Professional Documents

Culture Documents

Built of A Rattan Indian Style Bow: Author: Rolf Gerschwinat Translation and Drawing: Roland Sawicki

Built of A Rattan Indian Style Bow: Author: Rolf Gerschwinat Translation and Drawing: Roland Sawicki

Uploaded by

kcwelderOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Built of A Rattan Indian Style Bow: Author: Rolf Gerschwinat Translation and Drawing: Roland Sawicki

Built of A Rattan Indian Style Bow: Author: Rolf Gerschwinat Translation and Drawing: Roland Sawicki

Uploaded by

kcwelderCopyright:

Available Formats

Built of a Rattan Indian Style Bow

Author: Rolf Gerschwinat

Translation and drawing: Roland Sawicki

Introduction:

For quite a while now the material gained some ground as a bow building material. Rattan

(also known as Manau) is a liana with nearly unlimited availability at affordable prices.

Rattan is readily available on the market in diameters between 25 mm (1") to 45 mm

(1.77") and lengths of up to 3 meters (118").

Rattan bows are especially suitable for kid's bows. The material can be easily worked even

by laymen. It is very forgiving with tiller errors especially for bows with low strengths (up

to 20 #).

According to my opinion it would be unfair to use Rattan only for kid's bows. I want to

share these instructions to build an Indian style bow or horse bow with strengths up to

40-50# and a draw of up to 32". These bows do not lack aesthetics and efficiency.

You can buy Rattan polished (outer skin removed) or unpolished (outer skin still

remaining). Both can be used to build a bow but I believe the unpolished variation will

give your bow more speed

Using this instruction I built several bows with strength beyond 45# and an arrow speeds

up tp 145fps.

Materials and tools you would need:

1 Rattan cane, > 40 mm (1.57") in diameter with a length not more than 150 cm (59 ")

A planer

A knife

A work bench with a vise or a couple of clamps

Various files and rasps

A tiller board

A spring scale

Sanding paper 80 to 240 grid

For the finish and decoration:

Leather for the handle

Pieces for fur as a silencer

Needle and thread

Varnish and brush

Horn or antler of the tip overlays (0ptional)

For the bow string

Dacron B50

Serving string

For the tiller and steam bend of the tips: Patience

This document shall not be used for commercial purposes

Page 1 of 13

Step 1:

Measure, mark and plane

Measure the dry Rattan cane and mark the center line along the length of the cane and

the grip area. Pay attention to the natural bend of the cane and include in your design

(the canes are not always perfectly straight).

For a short bow like this move the grip section towards the lower bow limb with a ratio not

more than 3/5 to 2/5 otherwise the bow would look too asymmetrical.

Apply all the markings at the side of the stave.

For beginners it is highly recommended to achieve a rectangular cross section

over the entire length of the bow limbs. To avoid twist the bows limbs should

be rather wide and flat than thick and narrow.

For a bow with a recurved length of ~ 130 cm (51"), the median thickness of the limbs

should be between 1,5 cm (0.59") and 2,2 cm (0.86"). Of course these measures

determine the bow strength. I took theses measures from a bow I built with 57# and a

draw of 28".

Now clamp the cane and plane from the grip section towards the end of the bow. Stay

away about 3 cm (1.18") from your grip markings. You will get to a width of about 38 mm

(1.5") at the ends. Repeat this on both limbs and at the back and belly of the bow. The

result should look like two flat truncated wedges attached to the grip. The thickness of the

flat ends at the bow tips should not be more than 15 mm (0.59"

Pictures: 1, 2

This document shall not be used for commercial purposes

Page 2 of 13

Drawing 1: Layout

This document shall not be used for commercial purposes

Page 3 of 13

Step 2:

Plane the outlines

Transfer the markings for the grip to the back and belly of the bow. Mark a line from the

end of the bow. The distance is about 1/4 of the length of the bow limb. Mark a center

section at front end of your limbs about 1.5 cm (0.59") but not more than 1,8 cm (0.79")

wide. Now mark the outline of the bow, connect the center marks to the line drawn

before.

Plane away the side sections. Smooth the sides and start rounding the edges at the bows

belly. You will not touch the grip section. You now have a bow with flat limbs and

pyramidal ends.

Now you can cut the nocks for the bow string at the sides of the limb. Cut them about 1,5

cm (0.59") away from the ends at about 45°. Do not cut into the back of the bow.

Pictures 4 and 5

This document shall not be used for commercial purposes

Page 4 of 13

Step 3

Make the bow string

I make the bow string in my preferred way using a Flemish splice. The yarn used is

Dacron B50. For a bow with a planned strength of 45# a bow string with 12 strands would

be required.

To avoid splicing errors and of course it's also looking good I use two different colors of

yarn (e.g. black and white). You can vary the combinations of mixing the colors 2 bundles

of while and 1 bundle black, one bundle white one bundle black or completely mixed up.

The bow string should be about 1.4 times the length of the bow. A loop at one end and a

bowyers knot at the other end. This way you can use the bows final sting to tiller the bow.

Picture 6: looped end of bow string

This document shall not be used for commercial purposes

Page 5 of 13

Step 4

Rough tiller of the bow

Carefully align the bows grip section to the outline of your bows limbs. You can use a rasp

or a sharp knife for the job.

Optionally you can make an arrow shelf between grip and upper fade out. The shelf is not

a real requirement although the arrow will move closer to the center bow when used.

Now put the string in the bows notches. The string should fit lightly without any tension.

Check your bow at the tiller board for the curvature.

Start tiller your bow at the belly side of the bow. Carefully remove material with a rasp

and also pre-round the still sharp corners of the bow especially at the belly of the bow. Be

patient do not remove to much material at one pass, its better to check more often. Every

time material is removed draw the bow about 10-15 times to get the materials used to

bending (be careful do not fully draw the bow immediately)

The result should be a consistent round curve from the grip to the bows tips. The strength

after the first tiller passes should be about 40#.

Rattan has fibers and when mechanically worked with a plane or rasp these fibers will

stand up. Don't let yourself carry away pulling these fibers out of the stave. Almost certain

you will pull out more material out of the stave and create ugly grooves. If you don't like

the fibers slightly sand them away.

Picture 7

This document shall not be used for commercial purposes

Page 6 of 13

Step 5

Steam bend the recurves and deflex

Now the time has come to bend the recurves to give your bow the longed for strength and

arrow speed.

I use an old electrical water kettle (but any old pot with a heat source will do as well). The

pot/kettle should hold enough water to produce enough steam needed for steaming the

brecurves. I fill the pot about with water about 2" below the top and bring it to a boil.

Place the tips of your bow (yes you can already call it a bow at this stage) over the boiling

water. Make sure that the section where the bend will be is exposed to the steam

Cover everything with an old kitchen cloth to trap the steam around the bow. Steam the

tips between 5 and 15 minutes. The time required is depends on the quality of the Rattan

and the thickness of the tips of your bows limbs. It is important to always keep the water

at a boil to have a constant flow of steam.

After about 10 minutes take the bow from the steam and bend the recurves. Be careful

the Rattan will be very hot. I take an old cloth or some leather gloves to protect my hands

but still be able to have enough feeling in my hands in the contact to the bow.

Bend the recurves towards the bows back at an angle of about 45°-55° to the bows limbs.

The recurves should have a length of about 10cm - 15 cm (4" - 6"). Press the tips of the

limb carefully and without force to the floor. Now increase the pressure until the recurves

bend. Hold until cooled down. Bear in mind that the recurves flex back about 10%-20%

The bend should be round and smooth without any sharp bends. The recurves shall also

be static.

If unpolished Rattan is used no compression creases shall be visible at the bows back

When both limbs are recurved it is time now to steam bend the middle of the bow.

The same process is used as for the recurves only now a slight deflex is bend into the

bow. This deflex is useful at the final tiller stage of the bow. Without the deflex the bows

recurves might tend to flip or twist sideways when strung up. On the other hand a deflex

makes for a smoother draw.

This document shall not be used for commercial purposes

Page 7 of 13

Pictures: 8, 9, 10

This document shall not be used for commercial purposes

Page 8 of 13

Step 6

Final Tiller

Let the bow sit overnight at a warm place so it will loose the moisture it took up during

the steam bends. Now the final tiller stage of the bow can start.

Shorten the bow string using a bowyers knot until you can string to bow to desired

bracing height

It might or will happen that the bow twists if you attempt to build. But Rattan has a great

advantage. Possible twists / limbs misaligned from the center line can be easily

straightened using steam.

Again once more the advice the wider (and flat) the limbs the less the risk of

twists.

The final tiller can be achieved by rounding the limbs at the belly and removing material

as "stiff" sections.

If material has been removed draw the bow 15-20 times so the material gets used to

bending and to make changes in the curve visible. (Rattan is no different than wood in

this regards)

If the bows strength is too weak shorten the bows length to about 140 cm (55"). This step

can be done after tempering the bow.

Picture 11

This document shall not be used for commercial purposes

Page 9 of 13

Step 7:

Tempering

When the bow has reached the desired strength the final finish can be started. An

additional 5# - 10# of strength can be achieved by tempering the bow.

Tempering means "baking" the material. There are 2 prove methods that are explained

here. One watch out with tempering: the longer the bow is heated the more brittle it will

get.

1. In the oven

The limbs can be tempered using a forced air oven at about 120°C - 150°C (248°F -

302°F). The oven door needs to be covered with kitchen cloth to trap the heat in. Starting

with a temperature of 100°C (212°F) the temperature needs to be slowly increased in

steps of 10°C (50°F) to avoid longitudinal cracks in the grip section. These cracks are not

dangerous but unsightly and also avoidable. Do not temper longer than 10 minutes. Also

treat both limbs with the same temperature and duration.

2. Using a hot air gun

If no oven large enough is available a standard hot air gun can be used to temper. It is

important to control the heat so no scorch or brown marks will develop on the surface. So

be careful! One advantage of this method is that soft sections in the limb can be

selectively tempered. Also with this method it is important that the temperature and time

exposure of both limbs is the same.

Now overlays made of horn or antler can be glued to the tips. Use epoxy glue showed

best results and of course glue after the heat treatment to avoid the risk that the glues

softens and loosens in the heat.

This document shall not be used for commercial purposes

Page 10 of 13

Picture 12,13

This document shall not be used for commercial purposes

Page 11 of 13

Step 8

Finishing touches

Now it is time to give the bow the final touches tough these might not be necessary if you

worked thoroughly during the previous steps. In any case from now on only use a scrape

or sandpaper.

Sand the bow with a 80 grid sandpaper to remove all scratches, rasp marks or grooves

Finally sand the bow by gradually using finer sandpaper up to a grid of 240.

After dust removal the first layer of varnish can be applied. I prefer varnish. Varnish

prevents the Rattan fibers from sticking out when the bow is drawn. It basically binds the

fibers and keeps a smooth surface. But I also know bowyers that oil their Rattan bows.

When the varnish is dried sand the bow with 240 grid (or finer) sandpaper to remove the

fibers that will stick out after the first application of varnish. Now the second layer of

varnish can be applied. If necessary repeat sanding and varnishing one more time.

Now the bow should have a golden shimmer.

To apply the silencers string the bow and mark the string about 15-18 cm (6" - 7") from

both tips. Use some Dacron B50, a needle, roll the fur pieces around your bow string at

the marks and stitch the fur to the string making about 3 passes thru the string.

At last wrap the grip leather and the center serving of the string

Pictures 14,15

This document shall not be used for commercial purposes

Page 12 of 13

Although I have some fine bows made of yew, osage orange and hickory in my collection

it is always fun to shoot the lightweight but still fast Rattan bows.

Have fun building bows using these instructions

Regards

Rolf Gerschwinat „Broken Arrow“

This document shall not be used for commercial purposes

Page 13 of 13

You might also like

- Unintended ConsequencesDocument749 pagesUnintended ConsequencesTazman1602100% (3)

- Condor TailsDocument6 pagesCondor TailsEnrique CoronelNo ratings yet

- Cuddly Cacti CrochetDocument74 pagesCuddly Cacti Crochetmartincarrie100% (5)

- Welcome To (Removed) 'S Page of "Maglite Flashlight Conversions!"Document5 pagesWelcome To (Removed) 'S Page of "Maglite Flashlight Conversions!"GasMaskBob67% (3)

- Welcome To (Removed) 'S Page of "Maglite Flashlight Conversions!"Document5 pagesWelcome To (Removed) 'S Page of "Maglite Flashlight Conversions!"GasMaskBob67% (3)

- PonyPlansMv2Document17 pagesPonyPlansMv2anon-822633100% (2)

- Fleece Teddy and BunnyDocument24 pagesFleece Teddy and BunnyMulan vw100% (8)

- Tapestry Weaving for Beginners and Beyond: Create graphic woven art with this guide to painting with yarnFrom EverandTapestry Weaving for Beginners and Beyond: Create graphic woven art with this guide to painting with yarnRating: 5 out of 5 stars5/5 (1)

- Making A Flemish Twist Bowstring 1999Document6 pagesMaking A Flemish Twist Bowstring 1999MoreMoseySpeedNo ratings yet

- Manual For Building A Traditional English LongbowDocument6 pagesManual For Building A Traditional English LongbowZvonimirMalbašaNo ratings yet

- Simmons HolsterDocument31 pagesSimmons Holstergordonsanwey100% (3)

- Roller KiteDocument4 pagesRoller KiteRizza Loraine100% (1)

- Making A Guitar BodyDocument11 pagesMaking A Guitar Bodytrkonjic100% (2)

- Making A Baroque Violin BowDocument4 pagesMaking A Baroque Violin BowchellestteNo ratings yet

- CrossWrap by B D EhlerDocument62 pagesCrossWrap by B D EhleralbahacatomilloNo ratings yet

- Kyudo and Zen. A Coincidence Through MisunderstandingDocument8 pagesKyudo and Zen. A Coincidence Through Misunderstandingflor.del.cerezoNo ratings yet

- Making A Red Oak Board BowDocument51 pagesMaking A Red Oak Board BowStephen PoppleNo ratings yet

- Final Archery Unit PlanDocument32 pagesFinal Archery Unit Planapi-391472390No ratings yet

- The World of Darkness - Merit's Compendium 3Document200 pagesThe World of Darkness - Merit's Compendium 3Sam Thornton100% (1)

- Paulo Coelho - El Camino Del Arco PDFDocument29 pagesPaulo Coelho - El Camino Del Arco PDFDaniel CoxNo ratings yet

- Fire - Bow DrillDocument6 pagesFire - Bow DrillhalonearthNo ratings yet

- Arcuri 2017Document35 pagesArcuri 2017EmanuelNo ratings yet

- Bow DrillDocument7 pagesBow DrillcagedraptorNo ratings yet

- Making A Longbow by Simon C B DayDocument6 pagesMaking A Longbow by Simon C B DayLeJlleNo ratings yet

- First LongbowDocument3 pagesFirst LongbowGinshun Ray SpedowskiNo ratings yet

- How To Make A Bowie Knife SheathDocument9 pagesHow To Make A Bowie Knife SheathfreemedicNo ratings yet

- BBT026 A Mohair Bear in CrochetDocument22 pagesBBT026 A Mohair Bear in Crochetcraftycow62No ratings yet

- Manual For Building A C. 40 Lbs. LongbowDocument7 pagesManual For Building A C. 40 Lbs. LongbowO/JNo ratings yet

- Make Your Own EquipmentDocument56 pagesMake Your Own Equipmentgordonsanwey50% (2)

- Peteward-Com MAKING A BOWDocument5 pagesPeteward-Com MAKING A BOWdescaraoNo ratings yet

- Guia VeritasDocument10 pagesGuia VeritasNatalia DiazNo ratings yet

- Archery - StringsDocument2 pagesArchery - StringsCalujnaiNo ratings yet

- Hone Your Hand-Tool Skills: A Handful of Exercises Develops Competence and Confidence With Chisels, Planes, and SawsDocument8 pagesHone Your Hand-Tool Skills: A Handful of Exercises Develops Competence and Confidence With Chisels, Planes, and SawsAdrian Cocis100% (1)

- Making Plastic PC ReedsDocument6 pagesMaking Plastic PC ReedsJayNo ratings yet

- Hive-Bodies 20110323Document9 pagesHive-Bodies 20110323khaldoonNo ratings yet

- Making A Guitar Neck PDFDocument8 pagesMaking A Guitar Neck PDFhoskencues100% (1)

- Fig02: The Completed Pattern.Document6 pagesFig02: The Completed Pattern.Mauro RegisNo ratings yet

- Make Your Own EquipmentDocument56 pagesMake Your Own EquipmentIzali NizarNo ratings yet

- Making A Flemish BowstringDocument12 pagesMaking A Flemish Bowstringraydarkhorse100% (2)

- How To Make Boutique HairbowsDocument25 pagesHow To Make Boutique HairbowsCandace Goff Neeley80% (5)

- Construção Les PaulDocument6 pagesConstrução Les PaulMarcelo M. MachadoNo ratings yet

- BowsDocument44 pagesBowsGeraldina GarciaNo ratings yet

- How To Make BokkenDocument10 pagesHow To Make Bokkenkosen58100% (1)

- Dressing A Violin FingerboardDocument17 pagesDressing A Violin FingerboardJuan FernandezNo ratings yet

- Build A Simple RC Boat HullDocument39 pagesBuild A Simple RC Boat HullAbu-Abdullah SameerNo ratings yet

- Comfy Crown PatternDocument16 pagesComfy Crown PatternSilvia TeixeiraNo ratings yet

- Dino TailsDocument6 pagesDino TailsbaaabaaaNo ratings yet

- Cardboard Geodesic DomeDocument5 pagesCardboard Geodesic DomeJuan Burgaya100% (1)

- Hands DovetailsDocument5 pagesHands Dovetailsquique1967.ecNo ratings yet

- Rough As Guts Building InstructionsDocument5 pagesRough As Guts Building InstructionsRhonda RoedererNo ratings yet

- Build A BowsawDocument4 pagesBuild A Bowsawjon789100% (1)

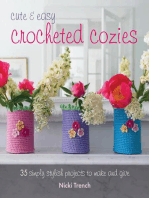

- Cute and Easy Crocheted Cosies: 35 simply stylish projects to make and giveFrom EverandCute and Easy Crocheted Cosies: 35 simply stylish projects to make and giveNo ratings yet

- Appendix ADocument4 pagesAppendix AAnonymous SAuK4CNo ratings yet

- Pen Turning OverviewDocument3 pagesPen Turning Overviewscooby dooNo ratings yet

- Caterpillar Book Binding: A Quick Guide To Preparing Your Boards and SignaturesDocument8 pagesCaterpillar Book Binding: A Quick Guide To Preparing Your Boards and SignaturesDaniella ZapataNo ratings yet

- Apple With SwingDocument12 pagesApple With SwingMilen Solakov100% (2)

- Basic Box MakingDocument16 pagesBasic Box Makingcerberus3385100% (3)

- Squirrel in A Tree: Carving Project - Pattern Provided in Pullout SectionDocument11 pagesSquirrel in A Tree: Carving Project - Pattern Provided in Pullout SectiondonguieNo ratings yet

- Pole School: With Bob NuddDocument7 pagesPole School: With Bob NudddaveagriffNo ratings yet

- Firecrest Construction NotesDocument5 pagesFirecrest Construction NotesSheikh MisbahNo ratings yet

- Blade Layout and CarvingDocument13 pagesBlade Layout and CarvingrapatigreNo ratings yet

- Slim Ballpoint Pen Hardware Kit: Preparing The Material BlanksDocument4 pagesSlim Ballpoint Pen Hardware Kit: Preparing The Material BlanksLachaud YvonNo ratings yet

- Let's Make A Pretty Zippered PouchDocument10 pagesLet's Make A Pretty Zippered Pouchmarah ketebeleceNo ratings yet

- How To Make A Bow and Arrow by HandDocument14 pagesHow To Make A Bow and Arrow by HandMephistoMarcan100% (1)

- Mel Tappan On SurvivalDocument91 pagesMel Tappan On Survivaljim100abNo ratings yet

- Rifling MachineDocument83 pagesRifling Machinekcwelder90% (10)

- Recurve BowDocument2 pagesRecurve BowCpotsedut TemulangNo ratings yet

- Unholy Night, by Seth Grahame-SmithDocument5 pagesUnholy Night, by Seth Grahame-SmithJinhi BaronNo ratings yet

- Traditional Archery TuningDocument22 pagesTraditional Archery TuningSumaKianBuNo ratings yet

- Re Curve Bow TuningDocument9 pagesRe Curve Bow TuningDoru DrăganNo ratings yet

- Ekalavya: Look at The Picture and Answer The Questions Given BelowDocument16 pagesEkalavya: Look at The Picture and Answer The Questions Given BelowvuppalasampathNo ratings yet

- Paulownia Archery BowsDocument3 pagesPaulownia Archery Bowssher123No ratings yet

- Archery PDFDocument5 pagesArchery PDFmetutorNo ratings yet

- Shogun - Total Unit GuideDocument9 pagesShogun - Total Unit Guidefernando_canato5422No ratings yet

- May 2022 S A ArcherDocument47 pagesMay 2022 S A ArcherRANo ratings yet

- Dynamic Spine Calculator Rev 5-12 2007Document8,037 pagesDynamic Spine Calculator Rev 5-12 2007Vergil DanteNo ratings yet

- CCI Ammunition 2011 CatalogDocument9 pagesCCI Ammunition 2011 CatalogAmmoLand Shooting Sports News100% (1)

- Peasant Quest CheatDocument5 pagesPeasant Quest Cheatikester2030No ratings yet

- BrochureDocument2 pagesBrochureAndrzej GutowiecNo ratings yet

- Longbow ArticleDocument6 pagesLongbow Articleapi-218061588No ratings yet

- Montana 2010 Black Bear RegulationsDocument12 pagesMontana 2010 Black Bear RegulationsAmmoLand Shooting Sports NewsNo ratings yet

- Air Gun CatalogueDocument200 pagesAir Gun CataloguentarylNo ratings yet

- Read The Text and Choose The Correct AnswersDocument2 pagesRead The Text and Choose The Correct AnswersSylvia YeoNo ratings yet

- Hoyt Catalog 2012Document30 pagesHoyt Catalog 2012bwelzNo ratings yet

- Lapua-Catalogue-2020 Letter ENG-USA WWW PDFDocument27 pagesLapua-Catalogue-2020 Letter ENG-USA WWW PDFNivaldo AlvesNo ratings yet

- Cyberpunk V 3.0 ErrataDocument3 pagesCyberpunk V 3.0 ErrataMike UrsuNo ratings yet

- National Ranking SystemDocument3 pagesNational Ranking Systemam7721No ratings yet

- Archery RequirementsDocument2 pagesArchery RequirementsmillersamsrNo ratings yet

- Target Shooter NovemberDocument96 pagesTarget Shooter NovemberTarget Shooter75% (4)

- Revised Martial Equipment - The HomebreweryDocument44 pagesRevised Martial Equipment - The HomebreweryMatheus CostaNo ratings yet

- IPSC Reglamento CarabinasDocument62 pagesIPSC Reglamento CarabinasskrungerNo ratings yet