Professional Documents

Culture Documents

Annexure VII.a QAP Aluminizing DCBL

Annexure VII.a QAP Aluminizing DCBL

Uploaded by

Mythri Metallizing Pvt Ltd ProjectsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annexure VII.a QAP Aluminizing DCBL

Annexure VII.a QAP Aluminizing DCBL

Uploaded by

Mythri Metallizing Pvt Ltd ProjectsCopyright:

Available Formats

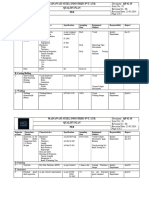

F:8.

6A-CPB-Rev 00

X`tralife to your wear prone components Quality Assurance Plan

Wearresist Wearresist Technologies Pvt. Ltd. Job details: QAP No: 01 Project: Dalmia Cement

Technologies 421-422 GIDC POR Ramangamdi, Application of dt: 13/01/2019 (Bharat) Ltd

Private Limited

Dist: Baroda Aluminization Page 1 of 1 (Dalmia DSP Unit-I)

An ISO 9001: 2015 Company

Sr. NO. Components of Achievement Class of Type of Quantum/freq WRTPL/Ag Remarks

operation check check uency of ency

check

1 2 3 4 5 6 7 8

1 Blasting 40-60 micron By Dial Manually Random P/V

roughness Surface

Profile

Gauge

2 Aluminizing by SVCC 150-200 micron By Manually Random P/V

process (Nominal) Thickness

thickness gauge

3 WR-AL - Sealent Coat 25-40 microns By Manually Random P/V

(Nominal Thickness

thickness)One gauge

Coat

P = Perform, For Dalmia Cement (Bharat) Ltd

V = Verification, W = Witness (Dalmia DSP Unit-I).

NA = Not applicable. WO NO. 4600044946 Date :- 07/01/2019

for Wearresist Technologies Pvt. Ltd.

Name & Designation

Mr. Arpit Pandya

QC Head

Authorized Signatory

Note:- All the consumables items we are used in our work site are manufacture & make by M/s WEARRESIST (as per PO)

You might also like

- 9202 2 QP InternationalChemistry G 11nov20 07 00 GMTDocument32 pages9202 2 QP InternationalChemistry G 11nov20 07 00 GMTBob yuNo ratings yet

- Coating Guide: Standards Contact UsDocument26 pagesCoating Guide: Standards Contact UsMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Aws D10.4Document43 pagesAws D10.4Riza Khan100% (1)

- FAPCCI Membership DirectoryDocument1,527 pagesFAPCCI Membership DirectoryMythri Metallizing Pvt Ltd Projects100% (1)

- Quality Assurance Plan: An ISO 9001: 2015 CompanyDocument1 pageQuality Assurance Plan: An ISO 9001: 2015 CompanyMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Report Angle of ReposeDocument2 pagesReport Angle of ReposeMonica Julius LieNo ratings yet

- 09 Dryer DesignDocument25 pages09 Dryer DesignFredrick MutungaNo ratings yet

- Certification Criteria of Painting Using JISDocument11 pagesCertification Criteria of Painting Using JISbujangmiayamNo ratings yet

- Annexure VII.b QAP Corrosion Protection DCBLDocument1 pageAnnexure VII.b QAP Corrosion Protection DCBLMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Quality Assurance Plan: Corrosion Protection Engineers IndiaDocument2 pagesQuality Assurance Plan: Corrosion Protection Engineers IndiaCorrosion Protection Engineers India Gnanasekaran DNo ratings yet

- Mpi Report Jvs FormatDocument2 pagesMpi Report Jvs FormatGauravNo ratings yet

- MPI ReportDocument2 pagesMPI Reportsushanto.mtbdNo ratings yet

- RT March 23Document1 pageRT March 23mathew.genesis.inspNo ratings yet

- 2.WGU-1289-AM Pivot Shaft D375 RHS, SN 9040123338Document1 page2.WGU-1289-AM Pivot Shaft D375 RHS, SN 9040123338wahyuNo ratings yet

- Incoming Material ChecklistDocument1 pageIncoming Material ChecklistPrathvi Raj SinghNo ratings yet

- YzcvfDocument2 pagesYzcvfCheeragNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- Non Destructive Testing of Primary Steel Components, Tower Sections and Embedment's For Vestas Wind TurbinesDocument5 pagesNon Destructive Testing of Primary Steel Components, Tower Sections and Embedment's For Vestas Wind TurbinesDavisTranNo ratings yet

- Insulation QAPDocument2 pagesInsulation QAPPavul RajNo ratings yet

- 1.request For Inspection (HEMT FO QC 01)Document1 page1.request For Inspection (HEMT FO QC 01)Balasai SabarinathNo ratings yet

- NDT UtDocument1 pageNDT UtMohd AshifNo ratings yet

- Content 20240115185834Document2 pagesContent 20240115185834BLY YEDEKPA NOEL BENITONo ratings yet

- Prds & Piping QapDocument2 pagesPrds & Piping QapPavul RajNo ratings yet

- Qap Dross ShedDocument21 pagesQap Dross ShedSasanka SekharNo ratings yet

- ITP RefractoryDocument1 pageITP RefractoryADOFSLNo ratings yet

- SEIP For 086-V-001: Amine Acid Gas KO DrumDocument6 pagesSEIP For 086-V-001: Amine Acid Gas KO DrumThinh NguyenNo ratings yet

- Coflexip Hose (Tr1-031851clm302)Document1 pageCoflexip Hose (Tr1-031851clm302)RonniNo ratings yet

- QAP Final - ASSAMNZRMM11Document2 pagesQAP Final - ASSAMNZRMM11Jaspreet SinghNo ratings yet

- MT RSDocument37 pagesMT RSdeari nur azisNo ratings yet

- Dry Type Transformer - Report (05.4.0482) 10Document46 pagesDry Type Transformer - Report (05.4.0482) 10Shaikh Tauqeer AhmedNo ratings yet

- Quality Assurance Plan For PEBDocument2 pagesQuality Assurance Plan For PEBBipin Vihari DasNo ratings yet

- Qap - NRL Rev - 1Document6 pagesQap - NRL Rev - 1Gopikrishnan ThangarajNo ratings yet

- Paut 16Document4 pagesPaut 16maroof mNo ratings yet

- ITP For Earth FillingDocument1 pageITP For Earth FillingRICPL - Quality Management Department- HONo ratings yet

- MPI Report 006 Swivel 531-12-19Document1 pageMPI Report 006 Swivel 531-12-19John DolanNo ratings yet

- TATA Painting Specification 43Document1 pageTATA Painting Specification 43Suleman KhanNo ratings yet

- Process Flow Diagram (PFD) : Casting Out Source ProcessDocument1 pageProcess Flow Diagram (PFD) : Casting Out Source ProcessPRAMODNo ratings yet

- PLR-WQT-GF-43 PautDocument2 pagesPLR-WQT-GF-43 PautSachchida Nand KumarNo ratings yet

- MPI Report 013 5inch DP Elevator A109-2Document1 pageMPI Report 013 5inch DP Elevator A109-2John DolanNo ratings yet

- Coflexip Hose (Tr1-031851clm301)Document1 pageCoflexip Hose (Tr1-031851clm301)RonniNo ratings yet

- MPI Report 005 Monkeyboard 001Document1 pageMPI Report 005 Monkeyboard 001John DolanNo ratings yet

- Qap TataDocument5 pagesQap TataDesign VardhNo ratings yet

- MPI Report 002 Mast 002 R.1Document1 pageMPI Report 002 Mast 002 R.1John DolanNo ratings yet

- SEIP For 089-H-001Document7 pagesSEIP For 089-H-001Thinh NguyenNo ratings yet

- Inspection Report: Shravya Precision Components CoDocument1 pageInspection Report: Shravya Precision Components CoYash UpadhyayNo ratings yet

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDocument6 pagesSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenNo ratings yet

- Welder CardDocument1 pageWelder CardRaju KumarNo ratings yet

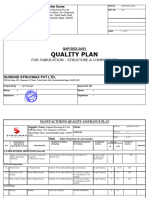

- Strucmax Ii MMS Ii Qap Ii 2023-24 Ii R0Document2 pagesStrucmax Ii MMS Ii Qap Ii 2023-24 Ii R0Prince MittalNo ratings yet

- Setup & Inprocess Inspection Report Twin AnchorDocument13 pagesSetup & Inprocess Inspection Report Twin AnchorMURALIDHRANo ratings yet

- MPI Report 012 5inch DP Elevator A109-1Document1 pageMPI Report 012 5inch DP Elevator A109-1John DolanNo ratings yet

- SEIP For 080-AC-002: GeneralDocument6 pagesSEIP For 080-AC-002: GeneralThinh NguyenNo ratings yet

- QAP - Rev - 0Document4 pagesQAP - Rev - 0Ravindra YogiNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- Collar Muffler MountDocument1 pageCollar Muffler MountPreetam KumarNo ratings yet

- Green Constro Infra PVT LTD Quality Assurance Plan (Qap) : Manufacture At: Qap No.:& DetailsDocument1 pageGreen Constro Infra PVT LTD Quality Assurance Plan (Qap) : Manufacture At: Qap No.:& DetailsNAGARJUNANo ratings yet

- Updated Standard Manufacturing Quality Plan For Battery ChargersDocument4 pagesUpdated Standard Manufacturing Quality Plan For Battery ChargersAbhilash KumarNo ratings yet

- Work Summary: J.Ray Mcdermott S.ADocument1 pageWork Summary: J.Ray Mcdermott S.AKarthick PandiyarajNo ratings yet

- Vishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationDocument13 pagesVishwas Electroplaters: Control Plan For Acid Zinc Barrel Plating & Hexavalent PassivationAnonymous YptJ5iDNo ratings yet

- Steam Trap QAPDocument2 pagesSteam Trap QAPPavul RajNo ratings yet

- Mpi Lube Tank 6000l 05Document3 pagesMpi Lube Tank 6000l 05Peter StanleyNo ratings yet

- Control Plan FormatDocument1 pageControl Plan FormatMagesh WaranNo ratings yet

- SEIP For 089-H-002Document7 pagesSEIP For 089-H-002Thinh NguyenNo ratings yet

- ITP For Handrail WeldingDocument2 pagesITP For Handrail WeldingKumar AbhishekNo ratings yet

- Ducting QAP R02 080822Document2 pagesDucting QAP R02 080822Pavul RajNo ratings yet

- Process Flow Chart (Pre-Launch / Production)Document1 pageProcess Flow Chart (Pre-Launch / Production)kumar0% (1)

- Quality Assurance Plan (QAP)Document1 pageQuality Assurance Plan (QAP)demas100% (1)

- Work Experience:: Bhagyalakshmi S E-Mail: Mobile No.: 9739175517Document3 pagesWork Experience:: Bhagyalakshmi S E-Mail: Mobile No.: 9739175517Mythri Metallizing Pvt Ltd ProjectsNo ratings yet

- SWWW Magazine - Sept-Oct 2021Document48 pagesSWWW Magazine - Sept-Oct 2021Mythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Datasheet and Certification Order: As Per Quotation No: 340946 Account No.: 116820-01Document2 pagesDatasheet and Certification Order: As Per Quotation No: 340946 Account No.: 116820-01Mythri Metallizing Pvt Ltd ProjectsNo ratings yet

- List of Audit ParticipantsDocument4 pagesList of Audit ParticipantsMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Scaffolding Safety Instruction (498 A)Document5 pagesScaffolding Safety Instruction (498 A)Mythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Getting Corrosion Prevention Services Provide A Lot of Benefits Other Than Extending The Longevity of Your EquipmentDocument7 pagesGetting Corrosion Prevention Services Provide A Lot of Benefits Other Than Extending The Longevity of Your EquipmentMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- SL - NO. Company Name Unit/Ref Rate ProcessDocument7 pagesSL - NO. Company Name Unit/Ref Rate ProcessMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- TSA Surface Preparation and ApplicationDocument7 pagesTSA Surface Preparation and ApplicationMythri Metallizing Pvt Ltd Projects100% (1)

- Production ReportDocument2 pagesProduction ReportMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- RavindiranDocument131 pagesRavindiranMythri Metallizing Pvt Ltd Projects100% (2)

- QM-ANN-07 Responsibility and AuthorityDocument6 pagesQM-ANN-07 Responsibility and AuthorityMythri Metallizing Pvt Ltd Projects100% (1)

- When Is It CostDocument7 pagesWhen Is It CostMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Managing Director Job DescriptionDocument3 pagesManaging Director Job DescriptionMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Next Assembly 202100950 ASK If in Doubt Refer 3D Cad Model For Further DetailsDocument2 pagesNext Assembly 202100950 ASK If in Doubt Refer 3D Cad Model For Further DetailsMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Process & Application of TSA On Preheater CyclonesDocument5 pagesProcess & Application of TSA On Preheater CyclonesMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Undertaking (EPF&ESIC)Document1 pageUndertaking (EPF&ESIC)Mythri Metallizing Pvt Ltd ProjectsNo ratings yet

- A External Painting For RoofDocument4 pagesA External Painting For RoofMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Wire Arc Spray Process: KeywordsDocument7 pagesWire Arc Spray Process: KeywordsMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Thermal Spray Aluminium CoatingDocument5 pagesThermal Spray Aluminium CoatingMythri Metallizing Pvt Ltd Projects100% (2)

- Cement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Document20 pagesCement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Mythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Cement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Document20 pagesCement Manufacturing: (Alan Gee-Lehigh Hanson Cement)Mythri Metallizing Pvt Ltd ProjectsNo ratings yet

- ISO 9001:2015 Certified CompanyDocument33 pagesISO 9001:2015 Certified CompanyMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Google Adwords Call Reports With Feedback-2Document7 pagesGoogle Adwords Call Reports With Feedback-2Mythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Production and Characterization of BiomaDocument5 pagesProduction and Characterization of BiomaKinshuk UdayakumarNo ratings yet

- LimeDocument33 pagesLimepriya dharshiniNo ratings yet

- Thermal PropertiesDocument14 pagesThermal PropertiesLivian TeddyNo ratings yet

- WaterAnalyses PDFDocument2 pagesWaterAnalyses PDFZenga Harsya PrakarsaNo ratings yet

- Data Bahan BakuDocument5 pagesData Bahan BakuTaofik NurdiansahNo ratings yet

- Aims03 22 002Document7 pagesAims03 22 002Jorge OrtegaNo ratings yet

- PaperDocument14 pagesPaperGabriel Ignacio SilvaNo ratings yet

- System FormworDocument55 pagesSystem FormworshallNo ratings yet

- Fully Report Lab 1Document17 pagesFully Report Lab 1zafirah zaidiNo ratings yet

- Chapter 8: Oxygen DemandDocument12 pagesChapter 8: Oxygen DemandYusuf MahardikaNo ratings yet

- Concrete Hinges in Bridge EngineeringDocument12 pagesConcrete Hinges in Bridge EngineeringMilchoNo ratings yet

- Chemcad KilnDocument9 pagesChemcad Kilningbarragan87No ratings yet

- Review of Cost Versus ScaleDocument13 pagesReview of Cost Versus ScaleCelina SanchezNo ratings yet

- 06 - The Process of Wort Boiling 2 - 2Document3 pages06 - The Process of Wort Boiling 2 - 2StaccNo ratings yet

- Training Session On Water TreatmentDocument141 pagesTraining Session On Water TreatmentKattukolu Kishorereddy50% (2)

- IS 8130 - Classes of Conductors - 2013 - Reaffiremed 2018Document12 pagesIS 8130 - Classes of Conductors - 2013 - Reaffiremed 2018piyush guptaNo ratings yet

- Atlas™ G-5000 Surfactant Atlox™ 4894 Surfactant Blend: Highly Effective Emulsifiers With A Variety of ApplicationsDocument7 pagesAtlas™ G-5000 Surfactant Atlox™ 4894 Surfactant Blend: Highly Effective Emulsifiers With A Variety of Applicationsherry prasetyo100% (1)

- Indian Roads Congress-Public Safety Standards of IndiaDocument6 pagesIndian Roads Congress-Public Safety Standards of IndiaBhavsar NilayNo ratings yet

- Plastic Manufacturing TeleDocument8 pagesPlastic Manufacturing Teleblinkfinance7No ratings yet

- FinalDocument72 pagesFinalRyan FisherNo ratings yet

- 9g V 09 PaintingDocument15 pages9g V 09 Paintingdiuska13100% (1)

- Summary of Mechanical Properties of MaterialsDocument1 pageSummary of Mechanical Properties of Materialsc r maselkowski100% (1)

- Polypoxy FC(S)Document2 pagesPolypoxy FC(S)Sam AhmedNo ratings yet

- Dielectric Phenomena in High Voltage Engineering, 2nd EdDocument326 pagesDielectric Phenomena in High Voltage Engineering, 2nd Edkgrhoads100% (7)

- 6 UOP. Honeywel Egypt - Technologies For Distillate Production - Hydrocracking - E SvenssonDocument17 pages6 UOP. Honeywel Egypt - Technologies For Distillate Production - Hydrocracking - E SvenssonCamilo inversionesNo ratings yet