Professional Documents

Culture Documents

Application Note On Glitches

Application Note On Glitches

Uploaded by

Sanjay NandalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application Note On Glitches

Application Note On Glitches

Uploaded by

Sanjay NandalCopyright:

Available Formats

Application note on Glitches:

"GLITCH"

Definition, Sources, and

Methods of Correcting

The term "GLITCH" is Bently Nevada Corporation's nomenclature

for describing all forms of vibration measurement error from an

observed shaft surface. This does not include other possible

noise and signal error sources, such as electrical line noise,

monitor problems, or problems associated with casing mounted

transducers. Casing mounted transducers, such as velocity coils

or accelerometers are also subject to signal error sources in the

form of cross axis vibrations, improper mountings, line noise as

well as several others particular to each type of transducer;

however, glitch deals with observed shaft surface anomalies

only. In order to clarify the sources of these vibration

measurement errors, sometimes referred to as runout, the

following discussion shall focus on the two categories of

"GLITCH", mechanical and electrical.

Sources of Glitch Mechanically Induced Runout:

Nonconcentric Surfaces/Bows

A shaft surface which has been improperly machined (egg shaped

or nonconcentric) will yield a sinusoidal displacement signal with a

frequency coincident with the rotational speed of the rotating

element. A second condition on a rotating element which will yield

the same apparent dynamic motion condition is manifest when the

rotating element has been physically bent or bowed.

Sources of improperly machined surfaces can usually be traced to

a worn or defective set of bearings on the machine used for final

machining or grinding or a worn-out set of lathe centers on a lathe.

Bows in a rotating element are typically introduced due to

improper handling of the rotor during its manufacturing cycle. This

may be the result of a sudden or jarring load applied or due to

long-term storage of the element with improper supports for the

rotor. In the case of the latter, an improperly supported rotor may

introduce a permanent sag or bow due to gravity forces.

Bows introduced into a rotor from asymmetrical heating or

improper cooling are generally referred to as thermal bows, and

can usually be removed by placing the rotor on turning gear, and

or slowly starting and heat soaking the machine at low speeds.

Surface Irregularities or The presence of surface imperfections or irregularities will yield a

Imperfections runout condition as observed by the proximity transducer. The

surface imperfections discussed herein are in the form of

scratches, dents, burrs, etc.

In general, surface irregularities are created due to improper

handling of the rotor during the manufacturing cycle. Care should

be taken to protect the shaft surface to be used for dynamic

motion measurements. In essence, these surface areas should be

given the same protective measures used to protect a bearing

journal surface. Crane lifts should be made with cables attached to

shaft areas away from the probe measurement surfaces. Support

fixtures for storage of rotors should not introduce surface

scratches, dents, etc.

Occasionally, surface irregularities are introduced via a machine

cutting tool. If the tool is dull or the feed is too rapid, some tool

chatter may occur which can introduce small ripples in the shaft

surface.

Electrically Induced In general, proximity transducers will operate satisfactorily in the

Runout: presence of magnetic field, as long as the field is uniform or

symmetrical and not localized to a particular location on the rotor.

If a particular area or zone of the shaft surface is highly magnetic

Residual Magnetism and the remaining surface is nonmagnetic or at a much lower

value, an electrical runout condition will be manifest. This is due to

the resultant change in sensitivity on the shaft surface to the

applied field from the proximity transducers.

Residual magnetism runout problems are seldom encountered.

However, various physical inspection techniques employed during

the manufacturing cycle, such as the use of magnetic chucks, can

introduce residual magnetism problems. The most common

inspection technique, where residual magnetism may be a

byproduct, is a Magnetic Particle inspection (Magnaflux®) to

check for cracks on castings, or weldments, or after other

manufacturing cycles. The magnetic field introduced to the rotor

for this inspection should be neutralized after the inspection

program is completed. This is done with the Magnaflux machine

and involves continuously reversing the polarity and passing a

current through the rotor at continuously decreasing amperes. If

done properly, this procedure should neutralize the magnetic

properties of the rotor. In some cases a proper polarity reversal is

not performed, and residual magnetism is produced.

Precipitation Hardening 17-4 pH steel nearly always presents an electrical runout problem.

Some form of material replacement (shrink a collar, overspray a

material) is normally required to eliminate glitch.

Other pH steels, such as 15-5 pH, seems less prone to glitch, but

any pH steel may cause difficulties.

Metallurgical Segregation The scale factor yielded from a proximity transducer is dependent

upon several variables. One variable involves the specific metal or

metallurgy it is to observe. Typically, steel alloys for shaft materials

contain a variety of alloying agents. In general, the final

metallurgical composition of these alloys is a homogenous

mixture. On some rotating elements microscopic segregation of

the steel alloys may occur. Since the proximity transducer

responds with different voltage outputs depending upon specific

metals, the lack of a homogenous metallurgical composition

around the circumference of a shaft may give rise to varying

electrical outputs.

Residual Stress During the normal manufacturing cycle of rotors, a variety of

Concentrations machining and surface treatment processes can introduce small

amounts of localized stress concentrations. Although these stress

areas do not adversely affect the mechanical properties of the

rotor, they may give rise to an electrical runout from the proximity

transducers. Since one of the variables affecting voltage output

from the transducer is the resistivity of the observed shaft surface,

any deviation of the resistance around the circumference of the

shaft (due to varying stress levels) will produce a voltage change.

Measurement of Glitch The observation of mechanical runout at a rotor speed below

which dynamic vibration is eliminated (typically less than 10% of

the rotor operating speed) on an oscilloscope will yield a

sinusoidal dynamic waveform for non-concentric surfaces or shaft

bows. Surface irregularities or imperfections will appear on an

oscilloscope as sharp voltage spikes superimposed on the

dynamic wave form.

Nonconcentric surfaces or shaft bows may also be measured by a

dial indicator mounted in the probe area of the shaft which in turn

is mounted at the bearing journals, in vee blocks, or roller

bearings. The circumference of the probe area is marked off in 36

positions (10 degree intervals) with zero in line axially with the

thrust collar keyway. Dial gauge readings are recorded at each

indicated position. Two sets of readings are taken, approximately

half an inch apart axially, one on each side of the probe position

centerline. The two sets of readings are averaged to give a record

of mechanical runout. American Petroleum Institute (API)

Standard 670 recommends that "the combined total electrical and

mechanical runout does not exceed 25 percent of the maximum

allowed peak to peak vibration amplitude or 0.25 mil (6

micrometers), whichever is greater." The shaft surface finish

should be from 16 to 32 micro inches (0.4 to 0.8 micrometers) root

mean square, also per API 670.

The observation of a residual magnetism runout condition on an

oscilloscope can yield a sinusoidal motion indication. However, the

sine wave will be distorted and to some extent tending toward a

square wave. A final check for residual magnetism embraces the

use of a small handheld field strength indicator manufactured by

Magnaflux Corp. Holding this meter at the shaft surface and hand

turning the rotor will confirm the presence or absence of magnetic

fields of less than 2 gauss with variations less than 1 gauss.

An oscilloscope observation of metallurgical segregation will

typically indicate a somewhat sinusoidal waveform with high

voltage, high frequency spikes superimposed on the waveform.

Observation of residual stress concentrations on an oscilloscope

will yield a sinusoidal waveform with high voltage, high frequency

spikes superimposed on the waveform.

It should be noted that the oscilloscope waveform in all the above

cases may also be very irregular, depending on the amount of

other shaft surface anomalies.

If desired, the electrical runout can be determined by subtraction

of mechanical runout from the total runout.

Glitch Reduction Various methods of reducing glitch are available and have been

successfully used by firms. It is not possible to define which

method is best because each can achieve the desired result.

However, it is possible to narrow the choice of methods when they

are considered on a cost and time basis.

It is also notable that proper material selection, heat treating, and

allow control can have a large effect on the runout condition of a

rotor. If rotors are to be replaced or rebuilt, it is far more cost-

effective to detect and correct glitch at the earliest stages of

machine assembly.

(a) Degaussing- Residual magnetism in a shaft, caused as

a result of magnetic particle crack detection or by working in

a magnetic field, can produce very serious electrical runout.

It is therefore prudent to measure residual magnetism in the

probe area of every shaft before attempting glitch removal.

A localized residual magnetism of field strength 5 gauss on

a rolling shaft can give an electrical runout in the order of

0.5 mil. Thus any shaft which exhibits residual magnetism

in excess of 2.0 gauss, or variations greater than 1 gauss,

should be degaussed. This is generally not a complete

glitch removal process on its own, but it does help to ensure

that glitch readings do not change as a result of a shaft

losing residual magnetism in service.

(b) Diamond Burnishing - This API recommended method

has a high success rate of reducing glitch to within

acceptable limits. The probe area is rolled under a diamond

burnishing tool to work a shaft surface to a uniform finish. In

effect, this procedure produces an even work-hardened

surface which requires no additional treatment. This method

is undoubtedly the easiest with very little skill required.

(c) Further Machining - Should a probe area be outside

acceptable limits, the target area can be reground, and

should be degaussed following grinding. This can be a hit

and miss method that could lead to even more

unacceptable results.

(d) Polishing or Stoning - Similar process to (c) but not

quite so drastic. However, the problem of making matters

worse still exists.

(e) Sleeving - Shrinking a sleeve onto the shaft has been

used, but it is rather an expensive way of producing results

as unpredictable as (c) and (d) above. As with both of those

methods, further treatment may well be necessary.

(f) Plasma Spray Finishing - Although not recommended

by API, metal coating has been used effectively as a

solution for stubborn runout problems. Aluminum - Nickel

flame spray coatings are currently being used very

successfully in industry to reduce glitch problems, often to

less than 1/2 mil pp.

The Metco® process consists of machining a 1-1/2 inch

wide, 0.060 deep grove around the shaft. The groove is

then grit blasted, and coated with a bond coat of Metco 447

to about 0.010 inch thick. The remainder of the grove is

then flame sprayed filled with Metco 52C aluminum silicon

composite and machined flat with the surface of the shaft.

Since the electrical properties are different than 4140 steel,

a specially calibrated Proximitor® must be used at these

locations.

Protection of Probe Areas The removal of glitch by one or a combination of the treatments

discussed above is essential for customer acceptance of levels of

recorded vibration. Having treated the probe areas, it is

essential to protect these areas to prevent corrosion damage,

scratching and indiscriminate "cleaning up". During production

and testing, this protection is afforded by the care taken by skilled

craftsmen who appreciate the sensitive nature of this surface.

Between acceptance testing and startup much less care can be

exercised. There have been many field reports of probe areas

being damaged by rust, scratches or dents. Cleaning up the

damage by stoning or polishing may give the desired appearance,

but the original glitch recordings will have been completely altered

and undoubtedly taken beyond acceptable limits. Glitch removal

then has to be carried out in the field by selective micropeening,

and considering the adverse conditions, the results are invariably

inferior to those which can be achieved in the shop. It is therefore

recommended that after glitch treatment and recordings are

taken in the shop, the probe areas be given a coating of non-

metallic epoxy resin which can remain in position for the life

of the machine. This coating will not affect probe readings but will

protect the probe area from corrosion and all minor mechanical

damage.

Compensation Obviously, shaft treatment to remove the source of runout is the

most desirable procedure. If this is done, there is no reason to

have to "account for'' runout in subsequent vibration signals.

However, the occasional shaft material or forging may not respond

well to the standard shaft treatment methods. The shaft may have

a "permanent" bow, or it may be impossible or impractical to treat

the shaft surface before a time when vibration data is required on

a given machine. If it is impractical to treat the shaft surface or

remove the shaft bow, an electronic method may be used. The

following is an explanation and discussion of this application.

Vector Nulling - Digital Also called slow roll compensation, this system is an integral part

Vector Filter of the Digital Vector Filter. It provides a means for nulling a slow

roll vector. It should be noted that the nulling operation is a true

vector subtraction (phase and amplitude) and not merely a voltage

suppression circuit. The nulling circuit operates on the filtered

vibration waveform (the vector information in the DVF). Since the

filter employed in the DVF-3 is tuned to the rotational (1X rpm)

frequency of the rotor, the nulling circuit eliminates that portion of

shaft runout which is coincident with the rotational frequency.

Typically, it is used to eliminate a 1X component of runout such as

a bow in the shaft or a nonconcentric (egg-shaped) shaft condition

at the probe measurement plane. All higher orders of runout (non

1X components, such as scratches, metallurgical irregularities,

etc.) are eliminated through the filter action of the DVF-3.

Once the initial slow-roll vector has been nulled, it is automatically

subtracted from all future dynamic signals. This system provides

the means for properly examining the mechanical response

and impedance of a system, definition of the balance

resonances (critical speeds), and amplification factors, over

the operating speed range. Vector nulling also allows for the

compensation of the residual unbalance vector after a balance

resonance, and for observation of a higher balance resonance

response.

It is possible, and even probable on larger machinery, that nominal

axial position changes and differential expansion up to running

speed will cause a vibration probe to observe a "new'' lateral

location on the shaft. When considering the overall runout pattern,

this "new'' shaft location may be significantly different than the

overall pattern observed with the machine at slow-roll.

Vector nulling does not, however, deal with the overall runout

pattern; because of the filter in the system, only the 1X runout

vector is considered. The once-per-turn runout vector is not likely

to change from slow-roll to operating speed and temperature. In

this regard, vector nulling offers a distinct advantage over any

other type of digital runout compensation. Vector nulling also

offers the capability of nulling the residual vector of shaft motion

after passing through a resonant speed region to observe the

action of the next higher resonance when Bode plots (amplitude

vs. rpm and phase vs. rpm) are made.

Recommendations The above considerations lead to the following conclusions and

recommendations by Bently Nevada:

1. Glitch often can be controlled at its source (the shaft) to a

level acceptable for monitoring purposes and in most cases

to levels usable for machine acceptance testing and

diagnostic purposes. Every reasonable attempt should be

made to correct the runout problem at its source.

2. The use of electronic runout compensation for

continuous machine monitoring should be avoided except

in rare cases (e.g. a damaged shaft that cannot be

corrected until the next turnaround). Bently Nevada does

not recommend the use of electronic runout

compensation in a vibration monitor system wired for

automatic machine shutdown.

3. Nulling - compensation for an initial 1X vector - can be

accomplished with the Digital Vector Filter 3.

4. When reproducing vibration data from magnetic tape,

special care should be taken to ensure proper

synchronization of the signal. Most tape recorders provide a

function whereby one channel can be dedicated as a

synchronizing signal for tape flutter compensation.

5. When runout compensation is used, it should be used as

a "last resort''. In all cases, both the original transducer

signal and the compensated signal must be available for

observation on external instruments.

References "New Techniques in overcoming Electrical Runout" by Dale W.

Beebe, Turbodyne Corporation, Hydrocarbon Processing, August

1976.

Electrical Runout and Eddy Current Displacement Proximity

Transducers, by Biggs, David H., ASME Paper, September 1975.

(Bently Nevada Literature No. L0360)

Elliot-Wiedeke paper

API 670, Second edition, Section 4.1.2: Machine Shaft

Requirements for Electrical and Mechanical Runout

You might also like

- Generator Stator End Winding Vibration Problems PDF FreeDocument5 pagesGenerator Stator End Winding Vibration Problems PDF Freeandikaubh100% (1)

- Fault DiagnosisDocument29 pagesFault DiagnosisAnish PaiNo ratings yet

- Dynamic Stresses Hydro Power Plant RKAggarwalDocument22 pagesDynamic Stresses Hydro Power Plant RKAggarwalDheeraj DhimanNo ratings yet

- Piezoelectric Actuators: Vector Control Method: Basic, Modeling and Mechatronic Design of Ultrasonic DevicesFrom EverandPiezoelectric Actuators: Vector Control Method: Basic, Modeling and Mechatronic Design of Ultrasonic DevicesNo ratings yet

- I/A Series Hardware Channel Isolated, Discrete I/O Interface Module (FBM241/FBM241b/FBM241c/FBM241d)Document8 pagesI/A Series Hardware Channel Isolated, Discrete I/O Interface Module (FBM241/FBM241b/FBM241c/FBM241d)Thomas BORNEY100% (1)

- Predicting, Measuring and Correcting For Electrical Run-Out Using A Burnishing and Degaussing ProcessDocument4 pagesPredicting, Measuring and Correcting For Electrical Run-Out Using A Burnishing and Degaussing ProcessMeetNo ratings yet

- Assessment 01Document5 pagesAssessment 01Vishwanathan RishanthNo ratings yet

- Rotor Shorted Turns - Detection and DiagnosticsDocument10 pagesRotor Shorted Turns - Detection and Diagnosticswaqas mahmoodNo ratings yet

- 03 - Thomson Et Al - Current Signature Analysis To Detect Induction Motors FaultsDocument9 pages03 - Thomson Et Al - Current Signature Analysis To Detect Induction Motors FaultsCar AljaNo ratings yet

- Bearing Insulation ResistanceDocument10 pagesBearing Insulation Resistancemurty0077754No ratings yet

- Generator Stator End-Winding Vibration ProblemsDocument5 pagesGenerator Stator End-Winding Vibration ProblemsVictor Hutahaean100% (1)

- Detecting and Identifying Vibration ProblemasDocument10 pagesDetecting and Identifying Vibration ProblemasClaylson Figueiredo JúlioNo ratings yet

- Common Vibration Monitoring and Analysis Techniques PDFDocument45 pagesCommon Vibration Monitoring and Analysis Techniques PDFCarlos Roberto Castellanos PaterninaNo ratings yet

- Enwinding Monitoring and VibrationDocument6 pagesEnwinding Monitoring and VibrationAnonymous BBX2E87aHNo ratings yet

- Balancing of Rotating El McsDocument59 pagesBalancing of Rotating El McsDeep SYNo ratings yet

- Rotor Degaussing Rev 1Document5 pagesRotor Degaussing Rev 1mariamalloney1730No ratings yet

- ME8097 NDT Unit 2 Class 5Document15 pagesME8097 NDT Unit 2 Class 5MICHEL RAJNo ratings yet

- Fault Zone Analysis "ROTOR"Document8 pagesFault Zone Analysis "ROTOR"abhe prasetyaNo ratings yet

- Alternator Protection (Negative Phase Seq.)Document9 pagesAlternator Protection (Negative Phase Seq.)Rakibul IslamNo ratings yet

- Vibration Analysis of Rolling BearingsDocument99 pagesVibration Analysis of Rolling BearingsDaniel_Ali_b100% (1)

- v79 44Document6 pagesv79 44bijupointk1No ratings yet

- Vibration Brochure (Final)Document12 pagesVibration Brochure (Final)duy ngo thanhNo ratings yet

- Picmicro™ Microcontroller Oscillator Design GuideDocument20 pagesPicmicro™ Microcontroller Oscillator Design GuideAmarnath M DamodaranNo ratings yet

- ناهممحوریDocument2 pagesناهممحوریzohrehmm2004No ratings yet

- Chapter 3 OperationDocument10 pagesChapter 3 OperationesutjiadiNo ratings yet

- Magnetic Particle InspectionDocument14 pagesMagnetic Particle InspectionJohn Kennedy RosalesNo ratings yet

- The Color of Runout: ApplicationsDocument14 pagesThe Color of Runout: ApplicationsWangunNo ratings yet

- Tpi WL 43-1189 - 2 Ea - 0307.current-Insulated Brngs. Prevent Damages Caused by Elect. CurrentDocument14 pagesTpi WL 43-1189 - 2 Ea - 0307.current-Insulated Brngs. Prevent Damages Caused by Elect. CurrentmiteshmechNo ratings yet

- Kiani, M., Lee, W.-J., Kenarangui, R., & Fahimi, B. (2007) - Detection of Rotor Faults in Synchronous GeneratorsDocument6 pagesKiani, M., Lee, W.-J., Kenarangui, R., & Fahimi, B. (2007) - Detection of Rotor Faults in Synchronous GeneratorsjuanNo ratings yet

- Detection of Rotor Winding Shorted TurnsDocument12 pagesDetection of Rotor Winding Shorted TurnsGheorghe BogdanNo ratings yet

- Runout Mecanico y ElectricoDocument6 pagesRunout Mecanico y ElectricoJuan Pablo Chumba LaraNo ratings yet

- Causes of Rotor Distortions and Applicable Common Straightening Methods For Turbine Rotors and ShaftsDocument6 pagesCauses of Rotor Distortions and Applicable Common Straightening Methods For Turbine Rotors and ShaftsIftekhar NizamNo ratings yet

- RunoutDocument14 pagesRunoutMajid SattarNo ratings yet

- Generator Shaft CurrentDocument2 pagesGenerator Shaft CurrentNishant Anthwal100% (1)

- Magnetism in MachineriesDocument3 pagesMagnetism in MachineriesGAGANNo ratings yet

- Anonymous Poster: Re: DegaussingDocument22 pagesAnonymous Poster: Re: DegaussingmanivannanNo ratings yet

- NDT by Donald DDocument7 pagesNDT by Donald DReda ElsayedNo ratings yet

- Analysis of Abnormal Short Circuit Between Turns of Generator Rotor WindingsDocument5 pagesAnalysis of Abnormal Short Circuit Between Turns of Generator Rotor WindingshamidrezaNo ratings yet

- Turbo GeneratorsDocument11 pagesTurbo Generatorscrazy doNo ratings yet

- 2 - Generator MaintenanceDocument34 pages2 - Generator MaintenanceAmba James AsukNo ratings yet

- Couplings PDFDocument34 pagesCouplings PDFAhmed El-Shafei100% (1)

- Overview and Selection Guide: Balluff Linear Position SensorsDocument76 pagesOverview and Selection Guide: Balluff Linear Position SensorsCheikh AhmedNo ratings yet

- Sesi 11Document39 pagesSesi 11Ahmad DzalfaNo ratings yet

- 4 Common Coupling Issues and How To Prevent ThemDocument6 pages4 Common Coupling Issues and How To Prevent ThemApple StarkNo ratings yet

- Sridhar 2013Document6 pagesSridhar 2013Bobby RinaldiNo ratings yet

- Controlling Shaft Voltages in Steam TurbinesDocument28 pagesControlling Shaft Voltages in Steam Turbinessatya krishna chagantiNo ratings yet

- Iemdc 1999 769189Document3 pagesIemdc 1999 769189hamidrezaNo ratings yet

- Rotor Rso Reflectometer TYPE TDR100 and TDR100RBDocument38 pagesRotor Rso Reflectometer TYPE TDR100 and TDR100RBDevas ShuklaNo ratings yet

- Grounding Brush Discharge MonitoringDocument4 pagesGrounding Brush Discharge MonitoringsurawutwijarnNo ratings yet

- Analysis and Diagnosis of The Different Defects of The Bearings and Gearings by Vibration AnalysisDocument6 pagesAnalysis and Diagnosis of The Different Defects of The Bearings and Gearings by Vibration AnalysisJournal of Computer Science and EngineeringNo ratings yet

- Vibration Monitoring and AnalysisDocument8 pagesVibration Monitoring and AnalysishashimtkmceNo ratings yet

- Thermal Instability Analysis of A Synchronous Generator Rotor Using Direct MappingDocument11 pagesThermal Instability Analysis of A Synchronous Generator Rotor Using Direct Mappingabdalla AljzNo ratings yet

- Loop Test and Core RepairDocument6 pagesLoop Test and Core Repairhino_kagu100% (1)

- GeneratorDocument17 pagesGeneratorsanjay sharmaNo ratings yet

- Magnetic Particle InspectionDocument6 pagesMagnetic Particle InspectionRaj Malhotra100% (1)

- Fundamentals of Fault Current and Grounding in Electrical SystemsFrom EverandFundamentals of Fault Current and Grounding in Electrical SystemsRating: 4 out of 5 stars4/5 (3)

- An Introduction to the Neutron Kinetics of Nuclear Power Reactors: Nuclear Engineering DivisionFrom EverandAn Introduction to the Neutron Kinetics of Nuclear Power Reactors: Nuclear Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- Failure Analysis in Engineering ApplicationsFrom EverandFailure Analysis in Engineering ApplicationsRating: 1 out of 5 stars1/5 (1)

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorFrom EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorNo ratings yet

- Jja 23169115Document1 pageJja 23169115Sanjay NandalNo ratings yet

- PO-5500000008 Part-3Document58 pagesPO-5500000008 Part-3Sanjay NandalNo ratings yet

- PO-5500000008 Part-2Document36 pagesPO-5500000008 Part-2Sanjay NandalNo ratings yet

- Shapes and PatternsDocument3 pagesShapes and PatternsSanjay NandalNo ratings yet

- Pump Axial ThrustDocument11 pagesPump Axial ThrustSanjay NandalNo ratings yet

- PO-5500000008 Part-1Document31 pagesPO-5500000008 Part-1Sanjay NandalNo ratings yet

- Rotor Balancing - Know How999southwDocument1 pageRotor Balancing - Know How999southwSanjay NandalNo ratings yet

- Flexibility Requirement in Indian Power SystemDocument62 pagesFlexibility Requirement in Indian Power SystemSanjay NandalNo ratings yet

- Flexibility Analysis of Thermal Generation For RE Integration in India 1Document564 pagesFlexibility Analysis of Thermal Generation For RE Integration in India 1Sanjay NandalNo ratings yet

- Haryana Secretary Notice For Retirement AgeDocument20 pagesHaryana Secretary Notice For Retirement AgeSanjay NandalNo ratings yet

- Operational Strategies For Flexing in Thermal PlantsDocument27 pagesOperational Strategies For Flexing in Thermal PlantsSanjay NandalNo ratings yet

- Fluke Corporation Industrial Control 7300790Document2 pagesFluke Corporation Industrial Control 7300790jesserussellNo ratings yet

- Optical Components: Ajmal Muhammad, Robert ForchheimerDocument35 pagesOptical Components: Ajmal Muhammad, Robert ForchheimerSara GulNo ratings yet

- MV Circuit Breaker Guide - Ansi Vs Iec ComparisonDocument18 pagesMV Circuit Breaker Guide - Ansi Vs Iec ComparisonMohammedSaadaniHassaniNo ratings yet

- Eletronics CompanyDocument12 pagesEletronics CompanyAshish SrivastavaNo ratings yet

- 0 Dumpacore 3rd Com - Samsung.android - App.contactsDocument2,528 pages0 Dumpacore 3rd Com - Samsung.android - App.contactsTarsilio GuitTarNo ratings yet

- Xerox Phaser 3260 Printer and Xerox Workcentre 3225 Multifunction PrinterDocument4 pagesXerox Phaser 3260 Printer and Xerox Workcentre 3225 Multifunction PrinterDeep_SpaceNo ratings yet

- Circuit Systems (India) Limited (ISO 9001:2009) : QR-720-04 Proforma Invoice/Order AcknowledgementDocument2 pagesCircuit Systems (India) Limited (ISO 9001:2009) : QR-720-04 Proforma Invoice/Order Acknowledgementamp divisionNo ratings yet

- A72 Steering Column Switch ClusterDocument2 pagesA72 Steering Column Switch ClusterEverton LuizNo ratings yet

- H50 Service ManualDocument246 pagesH50 Service ManualJackson NjarambaNo ratings yet

- FlashROM SPI Bios Motherboard Programar Por Puerto ParaleloDocument2 pagesFlashROM SPI Bios Motherboard Programar Por Puerto ParaleloAlberto Jovito100% (1)

- 3120b BrochureDocument12 pages3120b Brochurealex100% (1)

- What Is The Use of Voltage Stabilizer?Document9 pagesWhat Is The Use of Voltage Stabilizer?Naimish SukhadeveNo ratings yet

- g05 Frenos Be Sew-EurodriveDocument55 pagesg05 Frenos Be Sew-EurodriveedgarlimasNo ratings yet

- Ceragon Outdoor Enclosure Product DescriptionDocument14 pagesCeragon Outdoor Enclosure Product DescriptionnazloenNo ratings yet

- Specification Jumbo Drill Sandvik DD311D-40Document4 pagesSpecification Jumbo Drill Sandvik DD311D-40Nathania Boas E SNo ratings yet

- Kx6k Sc06 6611kv Transformer-2 Protection Rev Za 15.03.2018Document82 pagesKx6k Sc06 6611kv Transformer-2 Protection Rev Za 15.03.2018Ravi Shankar V100% (1)

- Achieving Frequency Reuse 1 in Wimax Networks With BeamformingDocument14 pagesAchieving Frequency Reuse 1 in Wimax Networks With Beamformingbulli babuNo ratings yet

- Introduction To Ultrasonic Testing TechniqueDocument52 pagesIntroduction To Ultrasonic Testing TechniqueDr. Akshay JainNo ratings yet

- Orcad PLDDocument8 pagesOrcad PLDmeeduma4582No ratings yet

- Advantage and Disadvantage of PIDDocument6 pagesAdvantage and Disadvantage of PIDNathaniel PascuaNo ratings yet

- P345 20Hz Stator Earth Fault Application GuideDocument25 pagesP345 20Hz Stator Earth Fault Application GuiderajeshNo ratings yet

- Carbon Nanotube: Properties and ApplicationsDocument22 pagesCarbon Nanotube: Properties and ApplicationsmanuNo ratings yet

- SS7MD PMDocument191 pagesSS7MD PMAkhil GuptaNo ratings yet

- CoolSiC™ MOSFET A Revolution For Power ConversionDocument7 pagesCoolSiC™ MOSFET A Revolution For Power Conversionhope1678481280No ratings yet

- SOYO SYSTEMS, Jalgaon: NBN Sinhgad Technical Institutes CampusDocument14 pagesSOYO SYSTEMS, Jalgaon: NBN Sinhgad Technical Institutes CampusShubham PatilNo ratings yet

- Avaya CISCO3750E-POE InteroperabilityDocument15 pagesAvaya CISCO3750E-POE InteroperabilityHeliosOmegaNo ratings yet

- Wavence 18 Installation Nokia EDUDocument113 pagesWavence 18 Installation Nokia EDUHIYEBININo ratings yet

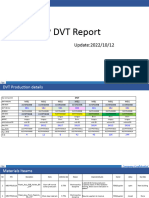

- CYP DVT Report 20221012Document17 pagesCYP DVT Report 20221012QuýNguyễnNo ratings yet

- AV1407 - 010universal InstructionDocument6 pagesAV1407 - 010universal InstructionSamir AhmadNo ratings yet