Professional Documents

Culture Documents

Dolphin

Dolphin

Uploaded by

kado0 ratings0% found this document useful (0 votes)

6 views5 pagesÇİZİM

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentÇİZİM

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

6 views5 pagesDolphin

Dolphin

Uploaded by

kadoÇİZİM

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 5

dlore’s DOLPHIN

By WILLIAM D. JACKSON, N.A.

A 16-foot boat specially designed for those

who move their craft about by trailer

Craft Print Project No. 62

HIS trailer boat, the Dolphin, is the answer

to low-cost travel over protected waters. The

hull is light enough to be transported any-

where by trailer and the boat is of a size to be

easily handled. It will accommodate two per-

sons for extended trips or a party of four for day

cruises and do it comfortably.

Construction ‘and operating costs are low. Ply-

wood is used throughout, and the hull is designed

to exact the utmost from low power motors. Any

engine of 2% to 8 horsepower will do. One like

the U. S. Falcon 24 hp. water cooled marine en-

gine will provide very low operating costs with

a maximum number of miles per gallon of fuel

consumed. This has been proved.

Outboard motors can be used with this hull

if a suitable opening is cut in the transom. Small,

water-cooled marine engines are considered best

for this boat, however, with air-cooled engines a

doubtful last choice. Impeded air-flow around

the cabin might create cooling difficulties with

BOAT BUILDER'S HANDBOOK

this last-mentioned type of motor.

Construction of the Dolphin is

not difficult. Each item has been

simplified as much as possible.

The form on which the boat is

to be built is mounted on legs,

similar to sawhorses, at. a con-

venient working height. To pro-

vide full size patterns of all mem-

bers and to serve as a check on

the plans, draw the lines of the

hull full size on a large sheet of

paper. Corrections or additions

can thus be made where needed

and full size patterns will assure better fit at all

joints. If you know in advance what engine you

are going to use, you can easily draw this into

the full size layout to get patterns of skeg and

engine bed before you start building:

Lay full size patterns on the frame material,

mark and cut to shape. Fasten all joints with

%" plywood gussets on each side, glued with

resinous glue and secured with 1” #8 flathead

‘screws as indicated.

‘The stem is cut to shape from the full size

patterns and the two parts are joined together

with %” carriage bolts, finished by beveling edges

of stem as marked on the full size layout. The

frames are notched for keel, chines and clamp

pieces and are then mounted atop the form in

their respective places, with wood strips, tempo-

rarily nailed in place, to hold them in proper

alignment during construction.

Attach the keel at the notches in the stem and

frames with two 2” #10 flathead screws to each

:

E

BOAT BUILDER'S HANDBOOK

73

eed

5-343" $338" CHINE

Ic-29§" atk" >

S30

ic-223"

Is.212"

ene"

~ TT0P view" = = =

DECK LINE,

VISUAL] TABLE OFFSE’ 3" DECK LINE

cs

; 1

i F SHEER UNE | 50 ie

a og” pp" 234" pat 36 Le

Bs H WATER LINE ‘CHINE LINE

a" ck" a" isi ae

i” ze ch

ee pa ei oi" ae weet LINE [92 it

4 nm 21% 21% 21" a au 0

a ote a ee Ge

21D VIEW PLASTIC WINDOWS &Y THICK

COCKPIT COAMING os

44-6 FRAME DOUBLED ca

eee os DECKING’

gypnee r : hy

" 1-2, CVLINDER 24-5 H.P. 4

HIPLYWOOD U.S, FALCON MED. DUTY,

SEAT

SEE SKEG NOTE

aT 36 5 a

'gfoR 0" DA PROP.

GUSSETS.

SIDE eatren|| CLAMP.

BUNK

KEEL

courer KEEL’

qheeussers

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Fisica Ejercicios Resueltos Soluciones Fisica Cuantica SelectividadDocument30 pagesFisica Ejercicios Resueltos Soluciones Fisica Cuantica SelectividadEsneider Juventud Compromiso DesarrolloNo ratings yet

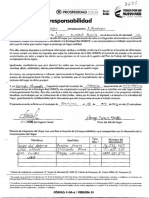

- Circular 029Document19 pagesCircular 029Esneider Juventud Compromiso DesarrolloNo ratings yet

- Acuerdo de CorresponsabilidadDocument1 pageAcuerdo de CorresponsabilidadEsneider Juventud Compromiso DesarrolloNo ratings yet

- Resolucion 3202 Del 2016Document72 pagesResolucion 3202 Del 2016Esneider Juventud Compromiso DesarrolloNo ratings yet

- NTC - 4194 - Ruidos (1) - Unlocked PDFDocument24 pagesNTC - 4194 - Ruidos (1) - Unlocked PDFJulian PérezNo ratings yet

- Infrome Ambiental Cda MagdalenaDocument138 pagesInfrome Ambiental Cda MagdalenaEsneider Juventud Compromiso DesarrolloNo ratings yet

- Proyecto Routing y ServerDocument7 pagesProyecto Routing y ServerEsneider Juventud Compromiso DesarrolloNo ratings yet