Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

151 viewsP.E.B. Mini Project Report

P.E.B. Mini Project Report

Uploaded by

umashankaryaligarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Final Year Project Report Design of A STDocument137 pagesFinal Year Project Report Design of A STumashankaryaligarNo ratings yet

- 18CVL77 B Section AttendanceDocument3 pages18CVL77 B Section AttendanceumashankaryaligarNo ratings yet

- Guru Nanak College of Education (B.Ed) : Teachers Colony Manhalli Road TQ & Dist: Bidar-585 403Document11 pagesGuru Nanak College of Education (B.Ed) : Teachers Colony Manhalli Road TQ & Dist: Bidar-585 403umashankaryaligarNo ratings yet

- 15cv653 Abm MODULE 4Document1 page15cv653 Abm MODULE 4umashankaryaligarNo ratings yet

- World Environment DayDocument3 pagesWorld Environment DayumashankaryaligarNo ratings yet

- TT 1Document1 pageTT 1umashankaryaligarNo ratings yet

- 17CV44Document2 pages17CV44umashankaryaligarNo ratings yet

- 17CV72 DRCSS ExecutionDocument66 pages17CV72 DRCSS ExecutionumashankaryaligarNo ratings yet

- Regulations Governing The Degree of Bachelor of Engineering/Technology (B.E./B.Tech.) Effective From The Academic Year 2021-22Document49 pagesRegulations Governing The Degree of Bachelor of Engineering/Technology (B.E./B.Tech.) Effective From The Academic Year 2021-22umashankaryaligarNo ratings yet

- 17CV741 Dob Performance CtreteriaDocument3 pages17CV741 Dob Performance CtreteriaumashankaryaligarNo ratings yet

- Eligiblity List 3rd Sem (Civil)Document4 pagesEligiblity List 3rd Sem (Civil)umashankaryaligarNo ratings yet

- Timetable Channel 15 Engineering Sciences, IIT MADRASDocument3 pagesTimetable Channel 15 Engineering Sciences, IIT MADRASumashankaryaligarNo ratings yet

- Guru Nanak Dev Engineering College, Bidar-585403.: Vision and Mission of The DepartmentDocument22 pagesGuru Nanak Dev Engineering College, Bidar-585403.: Vision and Mission of The DepartmentumashankaryaligarNo ratings yet

- Innovations by The FacultyDocument23 pagesInnovations by The FacultyumashankaryaligarNo ratings yet

- Peos, Psos, Pos, Cos Assessment and Attainment Manual For: Po Peo PsoDocument30 pagesPeos, Psos, Pos, Cos Assessment and Attainment Manual For: Po Peo PsoumashankaryaligarNo ratings yet

- MR M B Patil Environmental Engineering I Report Innovative Teaching Methodology CompressedDocument20 pagesMR M B Patil Environmental Engineering I Report Innovative Teaching Methodology CompressedumashankaryaligarNo ratings yet

- Innovative Teaching MethodsDocument14 pagesInnovative Teaching MethodsumashankaryaligarNo ratings yet

- Construction and Building Materials: Mathieu Robert, Brahim BenmokraneDocument11 pagesConstruction and Building Materials: Mathieu Robert, Brahim BenmokraneumashankaryaligarNo ratings yet

- Construction and Building Materials: Yining Ding, Xiliang Ning, Yulin Zhang, F. Pacheco-Torgal, J.B. AguiarDocument10 pagesConstruction and Building Materials: Yining Ding, Xiliang Ning, Yulin Zhang, F. Pacheco-Torgal, J.B. AguiarumashankaryaligarNo ratings yet

- Innovation in Teaching and Learning InstrumentationDocument28 pagesInnovation in Teaching and Learning InstrumentationumashankaryaligarNo ratings yet

- Participation Certificate - Akshata. MDocument1 pageParticipation Certificate - Akshata. MumashankaryaligarNo ratings yet

- Department of Civil Engineering: Guru Nanak Dev Engineering College, BIDAR-585403Document31 pagesDepartment of Civil Engineering: Guru Nanak Dev Engineering College, BIDAR-585403umashankaryaligarNo ratings yet

- Construction and Building Materials: Amr El-Nemr, Ehab A. Ahmed, Cristina Barris, Brahim BenmokraneDocument13 pagesConstruction and Building Materials: Amr El-Nemr, Ehab A. Ahmed, Cristina Barris, Brahim BenmokraneumashankaryaligarNo ratings yet

- Composites Part B: Fei Yan, Zhibin Lin, Mijia YangDocument14 pagesComposites Part B: Fei Yan, Zhibin Lin, Mijia YangumashankaryaligarNo ratings yet

- There Are Three Different Methods For Design of Steel StructureDocument6 pagesThere Are Three Different Methods For Design of Steel Structureumashankaryaligar100% (1)

- CE301 Design of Concrete Structures - I (1) .Image - MarkedDocument3 pagesCE301 Design of Concrete Structures - I (1) .Image - MarkedumashankaryaligarNo ratings yet

- Draft Time Table for-Arrear-Subjects-only July21Document9 pagesDraft Time Table for-Arrear-Subjects-only July21umashankaryaligarNo ratings yet

- Irjet V7i9576Document4 pagesIrjet V7i9576umashankaryaligarNo ratings yet

P.E.B. Mini Project Report

P.E.B. Mini Project Report

Uploaded by

umashankaryaligar0 ratings0% found this document useful (0 votes)

151 views27 pagesOriginal Title

P.e.b. Mini Project Report

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

151 views27 pagesP.E.B. Mini Project Report

P.E.B. Mini Project Report

Uploaded by

umashankaryaligarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 27

K.E. SOCIETY'S

RAJARAMBAPU INSTITUTE OF TECHNOLOGY, RAJARAMNAGAR, ISLAMPUR

(An Autonomous Institute) Affiliated to Shivaji University Kolhapur

2014-2015

DEPARTMENT OF CIVIL ENGINEERING

CERTIFICATE

This is to certify that the project work entitled “Analysis and derign of pre-esrgineered

building for industrial shed" is cartied out by students mentioned below, in partial

fulfillment for the award of degree of Third Year Bachelor of Technology in Civil

Engineering, RAJARAMBAPU INSTITUTE OF TECHNOLOGY, RAJARAMNAGAR,

affiliated to Shivaji University, Kolhapur during the academic year 2014-2015, Ikis certified

that all cortections/suggestions indicated for Imernal Assessment have beew incor porated in

the report deposited in the department library. ‘The project report has been approved as it

satisfies the academic requirements in respect of project work preseribed for the Bachelor of

Technology Degree

SIGNATURE

Shubham vilas parab

Akshay ashok nikam

‘Aniket kisan mane

nmnat sonwalkar

RUT, Rajaramng

‘Analysis and design of Pre Engineered Buildings for industrial shed”

In structural engineering, a pre-engineered building (PEB) is designed by a PEB supplier

or PEB manufacturer, 0 be fabricated using best suited inventory of raw materials available

fromall sources and manufacturing methods that can efficiently satisfy a wide range of structural

and aesthetic design requirements, as is becoming increasingly common due to the reduced

amount of pre-engineering involved in custom computer-aided designs, so it is also known as

simply Engineered Metal Buildings (EMB).

Pre-engineered building is an assembly of L-shaped members, often referred as I-beams.

In pre-engineered buildings, the I beams used are usually formed by welding together steel plates

to form the I section, The I beams are then field-assembled (eg. bolted connections) te form the

enlire frame of the pre-engineered building, Some manufacturers taper the framing members

(varying in web depth) according to the local loading effects, Larger plate dimensions are used in

areas of higher load effects

Typically, primary frames are 2D type frames (ie, may be analyzed using two-

dimensional techniques). Advances in computer-aided design technology, materials and

manufacturing capabilities have assisted a growth inaltemate forms of pre-engineered building.

For design a pre-engineered building, engineers consider the clear span between bear ing

points, bay spacing, rof slope, live loads, dead loads, collateral loads, wind uplift, deflection

ctiteria, intemal crane system and maximum practical size and weight of fabricated members

‘This design is done by computer aided system using software like STADD .PRO.so that we get

accurate load calculation and check suitability of sections

An efficiently designed pre-engineered building can be lighter than the conventional

steel buildings by up to 30%, Lighter weight equates to less steel and a potential price savings in

structural framework. This new technique is widely adopted in industrial sector

RALT,Rajaramngar.

CONTEN

TITLE PAGE

| CERTIFICATE

ABSTRACT

‘CONTENTS

LST OF TABLES

LST OF FIGURES

| NOMENCLATURE

| ABBREVIATIONS

INTRODUCTION

1 General

1.2 Motivation of the present work

1.3. Aims and objectives of the present work

1.4 Layout of the thesis Closure

LITERATURE REVIEW

MATERIALS AND METHODOLOGY

3.1, Load calculation

3.2. Loud combinations

3.3, Support specifications

EXPERIMENTAL ~ ANALYTICAL METHODOLOGY

4.1.Staad pro. design steps

4.2.Staad. Pro, Report

RIT,Rajaramngar,

RESULTS AND DISCUSSION

‘CONCLUSIONS AND SCOPE FOR FUTURE STUDY

REFERENCES

APPENDIX -1

APPENDIX-

APPROVED COPY OF SYNOPSIS

ACKNOWLEDGEMENT

RUT,Rajaramngar,

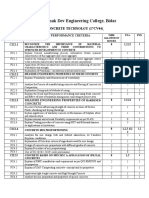

LIST OF TABLES

Caption

Maletial properlies For composite laminate

‘Normalized transverse displacement (W), inplane normal sires ( @, ) and

transverse shear stress (F_.) of an simply supported orthotropic beam in plane stress

condition subjected to sinusoidal lead.

Normalized tranverse displacement (W ), inplane normal sires ( @, } and

‘transverse shear stress (,_) of an simply supparted orthotropic plate in plane strain

‘condition subjected to sinusoidal loud.

Rajaramngar.

LIST OF FIGURES

Caption

‘A laminated nurow beam in plane suess condition subjected to wansverse

loading subjected to transverse loading.

An elastic plate in & plane Srain condition with positive set of displacement

components,

|Geomery of a simply (diaphragm) suppored smart laminate under

cylindrical bending attached with piezoelectric Layers at top and bottom and,

displacement components

RILT,Rajaramngar.

RAT, Rajaramngar.

PER

ODE

3D,2D, 1D

EBT

cLBT

cLPr

Fost

HosT

FE

RUT,Rajaramngar.

ABBREVATIONS

Pre engineered! building

Ondinary differential equation

‘Three, two and one dimension

Euler Bernoulli theory

Classical amination beam theary

Classical Lamination plate theory

First-order shear deformlion theory

Higher-onler shear deformation theory

e clement

Chapter 1

INTRODUCTION

1.1 Project Motivation:

Steel industry is growing rapidly in almost all parts of the world, The use of

steel structures is not only economical but also eco friendly. Here we refer “Economical”

with respect 10 time and cost. This can be Achieved by the application of Pre Engineered

Buildings.

Project Objectives

To study pre engineered building

To prepare a model of P.E.B

To analyze structure using Studd Pro,

To design sections, comnections ete,

ro study the effect of PLE.B, for follow

To reduce complexity on site.

To achieve aceuracy.

Speed of work,

1.3, Present theories and practices

Pre Engineered Buildings are nothing but steel buildings in which excess steel is avoided

by tapering the sections as per bending moment requirements, In Pre Engineered Buildings total

design is done in factory and as per the design. All the required components are assembled and

thereby reducing the time of completion,

1.4 Project Features:

Pre Engineered Building system is Computer assisted and designed to create a buil

for specific use

The complete building system is Pre Engineered to facilitate ewsy production and

assembly on site.

Colour coating is given on top surface for bright appearance with colour with customer"s

choice,

RIT, Rajaramnga

Advantages of Pre Engineeted Building:

PEB System is zero maintenance & superior in strength than conventional

Lower Cost

Quality Control,

Large Clear Spans

Project Applications:

+ Ware houses

+ Factories

+ Workshops

Offices

Gas stations

Vehicle parking sheds

Show rooms

Aircraft hangers

Schools

Sports and reerestional facilities

Rajaramngar,

Chapter 2

LITERATURE REVIEW

Report on major literature refered and studied, Literature review should include current

thinking, findings, and approaches to the problem, Following citation format should be adopted,

Generally following procedure is adopted,

Name of author ~ year-work done in our awn language (50 6 lines )

For ex Tumer (1963) presented analysis of structures using stiffness matrix meted, They

developed Sample Large-Angle-of-Atack Viscous Hypersonic Flows ever Complex Lift

Configurations, Various research carried out new development of analytical tools

RALT,Rajaramngar.

Chapter 3

MATERIALS AND METHODOLOGY

Analysis and design of Pre Engineered building for industrial shed.

Load calculations

Internal dimensions of building: l=60 m, b=15 m_

Height of building up w eaves level= 6m

Location of building= lampur (pune region)

Type of toofing = G.l.sheets

Area of opening {permeability of building 5% to 20%)

Angle of rafter = < 10)"

Spacing between two columns = 6m

Number of frames = 10

Rajaramngar,

Elevation

RUT,Rajaramngar.

Load calculations :

A. Dead load

Wight of purlin 5 kg/m?

Weight of sheeting :5 kg/m”

Total weight :10 kg/im?=0.1kIN/m?

Total uniformly distributed load = 0.16 =0.6 KN/M

Self weight of tapered section

B. Live load:

Live load =0,75 kN/m™ (Angle less than 10")

=075°6

45 kN/or

Collateral load:

(Assumed)

RIT,Rajaramngar.

D. Wind load :

Basic wind speed =39 mvs (pune region)

KiKoKsVi

L-Length of building (Greater hoz dim. Of

bldg.) meters

w-Width of building Lesser boz dim, Of bldg.)

hL-Height of plinth

h2-Eaves height from FFL

h-Eaves height from FGL

Roof Slope

‘Vb-Basic wind speed misec

N.Design life of structure; mean probable Years

‘Terrain Category

Category 1- Exposed open terrain with few or no obstructions having heights less than 1.Sm.

Category2- Open terrain with well scattered obstructions having heights between 1.Sm.de

10m.

Category3- Terrain with numerous closely spaced obstructions having heights around 10m,

Category. Terrain with numerous closely spaced high obstruct

Class of Building

Class-A - Structure & or compo like cladding, roofing ete having greatest Hoz Or Vert dim <20m,

Class-B - Structure & of compo like cladding, roofing etc having greatest Hoz Or Wert dim bet 20-50

Class-C - Structure & or compo like 12, roofing etc having greatest Hez Or Vert dim > 50m.

KLRisk Coeff. SS

HT Max Height of building from

FGL 6

K2-TerrainSt-height &size factor

K3-Topo graphy Factor

‘Va2-Design wind speed. msec 38.61

Pz-Design wind pressure KNfm*2 | 01804),

RA.T,Rajaramngar,

(Cpe-External Pressure coeff for walls

Table No.4 1S 875 (Par3)-1987

Elevation

0.467

4.000

Wind Angle | E ic

O° to wall

SOFT wall

(Cpe-External Pressure coeff for Pitched Roof of Single Span Bldg.

‘Table No.5 IS 875 (Pat3) - 1987

Roof Angle in degrees

Wind Angle 0" *to ridge

Elevation

Roof Angle-1

Roof Angle-2

RILT,Rajaramngar.

Roof [Wind Angleg = 0"

Angle EF ‘GH

5) 090) 0.80

t 1.20 0.40

Local oveft = -2.0

Wind Drag

Cpi-internal Pressure Coeff _

‘Opennings not more than 5% of wall area

Openings between 5% to 20% of wall area

of wall area

Opennings larger than than 2

RIGID FRAME COEFFICIENT

Wind 2

Surface

Lett Right Left Right

02 0.78 12 0.25

144 090) 044 0.10

090 -i44] 0100.44

O75 02) 025 12

Friction

0

0

0

0

FRONT / BACK SIDE WALL

"(19 WIND.

PRESSURESUCTION:

Wind Wind

“Pressure “Suction

1.073 0.894 .GirvHeader

1073 -0.894 Panel

1073 0.894 Jamb

Parapet

1073 0.884 Gin

EDGE) CORNER ZONE (MM}

LOCAL COEFF

RATIO LOCAL TO AVERAGE

Rajaramngar,

LEFT/RIGHT ENDWALL

*(38)WIND

PRESSURE/SUCTION:

Wind Wind

“Pressure "Suction

1073-0984 Column

1.073 -0.984 .Gir/Header

1073-0984 Jam

1073 0.984 Panel

Parapet

1.073 0.984 Girt

939) WIND COEFFICIENTS

Rafier_Wind_ 1 Rafter_ Wind Bracing Wind

Left Right Lent Right Left

02 0.75 12 0.25 02

“1.44 090 0.44 0.10 “144

0-144 0.10 44 0.90

D5 02 025 12 0.75

ROOF DESIGN

38) WIND

PRESSURESUCTION:

Wind = "Wind Wind

"Pressure *Suction *Suct_Roof

0.089 1.290 Purlins

0.089 -1.290 Purlins, Gable Extension

Interior Roof

0.089 -1.290 Panels

9.626 0.089 40894 Long Bracing. Building

1073 -0.537 Long Bracing, Wall Edge Zone

1073-0537 0394 Long Bracing, Facia/Parapet

EDGE/ CORNER ZONE (MM) 2250

LOCAL COEFF.(INCL INT SUCT 4 -2.05

RATIO LOCAL TO AVERAGE, 1.42108

Right

0.55

0.90

“144

02

Surface

Friction

0

0

0

0

Rajaramngar,

3.2. Load combinations:

. Load combination of strength:

Te. (D.L¢L Ly" 541,05 *C.L.

2. (DLAW.LS P15

3. DLAW.RP)S

4. (DLW RSLS

(DLAW.PP)LS

6. (DLAWP.S)PL5

Te (DLAL.LIM1.241,05°C.L40.6" WLP,

8. (D.L+L.LI*1.241.05°C.L06" WLS.

9. (DL +LLy1.241,05°C L406" WR.

10.0D.L+L.Ly"l2+1,05°C. L406" W.R.S.

LL (D.L4L.L11.2+1,05°C.L40.6" WP.

12. (D.L4L.L)°1.241,05°C.L406" WPS,

b. Load combination of serviceability:

1. (DLAL LCL)"

2. DLN IH LLACLAW.LP)08

3. DLP IH LLACLAW.LS)8.

4. DL" HLL AC.LAW RP)"O8

5. DLP IH LLACLAW.RS.)"O8

6. D.L* 1HLLACLAW PPS.

7. DL" IH{LLAC.LAW.PS.)°0.8

8. (LAWL)

9. (DLAW.LS)*1

10. (D.LAW.RP.)*1

LL (D.LAW.RS.)"1

12, (D.L+W.P.P.)*1

13. (D.L+W.PS.)*1

Rajaramngar.

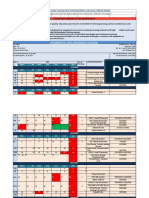

‘Table 4 Partial Safety Factors for Loads, 7, for Limit States

(Clauses 3.5.1 and $3.3)

Lie State of Serene Limit State of Servceaility

rr

a

Leading Accompanying

wu

w

Los 10

DisLbaChe 2 Los on

Wie 0

De WL P is =

DLOER 2 =

Del LeAL ass lo -

‘When nlon of flees iv late bs semascowsly comers, the enon Wve land all be comida be the ane easing tat

igher loa effets in he suanbeanes tot

"TWis vase bw be considoed when the dead tod comtnbotes my stabiity against avertrsing is critical OF the dead tod oases

Fructose def ahead

Abbreviation

[Di= Dont bo [= lene Sa (Live los, WL. = Wiad oa, CL = Cre hal (Verical/Mewigpsa), AL = Ascent lad, ER =

sco ba El. = Baa bad

NOTE — The effcos of ows (loads) intra of stress or tes estas may be oteited ham at approve met! of ana,

RI.T,Rajaramngar.

Chapter 4

ENTAL = ANALYTICAL METHODOLOGY

Staad .Pro. design steps:

Rajaramngar.

Rajaramngar.

Chapter 5

RESULTS AND DISCUSSION

RUT,Rajaramngar.

Rajaramngar.

Chapter 6

CONCLUSIONS AND SCOPE FOR FUTURE STUD

Alphabetic sequences

Aithraju, V.R., and Avedill, R.C. (1999). °C zig-zag finite element for analysis of laminated composite

beams”, ASCE Journal af Engineering Mechanics, 128(3),323-331

Allik, H. and Hughes, TLR. (1970), “Finite element method for pieaoelectiic vibration”, bnternurional

Jourmal for Numerical Methods in Engineering, 2, 151-157

Aluy, G. and DokmeTubular Structure, Technology Exchunge Center in Heilongjiang Province,

Chim, 112-118

http://www library.ve.edu.au/training /eltation/vanco uv. péf

ary.ug.edu.au/training/citation/harvard_6,pdt

http://www. lib.monash.edu.au/tutorials/eiting/vancouver. html

htto:// www. library.dmu.ac uk/Images/Selfst udy/Hary ard,

slibrary.uow.edu.au/cont ups, reb/@health/do-cuments/dioc/um

RI-T,Rajaramngar.

ACKNOWLEDGEMENT

of enormous help in the

development of this work, Pro£P.M.Mohite my supervisor, philosopher and encouraged us to carry this,

‘work, His continuous invaluable knowledgubly guidance thraughout the course of this study helped me ta

complete the work up to this stage and hope will continue in further research.

In addition, very energetic and competitive atmosphere of the Civil Engineering Department

‘had much to do with this work. [acknowledge with thanks to faculty, teaching and non-teaching staff of

the department, Central library and Calleagues.

I sincerely thank to Dr.S.8.Kulkarni, for supporting me to do this work and Iam very

much obliged to her

Last but not the least my futher, my mother, constantly supported me for this work in ull aspects

RIT Sakhrale, Shubham vilas parab- 1202016

Akshay ashok nikam 1202019

Aniketkisan mane 1202030

Sujit hanmant sonwalkar 1202015

Rajaramngar.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Final Year Project Report Design of A STDocument137 pagesFinal Year Project Report Design of A STumashankaryaligarNo ratings yet

- 18CVL77 B Section AttendanceDocument3 pages18CVL77 B Section AttendanceumashankaryaligarNo ratings yet

- Guru Nanak College of Education (B.Ed) : Teachers Colony Manhalli Road TQ & Dist: Bidar-585 403Document11 pagesGuru Nanak College of Education (B.Ed) : Teachers Colony Manhalli Road TQ & Dist: Bidar-585 403umashankaryaligarNo ratings yet

- 15cv653 Abm MODULE 4Document1 page15cv653 Abm MODULE 4umashankaryaligarNo ratings yet

- World Environment DayDocument3 pagesWorld Environment DayumashankaryaligarNo ratings yet

- TT 1Document1 pageTT 1umashankaryaligarNo ratings yet

- 17CV44Document2 pages17CV44umashankaryaligarNo ratings yet

- 17CV72 DRCSS ExecutionDocument66 pages17CV72 DRCSS ExecutionumashankaryaligarNo ratings yet

- Regulations Governing The Degree of Bachelor of Engineering/Technology (B.E./B.Tech.) Effective From The Academic Year 2021-22Document49 pagesRegulations Governing The Degree of Bachelor of Engineering/Technology (B.E./B.Tech.) Effective From The Academic Year 2021-22umashankaryaligarNo ratings yet

- 17CV741 Dob Performance CtreteriaDocument3 pages17CV741 Dob Performance CtreteriaumashankaryaligarNo ratings yet

- Eligiblity List 3rd Sem (Civil)Document4 pagesEligiblity List 3rd Sem (Civil)umashankaryaligarNo ratings yet

- Timetable Channel 15 Engineering Sciences, IIT MADRASDocument3 pagesTimetable Channel 15 Engineering Sciences, IIT MADRASumashankaryaligarNo ratings yet

- Guru Nanak Dev Engineering College, Bidar-585403.: Vision and Mission of The DepartmentDocument22 pagesGuru Nanak Dev Engineering College, Bidar-585403.: Vision and Mission of The DepartmentumashankaryaligarNo ratings yet

- Innovations by The FacultyDocument23 pagesInnovations by The FacultyumashankaryaligarNo ratings yet

- Peos, Psos, Pos, Cos Assessment and Attainment Manual For: Po Peo PsoDocument30 pagesPeos, Psos, Pos, Cos Assessment and Attainment Manual For: Po Peo PsoumashankaryaligarNo ratings yet

- MR M B Patil Environmental Engineering I Report Innovative Teaching Methodology CompressedDocument20 pagesMR M B Patil Environmental Engineering I Report Innovative Teaching Methodology CompressedumashankaryaligarNo ratings yet

- Innovative Teaching MethodsDocument14 pagesInnovative Teaching MethodsumashankaryaligarNo ratings yet

- Construction and Building Materials: Mathieu Robert, Brahim BenmokraneDocument11 pagesConstruction and Building Materials: Mathieu Robert, Brahim BenmokraneumashankaryaligarNo ratings yet

- Construction and Building Materials: Yining Ding, Xiliang Ning, Yulin Zhang, F. Pacheco-Torgal, J.B. AguiarDocument10 pagesConstruction and Building Materials: Yining Ding, Xiliang Ning, Yulin Zhang, F. Pacheco-Torgal, J.B. AguiarumashankaryaligarNo ratings yet

- Innovation in Teaching and Learning InstrumentationDocument28 pagesInnovation in Teaching and Learning InstrumentationumashankaryaligarNo ratings yet

- Participation Certificate - Akshata. MDocument1 pageParticipation Certificate - Akshata. MumashankaryaligarNo ratings yet

- Department of Civil Engineering: Guru Nanak Dev Engineering College, BIDAR-585403Document31 pagesDepartment of Civil Engineering: Guru Nanak Dev Engineering College, BIDAR-585403umashankaryaligarNo ratings yet

- Construction and Building Materials: Amr El-Nemr, Ehab A. Ahmed, Cristina Barris, Brahim BenmokraneDocument13 pagesConstruction and Building Materials: Amr El-Nemr, Ehab A. Ahmed, Cristina Barris, Brahim BenmokraneumashankaryaligarNo ratings yet

- Composites Part B: Fei Yan, Zhibin Lin, Mijia YangDocument14 pagesComposites Part B: Fei Yan, Zhibin Lin, Mijia YangumashankaryaligarNo ratings yet

- There Are Three Different Methods For Design of Steel StructureDocument6 pagesThere Are Three Different Methods For Design of Steel Structureumashankaryaligar100% (1)

- CE301 Design of Concrete Structures - I (1) .Image - MarkedDocument3 pagesCE301 Design of Concrete Structures - I (1) .Image - MarkedumashankaryaligarNo ratings yet

- Draft Time Table for-Arrear-Subjects-only July21Document9 pagesDraft Time Table for-Arrear-Subjects-only July21umashankaryaligarNo ratings yet

- Irjet V7i9576Document4 pagesIrjet V7i9576umashankaryaligarNo ratings yet