Professional Documents

Culture Documents

Flashback Arrestor Testing: Testing of Existing Flashback Arrestors To Comply To EN 730-1 / ISO 5175 Standards

Flashback Arrestor Testing: Testing of Existing Flashback Arrestors To Comply To EN 730-1 / ISO 5175 Standards

Uploaded by

in123Copyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- WHS PRO 004 Maintenance of Equipment ProcedureDocument10 pagesWHS PRO 004 Maintenance of Equipment ProcedureWekesa RobinsonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Alfa Romeo 156 FuseboxDocument9 pagesAlfa Romeo 156 FuseboxAlexTocuNo ratings yet

- IGN 07 Working at Height and Working at Height Rescue PlanDocument75 pagesIGN 07 Working at Height and Working at Height Rescue Planin123No ratings yet

- Nebosh IGC2 - Faq: Workplace Hazards & Risk ControlDocument22 pagesNebosh IGC2 - Faq: Workplace Hazards & Risk Controlin123No ratings yet

- Effective Communication For Health Care Providers: A Guide To Caring For People With DisabilitiesDocument44 pagesEffective Communication For Health Care Providers: A Guide To Caring For People With Disabilitiesin123No ratings yet

- Sheet: Personal Protective EquipmentDocument2 pagesSheet: Personal Protective Equipmentin123No ratings yet

- Flash Back Arrestor InspectionDocument5 pagesFlash Back Arrestor Inspectionin123No ratings yet

- Scaffolding OSHA 1Document50 pagesScaffolding OSHA 1in123No ratings yet

- Car Parking - Rules and Regulations For Patients and Visitors - SOP0084Document2 pagesCar Parking - Rules and Regulations For Patients and Visitors - SOP0084in123No ratings yet

- Excavation PermitDocument1 pageExcavation Permitin123No ratings yet

- Energy Efficiency and Energy Auditing in Bangladesh: Rob Hartley-Louis and Salma IslamDocument55 pagesEnergy Efficiency and Energy Auditing in Bangladesh: Rob Hartley-Louis and Salma Islamin123No ratings yet

- SHP Barbour April 2021 Legislation Update EbookDocument31 pagesSHP Barbour April 2021 Legislation Update Ebookin123No ratings yet

- Brochure Medium Voltage AssembliesDocument98 pagesBrochure Medium Voltage AssembliesfranNo ratings yet

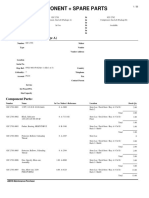

- Component + Spare Parts: Compressor, Gas Lift (Package A)Document30 pagesComponent + Spare Parts: Compressor, Gas Lift (Package A)VAN VIET NGONo ratings yet

- 320C, 320C L, 320C LN Excavator: Service Repair ManualDocument23 pages320C, 320C L, 320C LN Excavator: Service Repair ManualPatricio OrdóñezNo ratings yet

- Flexible Control Cables - 2YSLCYK-J 0,6/1kV: Technical AttributesDocument2 pagesFlexible Control Cables - 2YSLCYK-J 0,6/1kV: Technical AttributesChileshe MwansaNo ratings yet

- Air PreheaterDocument27 pagesAir Preheatershantanu_scribdNo ratings yet

- Guía de Inicio Getting Started: Configuración en Línea Online SetupDocument16 pagesGuía de Inicio Getting Started: Configuración en Línea Online SetupFast ServiceNo ratings yet

- Survey Instruments DetailsDocument2 pagesSurvey Instruments DetailsBarmer JaloreNo ratings yet

- P3 Sam Cab y Chas PDFDocument1 pageP3 Sam Cab y Chas PDFcells-crosser0xNo ratings yet

- Slab On Grade Utility Placement - DrawingDocument1 pageSlab On Grade Utility Placement - DrawingJamesNo ratings yet

- Panorama: Medium Voltage ProductsDocument6 pagesPanorama: Medium Voltage Productsdilo001No ratings yet

- Electrical Design ProcessDocument6 pagesElectrical Design ProcessUsha HaNo ratings yet

- Titan B RRV 33000 SeriesDocument2 pagesTitan B RRV 33000 SeriesBrandonNo ratings yet

- NQ Series Product Catalog 11Document45 pagesNQ Series Product Catalog 11Sasawahyu WahyukuNo ratings yet

- Fabrication of Motorized LiftDocument62 pagesFabrication of Motorized LiftANAND KRISHNANNo ratings yet

- Elitte Vip FerchoDocument18 pagesElitte Vip FerchoÑeco 10No ratings yet

- BOM (Tarmo4) - Sheet1Document1 pageBOM (Tarmo4) - Sheet1Francisco Ramon Monjo CentenoNo ratings yet

- Hand Tool SafetyDocument16 pagesHand Tool SafetyGallardo GarlanNo ratings yet

- Ameridrives Gear CouplingsDocument52 pagesAmeridrives Gear CouplingsJulivan SouzaNo ratings yet

- Allied Autovent 2000 3000 ManualDocument28 pagesAllied Autovent 2000 3000 ManualwiroarNo ratings yet

- Conector 7-16 Din Hembra 7/8" Cellflex.Document2 pagesConector 7-16 Din Hembra 7/8" Cellflex.SIMON S. FLORES G.No ratings yet

- Progard H3Document15 pagesProgard H3afie pio pioNo ratings yet

- Manipulator Elements Sergejs BoikoDocument14 pagesManipulator Elements Sergejs BoikoСергей БойкоNo ratings yet

- Hydra-Grip-O-Matic Puller and Straightener Tool: Safety PrecautionsDocument10 pagesHydra-Grip-O-Matic Puller and Straightener Tool: Safety PrecautionsTidak TahuNo ratings yet

- Activities: Internet and Computing Fundamentals IDocument4 pagesActivities: Internet and Computing Fundamentals IJONATHAN QUINTANONo ratings yet

- Lightining ArrestarDocument18 pagesLightining ArrestarRohan MittalNo ratings yet

- SIMPLEX 4099-9006 Ficha Técnica InglésDocument6 pagesSIMPLEX 4099-9006 Ficha Técnica Inglésjulian vargasNo ratings yet

- 2020-03-31 - WTP - MKV - Daily Report HSEDocument1 page2020-03-31 - WTP - MKV - Daily Report HSEavriamandaNo ratings yet

- Advantage M8 Service Manual - 20170703Document312 pagesAdvantage M8 Service Manual - 20170703Aravind BsNo ratings yet

Flashback Arrestor Testing: Testing of Existing Flashback Arrestors To Comply To EN 730-1 / ISO 5175 Standards

Flashback Arrestor Testing: Testing of Existing Flashback Arrestors To Comply To EN 730-1 / ISO 5175 Standards

Uploaded by

in123Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flashback Arrestor Testing: Testing of Existing Flashback Arrestors To Comply To EN 730-1 / ISO 5175 Standards

Flashback Arrestor Testing: Testing of Existing Flashback Arrestors To Comply To EN 730-1 / ISO 5175 Standards

Uploaded by

in123Copyright:

Available Formats

Flashback Arrestor Testing

Testing of existing Flashback Arrestors to

comply to EN 730-1 / ISO 5175 Standards.

INTRODUCTION:

Flashback Arrestors (FBAs) properly fitted and maintained are an important safety device in oxygen -

fuel gas applications. They are only effective for the designed purpose if their performance is within

the design specifications. Flashback arrestors that are not performing to the manufacturer’s

specifications may, in fact, cause problems. Therefore, it is important that flashback arrestors are

tested regularly to ensure their continued safe and effective operation.

DESCRIPTION:

The Ibeda FBA testing machine simply and quickly tests all common makes and models of flashback

arrestors for through flow - to ensure the unit maintains the correct flow rate to operate efficiently and

reverse flow - to ensure the non-return valve is operating correctly.

REQUIREMENTS:

It is the responsibility of the employer/owner/operator to ensure that Flashback Arrestors are fitted to

all oxy/fuel plants and comply to the manufacturer’s standard and NZ Health and Safety

requirements.

Manufacturers are required to ensure that the FBA is manufactured and tested to the design, used for

the purpose for which it is designed, that its installation, use, adjustment, maintenance, repair,

cleaning and dismantling will not cause harm to any person.

Manufacturers, Suppliers and Sellers of flashback arrestors shall provide clear and comprehensive

information to the purchaser or user concerning the use for which the FBA was designed,

manufactured and tested and information on its correct installation, use, adjustment, maintenance,

repair and any other relevant matters.

FBAs must be tested annually by a qualified technician, with a FBA Testing device which is

manufactured and approved by a FBA manufacturing company.

Standards for Flashback Arrestors:

AS 4603-1999 “Testing on Flashback Arrestors in service shall be carried out at a minimum interval of 12 months.”

AS 1674.1 1990 “The use of Flashback Arrestors is recommended”

AS 4267-1995 “Flashback Arrestors should be attached to regulators in Oxy-Fuel applications”

AS 4289-1995 “Flashback Arrestors shall be installed immediately downstream of each of the following:

a) Regulator, for regulated outlet points.

b) Isolation valve, for non-regulated outlet points.”

6.3.2 Twelve Monthly Maintenance

“Proper functioning of the non-return valves and flashback arrestors shall be checked.”

AS 4839-2001 “Optimum protection is provided when at the blowpipe end a flame arrestor and a non-return valve for

each gas line is fitted, and at the regulator end a flame arrestor, a non-return valve and a temperature

activated cut-off valve for each line is fitted.”

Testing Carried out by:

J.D.M Holdings Ltd

Unit D/17 Hobill Avenue, Wiri, Manukau, 2104. P.O Box 97622 Manukau City, Manukau 2241, New Zealand

Ph: +64 (09) 263 7099 Fax: +64 (09) 263 5062 Email: sales@digitalweld.co.nz Website: www.digitalweld.co.nz

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- WHS PRO 004 Maintenance of Equipment ProcedureDocument10 pagesWHS PRO 004 Maintenance of Equipment ProcedureWekesa RobinsonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Alfa Romeo 156 FuseboxDocument9 pagesAlfa Romeo 156 FuseboxAlexTocuNo ratings yet

- IGN 07 Working at Height and Working at Height Rescue PlanDocument75 pagesIGN 07 Working at Height and Working at Height Rescue Planin123No ratings yet

- Nebosh IGC2 - Faq: Workplace Hazards & Risk ControlDocument22 pagesNebosh IGC2 - Faq: Workplace Hazards & Risk Controlin123No ratings yet

- Effective Communication For Health Care Providers: A Guide To Caring For People With DisabilitiesDocument44 pagesEffective Communication For Health Care Providers: A Guide To Caring For People With Disabilitiesin123No ratings yet

- Sheet: Personal Protective EquipmentDocument2 pagesSheet: Personal Protective Equipmentin123No ratings yet

- Flash Back Arrestor InspectionDocument5 pagesFlash Back Arrestor Inspectionin123No ratings yet

- Scaffolding OSHA 1Document50 pagesScaffolding OSHA 1in123No ratings yet

- Car Parking - Rules and Regulations For Patients and Visitors - SOP0084Document2 pagesCar Parking - Rules and Regulations For Patients and Visitors - SOP0084in123No ratings yet

- Excavation PermitDocument1 pageExcavation Permitin123No ratings yet

- Energy Efficiency and Energy Auditing in Bangladesh: Rob Hartley-Louis and Salma IslamDocument55 pagesEnergy Efficiency and Energy Auditing in Bangladesh: Rob Hartley-Louis and Salma Islamin123No ratings yet

- SHP Barbour April 2021 Legislation Update EbookDocument31 pagesSHP Barbour April 2021 Legislation Update Ebookin123No ratings yet

- Brochure Medium Voltage AssembliesDocument98 pagesBrochure Medium Voltage AssembliesfranNo ratings yet

- Component + Spare Parts: Compressor, Gas Lift (Package A)Document30 pagesComponent + Spare Parts: Compressor, Gas Lift (Package A)VAN VIET NGONo ratings yet

- 320C, 320C L, 320C LN Excavator: Service Repair ManualDocument23 pages320C, 320C L, 320C LN Excavator: Service Repair ManualPatricio OrdóñezNo ratings yet

- Flexible Control Cables - 2YSLCYK-J 0,6/1kV: Technical AttributesDocument2 pagesFlexible Control Cables - 2YSLCYK-J 0,6/1kV: Technical AttributesChileshe MwansaNo ratings yet

- Air PreheaterDocument27 pagesAir Preheatershantanu_scribdNo ratings yet

- Guía de Inicio Getting Started: Configuración en Línea Online SetupDocument16 pagesGuía de Inicio Getting Started: Configuración en Línea Online SetupFast ServiceNo ratings yet

- Survey Instruments DetailsDocument2 pagesSurvey Instruments DetailsBarmer JaloreNo ratings yet

- P3 Sam Cab y Chas PDFDocument1 pageP3 Sam Cab y Chas PDFcells-crosser0xNo ratings yet

- Slab On Grade Utility Placement - DrawingDocument1 pageSlab On Grade Utility Placement - DrawingJamesNo ratings yet

- Panorama: Medium Voltage ProductsDocument6 pagesPanorama: Medium Voltage Productsdilo001No ratings yet

- Electrical Design ProcessDocument6 pagesElectrical Design ProcessUsha HaNo ratings yet

- Titan B RRV 33000 SeriesDocument2 pagesTitan B RRV 33000 SeriesBrandonNo ratings yet

- NQ Series Product Catalog 11Document45 pagesNQ Series Product Catalog 11Sasawahyu WahyukuNo ratings yet

- Fabrication of Motorized LiftDocument62 pagesFabrication of Motorized LiftANAND KRISHNANNo ratings yet

- Elitte Vip FerchoDocument18 pagesElitte Vip FerchoÑeco 10No ratings yet

- BOM (Tarmo4) - Sheet1Document1 pageBOM (Tarmo4) - Sheet1Francisco Ramon Monjo CentenoNo ratings yet

- Hand Tool SafetyDocument16 pagesHand Tool SafetyGallardo GarlanNo ratings yet

- Ameridrives Gear CouplingsDocument52 pagesAmeridrives Gear CouplingsJulivan SouzaNo ratings yet

- Allied Autovent 2000 3000 ManualDocument28 pagesAllied Autovent 2000 3000 ManualwiroarNo ratings yet

- Conector 7-16 Din Hembra 7/8" Cellflex.Document2 pagesConector 7-16 Din Hembra 7/8" Cellflex.SIMON S. FLORES G.No ratings yet

- Progard H3Document15 pagesProgard H3afie pio pioNo ratings yet

- Manipulator Elements Sergejs BoikoDocument14 pagesManipulator Elements Sergejs BoikoСергей БойкоNo ratings yet

- Hydra-Grip-O-Matic Puller and Straightener Tool: Safety PrecautionsDocument10 pagesHydra-Grip-O-Matic Puller and Straightener Tool: Safety PrecautionsTidak TahuNo ratings yet

- Activities: Internet and Computing Fundamentals IDocument4 pagesActivities: Internet and Computing Fundamentals IJONATHAN QUINTANONo ratings yet

- Lightining ArrestarDocument18 pagesLightining ArrestarRohan MittalNo ratings yet

- SIMPLEX 4099-9006 Ficha Técnica InglésDocument6 pagesSIMPLEX 4099-9006 Ficha Técnica Inglésjulian vargasNo ratings yet

- 2020-03-31 - WTP - MKV - Daily Report HSEDocument1 page2020-03-31 - WTP - MKV - Daily Report HSEavriamandaNo ratings yet

- Advantage M8 Service Manual - 20170703Document312 pagesAdvantage M8 Service Manual - 20170703Aravind BsNo ratings yet