Professional Documents

Culture Documents

HPT ICTTEN202 Job Safety Analysis.v1.1

HPT ICTTEN202 Job Safety Analysis.v1.1

Uploaded by

parvinder ranaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HPT ICTTEN202 Job Safety Analysis.v1.1

HPT ICTTEN202 Job Safety Analysis.v1.1

Uploaded by

parvinder ranaCopyright:

Available Formats

ACTIVITY 2 – JOB SAFETY ANALYSIS

Prior to commencing work you are required to complete a JSA. This JSA will be used during your

induction meeting.

If you are working with bare fibre and laser based equipment, you should give consideration to

manufacturers warning labels. When completing your JSA with fibre ensure you also make

reference to the manufacturers safe operating procedures and working with lasers and laser

equipment.

Note: This is a generic JSA and representative of what is found across industry. Your employer will

have their own variation on how risk is managed and how JSAs are completed.

You are required to demonstrate your ability to prepare for worksite activities by performing the

following activities. Based on the scenario below, you will need to complete a Job Safety Analysis.

Complete the job details on page 1 of the JSA

Identify the hazards associated with each of the job steps (at least 2 hazards for each

step)

Risk rank the hazards using the risk matrix

Identify controls the can be implemented to reduce the identified risk

Risk rank the hazards again to identify their risk now that controls are in place

Identify the person responsible for implementing these controls

You have artistic licence to fill any gaps the scenario does not provide

Scenario – You have received a Ticket of Work to attend site to carry out the Activity below.

The TOW details are:

Contact person – Mr Jones

Address – 123 Hogan Street, Casey, Victoria 3000

Contractor – Your name

Permit - Not Required

Activity

You are required to install a Madison box onto an external wall of a timber framed house. The

incoming cable will be contained in a conduit running along a wall to the bottom of the Madison

box.

Details of work order:

o An entry hole will be drilled at an upward angle into the inside of the timber

framed wall cavity.

o Madison box to be mounted on external wall

o A 25mm conduit is to be mounted to contain 2pr lead in cable

o Outdoor cable run into the Madison box and connected to two indoor UTP cables

using IDC connectors

o Two 4pair UTP cables will be run and terminated in a separate locations one on a

610 socket and the other on an 8P4C socket

JB Hunter Technology Page 1 of HPT-LA-ICTTEN202-v20.0.0

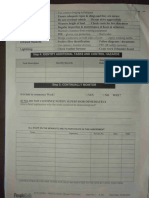

JOB SAFETY ANALYSIS GUIDE – PAGE 1

JOB DETAILS

Date: Workers 1.

on Site:

Company 2.

Name:

Site 3.

Address:

Prepared 4.

By:

RISK EXPOSURE MATRIX

(5) Extreme High Critical Critical Critical Critical

CONSEQUENCE

(4) Severe Medium High High High Critical

(3) Major Low Medium High High Critical

(2) Moderate Low Low Medium High High

(1) Minor Low Low Low Medium Medium

(A) Very (E) Very

(B) Unlikely (C) Possible (D) Likely

Unlikely Likely

LIKLIHOOD

LIKELIHOOD CONSEQUENCE

Letter Frequency of Rank No Description Rank

event

A 1 in 10-year Very 1 Injury or harm to one person, or Minor

event (Or less Unlikely Environmental impact is in immediate area area and with

frequent) (Or Rare) no residual impact

B 1 in 5-year Unlikely 2 Serious injuries or disability sustained to one person, or Moderate

event (Or less Environmental impact is in immediate area and with

frequent) short-term residual impact (< 1 year)

C 1 in 2-year Possible 3 Serious injuries or disability sustains to multiple persons, Major

event or

Environmental impact is in local area or medium-term

residual impact (2 to 5 years)

D Annual event Likely 4 Total permanent disability or fatality to one person, or Severe

Environmental impact extends across a region (But

within a state) or longer-term residual impact (5 to 20

years)

E Quarterly event Very Likely 5 Total permanent disability or fatality of multiple Extreme

(Or more (Or almost persons, or

frequent) certain) Environmental impact extends across regions (Across

states or nationally) or extensive residual impact

(>20 Years)

RISK EXPOSURE HIERARCHY OF CONTROLS

Do not commence Activity. Critical risk Best forms of 1) Elimination (Can the Hazard/Task

exposure. Introduce further high-level controls to control to use be eliminated)

Critical

lower the risk level and re-assess where possible. 2) Substitution (Is there a safer

Start at the product}

High risk exposure. Introduce further high-level top, and work 3) Engineering (Can the item be

controls to lower the risk level and reassess. down to find altered i.e. addition of guarding)

High Controls are to be actively monitored. Review if the most

there is a change to the activity, conditions, practicable

process, injury or illness occurs. solution

Medium risk exposure. Maintain monitoring of Where possible 4) Administration (Implementation of

Medium controls. Review if there is a change to the should only be Training procedure, Signage, etc,)

activity, conditions, process, injury or illness occurs used in 5) Personal Protective Equipment

Low risk exposure. Maintain monitoring of controls conjunction (PPE) – Gloves, Respirator

Low required. Review if there is a change to the with Controls equipment

activity, conditions, process, injury or illness occurs above the line

JOB SAFETY ANALYSIS – Page 2

Note: This is a generic JSA and representative of what is found across industry. Your employer

may have their own variation on how risk is managed and how JSAs are completed.

CONTROL MEASURE & CONTROL

WORK SEQUENCE IDENTIFY AND ASSESS

RE-ASSESS MANAGER

HAZARDS AND

STEP INITIAL RESIDUAL RESPONSIBLE

JOB STEP ENVIRIONMENTAL CONTROL

No RISK RISK FOR CONTROL

ASPECTS

1. Discuss

customer

requirements

and review

worksite

2. Site SetUp

(House)

3. Testing

4. Restoration &

CleanUp

(Ducts, Pits &

Cable)

Student name:

You might also like

- TEMPLATE - 30-60-90 Day Plan (Shared)Document1 pageTEMPLATE - 30-60-90 Day Plan (Shared)Wall Street Forex (WSFx)No ratings yet

- BSBLDR803 Partnership Task 1 Akash KaileyDocument18 pagesBSBLDR803 Partnership Task 1 Akash Kaileysuper neoNo ratings yet

- Personal Cash Flow Statement: GoalsDocument3 pagesPersonal Cash Flow Statement: GoalsWilliam ReeceNo ratings yet

- CRAP ChecklistDocument2 pagesCRAP ChecklistCheyenne Wilson67% (3)

- U 415Document18 pagesU 415saiNo ratings yet

- Introduction To Fluorescence Techniques: Fluorophores and Their Amine-Reactive DerivativesDocument8 pagesIntroduction To Fluorescence Techniques: Fluorophores and Their Amine-Reactive DerivativesManoj Kumar ChaurasiaNo ratings yet

- Prelim ExamDocument17 pagesPrelim Examsaci PTNo ratings yet

- Comparison of Software Development MethodologiesDocument14 pagesComparison of Software Development MethodologiesKamal TiwariNo ratings yet

- Training Performance AppraisalDocument4 pagesTraining Performance AppraisalJohnson FernandezNo ratings yet

- BSBCMM411 Assessment Task 2 - Part A, B and CDocument6 pagesBSBCMM411 Assessment Task 2 - Part A, B and CreeceNo ratings yet

- OIM Quality Assurance Program CharterDocument4 pagesOIM Quality Assurance Program CharterGaurav AgarwalNo ratings yet

- How To Prepare For ExamsDocument5 pagesHow To Prepare For ExamsMir Fida NadeemNo ratings yet

- VP Learning Development in Newark NJ Resume Mary BanenDocument2 pagesVP Learning Development in Newark NJ Resume Mary BanenMaryBanenNo ratings yet

- Sample Consultation ReportDocument18 pagesSample Consultation ReportJames Rovira0% (1)

- AP 03 Force Field AnalysisDocument12 pagesAP 03 Force Field AnalysisWidayanti IshakNo ratings yet

- Ey Recai 62 Top 40 Ranking v3 FinalDocument5 pagesEy Recai 62 Top 40 Ranking v3 FinalStathis MetsovitisNo ratings yet

- BSBPMG632 - Asessment Booklet - Student - V1.0Document28 pagesBSBPMG632 - Asessment Booklet - Student - V1.0Rishabh SinghNo ratings yet

- Khyber Medical College, Khyber Teaching Hospital, Peshawar Strategic Plan Template For Year 2020-2025Document3 pagesKhyber Medical College, Khyber Teaching Hospital, Peshawar Strategic Plan Template For Year 2020-2025Arsalan KhanNo ratings yet

- Future Managers Pty LTD 2011-2012 CatalogueDocument42 pagesFuture Managers Pty LTD 2011-2012 CatalogueFuture Managers Pty LtdNo ratings yet

- My4DX User Guide - v4Document13 pagesMy4DX User Guide - v4John Freddy ValenciaNo ratings yet

- The Power of Decisions: M. Akbar BhattiDocument21 pagesThe Power of Decisions: M. Akbar BhattiAkbar BhattiNo ratings yet

- GRC Governance Risk and Compliance in Oracle - OverviewDocument21 pagesGRC Governance Risk and Compliance in Oracle - OverviewVenkatesam BarigedaNo ratings yet

- Strategic Control and OutsourcingDocument5 pagesStrategic Control and OutsourcingSandeep KulkarniNo ratings yet

- Presentation Timeline - 5 Years: Internship at BPA & IdeationDocument2 pagesPresentation Timeline - 5 Years: Internship at BPA & IdeationPrarit AgarwalNo ratings yet

- 8 30 60 90 Performance ReviewDocument2 pages8 30 60 90 Performance Reviewbryan dela santaNo ratings yet

- Com3705 DEVIANCE PDFDocument325 pagesCom3705 DEVIANCE PDFAnonymous AvG4TzCNo ratings yet

- Business Plan Gift Service Store: Submitted By: - Harshita Saini M.SC Final Lady Irwin College Cover SheetDocument25 pagesBusiness Plan Gift Service Store: Submitted By: - Harshita Saini M.SC Final Lady Irwin College Cover SheetHarshita SainiNo ratings yet

- Training Need Analysis Questionnaire 168Document4 pagesTraining Need Analysis Questionnaire 168srechallaNo ratings yet

- Extreme NegotiationsDocument8 pagesExtreme Negotiationsgaurav aroraNo ratings yet

- Team Building Leadership Issues PendseDocument49 pagesTeam Building Leadership Issues Pendseirfanahmed.dba@gmail.com0% (1)

- Planning For Success Introduction Elearning CostsDocument39 pagesPlanning For Success Introduction Elearning CostsEdward RaagasNo ratings yet

- 5-Minute Meeting Planner: Topics Responsible TimeDocument2 pages5-Minute Meeting Planner: Topics Responsible TimeHeather Jackson-ReedNo ratings yet

- Quarterly Momentum PlannerDocument109 pagesQuarterly Momentum PlannerWANT Social MediaNo ratings yet

- Communication Plan: Presented By: Sakshi Khullar 39 Reeba Gulati 33Document11 pagesCommunication Plan: Presented By: Sakshi Khullar 39 Reeba Gulati 33SHivani GuptaNo ratings yet

- Assessment Task 2 of 2 Portfolio and Written Questions: Submission InformationDocument28 pagesAssessment Task 2 of 2 Portfolio and Written Questions: Submission InformationDiego Grecco100% (1)

- Improving Profitability : Why Farmers Need Farm Financial ManagementDocument42 pagesImproving Profitability : Why Farmers Need Farm Financial ManagementgildesenganioNo ratings yet

- Goal Setting PPT by PhaniDocument23 pagesGoal Setting PPT by PhaniBharat ThangarajNo ratings yet

- Leadership TraitsDocument5 pagesLeadership Traitsshafiqkhan12No ratings yet

- Marketing Plan R5J3D3Document10 pagesMarketing Plan R5J3D3Tushar MalikNo ratings yet

- Management and Leadership Skills Training 2008Document55 pagesManagement and Leadership Skills Training 2008KELVIN A JOHNNo ratings yet

- IBM Smarter Cities Challenge - Jacksonville Final ReportDocument50 pagesIBM Smarter Cities Challenge - Jacksonville Final ReportTimothy GibbonsNo ratings yet

- BSBLDR502 Lead and Manage Effective Workplace Relationships Learner Instructions 3 (Dispute Resolution Guidance Session) Submission DetailsDocument5 pagesBSBLDR502 Lead and Manage Effective Workplace Relationships Learner Instructions 3 (Dispute Resolution Guidance Session) Submission DetailsMadam BabygirlNo ratings yet

- Project Management ToolDocument16 pagesProject Management ToolKrishna437No ratings yet

- A Framework For Strategic AnalysisDocument12 pagesA Framework For Strategic AnalysisbeautylandNo ratings yet

- Strategic Business Planning Toolkit SummaryDocument2 pagesStrategic Business Planning Toolkit SummaryKandarp Gupta100% (1)

- Chief Quality Officer Job DescriptionDocument8 pagesChief Quality Officer Job Descriptionqualitymanagement246No ratings yet

- Agustin Career Plan WorksheetDocument5 pagesAgustin Career Plan WorksheetElijah Jade AgustinNo ratings yet

- How To Become A Project ManagerDocument9 pagesHow To Become A Project ManagerLaura LugoNo ratings yet

- Template Business ProposalDocument10 pagesTemplate Business ProposalOSCAR ARRIAGANo ratings yet

- Managerial Communication Session 28 - Email WritingDocument30 pagesManagerial Communication Session 28 - Email WritingRushabh VoraNo ratings yet

- Qualitative Risk Analysis مهمDocument7 pagesQualitative Risk Analysis مهمwskrebNo ratings yet

- Understanding The Process Develop Model CareDocument20 pagesUnderstanding The Process Develop Model Caredrestadyumna ChilspiderNo ratings yet

- Manpower Handling TrainingDocument20 pagesManpower Handling TrainingbuddeyNo ratings yet

- Stakeholder Analysis Matrix Template - Tools4devDocument4 pagesStakeholder Analysis Matrix Template - Tools4devMubashir SheheryarNo ratings yet

- Evolving From Performance Management To Talent Development Link Learning To Performance For Better Business OutcomesDocument27 pagesEvolving From Performance Management To Talent Development Link Learning To Performance For Better Business OutcomesAjisafe Jerry T-moneyNo ratings yet

- Flexing Your Social StyleDocument20 pagesFlexing Your Social StyleM A MandalNo ratings yet

- PMBOK Project Management Methodology Overview 6pDocument6 pagesPMBOK Project Management Methodology Overview 6pgserc100% (1)

- Balanced Scorecard - Definition: SmartDocument7 pagesBalanced Scorecard - Definition: SmartBelayhun BezabihNo ratings yet

- MarketPoint Infographic - Outsourcing 2015 OctoberDocument1 pageMarketPoint Infographic - Outsourcing 2015 OctoberMichael E. ZimmermanNo ratings yet

- Self Analysis Planning and PrioritizingDocument34 pagesSelf Analysis Planning and PrioritizingsimasolunkeNo ratings yet

- Human Performance Technology A Complete Guide - 2020 EditionFrom EverandHuman Performance Technology A Complete Guide - 2020 EditionNo ratings yet

- Generic Risk Register Template v2.0Document4 pagesGeneric Risk Register Template v2.0Rishabh SinghNo ratings yet

- BSBWRT401 Student GuideDocument30 pagesBSBWRT401 Student Guideparvinder rana0% (1)

- Troubleshoot of Basic Amplifier CircuitDocument4 pagesTroubleshoot of Basic Amplifier Circuitparvinder ranaNo ratings yet

- 5 V To 6 KV DC-DC Converter Using Switching Regulator With Cockcroft-Walton Voltage Multiplier For High Voltage Power Supply ModuleDocument7 pages5 V To 6 KV DC-DC Converter Using Switching Regulator With Cockcroft-Walton Voltage Multiplier For High Voltage Power Supply Moduleparvinder ranaNo ratings yet

- How Much Ac Ripple in A DC Power Supply Is Too Much?: Editor'S Note: Pdfs of This Article AreDocument2 pagesHow Much Ac Ripple in A DC Power Supply Is Too Much?: Editor'S Note: Pdfs of This Article Areparvinder ranaNo ratings yet

- Surface-Mount Technology.: NPN Transistor Circuit ConfigurationDocument6 pagesSurface-Mount Technology.: NPN Transistor Circuit Configurationparvinder ranaNo ratings yet

- Joan TemplateDocument1 pageJoan Templateparvinder ranaNo ratings yet

- Electrical Risk ReportDocument23 pagesElectrical Risk Reportparvinder ranaNo ratings yet

- BRS TestDocument2 pagesBRS TestMuhammad Ibrahim KhanNo ratings yet

- Material HPLCDocument19 pagesMaterial HPLCIsmil ImamaNo ratings yet

- Taino by The Sea Lunch MenuDocument8 pagesTaino by The Sea Lunch Menuinfo_tainobeach0% (1)

- Livebook ACBDocument420 pagesLivebook ACBShubhangi JagtapNo ratings yet

- Early Alt-RAMEC and Facial Mask Protocol in Class III MalocclusionDocument9 pagesEarly Alt-RAMEC and Facial Mask Protocol in Class III MalocclusionNievecillaNeiraNo ratings yet

- Module 7: Health Care Delivery SystemDocument9 pagesModule 7: Health Care Delivery SystemDanz KieNo ratings yet

- Emotional IntelligenceDocument43 pagesEmotional IntelligenceMelody ShekharNo ratings yet

- BRAC Annual Report 2017 PDFDocument116 pagesBRAC Annual Report 2017 PDFShoaib AhmedNo ratings yet

- Class 11 English Notes Studyguide360Document272 pagesClass 11 English Notes Studyguide360IsnatainiNo ratings yet

- 00000102Document108 pages00000102Scary CreaturesNo ratings yet

- NB Delivary Room ManagementDocument48 pagesNB Delivary Room ManagementDr.P.NatarajanNo ratings yet

- Physician'S Order/Progress Notes: 23 S. Avila Male JhonDocument2 pagesPhysician'S Order/Progress Notes: 23 S. Avila Male JhonKrizha Angela Nicolas100% (1)

- Hospital Management System: Dept. of CSE, GECRDocument30 pagesHospital Management System: Dept. of CSE, GECRYounus KhanNo ratings yet

- Microbial Ecology of Sourdough Fermentations: Diverse or Uniform?Document19 pagesMicrobial Ecology of Sourdough Fermentations: Diverse or Uniform?roadrunner100% (1)

- Manual Spray GunDocument6 pagesManual Spray GunSyazwan KhairulNo ratings yet

- Evaluating The Adjuvant Effect of Dexamethasone To Ropivacaine in Transversus Abdominis Plane Block For Inguinal Hernia Repair and Spermatocelectomy: A Randomized Controlled TrialDocument6 pagesEvaluating The Adjuvant Effect of Dexamethasone To Ropivacaine in Transversus Abdominis Plane Block For Inguinal Hernia Repair and Spermatocelectomy: A Randomized Controlled TrialGonzalo MendozaNo ratings yet

- Carbon & Its CompoundDocument13 pagesCarbon & Its CompoundNeeraj PoddarNo ratings yet

- John White Videos of Spooky2 InterfaceDocument24 pagesJohn White Videos of Spooky2 InterfaceTimothy M HallNo ratings yet

- Sierra Pine Green EncoreDocument1 pageSierra Pine Green EncoreBMCWest-LudwigGroupNo ratings yet

- Automatic Control Basic Course: Exercises 2021Document124 pagesAutomatic Control Basic Course: Exercises 2021Duc-Duy Pham NguyenNo ratings yet

- GRES Integrated Energy Storage SystemDocument33 pagesGRES Integrated Energy Storage SystemVadim PopovichNo ratings yet

- IPC in Family PlanningDocument12 pagesIPC in Family PlanningHari MurtiNo ratings yet

- What Can Science Tell Us About DeathDocument5 pagesWhat Can Science Tell Us About DeathGG7M1 gervacioNo ratings yet

- Heterocyclic Aromatic CompoundsDocument67 pagesHeterocyclic Aromatic CompoundsTuyenHHC100% (1)

- A Study On Occupational Hazards in Die Casting IndustriesDocument8 pagesA Study On Occupational Hazards in Die Casting IndustriesManik LakshmanNo ratings yet

- Is Your Body Infested With Self-Replicating Nano-FibersDocument4 pagesIs Your Body Infested With Self-Replicating Nano-Fibersthisdraft100% (3)

- Blue Bead McqsDocument11 pagesBlue Bead Mcqsanu minochaNo ratings yet

- Benzene - It'S Characteristics and Safety in Handling, Storing & TransportationDocument6 pagesBenzene - It'S Characteristics and Safety in Handling, Storing & TransportationEhab SaadNo ratings yet