Professional Documents

Culture Documents

JPG 2 PDF

JPG 2 PDF

Uploaded by

kakashi benaouda0 ratings0% found this document useful (0 votes)

13 views112 pagesOriginal Title

jpg2pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

13 views112 pagesJPG 2 PDF

JPG 2 PDF

Uploaded by

kakashi benaoudaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 112

(ja) Mayer & Cie. chapter a2

Rundstrickmaschinen Page 41/22/1

Drive systems

1. Toothed belt drive system 3. Belt tension

2, V-belt drive system

ATTENTIO!

‘© Before any interference in the machine's drive system. the main switch must be off and the motor

must be at a standstill

Safeguard the machine against unauthorized start-up.

Only under these circumstances may the drive covers be removed,

For machines with frequency controlled speed drive, the motor V-belt pulley may not be exchanged,

‘The machine speed for these machines is steplessy adjustable,

‘© For machines with two drive belts, belts may only be exchanged in pairs,

‘© _ Starting up only when gear cover is mounted correct

Inbetriebnahme nur bei ordnungsgemiBer Montage der Getriebe-Schutzabdeckungen

1. Toothed belt drive system

Exchanging the drive belt

© Release the gear covers § and lift off

© Loosen screws 1 (without removing)

© Release the belt 2 by turning adjusting

screw 3

© The motor carriage 4 and motor can be

pushed to the side together using

adjusting screw 3

‘© Pull the new belt onto the pulley when

not under tension, or using a tool

1.1 Variation 1

Reassembly and adjusting belt tensio

© Move the motor outwards using

adjusting screw 3 and adjust belt

tension

‘© When belt tension (Chap. 3) is correct,

tighten the screw 1

© Check belt tension

© Replace gear cover Sand tigh

correct

12/09 GB Drive systems 01 7249.0

® Mayer & Cie. chapter a2

Rundstrickmaschinen Page 41/22/2

1.1.2 Options

‘© Pay attention at open fabric systems for clockwise- or anticlockwise rotating,

Anticlockwise

Exchanging the drive belts:

© Remove V-belt 6 (Chap. 3)

# Release the gear covers § and lift off

Loosen screws 1 (without removing)

# Release the belt 2 by turning adjusting

Bearing housing 4 can be pushe to the

side

‘© Pull belt 2 over v-belt pulley $

# Pull the new belt onto the pulley when

not under tension, or using a tool

Reassembly and adjusting belt tension:

Move the bearing housing 4 outwards

and adjust belt tension using adjusting

‘© When belt tension (Chap. 3) is correct,

tighten the screw 1

© Check belt tension

eplace gear cover S and tighten

correct

|

%/O|

12/09 GB Drive systems 01 7249.0

Rundstrickmaschinen Page 41/22/3

® Mayer & Cie. chapter a2

2. V- belt drive system

Exchanging the drive belts:

‘+ Release the gear covers S and lift off

‘© Loosen screws 1 (without removing)

‘© Release the belt 2 by tuning adjusting

screw 3

©The motor carriage 4 and motor can be

pushed to the side together using

adjusting screw 3

‘© Pull the new belt onto the pulley when

not under tension, or using a tool

Reassembly and adjusting belt tension:

© Move the motor outwards using

adjusting screw 3 and adjust belt

tension

‘When belt tension (Chap. 3) is correct,

tighten the screw 1

Check belt tension

Replace gear cover § and tighten

correct

Ald A

\

3. Belt tension

3.1 Toothed belt

‘Setting the tension from toothed belt with some Frequenzy-Tester to 70 — 80 Hz,

3.2 V-belt

12/09 GB Drive systems 01 7249.0

® Mayer & Cie. coups sts

Rundstrickmaschinen Page 40/05/1

Machine Levelling Device:

(Page 40/05/1)

Only set up the machine on an even, solid foundation with sufficient load-bearing capacity.

Align the machine using a machine spirit level (1 graduation = 0,30 mm per meter)

Put the spirit level on the contact surface of the segment or on the cam ring.

1 = Adjusting screw

2= Locking nuts

11/09 GB Machine Levelling Device 00 72 22.0

Mayer & Cie.

Rundstrickmaschinen Page 0/1

Copy of the original

USER MANUAL

FOR

MAYER & CIE MACHINE CONTROL SYSTEM

Mayer & Cie.

BOS

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 0/2

About this manual:

This manual serves to explain the construction, function and operation of the machine control

system. The illustrations and drawings included illustrate the essential elements of the control

system but are not binding in relation to dimensional accuracy and details,

All rights are reserved with regard to deviations and changes,

This manual should be accessible to all concerned personnel at all times and should be read by

said before carrying out any work on the machine

All rights relating to this manual are reserved, in particular all rights of reproduction, distribution

and translation,

© 2000 Mayer & Cie, GmbH & Co., Albstadt, Germany

The information contained in this manual is not subject to guarantee and can be changed without

prior notice.

Mayer & Cie. GmbH & Co. is under no obligation in this respect

No part of this manual may be reproduced in any form (e.g. photocopy, microfilm or by other

means) or processed, reproduced or distributed through the use of electrical systems without

prior written permission from Mayer & Cie, GmbH & Co.

This manual describes all options relating to the operator's panel machine control system without

consideration of machine type or design,

Parts or equipment which do not belong to the standard machine design can only be delivered at

an extra cost when ordered by the customer,

No rights can be derived from this manual concerning the equipping of the machine with such

equipment or parts

The spare parts catalogue is the sole authority with regard to orders of spare parts

Attention is expressly drawn to safety instructions and measures in areas of risk. Safety and

protective equipment and fittings should only be carried out by a specialist under observation of

the general regulations governing safety and accident prevention

Operating personnel should be suitably trained and instructed

This manual is an integral part of the machine. It should be delivered with the machine in the

event of the machine being resold,

Mayer & Cie.

Rundstrickmaschinen

Postfach 201580 D-72498 Asta Telefon (07432}700-0

05/00 GB MCT Machine Control System 00 71 01.2

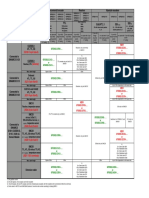

1, Contents:

0. Title page

About this manual

1. Contents.

2. Survey of operator's panel.

3. Key assignment

4, Function keys

5. Quick keys

6. Operating displays

Operating display "Ready for production’

Operating display "Wind up”

Operating display ”Production”

Operating display “Begin cleaning”

Operating display Cleaning”

Operating display Auto flush”

Operating display "Drive to position”

Operating display "JOG mode”

Operating display "Warm up”

Operating display "Warm up after power ON”

Operating display "Reduced revolution”.

Operating display "Production MAX-RPM”.

Operating display “Manual flush”

Operating display "Run-out feeder OFF”

6.1 Needle door function (Option)

7. Entering code

8. Display after switching on

9. Switching on the control system.

10, Menu survey

II, Menu 1, Doff counter”

Doff counter

Reset doff counter

1

Ll

1.2 Adjust dof counter

06/02 GB MCT Machine Control System,

Of... 0/2

o2

V1 1B

2n

af... 4/2.

6/1 ...6/11

62

62

6/3

4

of

oft

ofS

6/6

616

66

oT

67

8

8.

6/9... 6/11

W.. 72

8/1

Of... 9/5

10/1... 10/2

TAL... WS

ni

Ml

11/4

00 71 01.2

16,

18,

19,

Menu 2, “Select shift”

2. Select shift

Menu 3. "Reset shift counter”

3 Reset shift counter.

Menu 4. “Change machine data”

4. Change machine data

Menu 4.1 "Adjust machine”

4.1 Adjust machine.

Wind up, cleaning phase

Brake forces

Yar feed unit time, run-out sensor time, fan

Take-down force

Take-down force (electrical take-down, power controlled),

PRABA

1

1

1

1

1

BEORE

Menu 4.2” Take-down, fabric length, gears ”

4.2 Take-down, fabric length, gears (mechanical take-down),

4.2 Adjust take-down (electrical take-down, electrical shaft)

4.2 Adjust take-down (electrical take-down with change pinion)

4.2 Adjust take-down (electrical take-down, pattern controlled)

4.2 Adjust take-down (electr. take-down, pattern contr., change o}

4.2 Adjust take-down (electrical take-down electrical shaft)

4.2 Adjust take-down (electrical take-down, pattern controlled)

Menu 4.3 “Adjust oiler”

3 Adjust oiler.

1 Oil; group ON/OFF

2 Adjust oil quantity

3. Jet monitoring ON/OFF

Jet monitoring-start.

Flush; service

1 Flush; group ON/OFF.

2 Service, fill oil lines.

43

43

43

43

43

43

43

43

43.6 Check oil level

Menu 4.4 "Adjust ai

44 Adjust air,

4.4.1 Air, stationary/continuous

4.4.2 Continuous lint cleansing.

443° Ventilator ON/OFF

Menu 4.5 "Adjust drive”

45 Adjust drive

45.1. Speed, production.

4.5.2. Speed, reduced

45.3. Speed, jogging,

Tntus

1 Display

2 Set dispiay format

3 Allocate Coni

4.6.4 Monitoring

06/02 GB MCT Machine Control System

12/1... 12/2

12/1

3/1... 138

13/1

14/l... 14/3

14

15/1... 15/9

15/1

15/2

15/4

15/5

15/6

15/6

16/1... 16/36

16/1... 16/3

16/4... 16/7

16/8 ... 16/10

16/11... 16/15

16/16 ... 16/20

16/21... 16/24

16/25 ... 16/36

17... WTAG

17/

17/2

17/4

17/9

1/AL

17/3

1I4

17/16

178

18/1... 18/6

18/1

18/1

18/3

18/5

19/1... 19/6

19/1

19/2

19/4

19/5

20/1... 20/27

20/2

20/3

20/4

20/13

20/15

00 71 01.2

21. Menu 4.7 “More”

47 More

4.7.1 Storage feeder; manual

22. Menu 5 "Machine data logs”

5. Machine data logs.

23. Menu 5.1 "Worktime ~ 5.7 Further”

5.1 Worktime

24, Menu 6, "System"

6 System.

28. Menu 6.1” View program version ”

6.1 View program version

26. Menu 6.2” Constants”

62 — Constants.

27. Menu 6.3 ” Miscellaneous, clock ...”

63 Miscellaneous, clock

63.1 Edit date/time

28. Menu 6.4” Change language ”

64 — Change language

64.1 English

642 German

643. French

64.4 Spanish

645 Kalian

64.6 Portuguese

29, Menu 6.5” Edit code”

65 — Edit code

30. Graphic symbols and malfunctions

31. Text messages (errors, info)

32. Battery for machine control system data security

Update index

We reserve the right to make changes and additions!

© 2008 Mayer & Cie. GmbH &Co. , Albstadt, Germany

06/02 GB MCT Machine Control System,

2M... 213

20/1

21/2

22/1... 22/2

22/1

23/1... 23/11

23/1

24/1... 24/2

24/1

25/1

25/1

26/1... 26/7

26/1

271... 2718

27/1

27/2

28/1... 28/3

28/1

29/1... 29/4

2911

30/1... 30/5

31/1... 31/7

32/1... 32/3

U/l

00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 2/1

2. Survey of operator's panel:

Operator’s panel

Overall unit including text display, keypad and function keys,

Text display

This field indicates operating displays, error indications or menu displays

The texts can be accessed in a number of languages

3= Keypad

The keypad is used to enter and select the various operating modes and functions

See page 3/1 for details.

4= Quick keys

The quick keys facilitate direct and speedy access to certain menu items and operating

functions, See page 5/1 for details,

5= Funetion keys

The function keys are push buttons for operating functions which can be switched on and

off manually. A lamp illuminates on the key when a function key is on

See page 4/1 for details.

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 3/1

3. Key assignment:

TKOKS] Numerical keys: These keys are used to select or preselect the various menu

(28X83) y ‘7 ”

AVA items and numerical values

KS XK)

ENTER key: This key is used to confirm and activate a preselected menu

item or to enter a preselected numerical value

e ESC key: The ESC key can be used to interrupt a selected function before

activation

The ESC key returns you to the previous state in case of an error

when entering or selecting items from a menu, and the initiated

change is not executed

In the event of system faults itis possible to eliminate control system

blocking by pressing ESC. The basic menu or operating display

“Ready for production" appears after the key is activated.

M-key: The M-key enables one to switch from the operating display to the

basic menu,

Up / down arrow keys: These two keys enables you to switch from one menu item

to another (if preselected). The cursor can also be moved to another line in the

display using these keys

Co &

Left / right arrow keys: These two keys can be used to answer a system inquiry

(ie. to change from YES to NO (ON to OFF) or from NO to YES (OFF to ON)

The cursor can also be moved to a different line position using these keys.

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 4/1

4. Function keys:

Sn:

ymbol:

Key for warm-up phase “ON/OFF*

When key is “ON* the lamp in the key illuminates.

The warm-up phase is switched on, The machine runs at low speed

When key is “OFF* the lamp in the key is extinguished,

‘The warm-up phase is switched off. The machine runs at production speed.

Droplet symbol:

Key for manual flush “ON/OFF*

When key is “OFF* the lamp in the key is off

When key is “ON* the lamp in the key illuminates.

Disable phase: Key is “OFF* the lamp in the key is off.

No manual flushing routine can be executed

during the disable phase

A manual flushing routine is initiated when the machine is running after pressing

the key. A flush routine is executed every time the key is pressed. The machine is

lubricated with a greater quantity of oil

Further flushing routines are possible if the machine runs for at least 3 revolutions

after switching on,

The manual flush function can only be activated if switched on in the menu item

“4.3.5.1 Flush: group ON/OFF“

Manual flush when machine is running:

— Switch on the key

The machine changes to low speed

— The machine flush routine is actuated

— The machine switches back to production speed

Menu item “4.3.5.2 Service: fill oil lines“ contains a manual flush program initial

commissioning of the Senso oiler (e.g. for filling or checking the oil lines), A

continuous flushing process takes place while the key is activated. The key is only

effective in this menu item when the machine is at a standstill

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 4/2

Cleaning (air jet):

(Only applicable to machines with cleaning device)

Cleaning phase in the stitch forming area with joz mode “ON/OFF*

A manual cleaning process is executed in the stitch forming area when the cleaning

key is switched on. This cleaning process remains off when a start key is pressed

An automatic cleaning phase is executed at the end of a fabric roll, irrespective of the

“ON/OFF status of the cleaning key

The time for this automatic cleaning phase can be adjusted under the menu item

“4.1.1 Wind up, cleaning phase“ between 7 and 999 machine revolutions prior to the

end of the fabric roll

Fan:

Fan “ON/OFF*

‘The fan does not function while the fan key is switched off,

When the fan key is switched on the fan starts up when the machine starts through

actuation of the start or jog key, provided no delay time is entered for the fan start-

up.

The fan ON delay can be adjusted under the menu item “4.1.3 Feed unit,

run-out feeder, fan™ between 0 and 9 seconds,

The fan begins to run following the machine start after the adjusted delay time has

elapsed

Fan operation without starting the machine is possible in accordance with menu item

“4.4.3 Fan ON/OFF”.

Lamp:

Machine or fabric illumination “ON/OFF*

Display:

Key for changing the display brightness (bright/dark),

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 5/1

5. Quick key:

Quick keys are function keyswith which a menu item operating function can be selected directly

and quickly. The quick keys are located under the display.

The symbols become visible in the display after the power supply is switched on and the

operating display "Ready for production” appears

9 Help: Key not occupied

FL

Shift: Press this function key to select the menu displayed.

F2

Oiler: Press this function key to select the menu displayed

3

Press this function key to select the menu displayed

Intus: Press this function key to select the menu displayed.

Wilas| Fs

Computer: Press this function key to select the menu displayed.

F6 (patterning control, striping control)

Computer: Press this function key to select the menu displayed.

F6 (patterning control, striping control).

Speed: Speed

FS (see menu 4.5 "Stop drive”)

Speed: Speed +

& F6 (see menu 4.5 “Stop drive”)

Page: Display forwards / back.

fc FS see menu 4.2 "Stop take-down”

see menu 4.3 "Stop oiler”

Page: Display forwards / back

F6 see menu 4.2 "Stop take-down”

see menu 4.3 "Stop oiler”

05/00 GB MCT Machine Control System 00 71 01.2

M:

ayer & Cie.

Rundstrickmaschinen

15. Menu 4.1

Menu survey:

” Adjust machine”:

Menu item Title/Procedure/Adjustments

41 Adjust machine

4.1.1 Change machine data: Wind up

Cleaning phase

41 Brake forces

413 Yarn feed unit time.

Run-out sensor time

Fan

414 Take-down force

‘Adjust machine <<

Take-down, fabric length, gears

Adjust oiler

Adjust air

Adjust drive

Intus

More

Aaueen—

Menu item 4.1” Adjust machine ” flashes.

ENTER

ESC

Keys 1-7

Import menu item.

Exit menu item.

Select other menu item,

Enter code

Enter code: >> **** <<

Enter code (for details see page 7/1).

05/00 GB

MCT Machine Control System

Page 15/1

Page

1s/l

15/2

15/2

15/4

15/5

15/5

1S/5

15/6

00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

4.1.1 Wind up, cleaning phase:

Page 15/2

\

Wind up:

(Revolutions)

Setting value:

Adjusting range: 0-99 machine revolutions

Change machine data

Wind up — [rev] 10

Cleaning phase:

[rev before end] 080

With air/cleaning YES/NO

With oiler/autoflush : YES/NO

Stop after cleaning: YES/NO

Cc)

J

°

@

Or-©

@Do--©—

Wele}-—«

els)

@

@)

oO

@

machine revolution

‘The machine revolutions necessary for fabric wind-up of a new fabric roll are set here. The

machine runs slowly during the set revolutions

Cleaning phase

Functions

Revolutions before end

*) With air/cleaning

*) With oiler/autoflush

*) Stop after cleaning,

Setting value

machine ré

YES/NO

YES/NO

YES/NO

evolutions

*) This functions are only activated if the revolutions before the end and the setting value YES

are entered,

05/00 GB

MCT Machine Control System

00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 15/3

Revolutions before end

Setting value: machine revolution

Adjusting range: 7-999 machine revolutions

‘The machine revolutions made by the machine prior to the cleaning phase up to cutting the fabric

roll are set

The number of machine revolutions is set which the cleaning range runs in the fabric until

shortly behind the yarn take-down rollers (cutting area).

With air/cleaning: Setting value: YES/NO

YES: The machine runs slowly and is cleaned with air.

Cleaning is shown in the display

NO The machine is not cleaned.

With oiler/autoflush: Setting value: YES/NO

YES The machine runs slowly. Auto flush occurs.

Auto flush is shown in the display

The auto flush function should be switched on in oiler menu 4.3.5

NO No auto flush occurs

Oiler groups can be individually switched off in oiler menu 4.3.5 if an oiler group

auto flush is not desired

Stop after cleaning: Setting value: YES/NO

YES: The machine is stopped after the revolutions before the end are completed

Manual work (e.g. cleaning work) can be carried out.

New start with START or JOG key.

NO The machine is not stopped after the revolutions before the end are completed

(@) Select desired line

(©) Select cursor position in line

(©) Enter numerical value.

\ The flashing numbers can be changed

(@) With air/cteaning, select YES/NO

With oiler/autoflush, select YES/NO

Stop after cleaning, select YES/NO

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 15/4

4.1.2 Brake forces:

1

Change machine data

Brake forces

Normal stop [%] 010

Quick stop [%] 20

J

' on

(45)

Oe)

@

Normal stop. Setting value: % of maximum brake force

Adjusting range: 10% - 100%

DO

Wele

Quick stop Setting value: % of maximum brake force

Adjusting range: 20% - 100%

The brake force is set here for quick stop in case of stop functions for

running in and out sensors, needle break, safety doors, control sinker break

and electrical take-down,

»

ir

v

Select desired line

2)

Select cursor position in line.

r

Enter numerical value.

The flashing numbers can be changed.

WE

(s)

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 15/5

4.1.3 Yarn feed unit time, run-out sensor time, fan:

|

Yarn feed unit time (%)

(running-in time)

Run-out time (°%)

Change machine data

Yarn feed unit time [%] 01

Run-out sensor time [%] 1

Fan (%] 2

I (G qT

@ @®) ©)

y

Q Co

g

2

(4)

Ue)

@

Setting value: (%) of maximum delay

Maximum delay 500 milliseconds

Gels)

The yarn feed unit stop motion is set here.

The yarn feed unit stop motions are switched off during the delay time

(max. 500 milliseconds). It begins when the machine starts in start or

Jog mode

Fan: Setting value: seconds

Adjusting range: 0 — 9 seconds

The fan delay time is set here.

The fan is switched off during the delay time

It begins when the machine starts in start or

jog mode

The fan delay time is only effective with the symbol key

“Fan ON”.

Cay ct si

(@) Select desired line

(©) Select cursor position in line.

(©) — Enter numerical

The flashing nun

05/00 GB

value,

mbers can be changed

MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 15/6

4.1.4 Take-down force:

Program for electrically power-controlled fabric take-down,

This menu item only applies to machines with electrical take-down with variable power-

controlled yarn take-down force

The program is not activated or is invalidated if the machine is equipped with a different type of

take-down.

The yarn take-down must be adjusted to the new conditions after every change of knitting

structure, pattern, fabric quality (stitch length, fabric weight, yarn) or take-down force.

Always check the yarn take-down tension.

Do not reach into running machine.

Damage can be caused to the machine or errors occur in the fabric if the yarn take-down

force is too high or too low.

Change machine data

‘Take-down force

Range | (BI) from 0 force >>1S<< Force | (KI)

Range 2 (B2) from: 2500 force «17 Force 2 (K2)

Range 3 (B3) from: 5000 force 19 Force 3 (K3)

e Ae ©)

ao

a

Q

Coe)

12/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 15/7

The yarn take-down force is adjusted here.

There is a choice of two setting options

Constant take-down force

The take-down force remains the same from the start to the end of the fabric roll

=,

ble take-down force (increasing)

The take-down force increases in stages for fabric rolls which increase in size.

With variable take-down force the total size of the fabric roll can be divided among three

revolution ranges and a definite take-down force can be set for each revolution range.

Examples for increasing take-down force:

Bl: Orevolutions ~start of roll- Force 1:1. setting

B2: 1000 revolutions - 1/3 roll - Force 2: Il. setting

B3: 2000 revolutions - 2/3 roll - Force 3: IIL setting

3000 revolutions — end of roll

Caution:

The entered take-down force values are activated automatically when the machine is running,

Always check the yarn take-down tension manually after every manual or automatic change in

take-down force and when adjusting the fabric quality

Observe the rules governing take-down tension,

Range BI: Setting value: machine revolution 0

Adjusting range: not adjustable

Force (K1): Setting value: numerical value for take-down force

Adjusting range: 1-99 (minimum 1 - maximum 99)

Range B1 always commences at doff size 0 (start of roll).

Range B2: Setting value: machine revolution,

Adjusting range: 0 - 999998 machine revolutions

Always select a greater B2 take-down force than B1 if the take-down force is

increasing

Force (K2): Setting value: numerical value for take-down force

Adjusting range: 1-99 (minimum 1 - maximum 99)

Range B3: Setting value: machine revolution

Adjusting range: 0 - 999998 machine revolutions

Always select a greater B3 take-down force than B2 if the take-down force is

increasing

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 15/8

Force (K3): Setting value: numerical value for take-down force

Adjusting range: 1-99 (minimum 1 - maximum 99)

Adjusting rules governing increasing take-down force:

Adjustment of machine revolutions:

The revolution value of B2 should be always greater than BI

— The revolution value of B3 should be always greater or equal than B2

Adjusting the take-down force (force):

— The take-down force of force (K1) should be set to the take-down force initial setting,

The force value of force (K2) should be equal to or only

(Ki)

htly greater than that of force

— The force value of force (K3) should be equal to or only slightly greater than that of force

(K2)

‘The following should also be observed:

— The revolution values activate the respective set force value

They should be selected to suit the prevailing conditions.

— The force values (K1) - (K3) should only be graduated slightly in relation to each other.

The take-down force of the set force values (K1, K2, K3) should be manually checked and

corrected if necessary when producing the first fabric roll,

Damage can be caused to the machine or the fabric quality can chang

take-down force initial setting are too great

deviations from the

Adjusting rules governing constant:

Adjusting the machine revolutions:

— The revolution value of B1, B2, B3 must be zero.

Adjusting the take-down force (fore

— The force values of force(K1, K2, K3) should only be graduated slightly in relation to each

other.

‘These values should be selected to suit the correct take-down force.

— The set take-down force should in all cases be manually checked and corrected if necessary.

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

A

@) Select desired tine

(©) Select cursor position in line

(©) Enter numerical value

The flashing numbers can be changed.

Press ESC key to switch to main menu.

05/00 GB MCT Machine Control System

Page 15/9

00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/1

16. Menu 4.2” Take-down, fabric length, gears ”:

Program for mechanically-positive take-down.

Menu survey:

Menu item le/Procedure/Adjustments Page

4.2 (Mechanically-positive take-down) _Take-down, fabric length, gears ......16/1

4.2 (Electrically-positive take-down) Adjust take-down 16/4

42 (lectrically-positive take-down) Adjust take-down. 16/8

42 (Electrical pattern-controlled take-down) Adjust take-down. 16/11

42 (Electrical pattern-controlled take-down) Adjust take-down. 16/16

This menu item only applies to machines with mechanically-positive take-down

A computational value for setting the mechanically-positive take-down is determined with this

‘menu item,

The program is not activated or is invalidated if the machine is equipped with a different type of

take-down,

The take-down must be adjusted to the new conditions after every change of knitting

structure, pattern, fabric quality (stitch length, fabric weight, yarn) or take-down force.

Always check the take-down tension,

Do not reach into running machine.

Damage can be caused to the machine or errors occur in the fabric if the take-down force is

too low or too high.

Only applicable to machines with mechanically positive fabric take-down,

>> 1 Adjust machine <<

Take-down, fabric length, gears

Adjust oiler

Adjust air

Adjust drive

Intus

More

aousune

2

a

Adjust machine

Take-down, fabric length, gears <<

Adjust oiler

Adjust air

Adjust drive

Intus

More

aousene

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

Menu item 4,2” Take-down, fabric length, gears ” flashes.

ENTER Import menu item.

ESC Exit menu item.

Keys 1-7 Select other menu item.

1

Take-down setting

Calculate fabric length and gears

Example: Knitted systems 096

Systems [per row] 02

Stitches [per em] 10

® © ©

€

Knitted feeders Setting value: number of active feeders

Adjusting range : 1 ~ 199 feeders

q

©

Gels

Feeders (per row) Setting value: number of feeders for a full row

Adjusting range : | — 12 feeders per full row

Stitches (per em) Setting value number of stitches per em

Adjusting range : 1 — 30 stitches per em

a Select desired line

Select cursor position in line.

ZZ 7

c Enter numerical value.

The flashing numbers can be changed.

09/03 GB MCT-Machine Control System

Page 16/2

00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/3

1

Take-down setting

Result

Example: Fabric length [mm/rev] 52.7

Gears Z2 =40 Z1=54

Scale value = 18

This display only appears when the machine is at a standstill.

The result is a computational value. Gears and scale value must be changed and adjusted

manually

See table on fabric take-down for further details.

Mlustrated example: Fabric length is 52.7 mm per machine revolution

Gears Z2=40teeth Z1 = 54 teeth

Scale value graduation 18

Press ESC key to switch to main menu.

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/4

Menu 4.2” Adjust take-down ”:

Program for electrically-positive take-down.

Menu- survey:

Menu item Title/Procedure/Adjustments Page

42 Adjust take-down 16/4

electrical

This menu item only applies to machines with electrically-positive take-down

shaft

‘The program is not activated or is invalidated if the machine is equipped with a different type of

take-down

‘The take-down must be adjusted to the new conditions after every change of knitting

structure, pattern, fabric quality (stitch length, fabric weight, yarn) or take-down force.

Always cheek the take-down tension.

0 running machine.

be caused to the machine or errors occur in the fabric if the take-down force is

too low or too high,

‘Adjust machine <=

Adjust take-down

Adjust oiler

Adjust air

Adjust drive

Intus

More

sauewne|

2

Y

Adjust machine

Adjust take-down <<

Adjust oiler

Adjust air

Adjust drive

Intus

More

a

aousune

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/5

Menu item 4,2” Adjust take-down ” flashes,

ENTER Import menu item.

ESC Exit menu item.

Keys 1-7 Select other menu item.

‘The take down adjustiment for the electronically controlled fabric take down can be spé

this menue item,

1

Adjust Take-down

Feeders active >> 96 <<

Example: Feeders [1/line] ol

Stitches [I/em] 20

Tension [%] 50

© © © &

y y

OQ CeQ|h

(4K5)6)

VO

©

Feeders active Setting value: number of active feeders

Adjusting range : 1 ~ 199 feeders

Feeders (I/line) Setting value: number of feeders for a full row

Adjusting range : | ~ 12 feeders per full row

Stitches (I/em) Setting value: Number of stitches per em

Adjusting range : 1 — 45 stitches per cm

Tension (%) Setting value _ : Fabric stretching value at the take down

Adjusting range : 1 - 200

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

(2)

)» OCC

@

Example:

Select desired line

Enter numerical value.

The flashing numbers can be changed

Change cursor position in line.

Quick key: display forwards

This key is only for changing the display.

1

1

Adjust Take-down

Stitches [1/em]

Fabric length [mmvRev.]

Tension 2%]

[mm]

20

48

50

(F3) Quick key: display back

5 -: display bac

‘* This key is only for changing the display,

Press ESC key to switch to main menu.

09/03 GB

MCT-Machine Control System

Mayer & Cie.

Rundstrickmaschinen Page 16/7

Setting example for electronic positive fabric take-down:

Plain-knit machine, 72 feeders

Pattern with 36 knitting feeders

Take-down setting

Knitting feeders >> 36<<

Feeders [per row] 06

Stitches [per cm] 06

Stretch factor [%] 10

Knitting feeders:

The number of activated feeders (ie. knitting feeders or feeders with tuck on the needle)

Example

Machine feeder number: 72 feeders, every second feeder is active

= Input: 36 feeders

Feeders per row:

The number of feeders required to produce a complete row.

This value is derived from the pattern draft

Example:

1 complete row with 12 feeders, every second feeder is active

= Input: 6 feeders

Stitches per em:

The number of stitches per cm is entered here.

The number of stitches counted per om that restrict stretching should be entered,

The fabric should not be subject to tension when counting the stitches.

Example:

Cylinder: 12 stitches per em

Dial: 6 stitches per cm

=> Input: 6 stitches/em (rib stitches)

Streteh factor:

The stretch factor depends on the knitting structure, the yarn used and the machine setting and

should be individually set for each pattern,

A stretch factor that is too low or too high can lead to fabric flaws and/or machine damage

=> Input: 10%

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/8

Menue 4.2 "Adjust Take-down”:

Program for electrically-positive take-down with change pinion.

Menu survey:

Menu item Title/Procedure/Adjustments Page

42 Adjust take-down. 16/8

This menu item only applies to machines with electrically-positive yarn take-down with electrical

shaft.

Itis possible to adapt the take down adjustment to the respective conditions by using exchange

wheels

The program is not activated or is invalidated if the machine is equipped with a different type of

take-down,

The yarn take-down must be adjusted to the new conditions after every change of knitting

structure, pattern, fabric quality (stitch length, fabric weight, yarn) or take-down force.

Always check the yarn take-down tension,

Do not reach

0 running machine,

Damage can be caused to the machine or errors occur in the fabric if the yarn take-down

force is too low or too high.

Adjust machine <<

Adjust take-down

Adjust oiler

Adjust air

Adjust drive

Intus

More

aousune

2

a

Adjust machine

Adjust take-down <<

Adjust oiler

Adjust air

Adjust drive

Intus

More

aousene

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/9

Menu item 4.2” Adjust take-down ” flashes,

ENTER Import menu item.

ESC Exit menu item.

Keys 1-7 Select other menu item.

‘The take down adjustiment for the electronically controlled fabric take down can be specified with

this menue item

‘Adjust take-down

Feeders active >> 96 <<

Feeders [1/line] o1

Stitches [1/em] 25

Tension [%] 50

Teeths Motorritzel

Z13...Z19 selected 17

® ©

DO

DO

Q

()

o

©

Feeders active Setting value: number of active feeders

Adjusting range : 1 — 199 feeders

Feeders (1/line) Setting value: number of feeders for a full row

Adjusting range : | — 12 feeders per full row

Stitches (1/em) Setting value: Number of stitches per em

Adjusting range : 1 — 45 stitches per cm

Tension (%) Adjusting value : Fabric stretching value at the take down

Adjusting range : | - 200

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/10

Number of teeth on the motor pinion

One pinion can be chosen out of the 3 delivered pinions (z = 15, 17, 19).

Consider the following adjustment recommendation.

Recommendation of ajdustment:

10 ~25 stitches per cm pinion number of teeth 19

16~35 stitches percm pinion number of teeth 17

30-45 stitches perem pinion number of teeth 15

The corresponding pinion with the number of teeth chosen in the display has to be installed on the

shaft of take down motor

The count of teeth of the installed pinion has to correspond to the count of teeth stated on the

display.

Z

(@) Select desired line

(e) Saar

(©) Change cursor position in line

(©) Enter numerical value

~The flashing numbers can be changed.

(F6) Quick key: display forwards

This key is only for changing the display.

1

Adjust Take-down

Stitches [1/em] 28

Fabric length [mm/Rev.] 45

Tension —_[%] 50

[mm] 22.5

Press ESC key to switch to main menu,

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/11

Menu 4.2 ”Adjust take-down ”:

Program for electrical pattern-controlled take-down.

Menu survey:

Menu item Title/Procedure/Adjustments Page

42 Adjust take-down. 16/11

This menu item only applies to machines with electrical and pattern-controlled take-down with

electrical shaft

The program is not activated or is invalidated if the machine is equipped with a different type of

take-down,

The take-down must be adjusted to the new conditions after every change of knitting

structure, pattern, fabric quality (stitch length, fabric weight, yarn) or take-down force.

Always check the take-down tension.

Do not reach into running machine.

Damage can be caused to the machine or errors occur in the fabric if the take-down force is

too low or too high.

Details of initial setting:

‘The initial setting comprises the following two parameters and is set on the display

(page 16/13).

© The number of knitting feeders on a machine.

This is the number of feeders of a cam carrier on the machine which are active and forming

tuck and/or floating stitches.

Inactive feeders, dropping feeders and transfer feeders are not knitting feeders and are not

included

© The number of stitches per cm at rhythm 1.

This is the number of stitches per cm in the direction of the stitch wales in relaxed fabric.

Only the stitches are important for calculating the take-down factor. Tuck loops and floating

stitches are not included.

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/12

Rhythm:

The take-down rhythm is a factor equivalent to the sum of part rows (feeders) in a complete row

The take-down rhythm is identical for knitting structures with 3-way technique and transfer

structures

‘The take-down control differentiates between four different take-down rhythms (i.e. four different

basic take-down stages for four different structure sequences are involved)

Rhythm 1 A feeder forms a complete row.

Rhythm 2: ‘Two feeders form two part rows, these in turn forming a complete row.

Rhythm 3 Three feeders form three part rows, these in turn forming a complete row

Rhythm 4 Four feeders form four part rows, these in turn forming a complete row.

Take-down Patten No.of | No.of No. of No. of

rhythm rhythm feeders | partrow |comp. rows} magnets

2-way | 3-way | 2-way | 3-way 2-way | 3-way

1 a) 1 @) 1 E 1 1 @

2 Q) 2 (4) 2 2 1 2 @)

3 @) 3 (6) 3 3 1 3 6).

4 (4) 4 (8) 4 4 1 4 8)

The "Knitting feeders and stitches” parameters relate to the initial setting of the take-down at

rhythm 1

Knitting structure ranges with an other rhythm (e.g, 2, 3 or 4) are calculated by the machine

control and the take-down is automatically adjusted to suit the structure range (rhythm) currently

being knitted,

The initial take-down values for all structure ranges (rhythm 1 to 4) are fixed when the initial

setting is adjusted.

A central alteration of all initial take-down values is possible by changing the number of stitches,

per cm entered in accordance with the following criteria.

‘Agjutment of Effect on take-down values

stitches Quantity of fabric Fabric tension

per cm mm/rev. in take-down

No. of stitches plus Tess fabric Higher tension

more stitches

No. of stitches minus More fabric Tower tension

less stitches

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

Page 16/13

‘Adjust machine <<

Adjust take-down

Adjust oiler

Adjust air

Adjust drive

Intus

More

sau

2

i

‘Adjust machine

Adjust take-down <<

Adjust oiler

Adjust air

Adjust drive

Intus

More

>>

Aaunene

Menu item 4.2” Adjust take-down ” flashes.

ENTER Import menu item.

ESC Exit menu item.

Keys 1-7 ‘elect other menu item,

Display of initial setting:

H

Adjust Take-down

Feeders active >> 096 <<

Example: Stitches [1/em] 20.0

Tension [%] 20 20 20 20

[ b }

® © &

toy ro

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/14

=)

e7

»,

}

e

L@—

5B

ae

a

@

ee}

Geo

eee

Feeders active Setting value; number of active feeders

Adjusting range: 1 ~ 199 feeders

Stitches (I/em) Setting value: number of stitches per cm in direction of stitch wales

Adjusting range : 1 ~ 45 Stitehes per em

Tension (%) Adjusting value : Fabric stretching value at the take down

Adjusting range : 1 — 200

@) Select desired line

(©) Change eursor position in line.

©) — Enter numerical value.

The flashing numbers and the numbers occupied by the cursor can be changed.

(F6) Quick key: display forwards

~ This key is only for changing the display.

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/15

!

‘Adjust Take-down

Rhythm: 123 4

Quantity

{mnyUmdr] : 48 24 16 12

Tension [%] 20 20 20 20

[mm] 9.648 3.216

y

Adjust Take-down

Rhythm, activ 1

Quantit

[mm/Umdr] : 48

Tension — [%] : 20

[mm] 9.6

Press ESC key to switch to main menu

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/16

Menu 4.2 "Adjust take-down ”:

Program for electrical pattern-controlled take-down with change pinion.

Menu survey:

Menu item Title/Procedure/Adjustments Page

42 Adjust take-down, 16/16

This menu item only applies to machines with elect

electrical shaft

and pattern-controlled take-down with

Itis possible to adapt the take down adjustment to the respective conditions by using exchange

wheels

The program is not activated or is invalidated if the machine is equipped with a different type of

take-down,

The take-down must be adjusted to the new conditions after every change of knitting

structure, pattern, fabric quality (stitch length, fabric weight, yarn) or take-down force.

Always check the take-down tension,

Do not reach into running machine.

Damage can be caused to the machine or errors occur in the fabric if the take-down force is

too low or too high.

Details of

al setting:

‘The initial setting comprises the following two parameters ant

(page 16/18).

set on the display

© The number of ki

ting feeders on a machine.

This is the number of feeders of a cam carrier on the mac!

tuck and/or floating stitches,

Inactive feeders, dropping feeders and transfer feeders are not knitting feeders and are not

included

fe which are active and forming

© The number of stitches per em at rhythm 1.

This is the number of stitches per cm in the direction of the stitch wales in relaxed fabric.

Only the stitches are important for calculating the take-down factor, Tuck loops and floating

stitches are not included.

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/17

Rhythm:

The take-down rhythm is a factor equivalent to the sum of part rows (feeders) in a complete row

The take-down rhythm is identical for knitting structures with 3-way technique and transfer

structures

‘The take-down control differentiates between four different take-down rhythms (i.e. four different

basic take-down stages for four different structure sequences are involved)

Rhythm 1 A feeder forms a complete row.

Rhythm 2: ‘Two feeders form two part rows, these in turn forming a complete row.

Rhythm 3 Three feeders form three part rows, these in turn forming a complete row

Rhythm 4 Four feeders form four part rows, these in turn forming a complete row.

Take-down Patten No.of | No.of No. of No. of

rhythm rhythm feeders | partrows | compl magnets

2-way | 3-way_| 2-way | 3-wa rows | 2-way | 3-way

1 a) 1 2) 1 E 1 1 @,

2 Q) 2 (4) 2 2 1 2 @)

3 @) 3 (6) 3 3 1 3 6).

4 (4) 4 (8) 4 4 1 4 8)

The "Knitting feeders and stitches” parameters relate to the initial setting of the take-down at

rhythm 1

Knitting structure ranges with an other rhythm (e.g, 2, 3 or 4) are calculated by the machine

control and the take-down is automatically adjusted to suit the structure range (rhythm) currently

being knitted,

The initial take-down values for all structure ranges (rhythm 1 to 4) are fixed when the initial

setting is adjusted.

A central alteration of all initial take-down values is possible by changing the number of stitches,

per cm entered in accordance with the following criteria.

‘Agjutment of Effect on take-down values

stitches Quantity of fabric Fabric tension

per cm mm/rev in take-down

No. of stitches plus weniger Stoit Higher tension

more stitches

No. of stitches minus More fabric Tower tension

less stitches

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

Page 16/18

sau

‘Adjust machine <=

Adjust take-down

Adjust oiler

Adjust air

Adjust drive

Intus

More

2

i

>>

Aaunene

‘Adjust machine

Adjust take-down <<

Adjust oiler

Adjust air

Adjust drive

Intus

More

Menu item 4.2” Adjust take-down ” flashes.

ENTER

ESC

Keys 1-7

Display of initial setting:

Import menu item.

Exit menu item.

elect other menu item.

H

Adjust Take-down

Feeders active >> 096 <<

Example: Stiches [1/em] 20.0

tension [%] 20 20 20 20

Teeths Motorritzel

Z13...Z19 selected 17

66 > @

' ' |

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/19

=)

e7

»,

}

e

L@—

5B

ae

a

@

ee}

Geo

eee

Feeders active Setting value: number of active feeders

Adjsuting range: 1 ~ 199 feeders

Stitches (I/em) Setting value: number of stitches per em in direction of stitch wales

Adjusting range : 1 ~ 45 stitches per em

Tension (%) Adjusting value : Fabric stretching value at the take down

Adjusting range : 1 — 200

Number of teeth on the motor pinion

One pinion can be chosen out of the 3 delivered pinions (Z = 15, 17, 19),

Consider the following adjustment recommendation.

Recommendation of adjustment:

10~25 stitches perom _ pinion number of teeth 19

16~35 stitches percm —_ pinion number of teeth 17

30-45 stitches percm —_ pinion number of teeth 15

‘The corresponding pinion with the number of teeth chosen in the display has to be installed on the

shaft of take down motor.

The count of teeth of the installed pinion has to correspond to the count of teth stated on the

display

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

) Select desired tine

Change cursor position in line.

Enter numerical value.

The flashing numbers and the numbers occupied by the cursor can be changed

) Quick key: display forwards

This key is only for changing the display.

1

Adjust Take-down

Rhythm 1234

Quantity

[mm/Umdr] : 48 24 16 12

Tension —_[%] : 20 20 20 20

[mm] 9.6. 48 3.2 16

y

‘Adjust Take-down

Rhythm, activ 1

Quantity

[mm/Umdr] 48,

Tension [%] 20

[mm] 96

Press ESC key to switch to main menu,

09/03 GB

MCT-Machine Control System

Page 16/20

00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/21

Menu 4.2 Adjust take-down ”:

Program for electrically-positive take-down,

Menu survey:

Menu item Title/Procedure/Adjustments Page

42 Adjust take-down. 16/21

This menu item only applies to machines with electrically-positive take-down with electrical

shaft.

The program is not activated or is invalidated if the machine is equipped with a different type of

take-down,

The take-down must be adjusted to the new conditions after every change of knitting

structure, pattern, fabric quality (stitch length, fabric weight, yarn) or take-down force.

Always check the take-down tension.

Do not react

0 running machine.

Damage can be caused to the machine or errors occur in the fabric if the take-down force is

too low or too high.

‘Adjust machine <=

Adjust take-down

Adjust oiler

Adjust air

Adjust drive

Intus

More

sauewne|

2

Y

Adjust machine

Adjust take-down <

Adjust oiler

Adjust air

Adjust drive

Intus

More

a

aousune

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/22

Menu item 4,2” Adjust take-down ” flashes,

ENTER Import menu item.

ESC Exit menu item.

Keys 1-7 Select other menu item.

A take-down factor (computational value) for setting the electrically-controlled fabric take-down

is determined with this menu item.

1

Take-down setting

Set translation factor

Example: Knitted systems >> 048 <<

Systems [per row] 02

Stitches [per cm] 12.0

© © ©

y

©

B

We@e@--O

Wee)

a

(4)

O

©

Knitted feeders Setting value: number of active feeders

Adjusting range : | — 199 feeders

Feeders (per row) Setting value: number of feeders for a full row

Adjusting range : 1 — 12 feeders per full row

Stitches (per em) Setting value: Number of stitches per em

Adjusting range : 1 ~ 32 stitches per em

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/23

~

(@) Select desired line

a tion i

(©) Change cursor position in line

© Enter numerical value.

~The flashing numbers can be changed

(Fo) Quick key: display forwards

This key is only for changing the display

Take-down setting

Result

Example: Fabric length [mmvrev] =19

Take-down factor, calculated: 58

Take-down factor, setting : >> 0060 <<

a ©

Oe

@) Change cursor position in line.

(©) Enter numerical value.

~ The flashing numbers can be changed.

(Rs) 7 y

(F5) Quick key: display back

This key is only for changing the display.

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/24

Take-down factor: Setting value _ fabric take-down force

Adjusting range : 1-251

weakest take-down force

251 = strongest take-down force

‘The set take-down factor can deviate above or below the calculated take-down factor. Check

fabric tension.

Press ESC key to switch to main menu,

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/25

Menu 4.2 ”Adjust take-down”:

Program for electrical pattern-controlled take-down.

Menu survey:

Menu item Title/Procedure/Adjustments Page

42 Adjust take-down. 16/25

This menu item only applies to machines with electrical and pattern-controlled take-down with

electrical shaft

A take-down factor (computational value) for setting the electrically-controlled take-down is

determined with this menu item. This is converted by the control for other structure sequences and

the take-down is automatically adjusted to suit the conditions of the current structure sequence

being knitted

The program is not activated or is invalidated if the machine is equipped with a different type of

take-down,

The take-down must be adjusted to the new conditions after every change of knitting

structure, pattern, fabric quality (stitch length, fabric weight, yarn) or take-down force.

Always check the take-down tension.

Do not reach into running machine.

Damage can be caused to the machine or errors occur in the fabric if the take-down force is

too low or too high.

setting:

‘The initial setting comprises the following two parameters and is set

(page 16/27).

the display

© The number of knitting feeders on a machine.

This is the number of feeders of a cam carrier on the machine which are active and forming,

tuck and/or floating stitches,

Inactive feeders, dropping feeders and transfer feeders are not knitting feeders and are not

included

* The number of stitches per em at rhythm 1,

This is the number of stitches per cm in the direction of the stitch wales in relaxed fabric. Only

the stitches are important for calculating the take-down factor, Tuck loops and floating stitches

are not included

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/26

Rhythm:

The take-down rhythm is a factor equivalent to the sum of part rows (feeders) in a complete row

The take-down rhythm is identical for knitting structures with 3-way technique and transfer

structures

‘The take-down control differentiates between four different take-down rhythms (i.e. four different

basic take-down stages for four different structure sequences are involved)

Rhythm 1 A feeder forms a complete row.

Rhythm 2: ‘Two feeders form two part rows, these in turn forming a complete row.

Rhythm 3 Three feeders form three part rows, these in turn forming a complete row

Rhythm 4 Four feeders form four part rows, these in turn forming a complete row.

Take-down | Pattermrhythm | No.of | No.of No. of No. of

rhythm 2-way 3-way | feeders | partrows | compl magnets

2-way_3-way Rows _|_2-way 3-way

1 a) 1 @, 1 E 1 i 2)

2 1 @® 2 | @ 2 2 1 2 | @

3 @) 3 (6) 3 3 1 3 6).

4 (4) 4 (8) 4 4 1 4 8)

The "Knitting feeders and stitches” parameters relate to the initial setting of the take-down at

rhythm 1

Knitting structure ranges with an other rhythm (e.g, 2, 3 or 4) are calculated by the machine

control and the take-down is automatically adjusted to suit the structure range (rhythm) currently

being knitted,

The initial take-down values for all structure ranges (rhythm 1 to 4) are fixed when the initial

setting is adjusted.

A central alteration of all initial take-down values is possible by changing the number of stitches,

per cm entered in accordance with the following criteria.

‘Agjutment of Effect on take-down values

stitches Quantity of fabric Fabric tension

per cm mm/rev in take-down

No. of stitches plus Tess fabric Higher tension

more stitches

No. of stitches minus) More fabric Lower tension

less stitches

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

‘Adjust machine <=

Adjust take-down

Adjust oiler

Adjust air

Adjust drive

Intus

More

Bauer

2

>

Adjust machine

Adjust take-down <<

Adjust oiler

Adjust air

Adjust drive

Intus

More

Aounene

Menu item 4.2 Adjust take~

down ” flashes.

ENTER Import menu item.

ESC Exit menu item.

Keys 1-7 Select other menu item.

Display of initial setting:

1

Adjust take-down factor

Example: Knitted systems >> 048 <<

Stitches [per em] 12.0

5 6UCUS

a DY © 1

y y

CG) OO CeO hi

Q ASG)

vee

©

09/03 GB MCT-Machine Control System

Page 16/27

00 71 01.2

Knitted feeders

Stitches (per em)

Mayer & Cie.

Rundstrickmaschinen Page 16/28

Setting value

Adjusting range :1

number of active feeders

199 feeders

Setting value: number of stitches per em in direction of stitch wales

Adjusting range : 1.0 - 32.0

hes per om

(a) Select desired tine

CO)

(©) Enter numerical value

The flashing numbers and the numbers occupied by the cursor can be changed

(F6) Quick key: display forwards

This key is only for changing the display.

“Adjust take-down factor

Rhythm 1 2 3 4

oe [mm/rev] 399 199 133 99

ence: Take-down factor

Max. 418

Calculated 113 56

Setting Delis<< 55

{ 1 t

’

2

(4)

Oo)

©

We’)

factor.

The take-down factor can be individually set to each structure range (rhythm | to 4) independent

of another structure range. The set take-down factor can deviate from the calculated take-down

09/03 GB

MCT-Machine Control System

00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/29

Take-down factor: Setting value _: take-down force

Adjusting range : 1-418

lowest take-down force

418 = highest take-down force

(@) Change cursor position in fine

GY

(®) Enter numerical value.

The flashing numbers and the numbers occupied by the cursor can be changed.

(ce)

\©) Change rhythm/column

PA

(FS) Quick key: display back

This key is only for changing the display.

Fo) Quick key: display forwards

This key is only for changing the display.

The set/calculated take-down factor can deviate above or below the calculated/set take-down

factor.

Cheek fabric tension and adjust if necessary,

particularly during adjustments and/or changes to the machine and/or the fabric take-down

Such a test should also be carried out if the strength or type of yarn is changed, The current take-

down settings can be seen in the following display after ENTER.

The fabric tension can also be manually checked,

Control display:

Adjust take-down factor

Example: Rhythm active 1

‘Take-down factor: 115

This display is intended for viewing and checking the current rhythm function and the respective

allocated take-down setting. The display can be selected while the machine is at a standstill or

running.

The current active rhythm I and the respective set take-down factor 115 are displayed in this

example

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/30

Control display:

‘Adjust take-down factor

Rhythm active 2

Example:

Take-down factor: 55

The rhythm and respective set take-down factor displays also change in the machine function tact.

Example displayed : Rhythm 2

Take-down factor 55

Press ESC key to switch to main menu.

09/03 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/31

Menu 4.2 “Take-down adjustment:

Program for electrical pattern-controlled fabric take-down:

This menu item only applies to machines with a pattern-controlled fabric take-down.

Take-down adjustment depends on the respective pattern

‘The take-down volume varies according to the number of machine courses per machine revolution

(mm/tpm,).

Each pattern range can be allocated a separate take-down value (mmv/rpm.)

with the pattern control

The fabric take-down volume must be reset to suit new conditions after every alteration of

the structure, pattern and fabric quality (stitch length, fabric weight, ete.).

Always check the fabric take-down tension.

Never reach into the machine while it is running!

take-down tension is too lax

Machine damage or faults in the fabric can occur if the fal

or too severe.

The basic take-down volume value is determined when setting up the pattern and cannot be

changed in the machine control

A correction value of 50% can be entered in the machine control if fabric take-down is

inadequate or in the event of malfunctions occurring

This correction value has the same percentual influence on all pattern ranges.

‘The correction value is reset to “O" when the pattern is changed.

Example:

Pattern with four pattern ranges

Correction factor: —10%

Pattern range 1 | Pattern range 2 [ Patter range 3_[ Pattern range 4

Take-down value 40 35 55 20

(mm/rpm.)

Correction factor(%) =10 =10 =10 =10

Numerical value 4 3.5 5.5 2

Actual 36 315 49.5 18,

take-down value

05/05 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/32

>> 1 Machine setting <<

2 Adjust take-down

3 Adjust oiler

4 Adjust air

5 Adjust drive

6 Intus

7 Others

a

y

Machine setting

Adjust take-down <<

Adjust oiler

Adjust air

Adjust drive

Intus

Others

Aoausene

Menu item 4.2 "Take-down adjustment” flashes.

ENTER Import menu item,

ESC Quit menu item

Keys 1-7 Select another menu item.

‘The take-down setting for the pattern-controlled fabric take-down can be determined with this

‘menu item,

1

Take-down volume

Fabric volume

[mm/rpm.]: 43.0

Correction PLUS MINUS 0%

05/05 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/33

Le —

5

W@S--O

WEL

CoeQ)

‘The take-down volume can be increased or reduced by changing this correction value,

PLUS The take-down volume is increased percentually.

MINUS, The take-down volume is reduced percentually

Adjustment range +50%

(@) Select correction value

(©) Select PLUS or MINUS

(©) Enter numerical value

The flashing numbers can be edited

(Fo) Quick key: display forwards

This key is only for changing the display

The setting is imported with ENTER.

The display is quit with ESC

The take-down setting can be viewed with the following displays.

05/05 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

1

Take-down drive adjustment

Gear pair setting:

Current Act. :i3 (80:20)

Calculated Nom.:i3 (80:20)

NOTE:

Nom, = Act. for optimum operation

© ©)

(F5) Quick key FS changes the display backwards

(F6) Quick key F6 changes the display forwards

|

Take-down volume

Fabric volume

[mm/rpm,] 43.0

Correction PLUS MINUS 0%

Eff [mm/rpm.]: 43.0

Take-down factor: 339

05/05 GB MCT-Machine Control System

Page 16/34

00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/35

Quick key FS changes the display backwards

Quick key F6 changes the display forwards

1

‘Adjustment

Gear pair setting:

Current Act. :i3 (80:20)

Calculated Nom.:i3 (80:20)

®

@

3)

The display can be quit with ESC.

05/05 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/36

Error messages:

Error data: Take-down

(200)

Init; take-down

Data error, should machine still be

readied for operation? >>NO/YES<<

1 CAUTION

Check all input data

@ oO Select NO/YES

NO: The machine is not ready for operation

YES: The machine is ready for operation.

Only enter when all input data has been previously checked.

Acknowledge entry with ENTER,

05/05 GB MCT-Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/1

Menu 4.2 ”Adjust take-down”:

Program for electrically-positive yarn take-down with change pinion.

Menu survey:

Menu item Title/Procedure/Adjustments Page

42 Adjust take-down 16/4

This menu item only applies to machines with electrically-positive yarn take-down with

electrical shaft

The program is not activated or is invalidated if the machine is equipped with a different type of

take-down,

The yarn take-down must be adjusted to the new conditions after every change of knitting

structure, pattern, fabric quality (stitch length, fabric weight, yarn) or take-down force.

Always check the yarn take-down tension.

Do not reach into running machine.

Damage can be caused to the machine or errors occur in the fabric if the yarn take-dow'

force is too low or too high,

‘Adjust machine <=

Adjust take-down

Adjust oiler

Adjust air

Adjust drive

Intus

More

sauewne|

2

Y

Adjust machine

Adjust take-down <

Adjust oiler

Adjust air

Adjust drive

Intus

More

a

aousune

12/00 DE MCT-Maschinensteuerung 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

Menu item 4,2” Adjust take-down ” flashes,

ENTER

ESC

Keys 1-7

Import menu item.

Exit menu item

Select other menu item.

Page 16/2

‘The take down adjustiment for the electronically controlled fabric take down can be specified

with this menue item.

Example:

Feeders active

Feeders (I/line)

Stitches (I/em)

12/00 DE

1

Take-down setting

Feeders active >> 114 <<

Feeders [1/line] o1

itches [1/em] 25

Tension [%] 50

Teeths Motorritzel

ZA3...Z17 selected 15

== )—

©

©

(8X9) |

DO

a

©

(6)

23)

Cee

@)

Setting value: number of active feeders

Adjusting range : | ~ 199 feeders

Setting value

Adjusting range : 1 ~ 12 feeders per full row

Setting value; Number of stitches per em

Adjusting range : 1 — 45 stitches per em

MCT-Maschinensteuerung

number of feeders for a full row

00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 16/3

Tension (%) Adjusting value Fabric stretching value at the take down

Adjustement area: 1-200

Number of teeth on the motor pinion

One pinion can be chosen out of the 3 delivered pinions.

Consider the following adjustment recommenation

Recommendation of ajdustment:

10~25 stitches percm pinion number of teeth 17

16-35 stitches per cm —_ pinion number of teeth 15,

30-45 stitches per em —_pinion number of teeth 13

The corresponding pinion with the number of teeth chosen in the display has to be installed on

the shaft of take down motor

(@) Select desired line

(b) ange cursor position in line.

Enter numerical value,

The flashing numbers can be changed.

(F6) Quick key: display forwards

This key is only for changing the display.

1

1

Take-down setting

Stitches [1/em] 28

Fabric length [mm/Rev.] 45

Tension —_[%] 50

[mm] 22.5

Press ESC key to switch to main menu,

12/00 DE MCT-Maschinensteuerung 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 17/1

17. Menu 4.3 "Adjust oiler”:

The oiling functions should be adjusted to suit the respective machine operating conditions

The needle types must concur with manufacturer's recommendations,

Incorrect oiling adjustments, unsuitable oil types or dirt in the oiling system can cause damage

and/or malfunctions.

Ciling functions and oil system should be checked regularly and service and cleaning work

carried out if necessary

‘The machine oil type can be determined in menu item 6. Systemv/2. Constants

Menu survey:

Menu item Title/Procedure/Adjustments Page

43 Adjust oiler Wi

431 Oil; group ON/OFF 1772

432 Adjust oil quantity. 17/4

433 Jet monitoring ON/OFF. 17/9

434 Jet monitoring-start 1

435 Flush; service 17/3,

4351 Flush; group ON/OFF ia

4352 Service: fill oil lines 17/16

436 Cheek oil level 17/18

There are two options for sele:

© Quick key F3

© Keys: —4—ENTER ~3-ENTER

1g menu item 4.3 "Adjust oiler”.

Doff counter <<

Select shift

Reset shift counter

Change machine data

Machine data logs

System

Aounene

1

ae

©

Menu 2 can be quickly and directly selected with quick key F3.

A code must be entered for details of and changes to oiler settings.

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

!

Page 17/2

Enter code

Enter code: >> ** #* <<

Enter code (for details see page 7/1).

Senso P { Uniwave

>> 1 Oil, group ON/OFF <<

Adjust oil quantity

Jet monitoring ON/OFF

Jet monitoring-start

Flush, service

Check oil level

4

Menu item 4.3.1 “Oil, group ON/OFF”

flashes.

ENTER Import menu item.

ESC Exit menu item

Keys 1-7 Select other menu item.

Menu item 4.3.1 does not apply to Uniwave oiler.

'

'

05/00 GB MCT Machine Control System

Continued on page 17/13

00 71 01.2

Mayer & Cie.

Rundstrickmaschinen Page 17/3

\

Oil, group ON/OFF

Group 1: >> ON <<

Group 2; ON

Group 3: ON

Group 4: ON

I (hy

ae

(e

s

z

Do

Oiler: Setting value: Oil; group ON/OFF

AUS = Oil group and/or oiling is switched off

ON = Oil group and/or oiling is switched on

Group 1 =jets 1-3

Group 2 =jets 4-6

Group 3 =jets 7-9

Group 4 =jet 10-11

Number of groups and number of jets depends on machine design

~~

@

Cb)

()

Select desired line

Enter ON or OFF.

The flashing group can be changed or imported with ENTER.

05/00 GB MCT Machine Control System 00 71 01.2

Mayer & Cie.

Rundstrickmaschinen

\

>

1

7

4

5

6

a

Oil; group ON/OFF =<

Adjust oil quantity

Jet monitoring ON/OFF

ig-start

Jet monitor

Flush; service

Check oil level

2

i

Oil, group ON/OFF

Adjust oil quantity <<

Jet monitoring ON/OFF

Jet monitoring-start

Flush; service

Check oil level

'

Menu item 4.3.2 “Adjust oil quantity” flashes.

Import menu item.

Exit menu item.

ENTER

ESC

Keys 1-7 Select

other menu item,

Menu item 4.3.2 does not apply to Uniwave oiler.

05/00 GB

MCT Machine Control System

Page 17/4

00 71 01.2

Example:

Mayer & Cie.

Rundstrickmaschinen

\

Page 17/5

‘Adjust oil quantity

Nominal speed [RPM]: 035

Oil quantity (mV/hrijet)

Group 1:30

Group 2: 20

Group 3: 20

Group 4: 10

b) () (3) 6)

| !

y

Ee)

(5)

Oe)

@

Nominal speed (RPM):

@

@)

y

a

©

Colo)

Nominal speed of machine in revolutions per minute.

(Maximum permitted operating speed)

‘The nominal speed may not and/or can not be changed.

Th oil quantity per jet (0.19 mm @) at an operating pressure of 2.0 bar and an injection time of