Professional Documents

Culture Documents

60T0 Taurus v2 EN

60T0 Taurus v2 EN

Uploaded by

xianzaiegCopyright:

Available Formats

You might also like

- The Ultimate Guide to Pool Maintenance, Third EditionFrom EverandThe Ultimate Guide to Pool Maintenance, Third EditionRating: 3.5 out of 5 stars3.5/5 (2)

- TKT - TSD Series: Filler and Drain PlugsDocument5 pagesTKT - TSD Series: Filler and Drain Plugsmetin metinNo ratings yet

- Rev MR TATA 1 MGDocument6 pagesRev MR TATA 1 MGSurajNo ratings yet

- Robineti Sertar Pana - Pliant Date TehniceDocument2 pagesRobineti Sertar Pana - Pliant Date TehnicecocoNo ratings yet

- Pneumatic Connectors PDFDocument95 pagesPneumatic Connectors PDFYuDiNo ratings yet

- ES - Model W-M110-10.Document2 pagesES - Model W-M110-10.SANRAJ TECHNONo ratings yet

- ES Model W-M115-3Document2 pagesES Model W-M115-3moekimo3No ratings yet

- TA80B10A0L1P01Document2 pagesTA80B10A0L1P01Bryan CarcamoNo ratings yet

- Summary of Unserved MaterialsDocument1 pageSummary of Unserved Materialsa24gianNo ratings yet

- AQUATROL Series-69-51-55 VAL SEGURIDADDocument4 pagesAQUATROL Series-69-51-55 VAL SEGURIDADGregorio Mata MartínezNo ratings yet

- TFP1540 02 2017Document6 pagesTFP1540 02 2017Rashel HasanNo ratings yet

- 4way Diverter CatalogueDocument10 pages4way Diverter CatalogueMohd Khairi Mohd NorzianNo ratings yet

- Haydrant Pluit 2Document2 pagesHaydrant Pluit 2Gumanda siagianNo ratings yet

- List of Material'sDocument3 pagesList of Material'syoussef.gadalmawlaNo ratings yet

- KZ 2017 Bro Ka 2001XDocument1 pageKZ 2017 Bro Ka 2001XmarusahaNo ratings yet

- Enginneering Technical Service Project: Plarza Market Descrition: Accessoiries Fitting BOQDocument2 pagesEnginneering Technical Service Project: Plarza Market Descrition: Accessoiries Fitting BOQIm ChinithNo ratings yet

- 11 Specialty EquipmentDocument35 pages11 Specialty EquipmentVilius BukysNo ratings yet

- Technical DescriptionDocument5 pagesTechnical DescriptionAntonescu Ramona-IzabelaNo ratings yet

- HMBD 50B Drain ManualDocument14 pagesHMBD 50B Drain Manualindra bayujagadNo ratings yet

- Gemü B22: Manually Operated 2/2-Way Ball ValveDocument22 pagesGemü B22: Manually Operated 2/2-Way Ball ValveShania GintingNo ratings yet

- 카달로그 - 4Way Diverter ValveDocument9 pages카달로그 - 4Way Diverter Valvetazghat beghdadiNo ratings yet

- Spirax PN Series Pneumatic ActuatorsDocument7 pagesSpirax PN Series Pneumatic ActuatorsBSFNo ratings yet

- De Borboleta2-Actuação PneumaticaDocument2 pagesDe Borboleta2-Actuação PneumaticaHélder SilvaNo ratings yet

- 84-92-001 Avkcms enDocument3 pages84-92-001 Avkcms enShpresim KuchiNo ratings yet

- Technical Sheet Vacuum Tube Collectors CVTDocument2 pagesTechnical Sheet Vacuum Tube Collectors CVTgonzalez2678No ratings yet

- NPT SOP PDE 004 F11 BOM Diaphragm ValveDocument4 pagesNPT SOP PDE 004 F11 BOM Diaphragm ValveMohamed SelimNo ratings yet

- 1021FDocument3 pages1021Fshyju.grmNo ratings yet

- Druck Pv212 DatasheetDocument4 pagesDruck Pv212 Datasheetno nameNo ratings yet

- 851 41 001 - OptDocument3 pages851 41 001 - OptSabikun NaharNo ratings yet

- 1 ST Chain CatalogDocument19 pages1 ST Chain CatalogHamid SalmaniNo ratings yet

- Ee RQPDocument4 pagesEe RQPGerly Joy MaquilingNo ratings yet

- Druck Hydraulic Hand Pump: FeaturesDocument4 pagesDruck Hydraulic Hand Pump: FeaturesGia BaoNo ratings yet

- AccessoriesDocument1 pageAccessoriesFaisal NovredanaNo ratings yet

- MefaDocument250 pagesMefaStephane ChaminadeNo ratings yet

- 84-90-001 Avk002ax Eni 432447Document3 pages84-90-001 Avk002ax Eni 432447Gotica ManagementNo ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- Description: - Butterfly Valve DN 32 - 900Document8 pagesDescription: - Butterfly Valve DN 32 - 900neo dayNo ratings yet

- BQ 5Document1 pageBQ 5DANISH RAMLINo ratings yet

- Level Gauge - Reflex Type GBS-F 1000mmDocument1 pageLevel Gauge - Reflex Type GBS-F 1000mmPort VideoNo ratings yet

- Sanyata SAFEAir Large Linear Pneumatic 1.1Document4 pagesSanyata SAFEAir Large Linear Pneumatic 1.1HariHaran RajendranNo ratings yet

- MTO - KP60.7 Homa Aid Post Refurbishment UpdatedDocument4 pagesMTO - KP60.7 Homa Aid Post Refurbishment UpdatedmtokopaeNo ratings yet

- Bcn3d Moveo BomDocument2 pagesBcn3d Moveo BomXDXDXDNo ratings yet

- Avk Control Valve, Pressure Reducing, Pn10/16 859/000X-001: Reduced Bore, AISI 316 Pipes and FittingsDocument5 pagesAvk Control Valve, Pressure Reducing, Pn10/16 859/000X-001: Reduced Bore, AISI 316 Pipes and FittingsleejaemunNo ratings yet

- Ta2 enDocument3 pagesTa2 enRadu StamatinNo ratings yet

- Lva enDocument1 pageLva enДаниил СторчеусNo ratings yet

- Trunnion Mounted Metal Seated Ball Valve - As Per Shaikh Sir Req.-1Document11 pagesTrunnion Mounted Metal Seated Ball Valve - As Per Shaikh Sir Req.-1demblavalvesltd1989No ratings yet

- BOMBA DAB Divertron Sumergible 1Document2 pagesBOMBA DAB Divertron Sumergible 1Lisi BenassiNo ratings yet

- 32 Direct Acting Normally Closed Valve 22 MM PDFDocument2 pages32 Direct Acting Normally Closed Valve 22 MM PDFkarthikNo ratings yet

- Engg ItemsDocument1 pageEngg ItemsBIL Services LimitedNo ratings yet

- BCN3D Moveo BOMDocument2 pagesBCN3D Moveo BOMPurendra VishwakarmaNo ratings yet

- 6.B SED Valve 186Document9 pages6.B SED Valve 186MartinNo ratings yet

- Iwaki Electromagnetic Metering Pumps: High Speed Operation Double Ball Check ValvesDocument2 pagesIwaki Electromagnetic Metering Pumps: High Speed Operation Double Ball Check ValvesjayNo ratings yet

- 84-93-001 Avk002ax Eni 432477Document3 pages84-93-001 Avk002ax Eni 432477Gotica ManagementNo ratings yet

- Daftar Kalkulasi Pipa Penstock, Bifurcation, Dan Pintu AirDocument1 pageDaftar Kalkulasi Pipa Penstock, Bifurcation, Dan Pintu Airyoyok isbanuNo ratings yet

- 2 - ClassiCool Inverter Sales Catalogue - EnglishDocument5 pages2 - ClassiCool Inverter Sales Catalogue - EnglishxianzaiegNo ratings yet

- LG Governance CodeDocument36 pagesLG Governance CodexianzaiegNo ratings yet

- JOItmC 05 00071Document18 pagesJOItmC 05 00071xianzaiegNo ratings yet

- E-Government and E-Governance DefinitionDocument12 pagesE-Government and E-Governance DefinitionxianzaiegNo ratings yet

- WalkmakerDocument2 pagesWalkmakerxianzaiegNo ratings yet

- Ultra Broadband Optical Transmitter: 45 860Mhz Ve 950 2600MhzDocument2 pagesUltra Broadband Optical Transmitter: 45 860Mhz Ve 950 2600MhzxianzaiegNo ratings yet

- Bee Venom: Production, Composition, Quality: April 2016Document9 pagesBee Venom: Production, Composition, Quality: April 2016xianzaiegNo ratings yet

- SP43Document352 pagesSP43Umar MohammadNo ratings yet

- Work A RoundsDocument4 pagesWork A Roundsnoniggin nignogNo ratings yet

- Herbert SpencerDocument1 pageHerbert Spencerng kamchungNo ratings yet

- Intro To WW1 - Lesson 1Document24 pagesIntro To WW1 - Lesson 1Mrs_PPNo ratings yet

- SpeechDocument5 pagesSpeechNiza Pinky IchiyuNo ratings yet

- Object Oriented Programming Using C++ Viva Questions Coders LodgeDocument7 pagesObject Oriented Programming Using C++ Viva Questions Coders LodgeGulchetan SinghNo ratings yet

- Enforcement of IPRs at Border Book No.03Document32 pagesEnforcement of IPRs at Border Book No.03dhriti tutejaNo ratings yet

- CAT Test Series 2015Document2 pagesCAT Test Series 2015Nikhil SiddharthNo ratings yet

- Navasakam Grievance Application: Family DetailsDocument2 pagesNavasakam Grievance Application: Family DetailsmANOHARNo ratings yet

- Guda Guda Honnouji Rerun FAQDocument7 pagesGuda Guda Honnouji Rerun FAQRufus LoackerNo ratings yet

- Server Poweredge t610 Tech Guidebook PDFDocument65 pagesServer Poweredge t610 Tech Guidebook PDFMarouani AmorNo ratings yet

- Adc March 2018 SolvedDocument73 pagesAdc March 2018 SolvedKish BNo ratings yet

- Endurance Test Sit UpDocument2 pagesEndurance Test Sit UpDinyoga Bima WaskitoNo ratings yet

- Ncert Solutions Class 12 Accountancy Part 2 Chapter 1 Accounting For Share CapitalDocument42 pagesNcert Solutions Class 12 Accountancy Part 2 Chapter 1 Accounting For Share CapitalcchendrimadaNo ratings yet

- Embragues y Frenos - P-1960-CDocument4 pagesEmbragues y Frenos - P-1960-Cdéborah_rosalesNo ratings yet

- FortiOS 7.0.1 CLI ReferenceDocument1,751 pagesFortiOS 7.0.1 CLI ReferenceMoacir Nunes NetoNo ratings yet

- Astro-Logics Pub PDFDocument7 pagesAstro-Logics Pub PDFlbedar100% (1)

- Aerodynamics of Rugby BallDocument5 pagesAerodynamics of Rugby BallChandra Harsha100% (1)

- GrammarDocument23 pagesGrammarYMNo ratings yet

- New Jersey AG Questions Lakewood Schools' Lawyer's SalaryDocument2 pagesNew Jersey AG Questions Lakewood Schools' Lawyer's SalaryStaceyNo ratings yet

- Ase Sag 1 PDFDocument376 pagesAse Sag 1 PDFZack HastleNo ratings yet

- Heaptic EncephalopathyDocument16 pagesHeaptic Encephalopathydk.clinicalresearchNo ratings yet

- PT English-6 Q2Document7 pagesPT English-6 Q2Elona Jane CapangpanganNo ratings yet

- Lesson Plan - 2 1Document20 pagesLesson Plan - 2 1api-311773794No ratings yet

- Depth of FocusDocument7 pagesDepth of FocusDr-Riya MondalNo ratings yet

- Arlec Wireless SecurityDocument10 pagesArlec Wireless Securityalfi56kNo ratings yet

- Igcse Economics Rev NotesDocument69 pagesIgcse Economics Rev Noteskityk60% (5)

- Digital Communications Project ReportDocument14 pagesDigital Communications Project ReportSonal Pinto0% (1)

- 5) BL Corrector y Manifiesto de CargaDocument3 pages5) BL Corrector y Manifiesto de CargaKevin Yair FerrerNo ratings yet

- Business Administration PDFDocument185 pagesBusiness Administration PDFSarah MisekNo ratings yet

60T0 Taurus v2 EN

60T0 Taurus v2 EN

Uploaded by

xianzaiegOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

60T0 Taurus v2 EN

60T0 Taurus v2 EN

Uploaded by

xianzaiegCopyright:

Available Formats

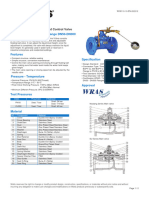

VALVES

rev: 2 TAURUS VALVE

Look through valve

Pressure

16 bar

Opening at very low pressure

Integrated

shut - off valve

Low pressure loss

and high KV

Hydrodynamic

design

The Hidroconta´s Taurus valve is

designed in “Y” shape, it allows a great

flow capacity maintaining a very low

pressure loss.

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

19

18

Assembly

17

Nº Description Material

1 Body Polyamide reinforced

with fiberglass 16

2 Screw M8x30 Stainless steel

3 O-ring 8x2 NBR

4 Inferior seal washer Polyamide reinforced 15

with fiberglass

5 Closing gasket NBR

6 Internal body Polyamide reinforced

14

with fiberglass 12

7 Screw M8 Brass

8 Diaphragm NR

13

9 Superior seal washer Polyamide reinforced

11

with fiberglass

10 Screw 4,8x19 Stainless steel

11 Shutter nut Polyamide reinforced 10

with fiberglass 8

9

12 Screw nut Polyamide reinforced

7

with fiberglass

13 O-ring 16x2,5 NBR

14 Spring Stainless steel 6

15 Lid Polyamide reinforced

3

with fiberglass 5

16 Allen Screw M6x30 Stainless steel

4

17 Valve wheel Polyamide reinforced 2

with fiberglass

18 Screw 3,9x32 Stainless steel

19 Lid screw Polyamide reinforced

1

with fiberglass

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

Dimensions

Adaptor for

Calibre L H D Weight Connection PVC pipe

(L1)

mm inch mm Kg mm

50 2" 230 162 74 1,1 Threaded 330,40

80 3" 310 236 108 2,7 Threaded 436,00

80 3" 320 278 200 3,8 Flanged

100 4" 335 291 225 4,22 Flanged

H

D

D

PVC ADAPTOR

2’’-3’’

L1

Technical specifications

Minimum Maximum pressure KV CV

Calibre opening pressure

bar bar m3/h US glm and psi

50 0,3 PN16 98,9 114,3

80 0,15 PN16 203,3 235,0

100 0,15 PN16 203,3 235,0

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

qv is the flow rate in m3 / h

ρ is the density of water in kg / m3

Calculation of ρ0 is the density of water at 15 ˚C in kg / m3

coefficient Kv Δpv is the loss pressure of the valve in bar

Pressure loss curve

psi bar 2" 3"- 4"

14 1,0

10

9

8

0,5

7

6

5

0,1

10 20 30 40 50 60 70 80 90 100 200 300 m3/h

glm us

40 50 60 70 80 90 100 200 300 400 500 600 700 800 9001000 1500

Operating curves

DN 50 DN 80 - 100

Flow m3 / h Flow m3 / h

80 200

180

70

160

60

140

50 120

40 100

80

30

60

20

40

10

20

0 0

0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0 1,1 1,2 1,3 1,4 1,5 1,6 1,7 1,8 0 0,10 0,20 0,30 0,40 0,50 0,60 0,70 0,80 0,90 1,00 1,10

Pressure (bar) Pressure (bar)

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

PRESSURE REDUCING VALVE

Functioning

Applications The pilot sets the downstream

pressure regardless the inlet pressure.

Used in places where pressure is If the outlet pressure is less than the

needed for: preset pressure, the valve is

completely open. If the upstream

- Adjust the pressure to consumption. pressure is less than the calibrated, the

pilot will open the valve, it will act just

- Protect instalations. when the pressure exceeds the set

pressure

The pilot acts on the valve so that it

has a modulating function, in order to

keep the downstream pressure

constant for the setting value. Ratios

Maximum reduction ratio: inlet pressure x 1/3

Precision Ratio: preset pressure ± 0,3 bar

REDUCING PRESSURE VALVE REDUCING PRESSURE 3 WAYS VALVE WITH

SOLENOIDE

2

2

2

3 1

0 2

3 1

4

0

O

P

1

1

3

3

1.- Taurus valve. 1.- Taurus valve.

2.- Reducer pilot. 2.- Reducer pilot.

3.- Filter. 3.- Filter.

4.- Solenoid.

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

SUSTAINING VALVE

Applications Functioning

It is used in installations where it is The pressure holding valve is designed

desired to maintain a minimum to maintain a minimum upstream

hydraulic pressure, such as: pressure if the pressure is higher than

the set value. Otherwise the valve will

- Pumping groups. close until the upstream pressure is

equal to or greater than the tare.

- Pipe lines with different

consumption.

- Filtering equipment.

The installation of this type of valves

allows to maintain a minimum pressure

Ratios

upstream set by the user.

Standard working rate: from 1 bar to 6.5 bar

Precision Ratio: preset pressure ± 0.3 bar

PRESSURE SUSTAINING 3 WAYS VALVE PRESSURE SUSTAINING 3 WAYS VALVE WITH

SOLENOID

2 2

2

2

3 1

4

3 1

0

O

P

1

1

3

3

1.- Taurus valve. 1.- Taurus valve.

2.- Sustenance pilot. 2.- Sustenance pilot.

3.- Filter. 3.- Filter.

4.- Solenoid.

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

REDUCING AND SUSTAINING VALVE

Applications Functioning

The combined reducing and sustaining The reducing pilot acts on the valve so

valve performs both functions that it has a modulating function, in

independently. Prevents on-site order to keep the downstream pressure

generation: constant for the set control value, the

holding pilot acts on the valve so that it

- Pressure drops. has a modulating function, in order to

maintain the upstream pressure above

- Overpressures. the minimum control value.

It is mainly used to automatically reduce

downstream pressure in the distribution

network and hold a minimum of pressure

in the main high pressure line regardless Ratios

of the demand for distribution.

Maximum reduction ratio: inlet pressure x

1/3

Precision Ratio: preset pressure ± 0.3 bar

Standard operating ratio: 1 bar to 6.5 bar

REDUCING AND SUSTAINING 3 WAYS VALVE

REDUCING AND SUSTAINING 3 WAYS VALVE

WITH SOLENOIDE

2 3 2 3

2 2

3 1 2 3 1

3 2

1 3 1

0 0

0 0

5

O

P

1 1

4 4

1.- Taurus valve. 1.- Taurus valve.

2.- Reducer pilot. 2.- Reducer pilot.

3.- Sustenance pilot. 3.- Sustenance pilot.

4.- Filter. 4.- Filter.

5.- Solenoid.

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

FLOW CONTROL VALVE

Applications Functioning

The installation of limiter flow control The pilot regulates the opening of the

valves allows to: valve according to the differential

pressure, providing the pre-set flow rate

- Avoid excessive consumption. and keeping the flow constant. By

actuating the screw of the pilot's tare it is

- Avoid pressure drops and therefore possible to vary the flow rate. By means of

supply deficiencies at points away from two sensors, installed on both sides of an

the grid. orifice plate that produces a certain

pressure drop, the circulating flow is

The flow limiting valves allow to limit the obtained, closing the hydraulic valve

flow of circulating water, ensuring that it partially until only allowing the

is equal to or less than adjusted. determined flow if this flow is to be

exceeded.

Ratios

After preselecting the flow to be limited, the

pilot is able to modify the flow rate set at ±

15%..

FLOW RATE 3 WAYS VALVE FLOW RATE 3 WAYS VALVE WITH SOLENOIDE

2 2

- -

2

5

3 1 2

3 1

O

0

P

0

A

1 1

+ - -

+

4 3

4 3

1.- Taurus Valve. 1.- Taurus Valve.

2.- Limiter pilot. 2.- Limiter pilot.

3.- Filter. 3.- Filter.

4.- Hole disc. 4.- Hole disc.

5.- Solenoid.

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

FLOW LIMITER AND PRESSURE REDUCER

Applications Functioning

The combined reducing and limiting valve The limiting and reducing valve performs

performs both functions independently. its function with the aid of a tared orifice

Prevents on-site generation: plate installed upstream. It includes a

differential pilot that regulates the

- Excessive consumption opening of the valve in function of the

- Pressure drops and therefore supply differential pressure, proportional to the

deficiencies at points away from the grid. flow, maintaining the constant flow. The

- Adjust the pressure to the consumption. reducing pilot acts on the valve so that it

- Protect facilities. has a modulating function in order to

keep the downstream pressure constant

for the set control value.

Ratios

Maximum reduction ratio: inlet pressure x 1/3

Precision Ratio: preset pressure ± 0.3 bar

After preselecting the flow to be limited, the pilot is able to modify the flow rate set at ± 15%..

FLOW LIMITER AND PRESSURE REDUCER 3 WAYS FLOW LIMITER AND PRESSURE REDUCER 3 WAYS

VALVE VALVE WITH SOLENOID

2 2 3

3

- -

2

2

3 1 2

6

3 1 2 3 1

3 1 0

O

0 0

0

P

1 1

+ - + -

5

5 4 4

1.- Taurus valve. 1.- Taurus valve.

2.- Limiter pilot. 2.- Limiter pilot.

3.- Reducer pilot. 3.- Reducer pilot.

4.- Filter. 4.- Filter.

5.- Hole disc. 5.- Hole disc.

6.- Solenoid.

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

ELECTROVALVE

Applications Functioning

The installation of solenoid valves

The VHM valve with solenoid or

allows us to act remotely, we can

electrovalve is an on / off valve.

control the opening and closing of the

The valve will operate fully open or

valve automatically.

fully closed when the solenoid is

energized.

The valve uses the own pressure of the

network for its operation.

In case of low pressure in the network

any external source of pressure can be

used.

ELECTROVALVE NA ELECTROVALVE NC O LACHT

P 2 2

P

O A

O A

1

1

3

3

1.- Taurus valve. 1.- Taurus valve.

2.- Solenoid. 2.- Solenoid.

3.- Filter. 3.- Filter.

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

FLOAT VALVE

Aplications Functioning

Float valves are used in water tanks or When the water level in the tank

regulation tanks. It is designed to fully reaches its maximum point, the buoy

open when the water level reaches a pilot closes the water passage,

preselected low and closes tightly accumulating the water pressure in the

when it reaches the selected high level. valve chamber and closing it.

When the water level in the tank drops

due to consumption, the buoy pilot

also descends, opening the water

passage and draining the chamber,

which opens the hydraulic valve.

1 LEVEL FLOAT VALVE 2 LEVELS FLOAT VALVE

3

4 5 3

6 5

6 7

4

4 3

1 2

1 1

2 2

1.- Taurus valve. 1.- Taurus valve.

2.- Filter. 2.- Filter.

3.- Inlet pressure manometer. 3.- Inlet pressure manometer.

4.- Spiral 4 mm. 4.- Needle valve pilot.

5.- Cut-off hidraulic valve. 5.- Float pilot.

6.- 1 level float. 6.- Cut-off hidraulic valve.

7.- Maximum level float.

8.- Float hidraulic switch.

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

PRESSURE RELIEF VALVE

Applications Functioning

The relief valve is designed to open in The pressure relief pilot sets the

case of exceeding a preset maximum maximum tare pressure limit through a

pressure. This valve is installed with set screw.

outlet to the atmosphere, relieving by If the upstream pressure exceeds the

opening the overpressure in the pipe. setting pressure, the piston is moved

upwards by communicating the valve

- Protection of hydraulic installations. chamber and the atmospheric

pressure. In this way the valve opens

to reduce excess pressure.

Ratios

Working pressures: From 2-16 bar

Precision Ratio: ± 0.5 bar

PRESSURE RELIEF VALVE

3 5

4 3

1 2

2

1.- Valve Hirodrovalve.

2.- Filter.

3.- Manometer 0-16 Bar.

4.- Spiral 4 mm.

5.- Pressure relief pilot.

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

Información de pedido

General characteristics

Valve diameter DN / mm / inches

Valve type membrane / piston

Maximum input pressure bar / MPa

Fittings plastic / metalic

Accesories plastic / metalic

Pilots plastic / metalic

Solenoid (Yes/Not) latch/24VDC/24VAC/220VAC

Estado de la válvula en reposo abierta/ cerrada

Reducer valve characteristics

Output pressure bar / MPa

Maximum flow m3 / h

Minimum flow m3 / h

Sustaining valve characteristics m3 / h

Pressure to hold bar / MPa

Maximum flow m3 / h

Minimum flow m3 / h

Working flow

m3 / h

Electrovalve characteristics m3 / h

Solenoid voltage V

Nº of wires 2/3

Use of the valve open / close

Float characteristics

Filling point 1/2

Pressure relief characteristics

Pressure relief bar / MPa

WHEN WATER COUNTS

rev: 2 TAURUS VALVE

FAQ

1- Why does not the valve open?

There may be insufficient pressure at the inlet pressure valve, you

should examine the insulation valves of the system upstream and

downstream, if they are closed open to allow the passage of

water and generate pressure.

Another reason may be that the solenoid is calcified, clean it and

replace parts as necessary.

2- Why does not the valve regulate at the desired control point?

It may be caused by the pilot because it is not adjusted properly,

check it by tightening and loosening the screwdriver to see if

there is a pilot reaction, so you can adjust the pilot to the desired

opening and closing speed.

Check if the upstream filter is clogged and causes insufficient

pressure to reach the pilot to activate the valve at the desired

control point.

3- Why does not the valve close?

It may be that the filter is clogged, to check it, disconnect the

copper line from the lid to see if there is water flow in the inlet. In

this case clean the filter mesh.

If the main valve membrane fails, it can also give this result,

replace the membrane for repair.

Another reason may be that the solenoid is calcified, clean it and

replace parts as necessary.

4- Why does the membrane leak water?

It is usually produced by the accumulation of dirt between the

membrane and its closing support, closing the valve manually, if

the problem persists open the valve to clean the area.

WHEN WATER COUNTS

You might also like

- The Ultimate Guide to Pool Maintenance, Third EditionFrom EverandThe Ultimate Guide to Pool Maintenance, Third EditionRating: 3.5 out of 5 stars3.5/5 (2)

- TKT - TSD Series: Filler and Drain PlugsDocument5 pagesTKT - TSD Series: Filler and Drain Plugsmetin metinNo ratings yet

- Rev MR TATA 1 MGDocument6 pagesRev MR TATA 1 MGSurajNo ratings yet

- Robineti Sertar Pana - Pliant Date TehniceDocument2 pagesRobineti Sertar Pana - Pliant Date TehnicecocoNo ratings yet

- Pneumatic Connectors PDFDocument95 pagesPneumatic Connectors PDFYuDiNo ratings yet

- ES - Model W-M110-10.Document2 pagesES - Model W-M110-10.SANRAJ TECHNONo ratings yet

- ES Model W-M115-3Document2 pagesES Model W-M115-3moekimo3No ratings yet

- TA80B10A0L1P01Document2 pagesTA80B10A0L1P01Bryan CarcamoNo ratings yet

- Summary of Unserved MaterialsDocument1 pageSummary of Unserved Materialsa24gianNo ratings yet

- AQUATROL Series-69-51-55 VAL SEGURIDADDocument4 pagesAQUATROL Series-69-51-55 VAL SEGURIDADGregorio Mata MartínezNo ratings yet

- TFP1540 02 2017Document6 pagesTFP1540 02 2017Rashel HasanNo ratings yet

- 4way Diverter CatalogueDocument10 pages4way Diverter CatalogueMohd Khairi Mohd NorzianNo ratings yet

- Haydrant Pluit 2Document2 pagesHaydrant Pluit 2Gumanda siagianNo ratings yet

- List of Material'sDocument3 pagesList of Material'syoussef.gadalmawlaNo ratings yet

- KZ 2017 Bro Ka 2001XDocument1 pageKZ 2017 Bro Ka 2001XmarusahaNo ratings yet

- Enginneering Technical Service Project: Plarza Market Descrition: Accessoiries Fitting BOQDocument2 pagesEnginneering Technical Service Project: Plarza Market Descrition: Accessoiries Fitting BOQIm ChinithNo ratings yet

- 11 Specialty EquipmentDocument35 pages11 Specialty EquipmentVilius BukysNo ratings yet

- Technical DescriptionDocument5 pagesTechnical DescriptionAntonescu Ramona-IzabelaNo ratings yet

- HMBD 50B Drain ManualDocument14 pagesHMBD 50B Drain Manualindra bayujagadNo ratings yet

- Gemü B22: Manually Operated 2/2-Way Ball ValveDocument22 pagesGemü B22: Manually Operated 2/2-Way Ball ValveShania GintingNo ratings yet

- 카달로그 - 4Way Diverter ValveDocument9 pages카달로그 - 4Way Diverter Valvetazghat beghdadiNo ratings yet

- Spirax PN Series Pneumatic ActuatorsDocument7 pagesSpirax PN Series Pneumatic ActuatorsBSFNo ratings yet

- De Borboleta2-Actuação PneumaticaDocument2 pagesDe Borboleta2-Actuação PneumaticaHélder SilvaNo ratings yet

- 84-92-001 Avkcms enDocument3 pages84-92-001 Avkcms enShpresim KuchiNo ratings yet

- Technical Sheet Vacuum Tube Collectors CVTDocument2 pagesTechnical Sheet Vacuum Tube Collectors CVTgonzalez2678No ratings yet

- NPT SOP PDE 004 F11 BOM Diaphragm ValveDocument4 pagesNPT SOP PDE 004 F11 BOM Diaphragm ValveMohamed SelimNo ratings yet

- 1021FDocument3 pages1021Fshyju.grmNo ratings yet

- Druck Pv212 DatasheetDocument4 pagesDruck Pv212 Datasheetno nameNo ratings yet

- 851 41 001 - OptDocument3 pages851 41 001 - OptSabikun NaharNo ratings yet

- 1 ST Chain CatalogDocument19 pages1 ST Chain CatalogHamid SalmaniNo ratings yet

- Ee RQPDocument4 pagesEe RQPGerly Joy MaquilingNo ratings yet

- Druck Hydraulic Hand Pump: FeaturesDocument4 pagesDruck Hydraulic Hand Pump: FeaturesGia BaoNo ratings yet

- AccessoriesDocument1 pageAccessoriesFaisal NovredanaNo ratings yet

- MefaDocument250 pagesMefaStephane ChaminadeNo ratings yet

- 84-90-001 Avk002ax Eni 432447Document3 pages84-90-001 Avk002ax Eni 432447Gotica ManagementNo ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- Description: - Butterfly Valve DN 32 - 900Document8 pagesDescription: - Butterfly Valve DN 32 - 900neo dayNo ratings yet

- BQ 5Document1 pageBQ 5DANISH RAMLINo ratings yet

- Level Gauge - Reflex Type GBS-F 1000mmDocument1 pageLevel Gauge - Reflex Type GBS-F 1000mmPort VideoNo ratings yet

- Sanyata SAFEAir Large Linear Pneumatic 1.1Document4 pagesSanyata SAFEAir Large Linear Pneumatic 1.1HariHaran RajendranNo ratings yet

- MTO - KP60.7 Homa Aid Post Refurbishment UpdatedDocument4 pagesMTO - KP60.7 Homa Aid Post Refurbishment UpdatedmtokopaeNo ratings yet

- Bcn3d Moveo BomDocument2 pagesBcn3d Moveo BomXDXDXDNo ratings yet

- Avk Control Valve, Pressure Reducing, Pn10/16 859/000X-001: Reduced Bore, AISI 316 Pipes and FittingsDocument5 pagesAvk Control Valve, Pressure Reducing, Pn10/16 859/000X-001: Reduced Bore, AISI 316 Pipes and FittingsleejaemunNo ratings yet

- Ta2 enDocument3 pagesTa2 enRadu StamatinNo ratings yet

- Lva enDocument1 pageLva enДаниил СторчеусNo ratings yet

- Trunnion Mounted Metal Seated Ball Valve - As Per Shaikh Sir Req.-1Document11 pagesTrunnion Mounted Metal Seated Ball Valve - As Per Shaikh Sir Req.-1demblavalvesltd1989No ratings yet

- BOMBA DAB Divertron Sumergible 1Document2 pagesBOMBA DAB Divertron Sumergible 1Lisi BenassiNo ratings yet

- 32 Direct Acting Normally Closed Valve 22 MM PDFDocument2 pages32 Direct Acting Normally Closed Valve 22 MM PDFkarthikNo ratings yet

- Engg ItemsDocument1 pageEngg ItemsBIL Services LimitedNo ratings yet

- BCN3D Moveo BOMDocument2 pagesBCN3D Moveo BOMPurendra VishwakarmaNo ratings yet

- 6.B SED Valve 186Document9 pages6.B SED Valve 186MartinNo ratings yet

- Iwaki Electromagnetic Metering Pumps: High Speed Operation Double Ball Check ValvesDocument2 pagesIwaki Electromagnetic Metering Pumps: High Speed Operation Double Ball Check ValvesjayNo ratings yet

- 84-93-001 Avk002ax Eni 432477Document3 pages84-93-001 Avk002ax Eni 432477Gotica ManagementNo ratings yet

- Daftar Kalkulasi Pipa Penstock, Bifurcation, Dan Pintu AirDocument1 pageDaftar Kalkulasi Pipa Penstock, Bifurcation, Dan Pintu Airyoyok isbanuNo ratings yet

- 2 - ClassiCool Inverter Sales Catalogue - EnglishDocument5 pages2 - ClassiCool Inverter Sales Catalogue - EnglishxianzaiegNo ratings yet

- LG Governance CodeDocument36 pagesLG Governance CodexianzaiegNo ratings yet

- JOItmC 05 00071Document18 pagesJOItmC 05 00071xianzaiegNo ratings yet

- E-Government and E-Governance DefinitionDocument12 pagesE-Government and E-Governance DefinitionxianzaiegNo ratings yet

- WalkmakerDocument2 pagesWalkmakerxianzaiegNo ratings yet

- Ultra Broadband Optical Transmitter: 45 860Mhz Ve 950 2600MhzDocument2 pagesUltra Broadband Optical Transmitter: 45 860Mhz Ve 950 2600MhzxianzaiegNo ratings yet

- Bee Venom: Production, Composition, Quality: April 2016Document9 pagesBee Venom: Production, Composition, Quality: April 2016xianzaiegNo ratings yet

- SP43Document352 pagesSP43Umar MohammadNo ratings yet

- Work A RoundsDocument4 pagesWork A Roundsnoniggin nignogNo ratings yet

- Herbert SpencerDocument1 pageHerbert Spencerng kamchungNo ratings yet

- Intro To WW1 - Lesson 1Document24 pagesIntro To WW1 - Lesson 1Mrs_PPNo ratings yet

- SpeechDocument5 pagesSpeechNiza Pinky IchiyuNo ratings yet

- Object Oriented Programming Using C++ Viva Questions Coders LodgeDocument7 pagesObject Oriented Programming Using C++ Viva Questions Coders LodgeGulchetan SinghNo ratings yet

- Enforcement of IPRs at Border Book No.03Document32 pagesEnforcement of IPRs at Border Book No.03dhriti tutejaNo ratings yet

- CAT Test Series 2015Document2 pagesCAT Test Series 2015Nikhil SiddharthNo ratings yet

- Navasakam Grievance Application: Family DetailsDocument2 pagesNavasakam Grievance Application: Family DetailsmANOHARNo ratings yet

- Guda Guda Honnouji Rerun FAQDocument7 pagesGuda Guda Honnouji Rerun FAQRufus LoackerNo ratings yet

- Server Poweredge t610 Tech Guidebook PDFDocument65 pagesServer Poweredge t610 Tech Guidebook PDFMarouani AmorNo ratings yet

- Adc March 2018 SolvedDocument73 pagesAdc March 2018 SolvedKish BNo ratings yet

- Endurance Test Sit UpDocument2 pagesEndurance Test Sit UpDinyoga Bima WaskitoNo ratings yet

- Ncert Solutions Class 12 Accountancy Part 2 Chapter 1 Accounting For Share CapitalDocument42 pagesNcert Solutions Class 12 Accountancy Part 2 Chapter 1 Accounting For Share CapitalcchendrimadaNo ratings yet

- Embragues y Frenos - P-1960-CDocument4 pagesEmbragues y Frenos - P-1960-Cdéborah_rosalesNo ratings yet

- FortiOS 7.0.1 CLI ReferenceDocument1,751 pagesFortiOS 7.0.1 CLI ReferenceMoacir Nunes NetoNo ratings yet

- Astro-Logics Pub PDFDocument7 pagesAstro-Logics Pub PDFlbedar100% (1)

- Aerodynamics of Rugby BallDocument5 pagesAerodynamics of Rugby BallChandra Harsha100% (1)

- GrammarDocument23 pagesGrammarYMNo ratings yet

- New Jersey AG Questions Lakewood Schools' Lawyer's SalaryDocument2 pagesNew Jersey AG Questions Lakewood Schools' Lawyer's SalaryStaceyNo ratings yet

- Ase Sag 1 PDFDocument376 pagesAse Sag 1 PDFZack HastleNo ratings yet

- Heaptic EncephalopathyDocument16 pagesHeaptic Encephalopathydk.clinicalresearchNo ratings yet

- PT English-6 Q2Document7 pagesPT English-6 Q2Elona Jane CapangpanganNo ratings yet

- Lesson Plan - 2 1Document20 pagesLesson Plan - 2 1api-311773794No ratings yet

- Depth of FocusDocument7 pagesDepth of FocusDr-Riya MondalNo ratings yet

- Arlec Wireless SecurityDocument10 pagesArlec Wireless Securityalfi56kNo ratings yet

- Igcse Economics Rev NotesDocument69 pagesIgcse Economics Rev Noteskityk60% (5)

- Digital Communications Project ReportDocument14 pagesDigital Communications Project ReportSonal Pinto0% (1)

- 5) BL Corrector y Manifiesto de CargaDocument3 pages5) BL Corrector y Manifiesto de CargaKevin Yair FerrerNo ratings yet

- Business Administration PDFDocument185 pagesBusiness Administration PDFSarah MisekNo ratings yet