Thermal Neutron Activation

technologies to lead the reductants. speed production of steel determinations in the time of (PFTNA) to determine

industry, both commercially plate and sheet. a standard OES analysis. elemental concentration in

and environmentally. bulk materials. The method

is deeply penetrative

Download › Watch › Watch › Download › and measures through

many centimeters of

material making it an ideal

technology for real-time

elemental analysis of bulk

materials on conveyor belts.

View ›

thermofisher.com/steel Share this eBook 30

About Thermo Fisher Scientific

Thermo Fisher Scientific is the world leader in serving science. Our mission is to enable our

customers to make the world healthier, cleaner and safer. We help our customers accelerate

life sciences research, solve complex analytical challenges, improve patient diagnostics,

deliver medicines to market and increase laboratory productivity. Through our premier brands

– Thermo Scientific, Applied Biosystems, Invitrogen, Fisher Scientific and Unity Lab Services –

we offer an unmatched combination of innovative technologies, purchasing convenience and

comprehensive services.

For additional information or to request a quote, please click below.

Request quote or info

thermofisher.com/steel

© 2020 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries. Specifications,

terms and pricing are subject to change. Not all products are available in all countries. Please consult your local sales representative for details.

thermofisher.com/steel

You might also like

- EPRI 3002001465 - Grade 91 Steel HandbookDocument120 pagesEPRI 3002001465 - Grade 91 Steel HandbookWillie NeptuneNo ratings yet

- KOMATSU D65PX-15 Service ManualDocument267 pagesKOMATSU D65PX-15 Service ManualLizardo Astudillo Cruz100% (9)

- The Essentials of Material Science and Technology for EngineersFrom EverandThe Essentials of Material Science and Technology for EngineersRating: 5 out of 5 stars5/5 (1)

- As 1163 - Hollow Sections For Structural SteelDocument26 pagesAs 1163 - Hollow Sections For Structural SteelIrene YuNo ratings yet

- PNS 113 RebarsDocument12 pagesPNS 113 RebarsKenneth Z. Peniano100% (3)

- Advanced Melting TechnologiesDocument52 pagesAdvanced Melting TechnologiesRam Charan100% (1)

- WRC 541Document150 pagesWRC 541Ganesh Patil100% (4)

- Nuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresFrom EverandNuclear Power Plant Safety and Mechanical Integrity: Design and Operability of Mechanical Systems, Equipment and Supporting StructuresRating: 5 out of 5 stars5/5 (1)

- Mechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsFrom EverandMechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsNo ratings yet

- Engineering Materials and Processes Desk ReferenceFrom EverandEngineering Materials and Processes Desk ReferenceRating: 5 out of 5 stars5/5 (2)

- Bs 6387 Catc-950deg Cel-HighlightedDocument1 pageBs 6387 Catc-950deg Cel-HighlightedAshik M RasheedNo ratings yet

- Coal in Direct Ironmaking ProcessesDocument101 pagesCoal in Direct Ironmaking ProcessesJanaína MachadoNo ratings yet

- Carbon Steel HandbookDocument172 pagesCarbon Steel Handbookmahasiswa lamaNo ratings yet

- A Comparison of Pressure-Less Silver Sintering Materials With ConDocument28 pagesA Comparison of Pressure-Less Silver Sintering Materials With ConGlennard GalangNo ratings yet

- Metals Ebook 202011 WebDocument13 pagesMetals Ebook 202011 WebRioZuNo ratings yet

- LCI Methodology Report 2017 VfinalDocument40 pagesLCI Methodology Report 2017 VfinalGaneshbhoiteNo ratings yet

- Handbook For Machining GuidelinesDocument135 pagesHandbook For Machining GuidelinesSyed NawazNo ratings yet

- Brazzalotto Luca 116609Document81 pagesBrazzalotto Luca 116609Alejandra HernandezNo ratings yet

- Expert Systems and Coal Quality in Power Generation - ccc186Document62 pagesExpert Systems and Coal Quality in Power Generation - ccc186Arzu AkarNo ratings yet

- Stainless Steel Guide Apr19Document139 pagesStainless Steel Guide Apr19Dominic100% (2)

- MBCMTS9 5 5x8 5 MCDocument32 pagesMBCMTS9 5 5x8 5 MCCRC PressNo ratings yet

- Machining Difficult-to-Cut Materials: Hossam A. Kishawy Ali HosseiniDocument253 pagesMachining Difficult-to-Cut Materials: Hossam A. Kishawy Ali HosseiniAnis dakhlaouiNo ratings yet

- 5384 - en P PDFDocument25 pages5384 - en P PDFamitsonuksmsNo ratings yet

- BAS Catalogue No. 822a - September 2014Document31 pagesBAS Catalogue No. 822a - September 2014inorwoodNo ratings yet

- Stainless Steel Guide Apr19 PDFDocument151 pagesStainless Steel Guide Apr19 PDFIrinaNo ratings yet

- Review of The Performance of High of High Strength Steels Used OffshoreDocument130 pagesReview of The Performance of High of High Strength Steels Used OffshoreEmad A.AhmadNo ratings yet

- Voluntary Product Standard Ps2-04 Performance Standard For Wood-Based Structural-Use PanelsDocument56 pagesVoluntary Product Standard Ps2-04 Performance Standard For Wood-Based Structural-Use Panelsalicarlos13No ratings yet

- Gas RavourDocument8 pagesGas RavourddvNo ratings yet

- Assessment of Metal Condition and Remaining Life of In-Service Power Plant Components Operating at High TemperatureDocument119 pagesAssessment of Metal Condition and Remaining Life of In-Service Power Plant Components Operating at High TemperatureAlok SinghNo ratings yet

- Analysis of Novel Corrosion Resistant Maraging Steels For Use in Additive ManufacturingDocument36 pagesAnalysis of Novel Corrosion Resistant Maraging Steels For Use in Additive ManufacturingJinsoo KimNo ratings yet

- Evolution of Metal Casting Technologies (2017)Document49 pagesEvolution of Metal Casting Technologies (2017)LuisNo ratings yet

- Powder Material For Inductor Cores: Evaluation of MPP, Sendust and High Flux Core CharacteristicsDocument62 pagesPowder Material For Inductor Cores: Evaluation of MPP, Sendust and High Flux Core Characteristicsdwie agung prasetyoNo ratings yet

- Stainless Steel Guide Dec20Document151 pagesStainless Steel Guide Dec20emre ozdemirNo ratings yet

- PNS 113 Rebars PDFDocument12 pagesPNS 113 Rebars PDFKenneth PenianoNo ratings yet

- Metallurgy: Technical Activities 1997Document128 pagesMetallurgy: Technical Activities 1997borgiamatriceNo ratings yet

- Temperature Influence On Abrasive Resistance of Quenched and Tempered SteelsDocument66 pagesTemperature Influence On Abrasive Resistance of Quenched and Tempered SteelsNABIL HUSSAINNo ratings yet

- Stalkretsloppet Slutrapport Miljohandbok Engelsk WebDocument120 pagesStalkretsloppet Slutrapport Miljohandbok Engelsk WebChester SmithNo ratings yet

- Mat Spec, Astm A 694 F65 Low Alloy Steel Forgings: SubseaDocument14 pagesMat Spec, Astm A 694 F65 Low Alloy Steel Forgings: SubseaJones Pereira Neto100% (1)

- Optimization of Decarbonization On Steel IndustryDocument28 pagesOptimization of Decarbonization On Steel Industrymsantosu000No ratings yet

- Ni Aisi 9004 HightemperaturecharacteristicsDocument47 pagesNi Aisi 9004 HightemperaturecharacteristicsGregory Alberto Artavia SalazarNo ratings yet

- Surface Engineering Measurement Standards For Inorganic MaterialsDocument264 pagesSurface Engineering Measurement Standards For Inorganic MaterialsAmauri Ghellere Garcia Miranda100% (1)

- High-Temperature Characteristics of Stainless Steels: A Designers' Handbook Series N 9004Document47 pagesHigh-Temperature Characteristics of Stainless Steels: A Designers' Handbook Series N 9004aemis2010No ratings yet

- Ips M TP 750 PDFDocument183 pagesIps M TP 750 PDFHossein AhmadiNo ratings yet

- Material Deformation and FailuresDocument18 pagesMaterial Deformation and FailuresEnjilaNo ratings yet

- ITW Cored Wire Catalogue ENG PDFDocument70 pagesITW Cored Wire Catalogue ENG PDFPhạm Văn ĐảngNo ratings yet

- Fivi SW43SDocument20 pagesFivi SW43Sdaducageorsa86No ratings yet

- Steel Casting HandbookDocument74 pagesSteel Casting Handbooktang weng wai100% (2)

- Welding ImprovementsDocument35 pagesWelding ImprovementsHasnain TariqNo ratings yet

- COE-101.06, Materials Selection For Corrosion ControlDocument60 pagesCOE-101.06, Materials Selection For Corrosion Controlehsan hatamiNo ratings yet

- BCSA - P50-09 Typical Welding Procedure Specifications For Structural Steelwork - Welding BookDocument0 pagesBCSA - P50-09 Typical Welding Procedure Specifications For Structural Steelwork - Welding BookDifa Liu100% (1)

- Steel Technology PDFDocument125 pagesSteel Technology PDFArup MondalNo ratings yet

- Sic 33991Document38 pagesSic 33991Aldo J AN0% (1)

- Mechanics of Carbon Nanotubes: Fundamentals, Modeling and SafetyFrom EverandMechanics of Carbon Nanotubes: Fundamentals, Modeling and SafetyNo ratings yet

- Engineered Ceramics: Current Status and Future ProspectsFrom EverandEngineered Ceramics: Current Status and Future ProspectsTatsuki OhjiNo ratings yet

- Advances in Materials Science for Environmental and Energy Technologies IIIFrom EverandAdvances in Materials Science for Environmental and Energy Technologies IIITatsuki OhjiNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Electrician (Steel Plant) - ATS - NSQF-5 - 0Document48 pagesElectrician (Steel Plant) - ATS - NSQF-5 - 0Junaid AliNo ratings yet

- Operator (Steel Plant) : CurriculumDocument47 pagesOperator (Steel Plant) : CurriculumJunaid AliNo ratings yet

- Candidate's Over-All ProfileDocument6 pagesCandidate's Over-All ProfileJunaid AliNo ratings yet

- Zoom SessionDocument4 pagesZoom SessionJunaid AliNo ratings yet

- Byjus NotesDocument1 pageByjus NotesJunaid AliNo ratings yet

- Casio 991 Es Rechniques MathDocument36 pagesCasio 991 Es Rechniques Mathlino2320No ratings yet

- Indoor Voltage Transformers: TJP 5.0-FDocument2 pagesIndoor Voltage Transformers: TJP 5.0-FEbrahim ArzaniNo ratings yet

- Yordyqlq LQLQLQLQ LQLQLQLQ LQLLQLQL QLQLQL: Professional Development Seminar Series - NEC Requirements For GeneratorsDocument17 pagesYordyqlq LQLQLQLQ LQLQLQLQ LQLLQLQL QLQLQL: Professional Development Seminar Series - NEC Requirements For GeneratorsYordi AlvitresNo ratings yet

- TRIGONOMETRYDocument61 pagesTRIGONOMETRYMapurisa TriciahNo ratings yet

- Transport and InstallationDocument11 pagesTransport and InstallationalbertoNo ratings yet

- Chapter 3 - Operational AmplifierDocument72 pagesChapter 3 - Operational AmplifierMOHAMMAD BANIN ISMANo ratings yet

- Std. X Chemistry PAPER IV ExtendedDocument8 pagesStd. X Chemistry PAPER IV ExtendedYashodhaNo ratings yet

- Algebra Exam ContributionDocument2 pagesAlgebra Exam ContributionDan CasuraoNo ratings yet

- Me8594-Dynamics of Machines - Part A and Part B Questions and AnswersDocument116 pagesMe8594-Dynamics of Machines - Part A and Part B Questions and AnswersSYLVIA ANITANo ratings yet

- EDC Key FinalDocument17 pagesEDC Key FinalVignesh GNo ratings yet

- ENGG1300 Lecture 1 Force VectorsDocument47 pagesENGG1300 Lecture 1 Force Vectorsnomi khanNo ratings yet

- Lifetime Testing of Metallized Thin Film Capacitors For Inverter ApplicationsDocument3 pagesLifetime Testing of Metallized Thin Film Capacitors For Inverter ApplicationsMohammed Al gobariNo ratings yet

- International Journal of Pavement Research and Technology: Innocent Kafodya, F OkontaDocument13 pagesInternational Journal of Pavement Research and Technology: Innocent Kafodya, F OkontaJane DDNo ratings yet

- M30 Knig2461 04 Ism C30Document34 pagesM30 Knig2461 04 Ism C30Hanzala TahirNo ratings yet

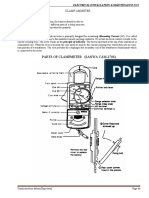

- Parts of Clampmeter (Sanwa Cam-270S) : Clamp AmmeterDocument4 pagesParts of Clampmeter (Sanwa Cam-270S) : Clamp AmmeterFERDINAND BANAGANo ratings yet

- CH (3) Than Htet AungDocument25 pagesCH (3) Than Htet AungMyat MyatNo ratings yet

- GEB22A Electric MotorDocument140 pagesGEB22A Electric Motorerminhusagic2308No ratings yet

- Ca 1 Medicine1Document16 pagesCa 1 Medicine1Dimitri Valdes TchuindjangNo ratings yet

- Arteche DS Acf-36 enDocument2 pagesArteche DS Acf-36 enasistente.licitacionesNo ratings yet

- DD Cen TS 15534-3-2007Document14 pagesDD Cen TS 15534-3-2007MladenMarkovicNo ratings yet

- Problem 1: Solution: Fluid Mechanics and HydraulicsDocument11 pagesProblem 1: Solution: Fluid Mechanics and HydraulicsJacob Santos100% (2)

- DMB-01-C-M24: TIMER M/FUNCTION 24VDC/24-240VAC SUPPLY 1 C/O 0.1S-100H Catalogue NoDocument4 pagesDMB-01-C-M24: TIMER M/FUNCTION 24VDC/24-240VAC SUPPLY 1 C/O 0.1S-100H Catalogue Noyassine yassineNo ratings yet

- Chemistry - Xii 2020-21 - Revised & Reduced Syllabus - Sulekha PDFDocument7 pagesChemistry - Xii 2020-21 - Revised & Reduced Syllabus - Sulekha PDFanshuman roy0% (1)

- Models Line Up: Inverter SingleDocument27 pagesModels Line Up: Inverter SingleReikort LászlóNo ratings yet

- General Purpose 3-Phase Induction Motors: Product CatalogueDocument36 pagesGeneral Purpose 3-Phase Induction Motors: Product CatalogueGea Mandiri ciptaNo ratings yet

- Working Principle of Arc Quenching in HVDC: RABINO, Bruce Jerard SDocument14 pagesWorking Principle of Arc Quenching in HVDC: RABINO, Bruce Jerard Srare machineNo ratings yet

- Rapid Shutdown Product Manual BCG.00884.0AP revACDocument36 pagesRapid Shutdown Product Manual BCG.00884.0AP revACmarkmarkchanchan0902No ratings yet

- New Scientist International Edition - April 15, 2023Document62 pagesNew Scientist International Edition - April 15, 2023Nikolai LazarovNo ratings yet