Professional Documents

Culture Documents

U2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1A

U2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1A

Uploaded by

Tommy ArjanggiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

U2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1A

U2004-015-PYD-M04-T0288 Mechanical Data Sheet For Expansion Bellow Joint Rev 1A

Uploaded by

Tommy ArjanggiCopyright:

Available Formats

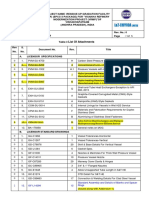

REVITALIZATION PROJECT OFF RCC UNIT

PERTAMINA RU VI BALONGAN

MECHANICAL DATA SHEET FOR EXPANSION

BELLOW JOINTS (15-EBJ-101/102/103[A/B/C/D]/

105/106/107[A/B/C]/110/112/113)

PAGE

REV.NO. 1A 1 / 14

NO.

MECHANICAL DATA SHEET FOR

EXPANSION BELLOW JOINTS

(15-EBJ-101/102/103[A/B/C/D]/

105/106/107[A/B/C]/110/112/113)

OWNER : PT. PERTAMINA (Persero)

PROJECT : REVITALIZATION RCC UNIT PROJECT

REFINERY UNIT VI

LOCATION : BALONGAN, JAWA BARAT

CONTRACTOR : CONSORTIUM OF ETI, YUHANTECH, PBAS

DOCUMENT NO. : U2004-015-PYD-M04-T0288

Re-Issued for

1A 30-MAR-21 RDM ISA BBS

Approval

1 04-FEB-21 Issued for Approval RDM ISA JYG

0 22-JAN-20 Issued for Review RDM ISA JYG

PREPARED CHECKED APPROVED APPROVED

REV. DATE DESCRIPTION

BY BY BY BY OWNER

REVITALIZATION PROJECT OFF RCC UNIT

PERTAMINA RU VI BALONGAN

MECHANICAL DATA SHEET FOR

EXPANSION BELLOW JOINTS

PAGE

REV.NO. 1 2 / 14

NO.

REVISION HISTORICAL SHEET

REV. DATE DETAIL DESCRIPTION REVISED BY

Added information after review by PERTAMINA

1 24-JAN-2021

and WOOD

Added MDMT 19 Deg C after review by

1A 18-FEB-2021

PERTAMINA and WOOD

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-101

2 P&ID D-15-1225-206

3 Line Lite First stage regenerator air inlet

4 Drawing Number D-7-7539 Rev D (for Ref)

5 Quantity 1 (ONE)

6 Orientation Horizontal

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Double ply, Pressure Balanced

8 Size OD in / outlet 30" ( 762 mm) 41,578" ( 1056 mm)

9 Thickness/ Connection Type 0,5 inch (13 mm) Welding

End Connection

10 Material ASTM A516 Gr 70

11 Design 3,94 Kg/cm2G

12 Pressure Operating VTA

13 Test VTA

343 deg C 1A

14 Design Bellows

15 Design Pipe 343 deg C

16 Process Temperature Design 343 deg C

Temperature

17 Process Temperature Operating 260 deg C / 343 deg C

18 MDMT 19 deg C 1A

19 Installation Amb deg C

20 Media FCC Catalyst

21 Media Flow Velocity 3803469 kg/hr

22 Flow Direction Horizontal

23 Axial Extension in / outlet 0 4,33 inch (110 mm)

24 Axial Compression in / outlet 4,92 Inch (125mm) 0

25 Design Movement Lateral in / outlet 2,17 inch (55 mm) 1,77 inch (45 mm)

26 Angular in / outlet 0,5 Deg 0,5 Deg

27 Number of Cycle in / outlet 200 200

28 Bellows B443-625 Gr 1

29 Liner A516-70

30 Sleeve A240-T304

Material

31 Cover C/S

32 Insullation Internal KAOWOOL

33 Cover C/S

34 Overall Length 326,75 inch (8300 mm)

35 Dimension Maximum O.D. 45,5 Inch (1156 mm)

36 Minimum I.D. 41,563 Inch (1056 mm)

37 Maximum Axial Spring Rate VTA

38 Spring Rates Maximum Lateral Spring Rate VTA

39 Maximum Angular Spring rate VTA

40 Bellows Long Seam Weld YES (100% Radiography)

41 Piping YES (100% Radiography)

42 U-2 Forms YES

43 Quality Assurance Pressure Testing YES

44 Leak Test YES

45 Refractory Test N/A

46 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Outlet expansion joint to be capable of 3 min duration upset of design pressure at 538°C.

3. Outlet expansion joint to be installed with a 35mm lateral offset as shown on drawings.

4. Vendor should provide max possible movements

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 3 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-102

2 P&ID D-15-1225-206F

3 Line Lite Recirculation Catalyst

4 Drawing Number 9038848-327-66-A1 and 9038848-805-01-A1 (for Ref)

5 Quantity 1 (ONE)

6 Orientation Vertical

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Untied universal,double ply, & pantograph

8 Size I.D 58,25" (1480 mm)

9 Thickness/ Connection Type 0,63 inch (16 mm) Welding

End Connection

10 Material ASTM A516 Gr 70

11 Design 4,7 Kg/cm2G

12 Pressure Operating 2,38 Kg/cm2G

13 Test VTA

14 Design Bellows 650 deg C

15 Design Pipe 343 deg C

16 Process Temperature Design 774 deg C

Temperature

17 Process Temperature Operating 727 deg C

1A

18 MDMT 19 deg C

19 Installation Amb deg C

20 Media FCC Catalyst

21 Media Flow Velocity 3386000 kg/hr

22 Flow Direction Vertically down

23 Axial Extension 1,97 inch (50 mm)

24 Axial Compression 1,97 inch (50 mm)

25 Design Movement Lateral in plane/out plane +0,55/2,52 inch (+14 / -64 mm) +/- 1 inch (+/-25mm)

26 Angular 0,5 Deg

27 Number of Cycle 200

28 Bellows B443-625 Gr 1

29 Liner / pipe A516-70

30 Sleeve A240-T304

31 Material Cover C/S

32 Refractory RESCO RS 17 EC or EQ

33 Refractory Abrasion RESCO AA-22

34 Woven wire Mesh/Hose Braid A240 T309

35 Overall Length 122,047 inch (3100 mm)

36 Dimension Maximum O.D. VTA

37 Minimum I.D. VTA

38 Maximum Axial Spring Rate VTA

39 Spring Rates Maximum Lateral Spring Rate VTA

40 Maximum Angular Spring rate VTA

41 Bellows Long Seam Weld YES (100% Radiography)

42 Piping YES (100% Radiography)

43 U-2 Forms YES

44 Quality Assurance Pressure Testing YES

45 Leak Test YES

46 Refractory Test as per API 936

47 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. blast condition Expansion joint to be capable of 3min duration upset of 7.38 kg/cm^2(g) at 343°C, bellows design temp 510°C.

3. Vendor should provide max possible movements

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 4 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-103A

2 P&ID D-15-1225-214F

3 Line Lite Flue Gas line

4 Drawing Number D-8-7539 Rev C (for Ref)

5 Quantity 1 (ONE)

6 Orientation Vertical

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Single Hinged, Double ply

8 Size O.D 136,8125Inch (3475 mm)

9 Thickness/ Connection Type 0,63 inch (16 mm) Welding

End Connection

10 Material ASTM A516 Gr 70

11 Design 1,7 Kg/cm2G

12 Pressure Operating VTA

13 Test 1,97 Kg/cm2G

14 Design Bellows 650 deg C

15 Design Pipe 343 deg C

16 Process Temperature Design 788 deg C

Temperature 1A

17 Process Temperature Operating 727 deg C

18 MDMT 19 deg C

19 Installation Amb deg C

20 Media Flue Gas

21 Media Flow Velocity VTA

22 Flow Direction Vertically down

23 Axial Extension 0

24 Axial Compression 0

25 Design Movement Lateral 0

26 Angular ± 1,5 Deg

27 Number of Cycle 200

28 Bellows B443-625 Gr 1

29 Liner / pipe A516-70

30 Sleeve A240-T304

31 Material Cover C/S

32 Refractory RESCO RS 17 EMC or RS 17 EMG (No Fibers)

33 Refractory Abrasion RESCO AA-22

34 Woven wire Mesh/Hose Braid A240 T309

35 Overall Length 78.75 Inch (2000 mm)

36 Dimension Maximum O.D. 147,3125Inch (3742 mm)

37 Minimum I.D. 142,8125Inch (3627 mm)

38 Maximum Axial Spring Rate VTA

39 Spring Rates Maximum Lateral Spring Rate VTA

40 Maximum Angular Spring rate VTA

41 Bellows Long Seam Weld YES (100% Radiography)

42 Piping YES (100% Radiography)

43 U-2 Forms YES

44 Quality Assurance Pressure Testing YES

45 Leak Test YES

46 Refractory Test as per API 936

47 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Vendor should provide max possible movements

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 5 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-103B

2 P&ID D-15-1225-214F

3 Line Lite Flue Gas line

4 Drawing Number D-9-7539 Rev C (for Ref)

5 Quantity 1 (ONE)

6 Orientation Vertical

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Single Hinged, Double ply

8 Size O.D 136,8125 Inch (3475 mm)

9 Thickness/ Connection Type 0,63 inch (16 mm) Welding

End Connection

10 Material ASTM A516 Gr 70

11 Design 0,5 Kg/cm2G

12 Pressure Operating VTA

13 Test 0,562 Kg/cm2G

14 Design Bellows 650 deg C

15 Design Pipe 343 deg C

16 Process Temperature Design 788 deg C

Temperature 1A

17 Process Temperature Operating 727 deg C

17 MDMT 19 deg C

18 Installation Amb deg C

19 Media Flue Gas

20 Media Flow Velocity VTA

21 Flow Direction Vertically down

22 Axial Extension 0

23 Axial Compression 0

24 Design Movement Lateral 0

25 Angular ± 1,5 Deg

26 Number of Cycle 200

27 Bellows B443-625 Gr 1

28 Liner / pipe A516-70

29 Sleeve A240-T304

30 Material Cover C/S

31 Refractory RESCO RS 17 EMC or RS 17 EMG (No Fibers)

32 Refractory Abrasion RESCO AA-22

33 Woven wire Mesh/Hose Braid A240 T309

34 Overall Length 78.5 Inch (1994 mm)

35 Dimension Maximum O.D. 147,3125 Inch (3742 mm)

36 Minimum I.D. 142,8125 Inch (3627 mm)

37 Maximum Axial Spring Rate VTA

38 Spring Rates Maximum Lateral Spring Rate VTA

39 Maximum Angular Spring rate VTA

40 Bellows Long Seam Weld YES (100% Radiography)

41 Piping YES (100% Radiography)

42 U-2 Forms YES

43 Quality Assurance Pressure Testing YES

44 Leak Test YES

45 Refractory Test as per API 936

46 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Vendor should provide max possible movements

3.

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 6 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-103C/D

2 P&ID D-15-1225-214F

3 Line Lite Flue Gas line

4 Drawing Number D-9-7539 Rev C (for Ref)

5 Quantity 2 (TWO)

6 Orientation Horizontal

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) double ply, Slotted hinge (New Design)

8 Size O.D 136,8125 Inch (3475 mm)

9 Thickness/ Connection Type 0,63 inch (16 mm) Welding

End Connection

10 Material ASTM A516 Gr 70

11 Design 0,5 Kg/cm2G

12 Pressure Operating VTA

13 Test 0,562 Kg/cm2G

14 Design Bellows 650 deg C

15 Design Pipe 343 deg C

16 Process Temperature Design 788 deg C

Temperature 1A

17 Process Temperature Operating 727 deg C

17 MDMT 19 deg C

18 Installation Amb deg C

19 Media Flue Gas

20 Media Flow Velocity VTA

21 Flow Direction Horizontal

22 Axial Extension 0

23 Axial Compression VTA

24 Design Movement Lateral 0

25 Angular ± 1,5 Deg

26 Number of Cycle 200

27 Bellows B443-625 Gr 1

28 Liner / pipe A516-70

29 Sleeve A240-T304

30 Material Cover C/S

31 Refractory RESCO RS 17 EMC or RS 17 EMG (No Fibers)

32 Refractory Abrasion RESCO AA-22

33 Woven wire Mesh/Hose Braid A240 T309

34 Overall Length 78.5 Inch (1994 mm)

35 Dimension Maximum O.D. 147,3125 Inch (3742 mm)

36 Minimum I.D. 142,8125 Inch (3627 mm)

37 Maximum Axial Spring Rate VTA

38 Spring Rates Maximum Lateral Spring Rate VTA

39 Maximum Angular Spring rate VTA

40 Bellows Long Seam Weld YES (100% Radiography)

41 Piping YES (100% Radiography)

42 U-2 Forms YES

43 Quality Assurance Pressure Testing YES

44 Leak Test YES

45 Refractory Test as per API 936

46 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Vendor should provide max possible movements

3. vendor must be stated that a line analysis would be required to determine requirement for guides and assess compression required

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 7 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-105

2 P&ID D-15-1225-209F

3 Line Lite Spent catalyst standpipe

4 Drawing Number D-1-7539 Rev C (for Ref)

5 Quantity 1 (ONE)

6 Orientation 35˚ From Vertical

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Dual Pantograph, Double ply

8 Size I.D 50 Inch (1270 mm)

9 Thickness/ Connection Type 0,63 inch (16 mm) Welding

End Connection

10 Material A387 Gr 11 Cl.2

11 Design 5,05 Kg/cm2G

12 Pressure Operating 2,31 Kg/cm2G

13 Test 5,624 Kg/cm2G

14 Design Bellows 550 deg C

15 Design Pipe 550 deg C

16 Process Temperature Design 550 deg C 1A

Temperature

17 Process Temperature Operating 532 deg C

17 MDMT 19 deg C 1A

18 Installation Amb deg C

19 Media FCC Catalyst

20 Media Flow Velocity 3803469 kg/hr

21 Flow Direction Downwards at 35° to vertical.

22 Axial Extension 2,2 inch (56 mm)

23 Axial Compression 14,2 inch (361 mm)

24 Design Movement Lateral in plane/out plane 5,71 inch (145 mm) 3,94 inch (100 mm)

25 Angular 0,5 Deg

26 Number of Cycle 200

27 Bellows B443-625 Gr 1

28 Liner / pipe A387 Gr 11 Cl.2

29 Sleeve A387 Gr 11 Cl.2

Material

30 Cover C/S

31 Installation KAOWOOL

32 Refractory Abrasion RESCO AA-22

33 Overall Length 143,7 Inch (3650 mm)

34 Dimension Maximum O.D. 61,1875 inch (1554 mm)

35 Minimum I.D. 56,25 inch (1429 mm)

36 Maximum Axial Spring Rate VTA

37 Spring Rates Maximum Lateral Spring Rate VTA

38 Maximum Angular Spring rate VTA

39 Bellows Long Seam Weld YES (100% Radiography)

40 Piping YES (100% Radiography)

41 U-2 Forms YES

42 Quality Assurance Pressure Testing YES

43 Leak Test YES

44 Refractory Test as per API 936

45 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Include upset condition as a note: Unit shall be capable of 3min upset of 7.03 kg/cm^2(g) at 532°C.

3. Joint to be installed with 70mm lateral offset.

4. Pantograph to be designed for a variation in expansion joint length from 3370mm to 3820mm.

5. Vendor should provide max possible movements

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 8 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-106

2 P&ID D-15-1225-211F

3 Line Lite Withdrawal Catalyst standpipe

4 Drawing Number D-3-7539 Rev B (for Ref)

5 Quantity 1 (ONE)

6 Orientation 35˚ From Vertical

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Dual Patograph, Double ply

8 Size O.D 18 Inch

9 Thickness/ Connection Type ANSI CL 300 RF WN FLANGE

End Connection

10 Material A106 Gr B

11 Design 5,3 Kg/cm2G

12 Pressure Operating 2,42 Kg/cm2G

13 Test 6,257 Kg/cm2G

14 Design Bellows 650 deg C

15 Design Pipe 343 deg C

16 Process Temperature Design 774 deg C

Temperature

17 Process Temperature Operating 727 deg C

17 MDMT 19 deg C 1A

18 Installation Amb deg C

19 Media FCC Catalyst

20 Media Flow Velocity 4500 kg/hr

21 Flow Direction Downwards at 35° to vertical.

22 Axial Extension 1 inch (25 mm)

23 Axial Compression 2,94 inch (75 mm)

24 Design Movement Lateral in plane/out plane ± 1,57 inch (40 mm) 0,5 inch (13 mm)

25 Angular ± 0,5 Deg

26 Number of Cycle 200

27 Bellows B443-625 Gr 1

28 Liner / pipe A106 Gr B

29 Sleeve A240-T304H

30 Material Cover C/S

31 Refractory RESCO RS 17 EC w/fibers

32 Refractory Abrasion RESCO AA-22

33 Woven wire Mesh/Hose Braid A240 T309

34 Overall Length 72 Inch (1830 mm)

35 Dimension Maximum O.D. 27 inch (686 mm)

36 Minimum I.D. 23 inch (584 mm)

37 Maximum Axial Spring Rate VTA

38 Spring Rates Maximum Lateral Spring Rate VTA

39 Maximum Angular Spring rate VTA

40 Bellows Long Seam Weld YES (100% Radiography)

41 Piping YES (100% Radiography)

42 U-2 Forms YES

43 Quality Assurance Pressure Testing YES

44 Leak Test YES

45 Refractory Test as per API 936

46 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Include upset condition as a note: Unit shall be capable of 3min upset of 7.03 kg/cm^2(g) at 343°C.

3. Joint to be installed with 13mm lateral offset.

4. Pantograph to be designed for a variation in expansion joint length from 1165mm to 1275mm.

5. Vendor should provide max possible movements

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 9 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-107A/B

2 P&ID D-15-1225-211F

3 Line Lite Ventilation Line

4 Drawing Number D-6-7539 Rev C (for Ref.)

5 Quantity 2 (TWO)

6 Orientation Vertical

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Single Hinged, Double ply

8 Size O.D 24 Inch (607 mm)

9 Connection in/out ANSI CL 300 RF WN FLANGE Welding

End Connection

10 Material in/out A105 A106 Gr B

11 Design 5 Kg/cm2G

12 Pressure Operating VTA

13 Test 5,624 Kg/cm2G

14 Design Bellows 650 deg C

15 Design Pipe 343 deg C

16 Process Temperature Design 774 deg C

Temperature 1A

17 Process Temperature Operating 727 deg C

17 MDMT 19 deg C

18 Installation Amb deg C

19 Media FCC Catalyst

20 Media Flow Velocity VTA

21 Flow Direction Vertically upwards

22 Axial Extension 0

23 Axial Compression 0

24 Design Movement Lateral 0

25 Angular 2,5 Deg (for each bellows)

26 Number of Cycle 200

27 Bellows B443-625 Gr 1

28 Liner / pipe A106 Gr B

29 Flange A105

30 Sleeve A240-T304

Material

31 Woven Wire Mash T304H

32 Cover C/S

33 Refractory RESCO RS 17 EC w/fibers

34 Refractory Abrasion RESCO AA-22

35 Overall Length 131,875 Inch (3350 mm)

36 Dimension Maximum O.D. 30.25 inch (768 mm)

37 Minimum I.D. 27.625 inch (702 mm)

38 Maximum Axial Spring Rate VTA

39 Spring Rates Maximum Lateral Spring Rate VTA

40 Maximum Angular Spring rate VTA

41 Bellows Long Seam Weld YES (100% Radiography)

42 Piping YES (100% Radiography)

43 U-2 Forms YES

44 Quality Assurance Pressure Testing YES

45 Leak Test YES

46 Refractory Test As Per API 936

47 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Rotational spring constant shall not exceed a gradient of 755N-m

3. Include upset condition as a note: Unit shall be capable of 3min upset of 7.03 kg/cm^2(g) at 343°C.

4. Vendor should provide max possible movements

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 10 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-107C

2 P&ID D-15-1225-211F

3 Line Lite Ventilation Line

4 Drawing Number D-6-7539 Rev C (for Ref.)

5 Quantity 1 (ONE)

6 Orientation Horizontal

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Single Hinged, Double ply

8 Size O.D 24 Inch (607 mm)

9 Connection in/out Welding ANSI CL 300 RF WN FLANGE

End Connection

10 Material in/out A106 Gr B A105

11 Design 5 Kg/cm2G

12 Pressure Operating VTA

13 Test 5,624 Kg/cm2G

14 Design Bellows 650 deg C

15 Design Pipe 343 deg C

16 Process Temperature Design 774 deg C

Temperature 1A

17 Process Temperature Operating 727 deg C

17 MDMT 19 deg C

18 Installation Amb deg C

19 Media Catalyst

20 Media Flow Velocity VTA

21 Flow Direction Horizontal

22 Axial Extension 0

23 Axial Compression 0

24 Design Movement Lateral 0

25 Angular 2,5 Deg

26 Number of Cycle 200

27 Bellows B443-625 Gr 1

28 Liner / pipe A106 Gr B

29 Flange A105

30 Sleeve A240-T304

Material

31 Woven Wire Mash T304H

32 Cover C/S

33 Refractory RESCO RS 17 EC w/fibers

34 Refractory Abrasion RESCO AA-22

35 Overall Length 42,047 Inch (1068 mm)

36 Dimension Maximum O.D. 30.25 inch (768 mm)

37 Minimum I.D. 27.625 inch (702 mm)

38 Maximum Axial Spring Rate VTA

39 Spring Rates Maximum Lateral Spring Rate VTA

40 Maximum Angular Spring rate VTA

41 Bellows Long Seam Weld YES (100% Radiography)

42 Piping YES (100% Radiography)

43 U-2 Forms YES

44 Quality Assurance Pressure Testing YES

45 Leak Test YES

46 Refractory Test As Per API 936

47 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Rotational spring constant shall not exceed a gradient of 755N-m

3. Include upset condition as a note: Unit shall be capable of 3min upset of 7.03 kg/cm^2(g) at 343°C.

4. Vendor should provide max possible movements

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 11 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-110

2 P&ID D-15-1225-203F

3 Line Lite MAB Outlet

4 Drawing Number D-1-8926 Rev B (for Ref.)

5 Quantity 1 (ONE)

6 Orientation Vertical

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Duel Tied, Double ply

8 Size I.D 55 inch (1397 mm)

9 Thickness/ Connection Type 0,5 inch (13 mm) Welding

End Connection

10 Material A516 Gr 70

11 Design 4,9 Kg/cm2G

12 Pressure Operating VTA

13 Test 5,414 Kg/cm2G

1A

14 Design Bellows 396 deg C

15 Design Pipe 396 deg C

1A

16 Process Temperature Design 396 deg C

Temperature

16 Process Temperature Operating 212 deg C

16 MDMT 19 deg C 1A

17 Installation Amb deg C

18 Media Air

19 Media Flow Velocity VTA

20 Flow Direction Vertical downwards

21 Axial Extension 0,19 inch (4,8 mm)

22 Axial Compression 0

23 Design Movement Lateral in plane/out plane 2,40 inch (61 mm) 0,40 inch (10 mm)

24 Angular 0,5 Deg

25 Number of Cycle 200

26 Bellows B443-625 Gr 1

27 Liner / pipe A516 Gr 70

28 Material Sleeve A516 Gr 70

29 Cover C/S

30 Insulation VTA

31 Overall Length 154,625 Inch (3928,4 mm)

32 Dimension Maximum O.D. 65.563 inch (1665 mm)

33 Minimum I.D. 60 inch (1524 mm)

34 Maximum Axial Spring Rate VTA

35 Spring Rates Maximum Lateral Spring Rate VTA

36 Maximum Angular Spring rate VTA

37 Bellows Long Seam Weld YES (100% Radiography)

38 Piping YES (100% Radiography)

39 U-2 Forms YES

Quality Assurance

40 Pressure Testing YES

41 Leak Test YES

42 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Maximum allowable joint stiffnesses are: lateral: 60N/m & rotational: 1200Nm/deg

3. Vendor should provide max possible movements

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 12 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-112

2 P&ID D-15-1225-203F

3 Line Lite MAB Outlet

4 Drawing Number D-1-8926 Rev B (for Ref.)

5 Quantity 1 (ONE)

6 Orientation Horizontal

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Single Hinged, Double ply

8 Size I.D 55 inch (1397 mm)

9 Thickness/ Connection Type 0,5 inch (13 mm) Welding

End Connection

10 Material A516 Gr 70

11 Design 4,9 Kg/cm2G

12 Pressure Operating VTA

13 Test 5,414 Kg/cm2G

396 deg C 1A

14 Design Bellows

15 Design Pipe 396 deg C

16 Process Temperature Design 396 deg C

Temperature 1A

16 Process Temperature Operating 212 deg C

16 MDMT 19 deg C

17 Installation Amb deg C

18 Media Air

19 Media Flow Velocity VTA

20 Flow Direction Horizontal

21 Axial Extension 0

22 Axial Compression 0

23 Design Movement Lateral 0

24 Angular 0,5 Deg

25 Number of Cycle 200

26 Bellows B443-625 Gr 1

27 Liner / pipe A516 Gr 70

28 Sleeve A479-T304

Material

29 Cover C/S

30 Insulation Blanket KAOWOOL

30 Insulation Pillow kaowool,fiberglass cloth wire mesh

31 Overall Length 154,625 Inch (3928,4 mm)

32 Dimension Maximum O.D. 65.563 inch (1665 mm)

33 Minimum I.D. 60 inch (1524 mm)

34 Maximum Axial Spring Rate VTA

35 Spring Rates Maximum Lateral Spring Rate VTA

36 Maximum Angular Spring rate VTA

37 Bellows Long Seam Weld YES (100% Radiography)

38 Piping YES (100% Radiography)

39 U-2 Forms YES

Quality Assurance YES

40 Pressure Testing

41 Leak Test YES

42 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Maximum allowable rotational stiffness: 1200Nm/deg

3. Vendor should provide max possible movements

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 13 of 14

Project No.

SP-20167

DATA SHEET FOR Doc. No.

EXPANSION BELLOW JOINT U2004-015-PYD-M04-T0288

Date

30-Mar-21

Applicable Codes and Standards: B31.1, B31.3, Section 8 Div 1, EJMA

1 Tag Number 15-EBJ-113

2 P&ID D-15-1225-212F

3 Line Lite 15-V-110 Baypass Line

4 Drawing Number D-1-E1692 Rev A (for Ref.)

5 Quantity 1 (ONE)

6 Orientation Vertical

7 Style or Type (Single, Universal, Hinged, Gimbal, etc) Single X-Press, Double ply

8 Size O.D 3 inch(Std 80)

9 Connection in/out ANSI CL 300 RF WN FLANGE ANSI CL 300 RF WN FLANGE

End Connection

10 Material in/out A105 A105

11 Design 11 Kg/cm2G

12 Pressure Operating VTA

13 Test VTA

1A

14 Design Bellows 400 deg C

15 Design Pipe 400 deg C

16 Process Temperature Design 400 deg C

Temperature

16 Process Temperature Operating 343 deg C 1A

16 MDMT 19 deg C

17 Installation Amb deg C

18 Media Catalyst

19 Media Flow Velocity VTA

20 Flow Direction Vertical downwards

21 Axial Extension 5,9 inch (150 mm)

22 Axial Compression 5,9 inch (150 mm)

23 Design Movement Lateral 0

24 Angular 0

25 Number of Cycle 200

26 Bellows B443-625 Gr 1

27 Liner / pipe A 53B SLMS /A106 B

Material

28 Flange A105

29 Cover C/S

31 Overall Length 49 Inch (1245 mm)

32 Dimension Maximum O.D. 5,75 inch (146 mm)

33 Minimum I.D. 4,5 inch (114 mm)

34 Maximum Axial Spring Rate VTA

35 Spring Rates Maximum Lateral Spring Rate VTA

36 Maximum Angular Spring rate VTA

37 Bellows Long Seam Weld YES (100% Radiography)

38 Piping YES (100% Radiography)

39 U-2 Forms YES

Quality Assurance

40 Pressure Testing YES

41 Leak Test YES

42 NDT Full include PT, RT and MT

Note:

1. VTA (Vendor to Advise)

2. Vendor should provide max possible movements

3.

4.

DATA SHEET FOR

1A RDM ISA BBS Re-Issued for Approval

EXPANSION BELLOW JOINT

1 RDM ISA JYG Issued for Approval

0 RDM ISA JYG Issued for Review

Rev Prepared Checked Approved Description Page 14 of 14

You might also like

- Operating - Instructions SD20 - SD185 - enDocument6 pagesOperating - Instructions SD20 - SD185 - enAswin AntonyNo ratings yet

- Gasket Fasteners AMLDocument5 pagesGasket Fasteners AMLoluyemisi FajogunNo ratings yet

- PH Lab ReportDocument8 pagesPH Lab ReportHaider Ali ShahidNo ratings yet

- Tendernotice 5 PDFDocument148 pagesTendernotice 5 PDFAbhijit BhandarkarNo ratings yet

- Operations Manual PDFDocument29 pagesOperations Manual PDFThanhsonAminoNo ratings yet

- ZA0-2 35,0ae-03 00Document15 pagesZA0-2 35,0ae-03 00Marcos Dos Santos VieiraNo ratings yet

- F5063a-K-003-00 NDT Procedure PDFDocument11 pagesF5063a-K-003-00 NDT Procedure PDFJatmika Budi SantosaNo ratings yet

- Compiled Vol IIDocument69 pagesCompiled Vol IIashish.mathur1No ratings yet

- MS-DD-KMY01-MEC-GA-0002 (Shell) R3-4Document1 pageMS-DD-KMY01-MEC-GA-0002 (Shell) R3-4Muhammad Rizky ImaduddinNo ratings yet

- 1.0 Scope: Welding of Carbon Steel PipingDocument3 pages1.0 Scope: Welding of Carbon Steel PipingandhucaosNo ratings yet

- 7-12-0009 Rev 7Document2 pages7-12-0009 Rev 7sahilNo ratings yet

- One Direction Guide For Vertical Cryogenic Pipes 2" - 24" NpsDocument3 pagesOne Direction Guide For Vertical Cryogenic Pipes 2" - 24" NpsMainuddin AliNo ratings yet

- AB-031A Minimum Required Information Form The Submitter For Pressure Vessels Heat Exchangers and BoilersDocument1 pageAB-031A Minimum Required Information Form The Submitter For Pressure Vessels Heat Exchangers and BoilersTrung NguyenNo ratings yet

- Data Sheet For Barred Tee 010719 PDFDocument1 pageData Sheet For Barred Tee 010719 PDFkandraNo ratings yet

- API Data Sheet - Wet Crude Storage TankDocument10 pagesAPI Data Sheet - Wet Crude Storage TankNatarajan RavisankarNo ratings yet

- HAL 96-112 105389.023-Rep-Basic Design Report - FINAL - housestyled-BASH-pages-96-112 PDFDocument17 pagesHAL 96-112 105389.023-Rep-Basic Design Report - FINAL - housestyled-BASH-pages-96-112 PDFcomsindo commodity survey indonesiaNo ratings yet

- 645295-P56790A-0154 - 01 Acoustic Insulation PDFDocument18 pages645295-P56790A-0154 - 01 Acoustic Insulation PDFAnsar AliNo ratings yet

- 7-12-0018 Rev 5Document1 page7-12-0018 Rev 5cynideNo ratings yet

- Praxair en 55Document34 pagesPraxair en 55StefanoNo ratings yet

- BMH-FED-SYN-00-L0-DS-001 - Datasheet For Manual Valve - Rev A - ANDocument20 pagesBMH-FED-SYN-00-L0-DS-001 - Datasheet For Manual Valve - Rev A - ANAfif FadhliNo ratings yet

- Design Drawing - Tower Kamuflase 25mDocument4 pagesDesign Drawing - Tower Kamuflase 25mMuhammad AmarNo ratings yet

- Fabrication of Piping SpecificationDocument35 pagesFabrication of Piping SpecificationLeilei WangNo ratings yet

- Specifications of LR BendDocument11 pagesSpecifications of LR BendPrafulla PatilNo ratings yet

- Tubing Data ChartsDocument30 pagesTubing Data ChartsIvo NunesNo ratings yet

- TH26 - Design of Fabric Expansion Joint Gas Seal Membranes PDFDocument9 pagesTH26 - Design of Fabric Expansion Joint Gas Seal Membranes PDFAnonymous cm4WdCZJtiNo ratings yet

- Estandar de SoporteriaDocument74 pagesEstandar de SoporteriaRuth Tecsi TCNo ratings yet

- 03-M-U-300819 Installation Instruction For Cold Box of Air Separation PlantDocument40 pages03-M-U-300819 Installation Instruction For Cold Box of Air Separation PlantmahmoudNo ratings yet

- Steam Traps: 5-11-2 BP Oil Co. RPDocument14 pagesSteam Traps: 5-11-2 BP Oil Co. RPHardik AcharyaNo ratings yet

- Bolt Tighting ProcedureDocument4 pagesBolt Tighting ProcedureAL-Kafaji HaithamNo ratings yet

- A545-736-11-42-DS-0034 - A - Flow TeeDocument2 pagesA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranNo ratings yet

- Murphy Offshore Inspection and Maintenance ReportDocument20 pagesMurphy Offshore Inspection and Maintenance ReportJaowad DabielNo ratings yet

- Pipe Support StandardDocument32 pagesPipe Support StandardHema Nandh100% (1)

- Expansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)Document14 pagesExpansion Tank (Et) : Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- Aogc 036 Pi Ess 001 (B1)Document19 pagesAogc 036 Pi Ess 001 (B1)amini_mohiNo ratings yet

- Punch List: 1798-PL-FCB-27 Fabcon Industrial Services FZ LLC ITT-1798 Daelim 19441-1798-2-R0 19441-1798-2-R0Document3 pagesPunch List: 1798-PL-FCB-27 Fabcon Industrial Services FZ LLC ITT-1798 Daelim 19441-1798-2-R0 19441-1798-2-R0Brain AliveNo ratings yet

- WPS-Nozzle With Reinforcement Pad (CS-CS) .Document1 pageWPS-Nozzle With Reinforcement Pad (CS-CS) .suria qaqcNo ratings yet

- Flange Bolt Torque TableDocument3 pagesFlange Bolt Torque Tablealif suryantoNo ratings yet

- How02 Z01uab12&cdc112 Ga 117Document1 pageHow02 Z01uab12&cdc112 Ga 117Ajizul Rohim AkbarNo ratings yet

- Pipeline Welding02776E03Document81 pagesPipeline Welding02776E03EL-Hamra Terminal projectsNo ratings yet

- Dgar Famegvir: Laftetitersigineas India Umit1EdDocument2 pagesDgar Famegvir: Laftetitersigineas India Umit1EdcynideNo ratings yet

- Projects Engineering Department Engineering Standard: BES-L001Document42 pagesProjects Engineering Department Engineering Standard: BES-L001Fox Alpha DeltaNo ratings yet

- Galfar MS 000-ZX-E-77758Document22 pagesGalfar MS 000-ZX-E-77758Ramaraju RNo ratings yet

- IS, I I I: Name of ManufacturerDocument1 pageIS, I I I: Name of ManufacturercynideNo ratings yet

- BN-MLS-21-PTSC-307302 - Rev02 UFD - Vent and Drains System - Code 2Document2 pagesBN-MLS-21-PTSC-307302 - Rev02 UFD - Vent and Drains System - Code 2citramuaraNo ratings yet

- Thread Types and UsesDocument1 pageThread Types and UsesJDPNetoNo ratings yet

- Eds L 1Document267 pagesEds L 1Sam Jose100% (1)

- List of Revision Description (Form-1) : Package 4 (Coker Unit) For Jubail Export Refinery ProjectDocument10 pagesList of Revision Description (Form-1) : Package 4 (Coker Unit) For Jubail Export Refinery ProjectrajeevfaNo ratings yet

- PU P ROA02164227803 DE ME DTA 001 01 B - Tank - 200m3 - R5 PDFDocument8 pagesPU P ROA02164227803 DE ME DTA 001 01 B - Tank - 200m3 - R5 PDFDDA7No ratings yet

- High-Strength, Wrought, Butt-Welding Fittings: MSS SP-75-2014Document33 pagesHigh-Strength, Wrought, Butt-Welding Fittings: MSS SP-75-2014LUISNo ratings yet

- AA 09/15/00 EJL TD DJ KM MWJ Issued For Bid: Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco RevisionDocument26 pagesAA 09/15/00 EJL TD DJ KM MWJ Issued For Bid: Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco RevisionThinh NguyenNo ratings yet

- 4390 Ps Uah C SCD 3000 Piping Support Standard - 04.1cDocument133 pages4390 Ps Uah C SCD 3000 Piping Support Standard - 04.1cGEORGE GAITANELISNo ratings yet

- Flare - Systems - MACH-1 SONIC FLARES Product Sheet FINALDocument2 pagesFlare - Systems - MACH-1 SONIC FLARES Product Sheet FINALCira RojasNo ratings yet

- 6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFDocument20 pages6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFsumit kumarNo ratings yet

- DBB (DN50 CL600)Document1 pageDBB (DN50 CL600)hameed100% (1)

- TABLE-3 LIST OF ATTACHMENTS - Rev 0Document5 pagesTABLE-3 LIST OF ATTACHMENTS - Rev 0Anonymous AyDvqgNo ratings yet

- DBB Datasheet WHRP PDFDocument48 pagesDBB Datasheet WHRP PDFRajendraNo ratings yet

- SA 980 P 11430 CS FGD Ball Valve Rev T02Document3 pagesSA 980 P 11430 CS FGD Ball Valve Rev T02altipatlarNo ratings yet

- Po SR No-112 (170159) 6X150 2150 MM ExtDocument1 pagePo SR No-112 (170159) 6X150 2150 MM ExtDebasis Pattnaik DebaNo ratings yet

- 50.0m GUYED Tower-TA-ZRI681 - A-040811-ADocument105 pages50.0m GUYED Tower-TA-ZRI681 - A-040811-Aredflex9001889No ratings yet

- 11d Pms Rev00a Ongc 27jul15Document3 pages11d Pms Rev00a Ongc 27jul15abhiNo ratings yet

- KU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFDocument7 pagesKU-TWK-10-ME-DTS-0304 Rev 2 Data Sheet For Common Electrostatic Coalescer Package PDFRexx Mexx100% (1)

- Equalizing Line Mbe 6 WTRDocument2 pagesEqualizing Line Mbe 6 WTRMuhamad Hifni SyahbanaNo ratings yet

- Unprice Forged Valve PT. ArfluDocument3 pagesUnprice Forged Valve PT. ArfluTommy ArjanggiNo ratings yet

- Epc Revitalization Project of RCC Ru Vi Balongan: Attachment - 1Document1 pageEpc Revitalization Project of RCC Ru Vi Balongan: Attachment - 1Tommy ArjanggiNo ratings yet

- Unprice Penawaran RAME RQ2108015 (Forging) R2 - ETI 18.08.21Document2 pagesUnprice Penawaran RAME RQ2108015 (Forging) R2 - ETI 18.08.21Tommy ArjanggiNo ratings yet

- Unprice Quotation - Forged Steel ValveDocument3 pagesUnprice Quotation - Forged Steel ValveTommy ArjanggiNo ratings yet

- Datasheet StrainerDocument4 pagesDatasheet StrainerTommy ArjanggiNo ratings yet

- Line Class FHC1 - R3Document6 pagesLine Class FHC1 - R3Tommy ArjanggiNo ratings yet

- MS13Document5 pagesMS13Tommy ArjanggiNo ratings yet

- A1A2Document6 pagesA1A2Tommy ArjanggiNo ratings yet

- ' 5° ' 56 1234-1113331 3nilaia, 1 - I1Ins - 1I.Ia1Aiai - . .,..P°2A02I-Aos - Aiiviii IDocument9 pages' 5° ' 56 1234-1113331 3nilaia, 1 - I1Ins - 1I.Ia1Aiai - . .,..P°2A02I-Aos - Aiiviii ITommy ArjanggiNo ratings yet

- Hardness Test: NO: 3 Supervised By: Dr. OsmanDocument9 pagesHardness Test: NO: 3 Supervised By: Dr. Osmanwrya hussainNo ratings yet

- The GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...Document18 pagesThe GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...jlfyNo ratings yet

- 1 - 7UT6 Diff - Principles - enDocument24 pages1 - 7UT6 Diff - Principles - encacobecoNo ratings yet

- Accepted Manuscript: 10.1016/j.electacta.2017.12.028Document32 pagesAccepted Manuscript: 10.1016/j.electacta.2017.12.028Евгений ГречушниковNo ratings yet

- PolyflameDocument2 pagesPolyflameumn_mlkNo ratings yet

- Heidenhain Touch ProbeDocument72 pagesHeidenhain Touch ProbeHoho Hahov100% (1)

- Rajasthan Public Service Commission, Ajmer: Inspector of Factories & BoilersDocument3 pagesRajasthan Public Service Commission, Ajmer: Inspector of Factories & Boilerstwinkle mandawatNo ratings yet

- Active Infrared Thermography Technique F PDFDocument14 pagesActive Infrared Thermography Technique F PDFsidNo ratings yet

- Fuserbloc - Front - Side Control Fuse Combination Switches - Catalogue - Pages - 2023 03 - DCG01094 - enDocument22 pagesFuserbloc - Front - Side Control Fuse Combination Switches - Catalogue - Pages - 2023 03 - DCG01094 - ensachusunil008No ratings yet

- Which Metal Cutting Process Is Best For Your Application?Document6 pagesWhich Metal Cutting Process Is Best For Your Application?Ronny De La CruzNo ratings yet

- Marble Run 1Document16 pagesMarble Run 1api-638167530No ratings yet

- 5SL Miniature Circuit BreakersDocument8 pages5SL Miniature Circuit BreakersSandeep ChandranNo ratings yet

- N2019-20 Power T and D L17Document30 pagesN2019-20 Power T and D L17guddu guptaNo ratings yet

- See WFM: Wire Feed Module (Optional) K924-5 Remote Control (Optional)Document1 pageSee WFM: Wire Feed Module (Optional) K924-5 Remote Control (Optional)Coordinador - MantenimientosNo ratings yet

- Rectifier Half Wave PDFDocument8 pagesRectifier Half Wave PDFdevi larasatiNo ratings yet

- S1 - Tutorial Problem Sheet 1Document2 pagesS1 - Tutorial Problem Sheet 1iliescu_oana_1No ratings yet

- Semi-Detailed Lesson Plan in Physics Force, Motion and EnergyDocument7 pagesSemi-Detailed Lesson Plan in Physics Force, Motion and EnergyAly SobosoboNo ratings yet

- Hybrid Amplifier by Andrea CiuffoliDocument24 pagesHybrid Amplifier by Andrea CiuffoliimrefodorNo ratings yet

- TGD Part EDocument88 pagesTGD Part EOlivia SaferNo ratings yet

- Astaxanthin - Marinedrugs-15-00231Document23 pagesAstaxanthin - Marinedrugs-15-00231Ulises SandovalNo ratings yet

- Karajet ProfileDocument5 pagesKarajet ProfileiezohreNo ratings yet

- Irfd9120, Sihfd9120: Vishay SiliconixDocument9 pagesIrfd9120, Sihfd9120: Vishay SiliconixNilton sergio gomes linsNo ratings yet

- Electrical Motors - Frame Sizes PDFDocument5 pagesElectrical Motors - Frame Sizes PDFGustavo CuatzoNo ratings yet

- Ts-100 Operation Manual 11 VerDocument373 pagesTs-100 Operation Manual 11 VersunhuynhNo ratings yet

- Chemistry Lab e Content Updated 2Document35 pagesChemistry Lab e Content Updated 2Debarghya DuttaNo ratings yet

- E70 PDFDocument900 pagesE70 PDFАлексей100% (1)

- Triangle Trigonometry and Circles TeacherDocument7 pagesTriangle Trigonometry and Circles TeacherClauciane Dias de LimaNo ratings yet

- 2024 Stoichiometry and SolutionsDocument32 pages2024 Stoichiometry and Solutionsphamgiakhanh112No ratings yet